Immersed self-flow-interfering shell-and-tube-type heat exchanger

A heat exchanger and self-disturbance technology, applied in indirect heat exchangers, lighting and heating equipment, cooling fluid circulation devices, etc., can solve problems such as low heat exchange efficiency, and achieve high heat exchange efficiency, uniform heat exchange, resistance to heat small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

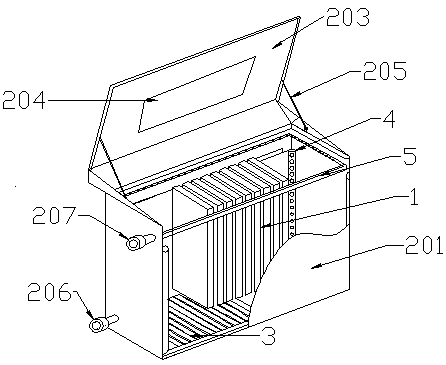

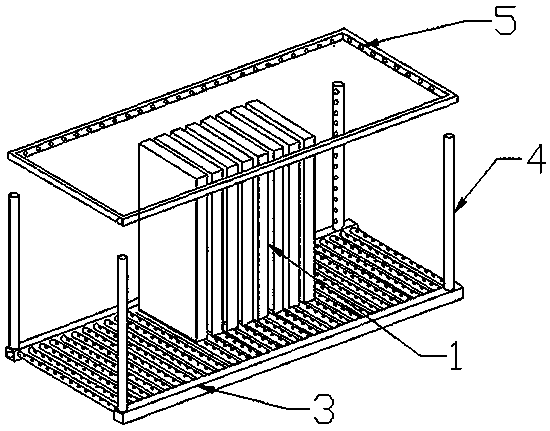

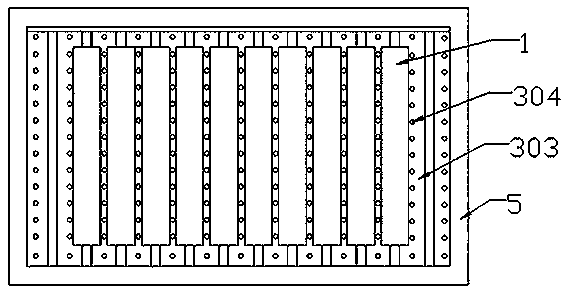

[0047] Figure 1-4 The submerged "four-corner tangential circle" self-turbulence cooling system of the present invention is shown. Such as Figure 1-4 As shown, the system includes a heat source 1 (or a heat source packaging shell 6 ), a shell 2 , a liquid dispensing device 3 , a self-disturbing device 4 and a liquid collection device 5 for "circle tangent". The housing 2 is provided with a cooling liquid inlet 206 and a cooling liquid outlet 207, the cooling liquid inlet 206 is located at the lower part of the housing side wall 201, the cooling liquid inlet 206 and the liquid separator 3 The liquid separating device 3 is connected with the "square tangential circle" spoiler 4, the liquid collecting device 5 is located below the liquid surface of the insulating cooling liquid, and the liquid collecting device 5 is connected with the cooling liquid outlet 207 Pass. The insulating cooling liquid passes through the cooling liquid inlet 206 and then enters the casing 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com