A Heat Pipe System with Varying Jet Hole Height

A technology of jet tubes and jet holes, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of heat pipes being unevenly heated and unable to be effectively used, so as to avoid local overheating, Calculate the effect of increased deployment density and increased heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

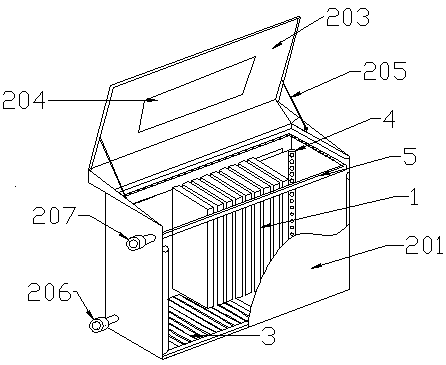

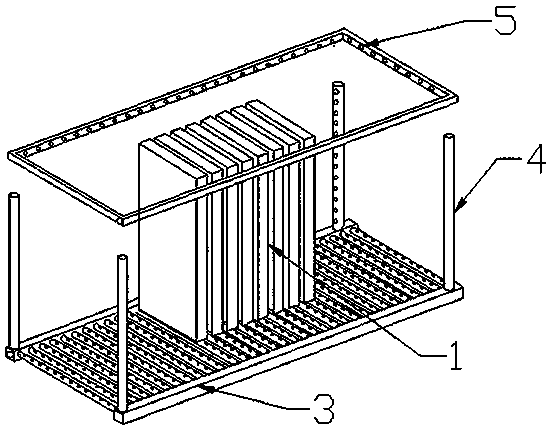

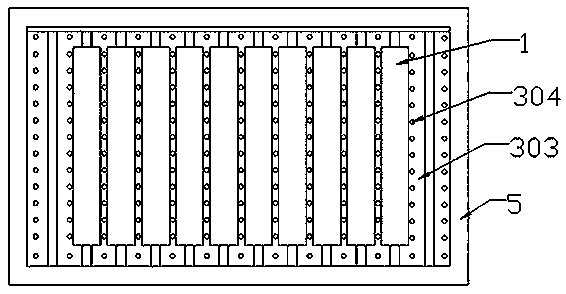

[0050] Figure 1-4 The submerged "four-corner tangential circle" self-turbulence cooling system of the present invention is shown. Such as Figure 1-4 As shown, the system includes a server 1 (or a server packaging box 6 ), a cabinet 2 , a liquid dispensing device 3 , a self-disturbance device 4 and a liquid collecting device 5 with a "square tangent circle". The cabinet 2 is provided with a cooling liquid inlet 206 and a cooling liquid outlet 207, the cooling liquid inlet 206 is located at the lower part of the side wall 201 of the cabinet, and the cooling liquid inlet 206 communicates with the liquid separator 3 , the liquid separating device 3 communicates with the "square tangential circle" spoiler 4, the liquid collecting device 5 is located below the liquid surface of the insulating cooling liquid, and the liquid collecting device 5 communicates with the cooling liquid outlet 207. The insulating cooling liquid passes through the cooling liquid inlet 206 and enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com