Patents

Literature

36results about How to "Large film forming area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

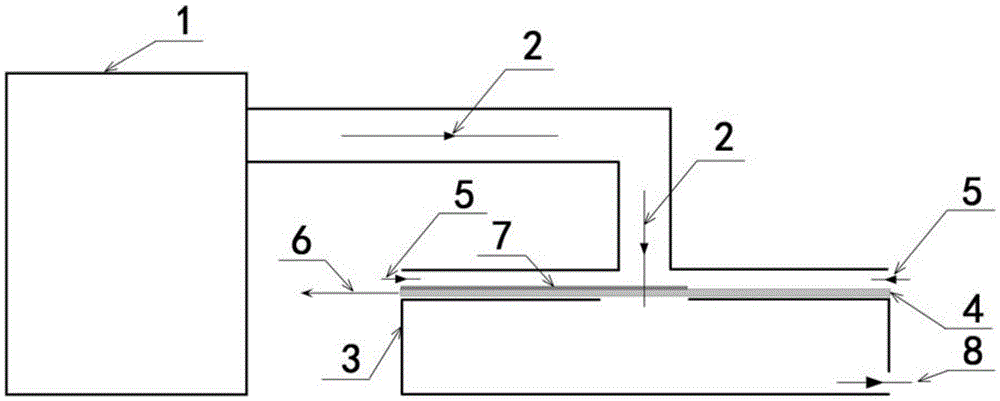

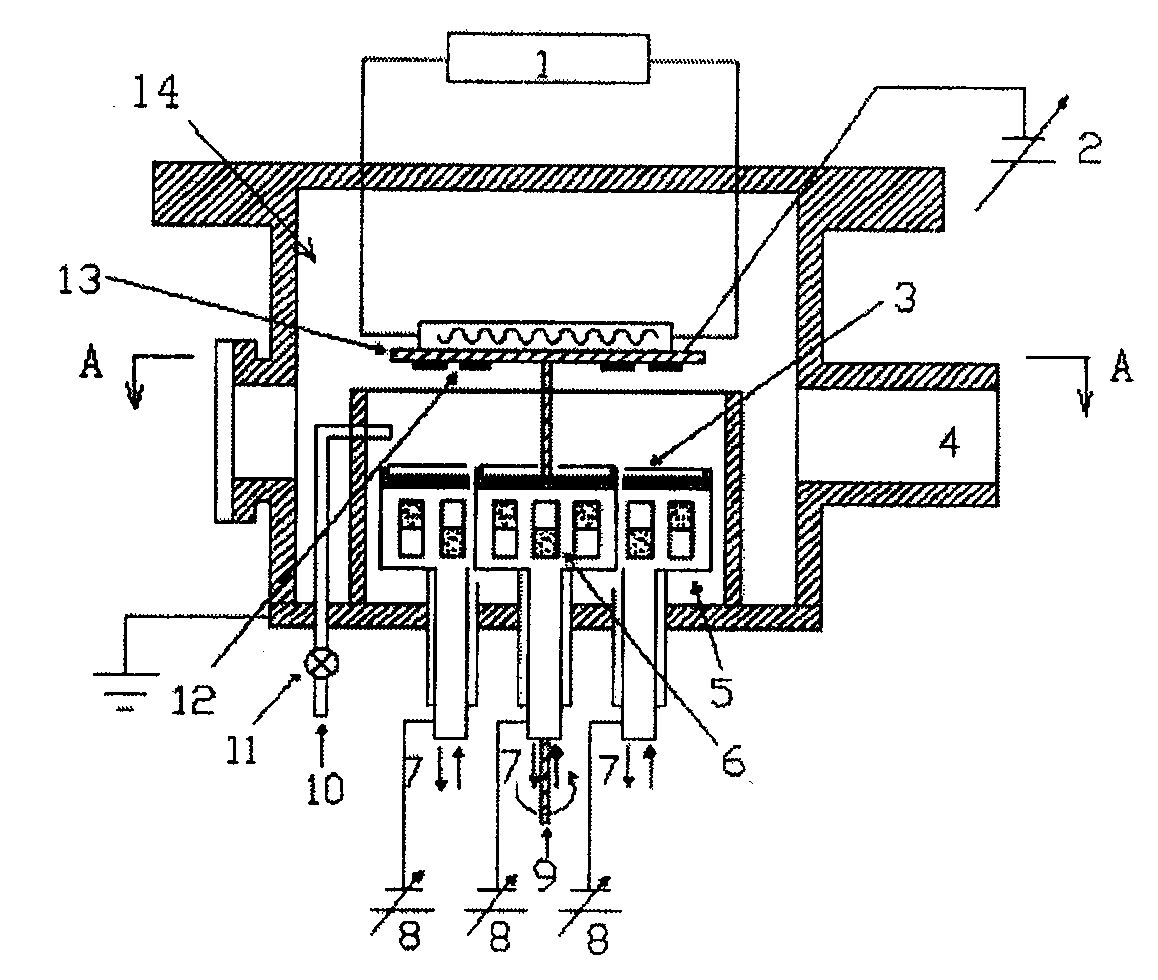

Method and device for preparing rare earth doped gallium nitride light-emitting film

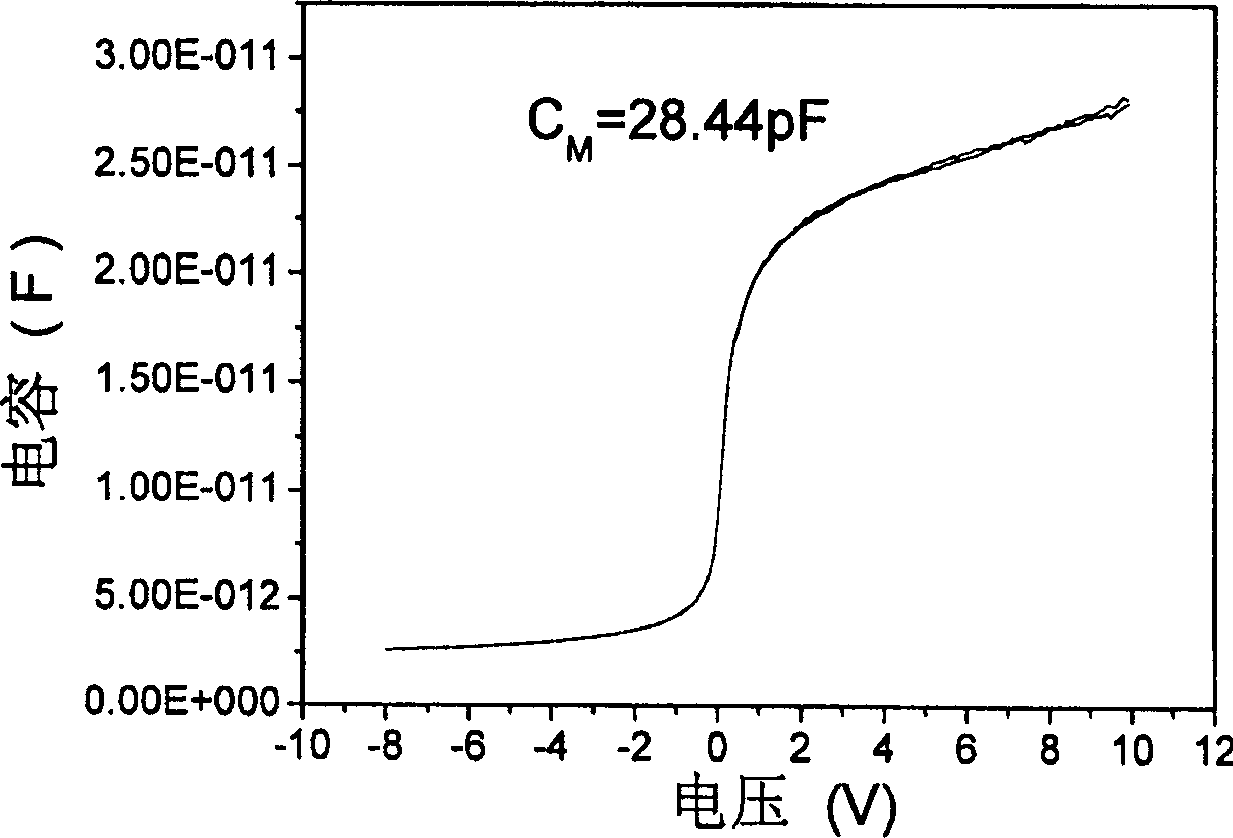

InactiveCN1962932ALow deposition temperatureLarge film forming areaVacuum evaporation coatingSputtering coatingNitrogen gasMetal

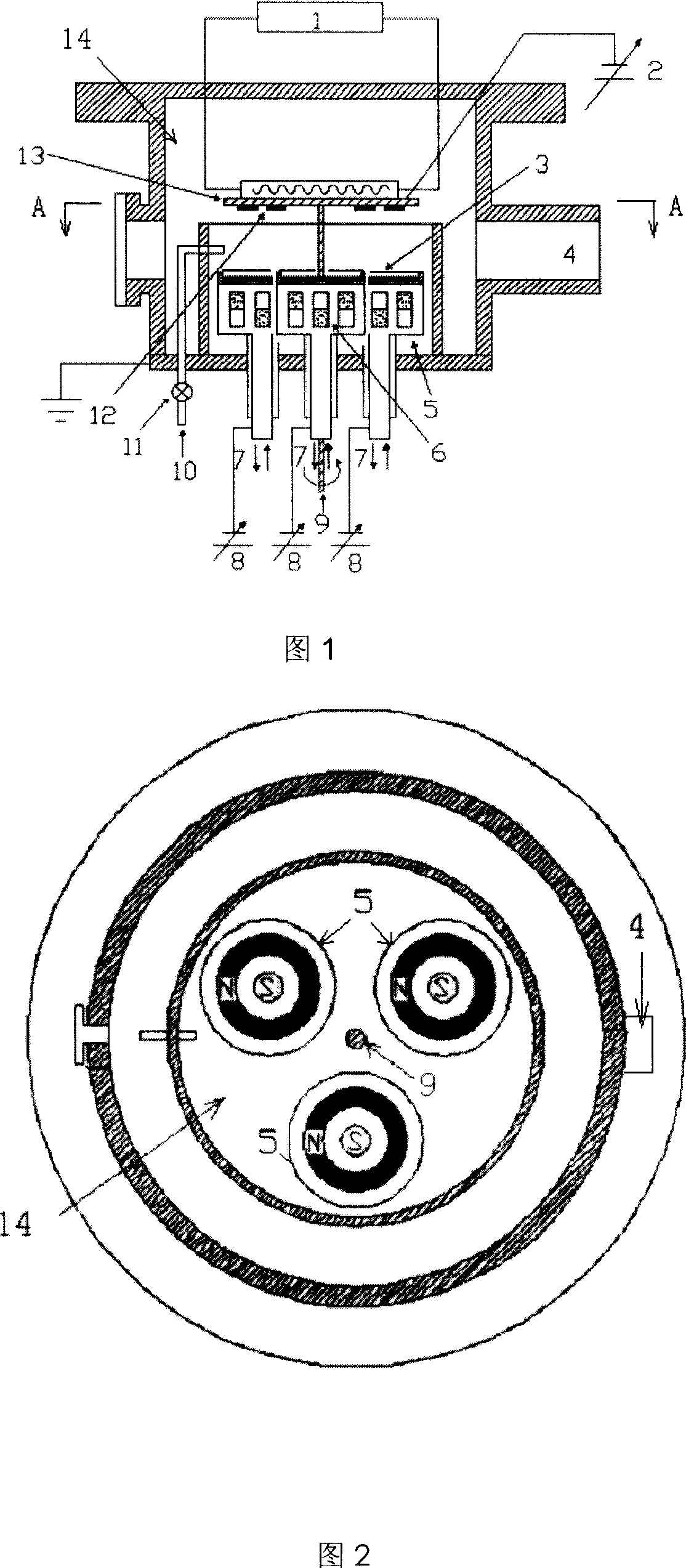

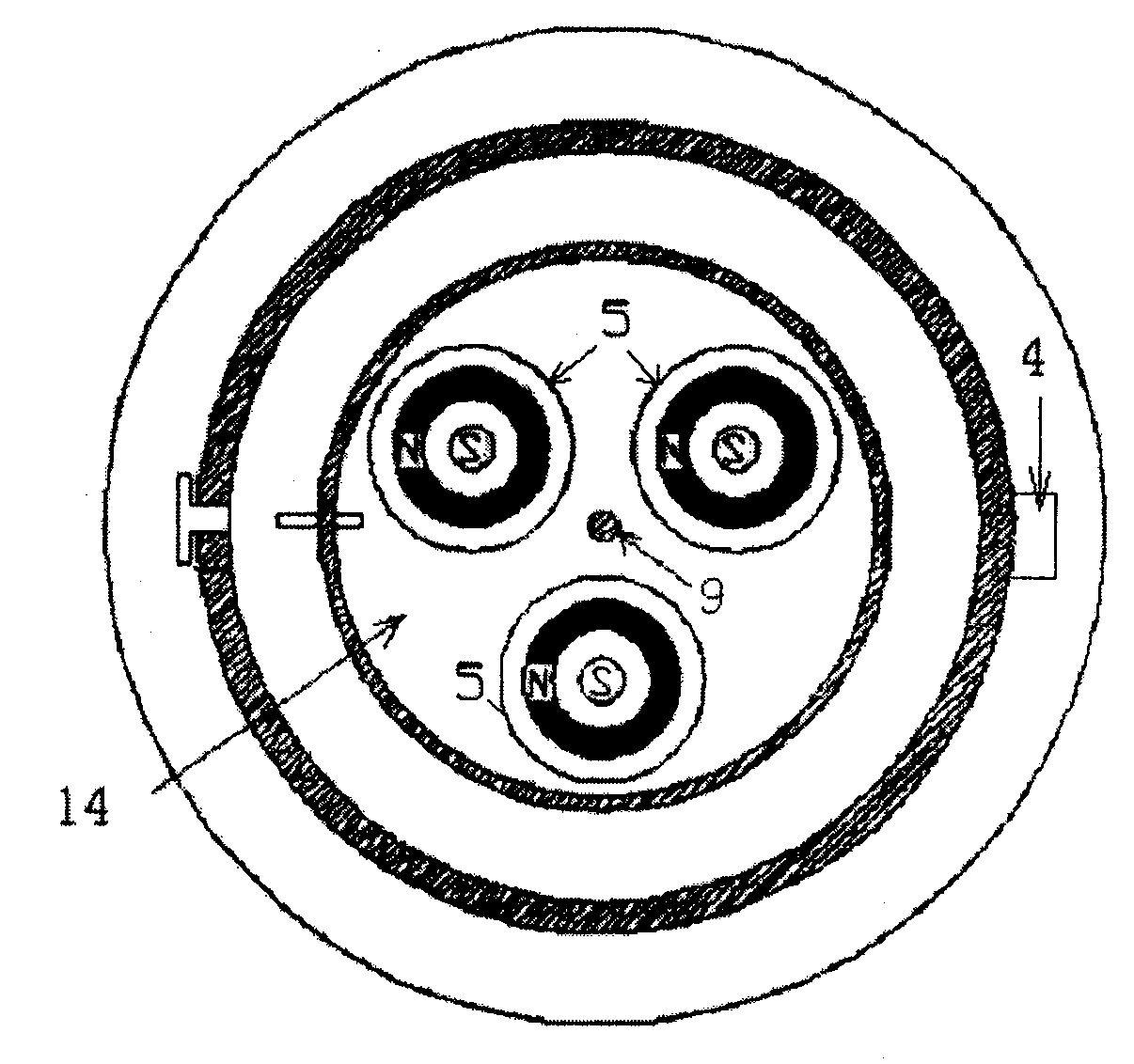

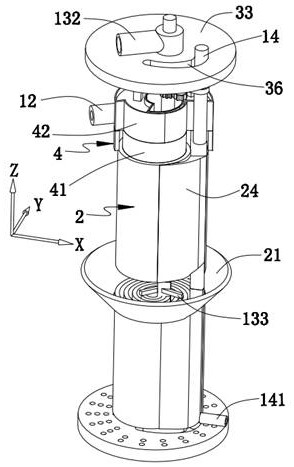

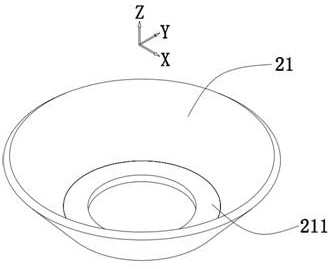

The invention discloses a preparing method of gallium nitride luminous film doped by rare earth, which is characterized by the following: controlling the substrate temperature within 0-500 Deg C; adopting nitrogen or composite gas of nitrogen and argon as splashing gas; proceeding magnetic control splashing for metal gallium of doped rare earth powder in the vacuum; sedimenting rare earth doped gallium nitride luminous film on the substrate of target position. The invention also provides magnetic control splashing device to prepare the product, which contains vacuum chamber; the rotary substrate rack with substrate and 3-5 magnetic targets are set in the vacuum chamber; the magnetic control target is set on the substrate, which makes substrate bottom parallel the magnetic control target; each magnetic control target connects DC anode directly; the cooling chamber is set in the magnetic control target, which possesses cooling dielectric inlet an outlet.

Owner:WUHAN UNIV

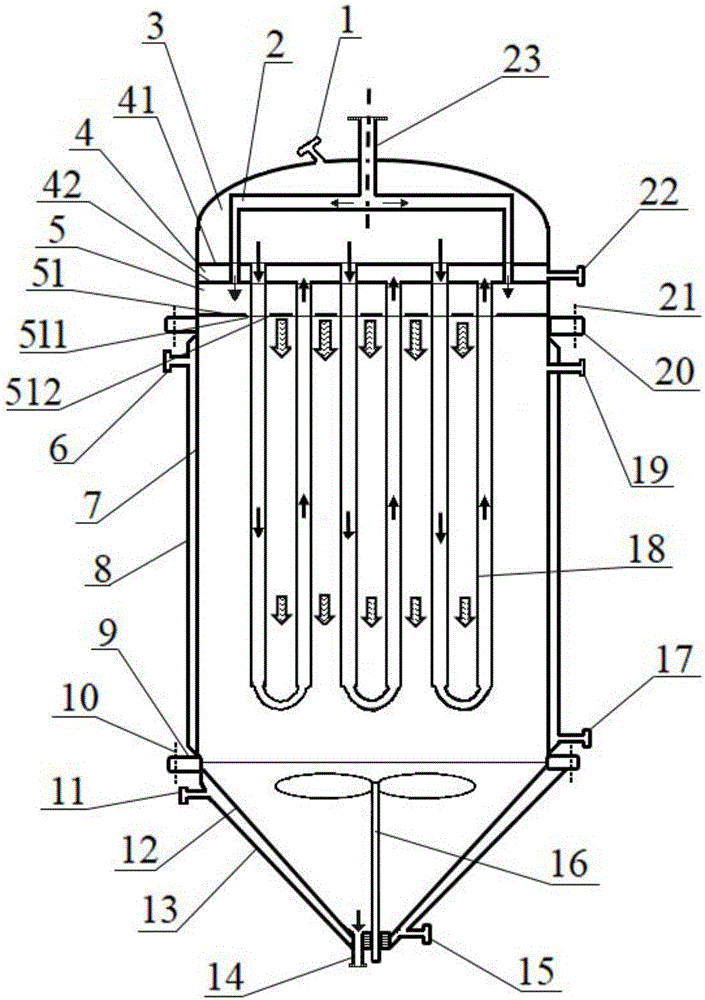

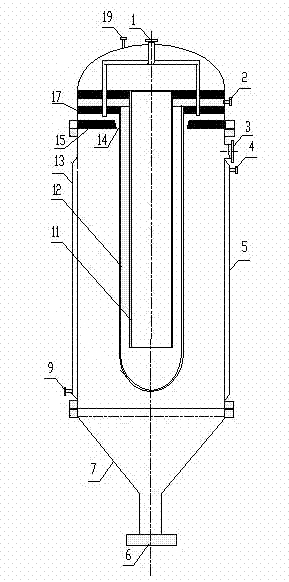

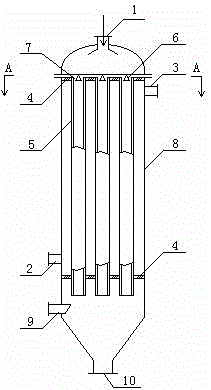

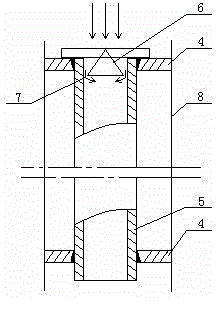

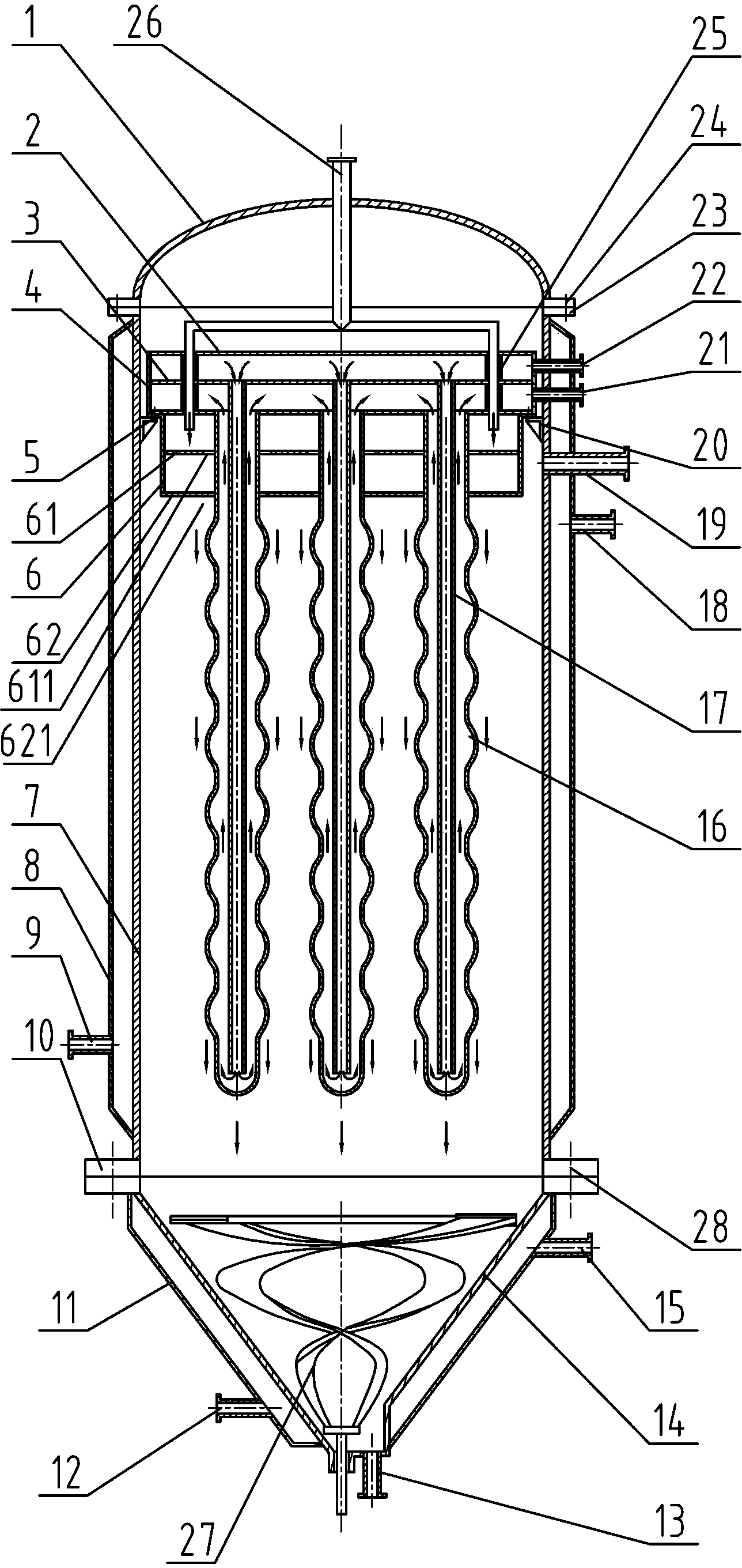

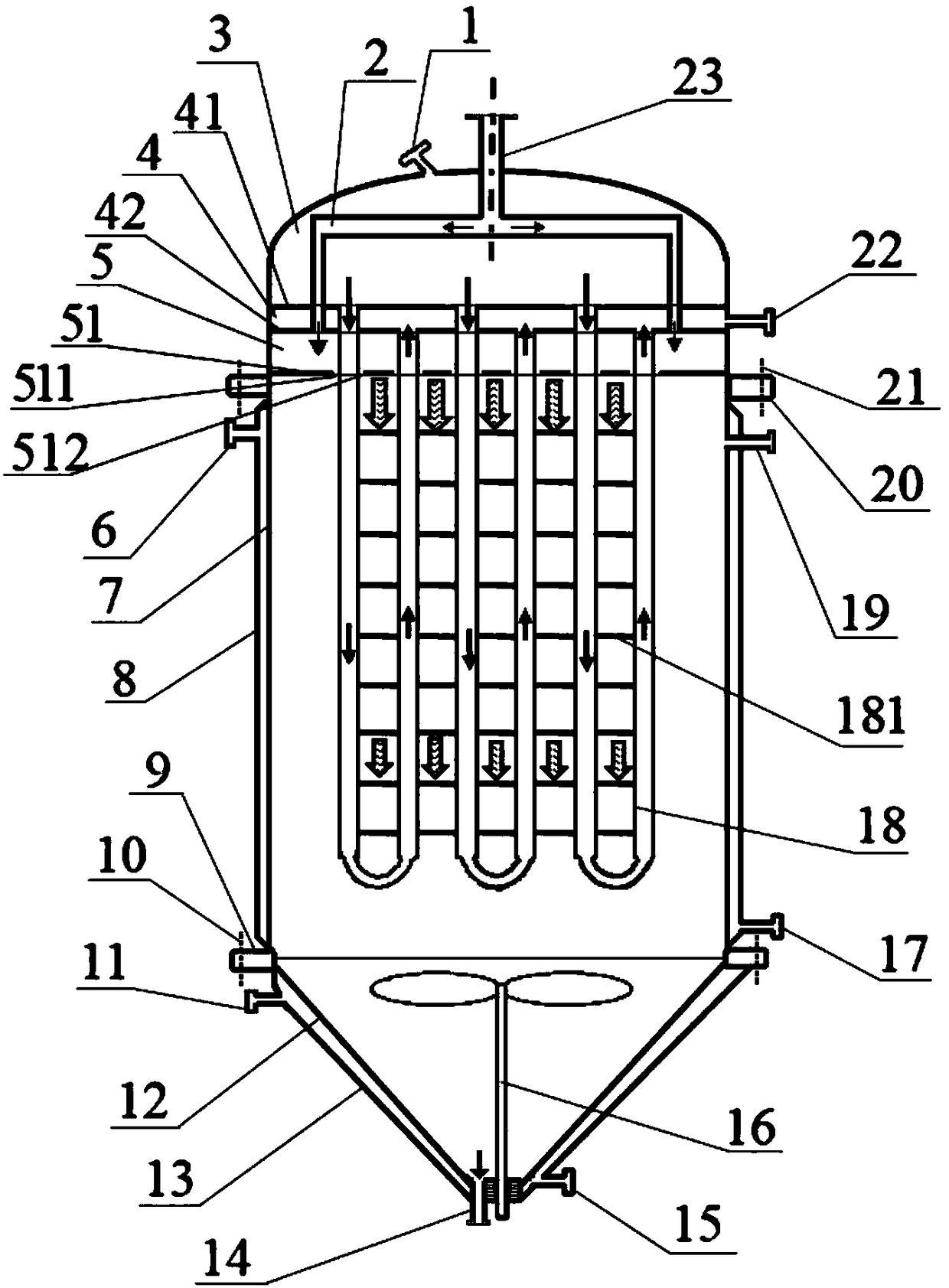

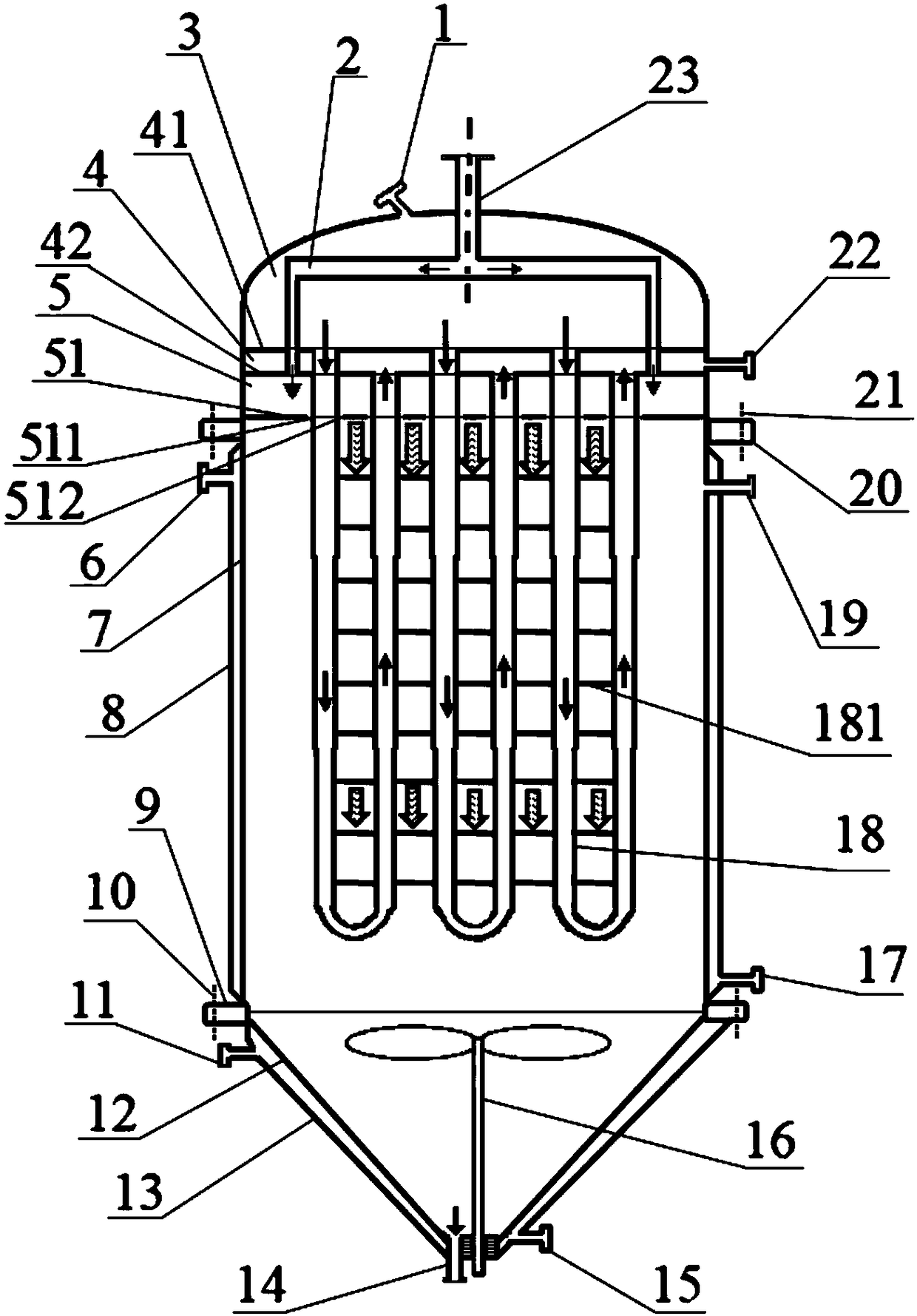

Tube alignment type condensation polymerization reaction kettle

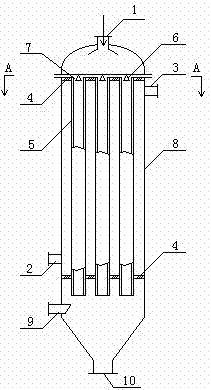

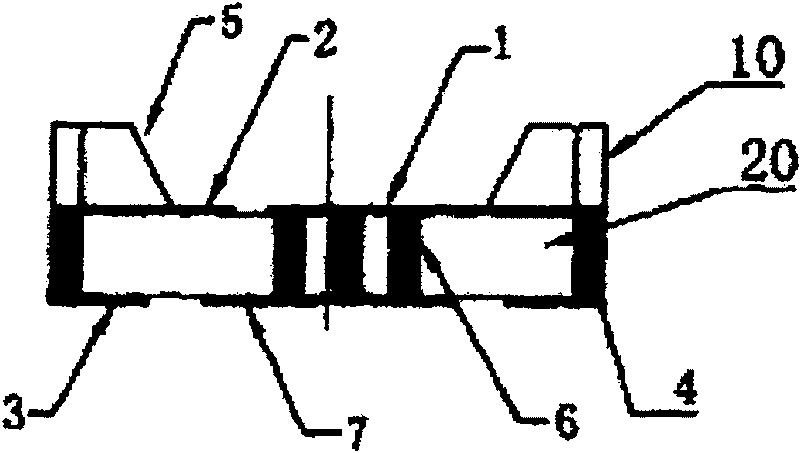

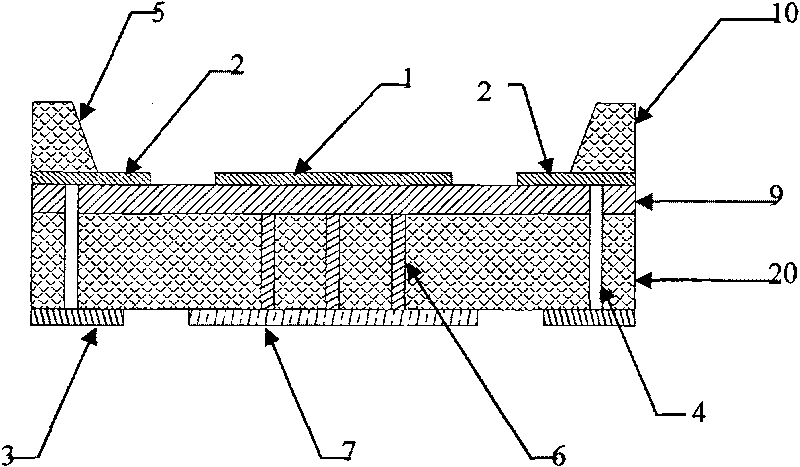

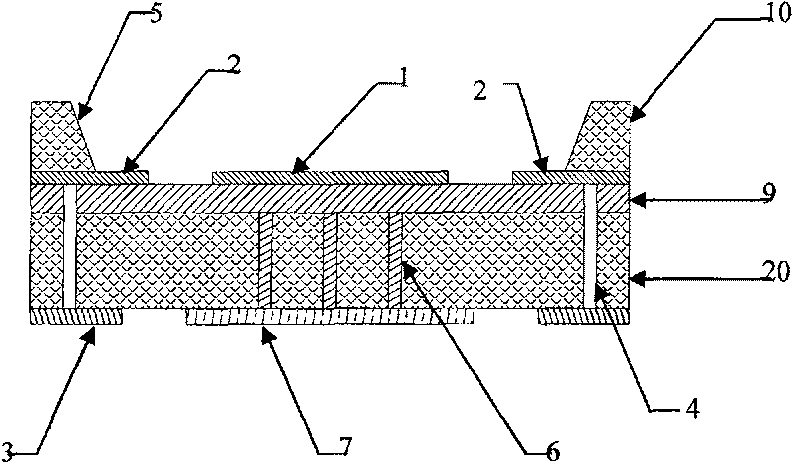

The invention discloses a tube alignment type condensation polymerization reaction kettle. According to the kettle, tube plates (4) are arranged inside a vertical casing (8); the tube plates (4) are connected with a tube alignment (5); material distributors (6) are arranged on the upper end tube openings of the tube alignment (5); annular gaps (7) are arranged between the upper end tube openings of the tube alignment (5) and the material distributors (6); the top end of the vertical casing (8) is provided with a material inlet (1), and the lower end of the vertical casing (8) is provided witha material outlet (10); the lower part of the side surface of the vertical casing (8) is provided with a heating medium inlet tube (2), the upper part of the side surface of the vertical casing (8) is provided with a heating medium outlet tube (3), and the middle-lower part of the side surface of the vertical casing (8) is provided with a vacuum pumping port (9). According to the present invention, material naturally flows downward by gravity, if the tube alignment is large, the film forming of the inner wall of tube alignment is sufficient, such that the blocking problem can not be generated; the tube alignment type condensation polymerization reaction kettle of the present invention has characteristics of good film forming effect, reliable use, and high work efficiency, and can be used for productions of PET and other high viscosity polymers. In addition, a plurality of the tubes can be aligned in the tube alignment.

Owner:ZHEJIANG UNIFULL IND FIBER

A kind of preparation method of single crystal graphene

InactiveCN102296361ALarge film forming areaQuality improvementPolycrystalline material growthFrom chemically reactive gasesMetal foilDecomposition

The invention relates to a preparation method of single crystal graphene and belongs to the technical field of functional thin-film materials. The preparation method comprises the following steps of: wrapping hydrocarbon into a metal foil; performing thermal decomposition under a vacuum environment or a mixed atmosphere environment of hydrogen and inert gas; and cooling to room temperature under the vacuum environment or the mixed atmosphere environment of the hydrogen and the inert gas to obtain single crystal graphene (comprising intrinsic or doped single crystal graphene) positioned on thesurface of the outer side of the metal foil, wherein the thermal decomposition temperature is higher than the decomposition temperature of the hydrocarbon and lower than and close to the melting temperature of the metal foil. The preparation method has the characteristics of simpleness, low cost and no pollution and can be used for preparing graphene with large area, high quality and high electronic mobility. The preparation method can be applied in the field of graphene-based electronic devices. By the method, research on the graphene can be promoted.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

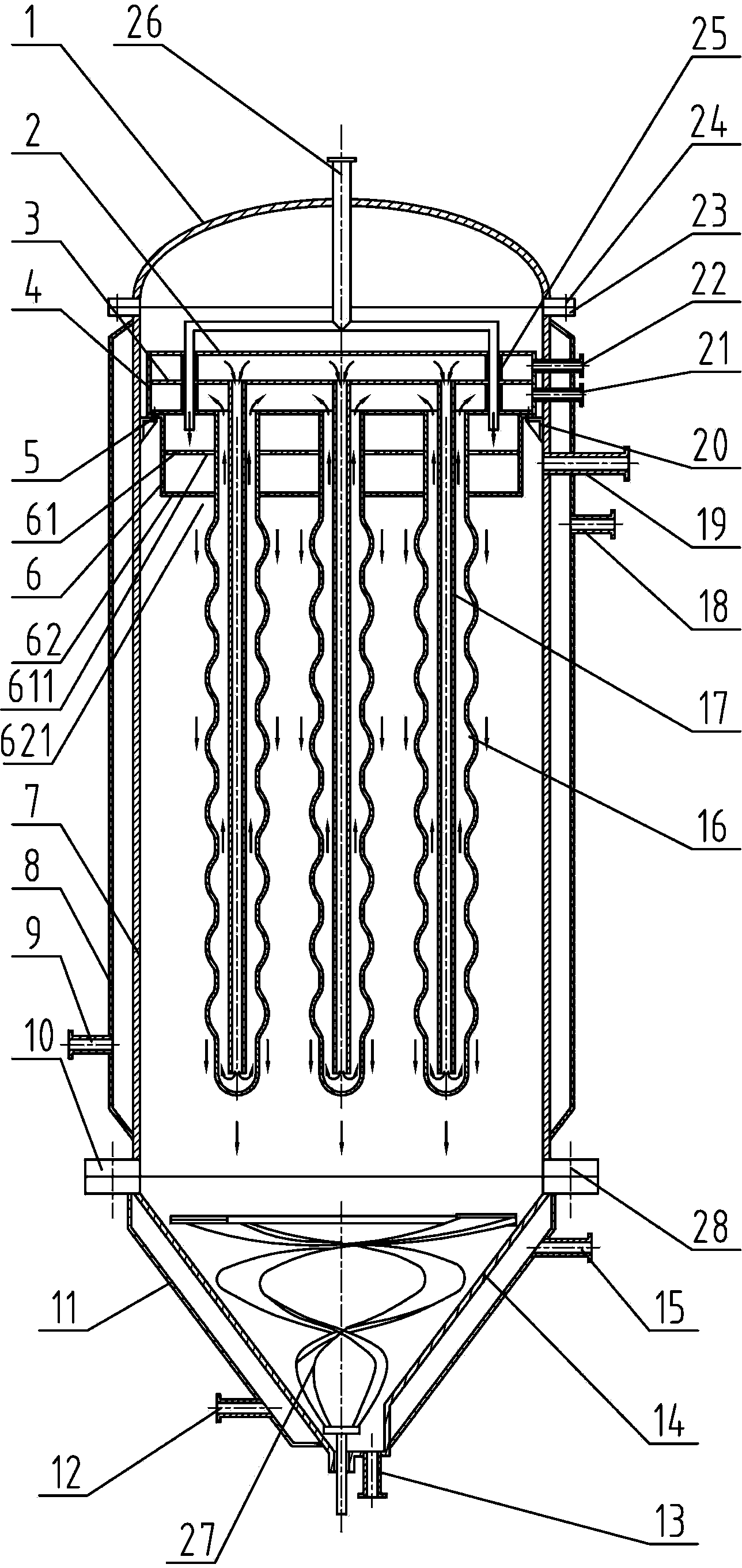

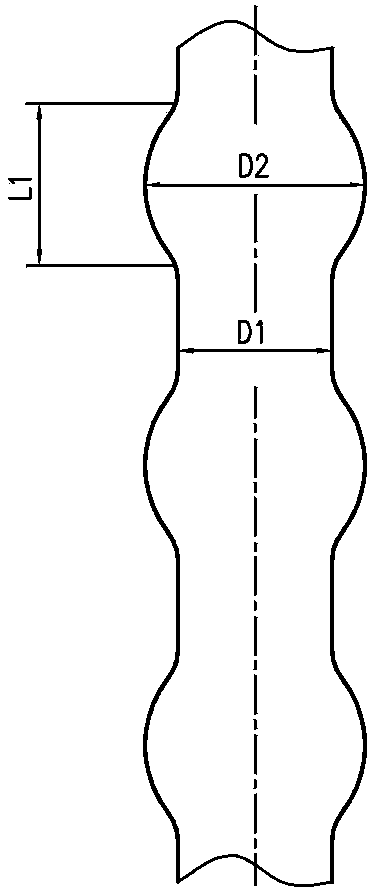

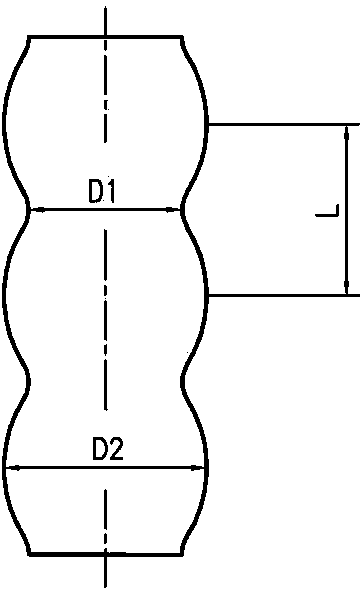

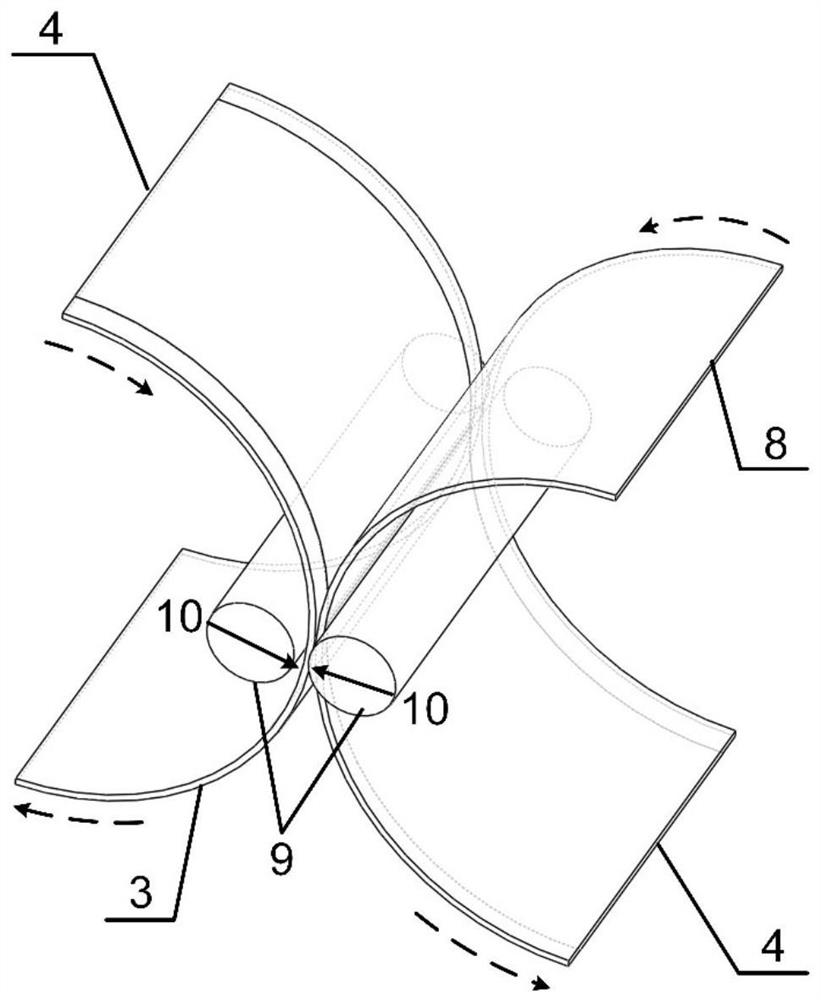

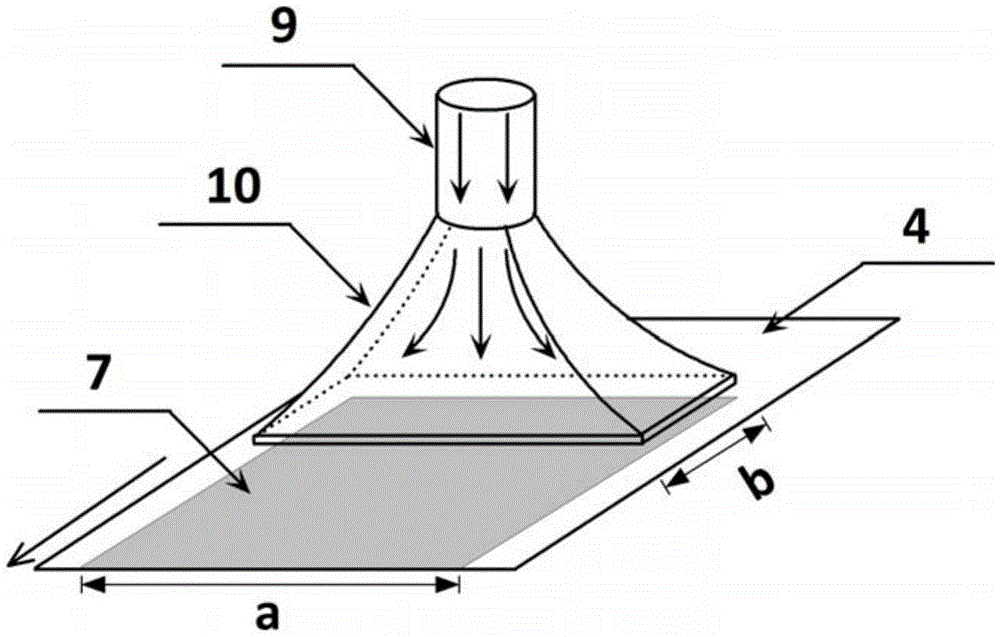

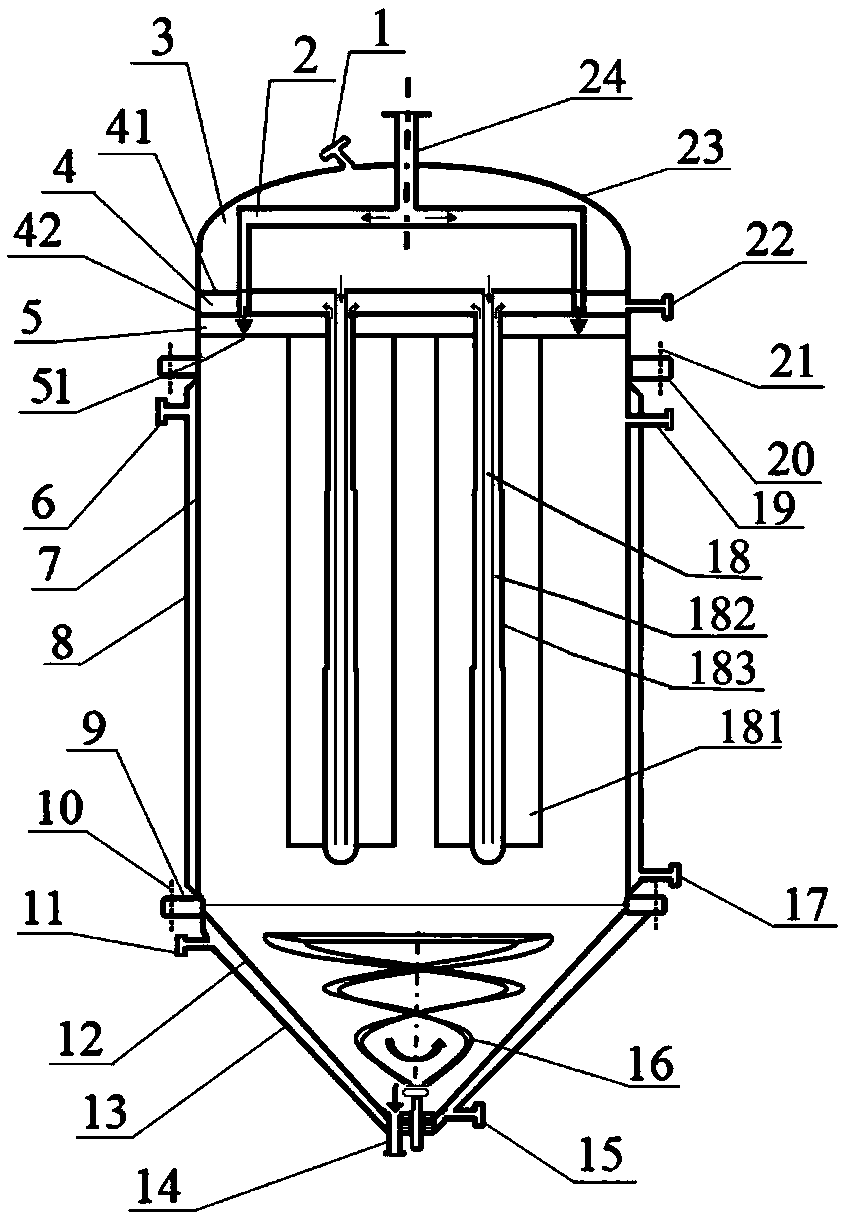

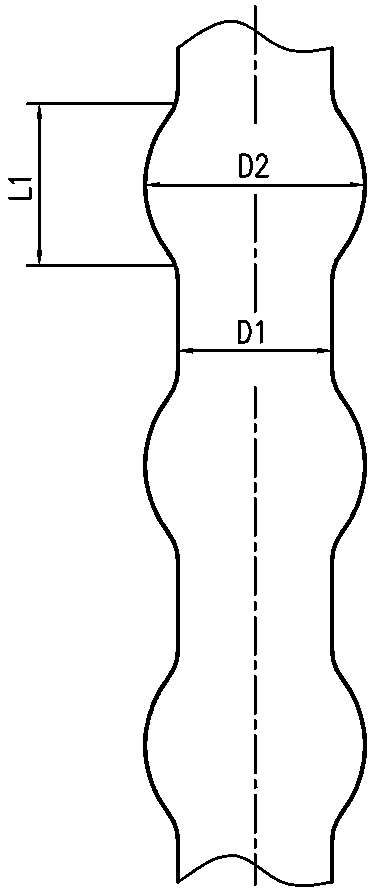

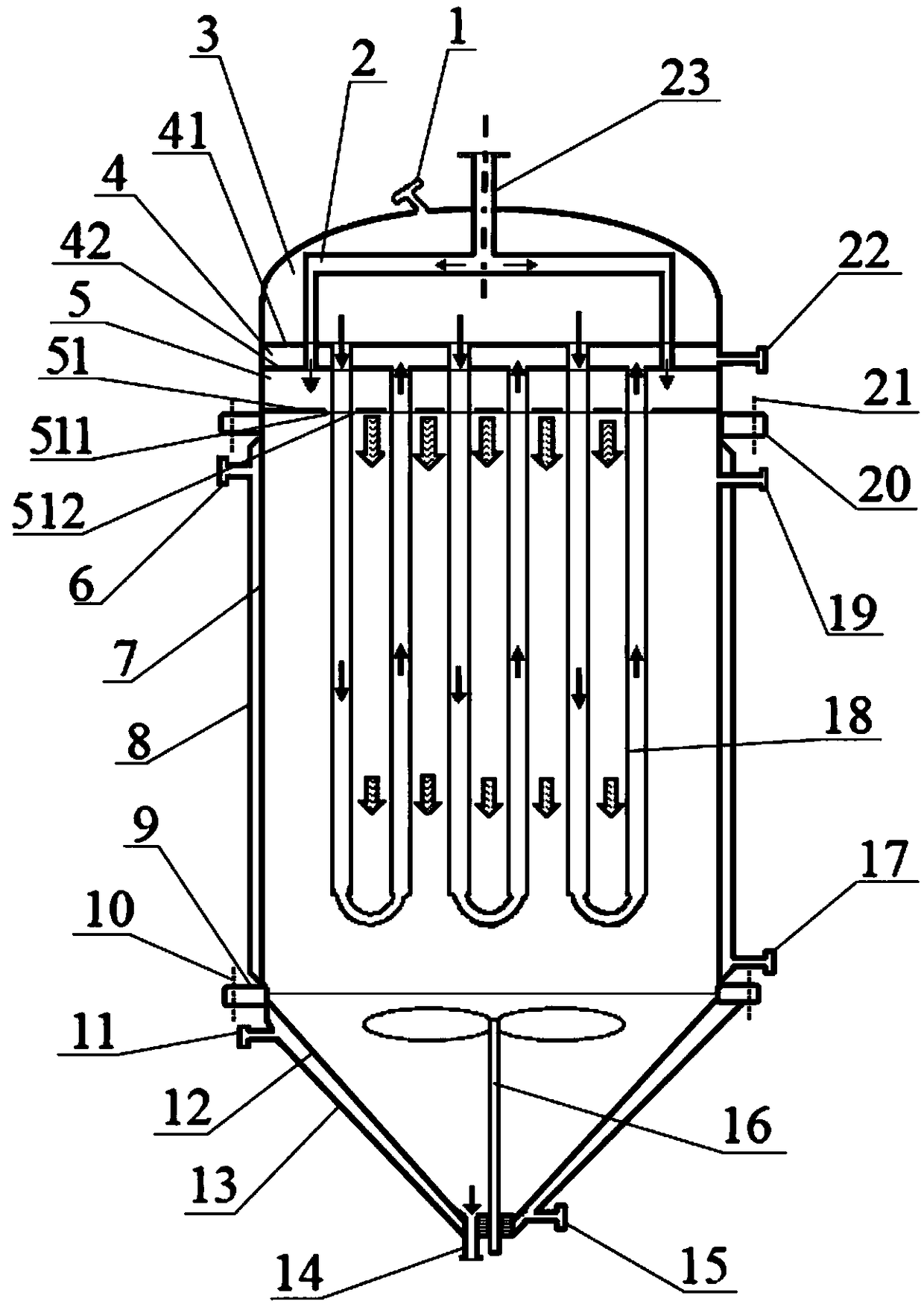

Melt polycondensation method, special reactor and falling-film elements

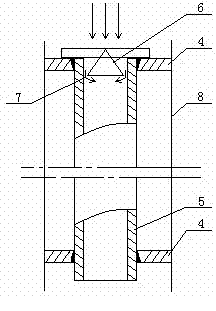

ActiveCN103360587AUniform melt residence timeNarrow molecular weight distributionChemical/physical/physico-chemical stationary reactorsPolytetramethylene terephthalateReaction temperature

The invention discloses a melt polycondensation method. Melted monomer blends or prepolymers slide down along the outer walls of tubular falling-film elements so as to be subjected to polycondensation, melts on all the falling-film elements gather at the bottom of a polycondensation reactor so as to be further stirred for reaction and mixed uniformly, and materials are discharged after the reaction finishes. The polycondensation reactor for implementing the method comprises a vertical shell, an end enclosure on the upper end, a bottom shell on the lower end, the falling-film elements, a heat transfer system, a film distributor and a helical ribbon stirrer, wherein the falling-film elements are corrugated pipes with optimized structural parameters. The polycondensation reactor has the advantages of simple structure, sufficient heat exchange, large film forming area, uniform reaction temperature and high polycondensation efficiency, guarantees the laminar flow in the process and can be used for the melt polycondensation of polyethylene glycol terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, polyamide and polycarbonate.

Owner:ZHEJIANG SCI-TECH UNIV

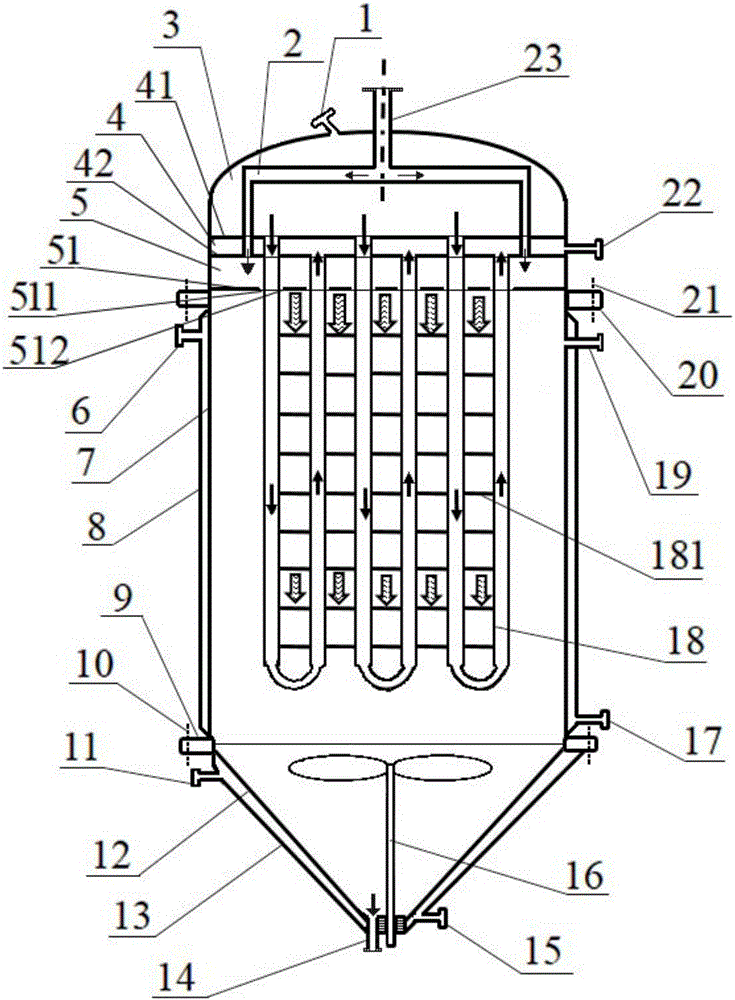

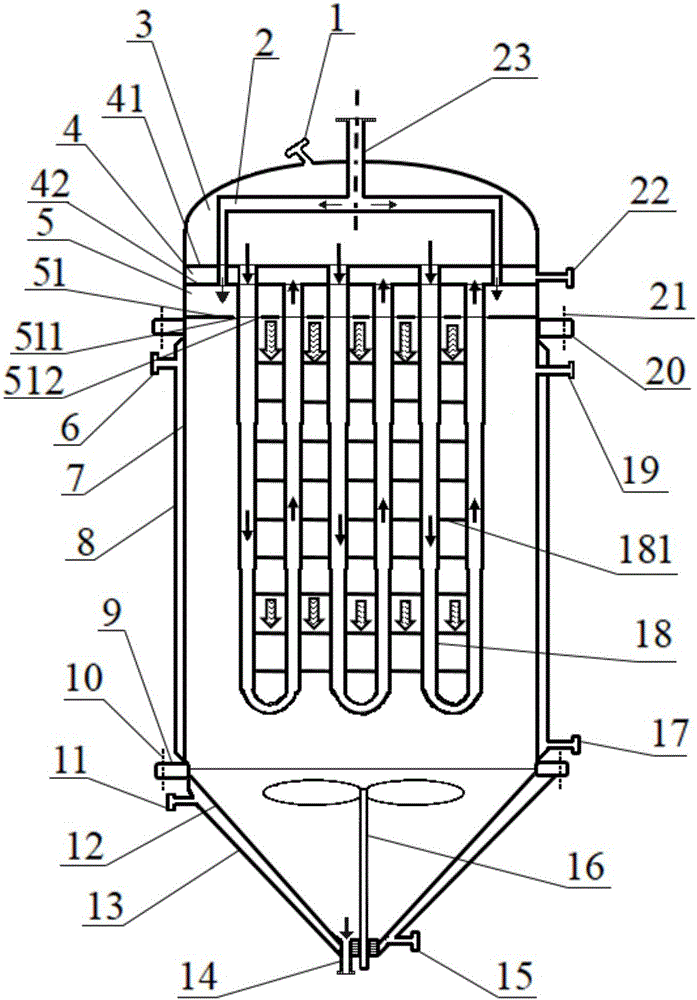

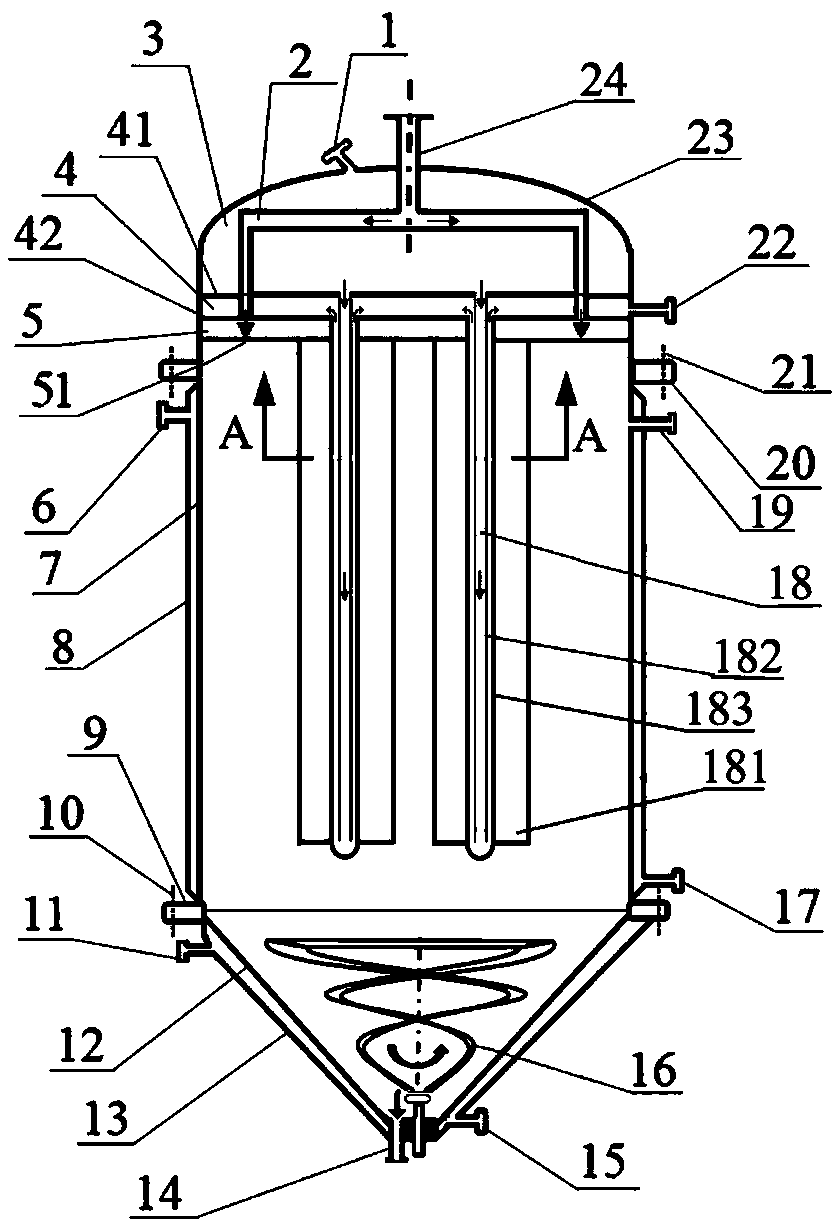

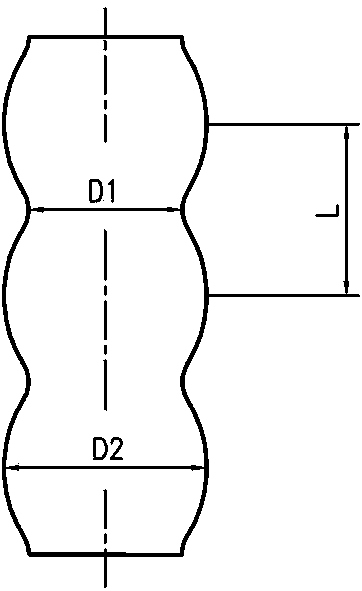

Row inter-tube falling film melt phase polycondensation reaction method and reactor thereof

ActiveCN106000250AGood dispersionEnhanced mixing processChemical/physical/physico-chemical stationary reactorsPolyethylene glycolEngineering

The invention relates to a row inter-tube falling film melt phase polycondensation reaction method. A melt prepolymer flows downwards from a film distribution plate and holes between tubes, a waterfall falling film flowing is formed between the U-shaped tubes in rows so that a melt phase polycondensation can be performed, and a melt slides down from the tubes, then condensed at the bottom of a reactor and discharged after stirring is performed to be homogenized through a stirrer. The reactor implementing the method is of an overall vertical structure and comprises a shell, a heating medium box at the upper end, a material box connected with the heating medium box, the U-shaped tubes, a bottom shell at the lower end, a stirrer and the like. The U-shaped tubes are perpendicularly suspended and arranged in rows, uniformly penetrate through holes in the film distribution plate, and the ends of the U-shaped tubes and the heating medium box are communicated to allow a heating medium to flow. The reactor has the advantages that the flowing resistance is small, no dead zone is generated, the film forming area is large, the surface updating speed is high, the standing time is uniform and controllable, and flexible production is met. The method is applicable to production of polyethylene glycol terephthalate and other polymers.

Owner:ZHEJIANG SCI-TECH UNIV

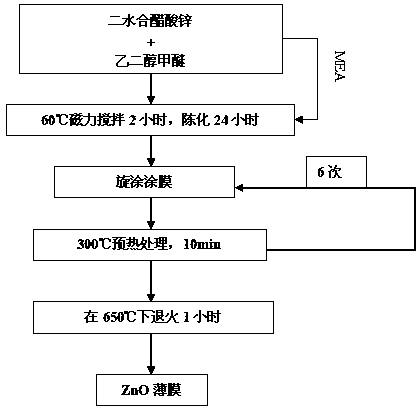

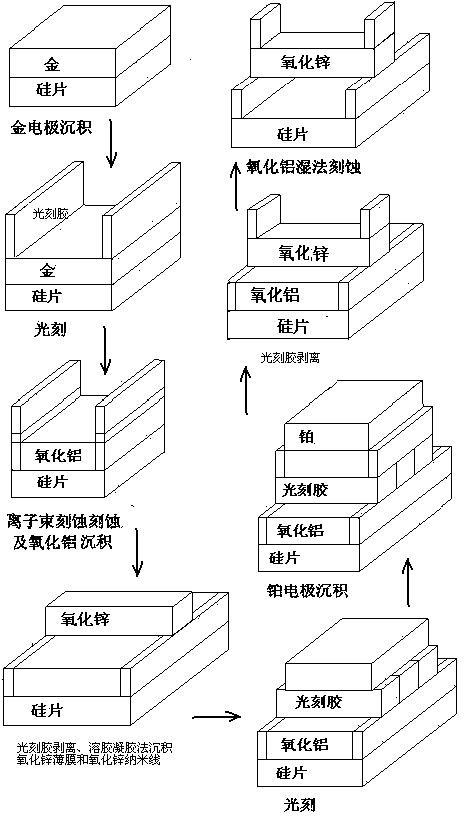

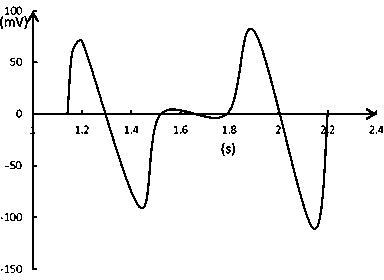

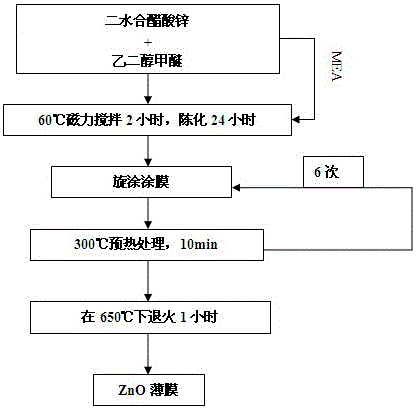

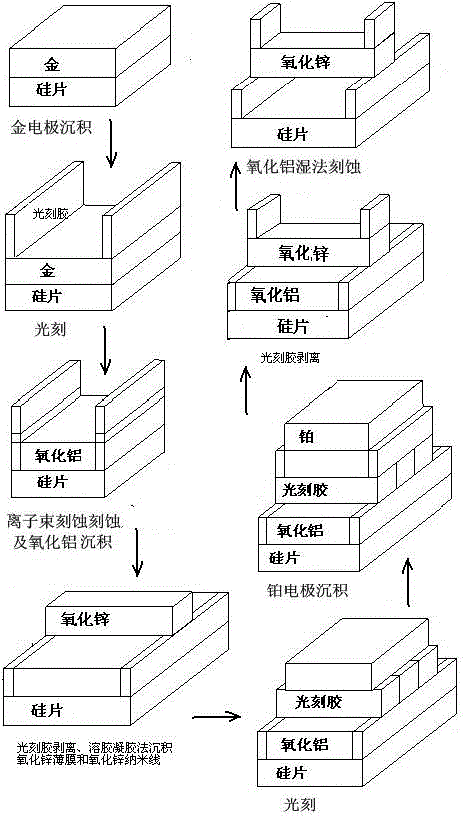

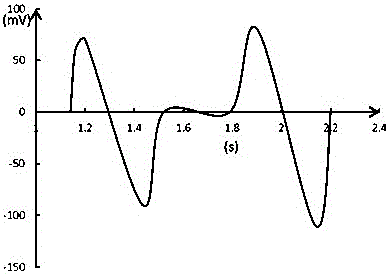

Large area manufacturing method for zinc oxide nano micro generators

ActiveCN104037320ASynthesis temperature is lowOptimizing Process ParametersPiezoelectric/electrostrictive device manufacture/assemblyNanogeneratorEvaporation

A large area manufacturing method for zinc oxide nano micro generators comprises depositing a gold electrode on a substrate; coating photoresist in a spinning mode to form into a photoresist nano micro wire structure in the Y direction; etching gold electrode materials which are free of photoresist protection through ion beam etching, depositing hard mask material, namely aluminum oxide and etching aluminum oxide materials on the lateral wall to enable the photoresist to be exposed; stripping the photoresist and aluminum oxide on the photoresist through acetone and depositing a zinc oxide film through a sol-gel method; performing photoresist stripping through the ion beam etching and the acetone to form into zinc oxide nano wires; coating photoresist in a spinning mode and exposing the zinc oxide nano wires at two ends after exposure and forming; depositing a platinum electrode through electron beam evaporation, stripping the photoresist through the acetone and etching the aluminum oxide to form into a piezoelectric nano generator structure; exposing the piezoelectric nano generator to a vibration source to generate piezoelectric conversion and nano micro piezoelectric power generation. The large area manufacturing method for the zinc oxide nano micro generators achieves large area controllable production and manufacture of the low cost high mechanical energy to electric energy conversion nano generators.

Owner:NANJING YIDEGUAN ELECTRONICS TECH +1

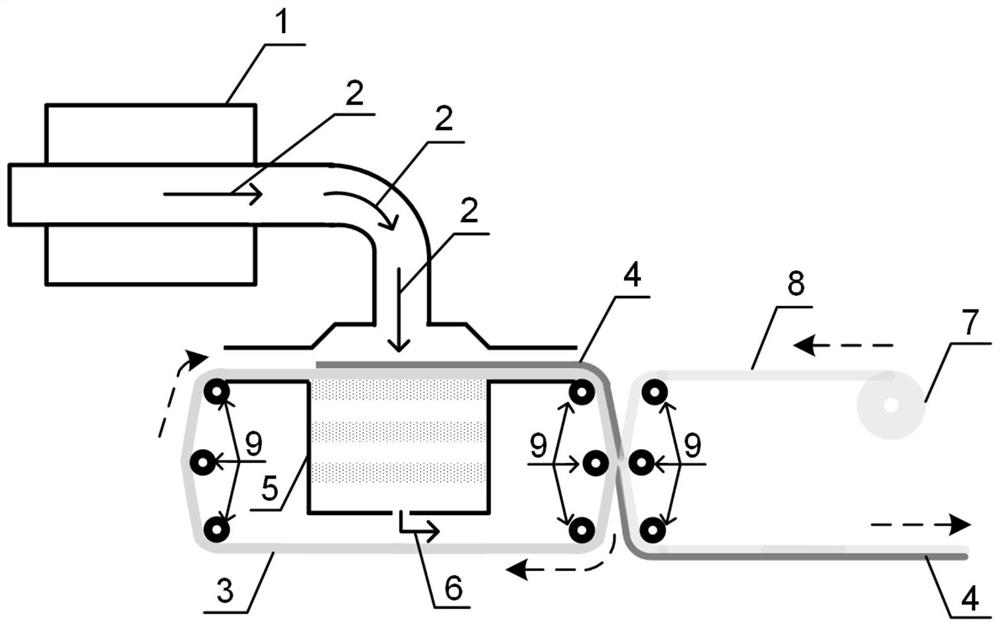

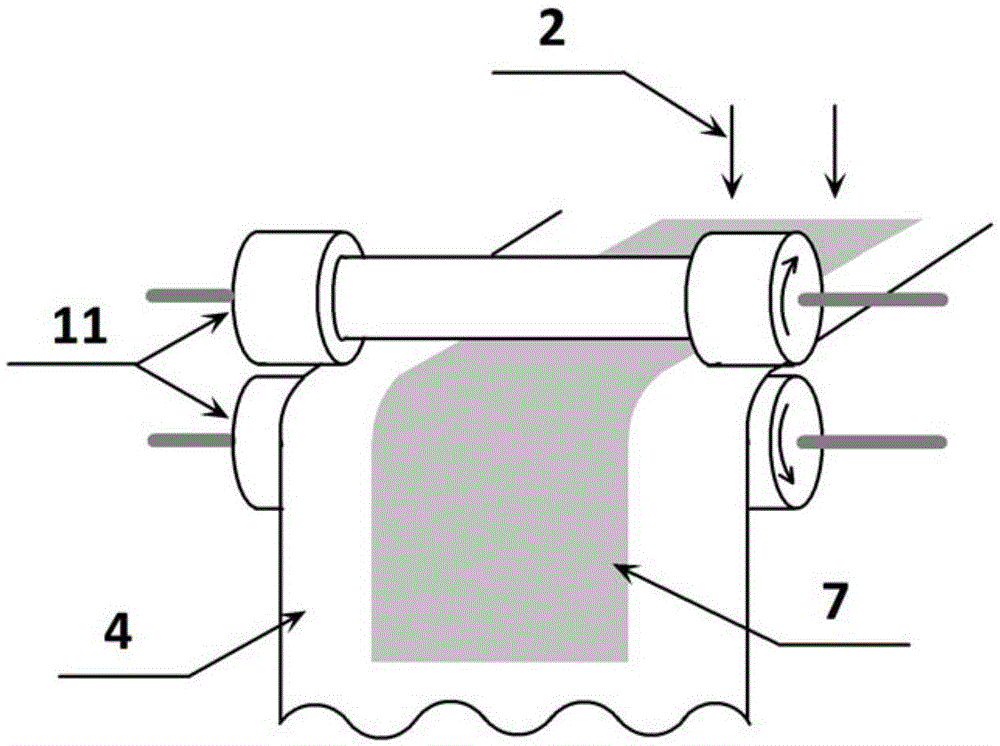

Continuous preparation and transfer method for meter-scale single-walled carbon nanotube film and special device

PendingCN111908454AUniform preparationLarge film forming areaMaterial nanotechnologySingle-walled nanotubesPtru catalystCarbon nanotube

The invention relates to a continuous preparation and transfer technology of a single-walled carbon nanotube film, in particular to a reel-to-reel continuous preparation and transfer method of a meter-scale single-walled carbon nanotube film and a special device. The method comprises the following steps: synthesizing a single-walled carbon nanotube by adopting a floating catalyst chemical vapor deposition method, and uniformly and continuously depositing a single-walled carbon nanotube film on the surface of a microporous filter membrane capable of continuously running by adopting a vapor suction filtration method; employing a roll-to-roll imprinting mode, wherein the carbon nanotube film can be transferred to the flexible plastic substrate from the surface of the microporous filter membrane, so the large-area uniform single-walled carbon nanotube film with the width reaching the meter level and the unlimited length is obtained. According to the roll-to-roll continuous preparation andtransfer technology of the single-walled carbon nanotube film, large-area and uniform macro preparation of the single-walled carbon nanotube film is achieved under the conditions of normal pressure and room temperature, and the roll-to-roll continuous preparation and transfer technology has important significance in promoting large-scale preparation and application of the single-walled carbon nanotube film in the field of transparent and flexible photoelectric devices in the future.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Polycondensation kettle for falling film outside vertical tube

ActiveCN102746499BNo cloggingUniform film formationPressure vessels for chemical processVertical tubeVacuum pumping

The invention relates to a polycondensation kettle for a falling film outside a vertical tube. The kettle comprises a vertical casing (13); a head and a cone (7) are connected to the upper end and the lower end of the vertical casing (13) respectively; a feed inlet (1) and a heating medium inlet (19) are arranged at the top of the head; a discharge port (6) is arranged at the bottom of the cone (7); a vacuum pumping port (3) is arranged on the upper portion of the vertical casing (13); the feed inlet (1) is communicated with a buffer area between a lower tube plate (15) and a middle tube plate (17) through a pipeline; the vertical tube (12) is arranged in the center of the vertical casing (13), connected with the middle tube plate (17), and communicated with a heating medium outlet (2); and an annular gap (14) is reserved between the vertical tube (12) and the lower tube plate (15), and a central tube (11) arranged in the vertical tube (12) is communicated with the heating medium inlet (19). The polycondensation kettle has the advantages that the film formation of the materials is even, the reaction efficiency can be improved, and the kettle can be used for production of highly viscous polymers such as polyethylene terephthalate (PET).

Owner:ZHEJIANG UNIFULL IND FIBER

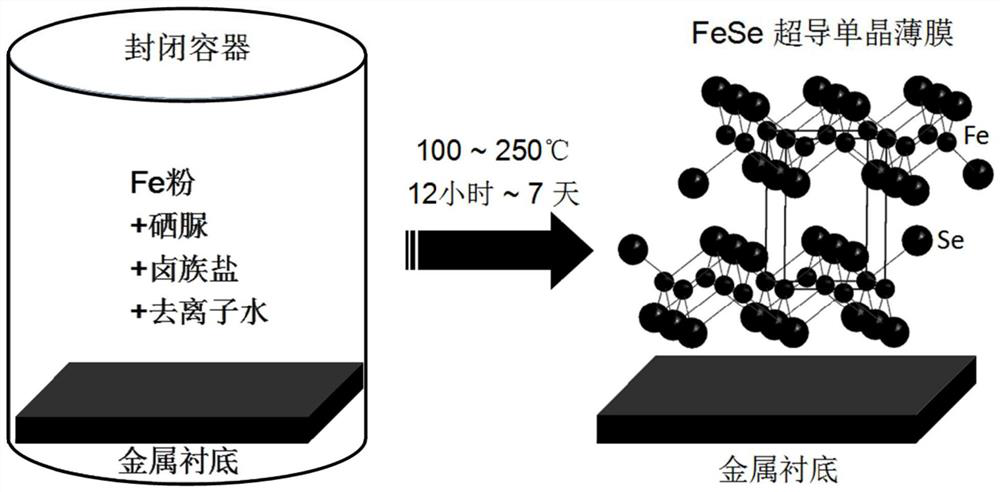

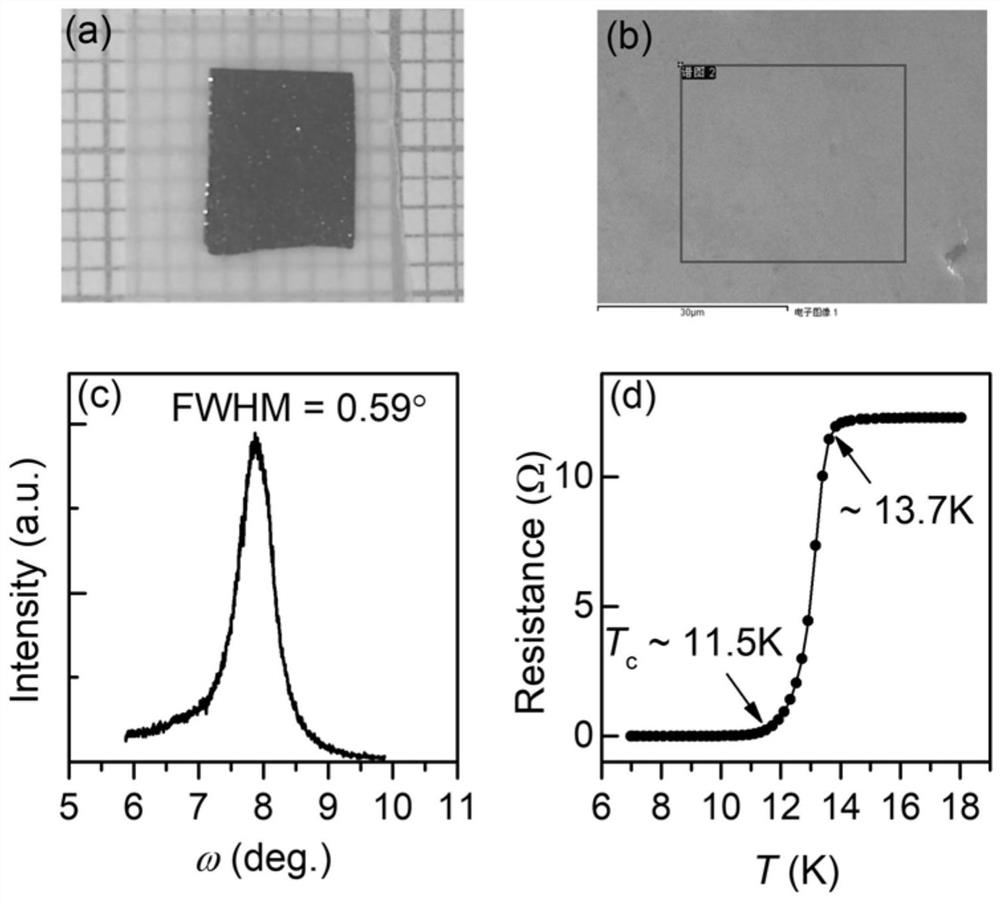

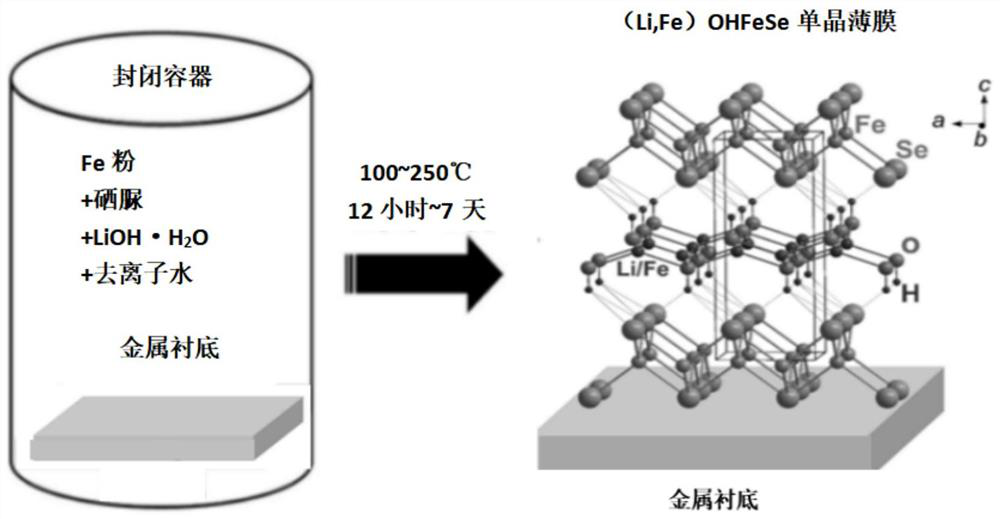

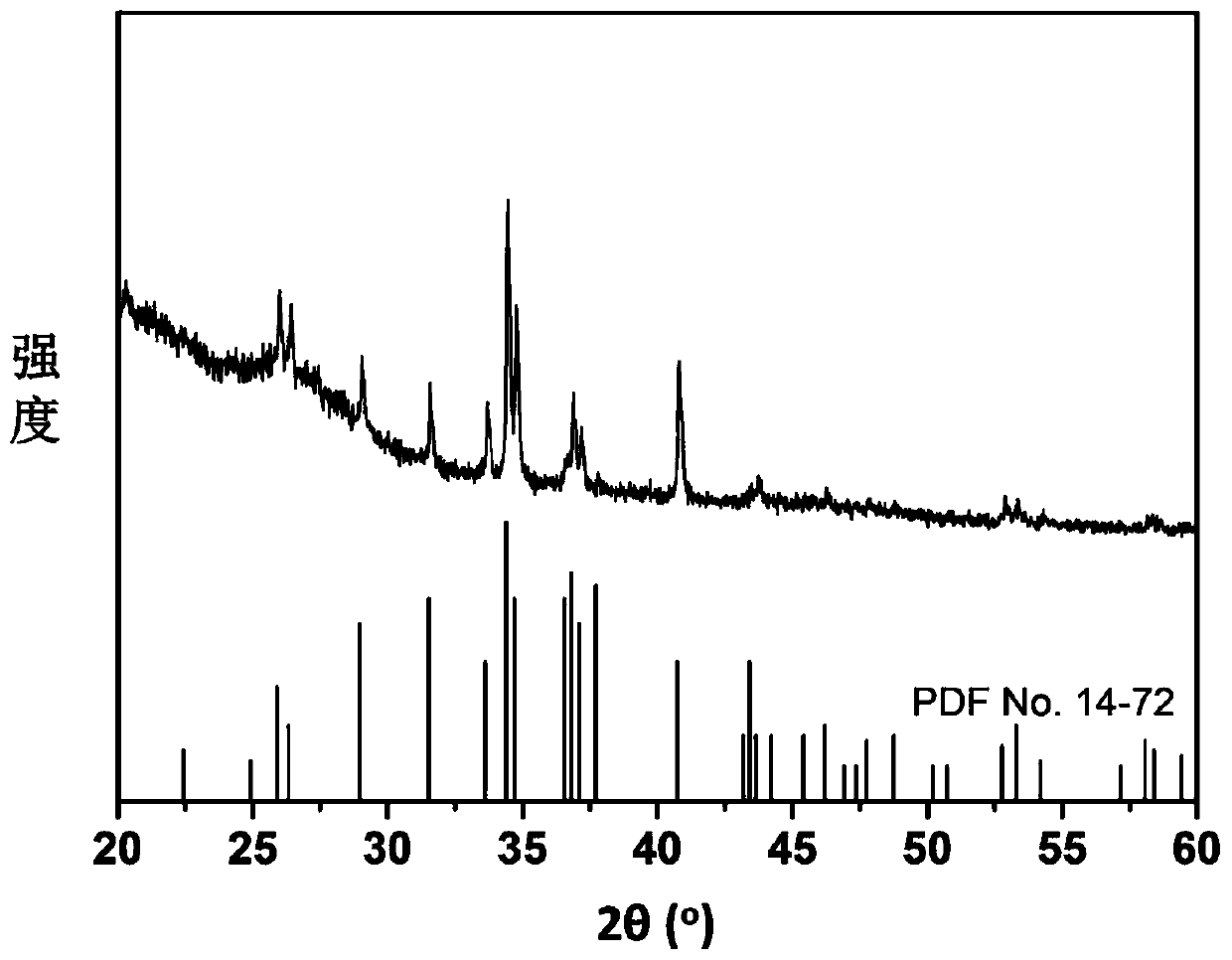

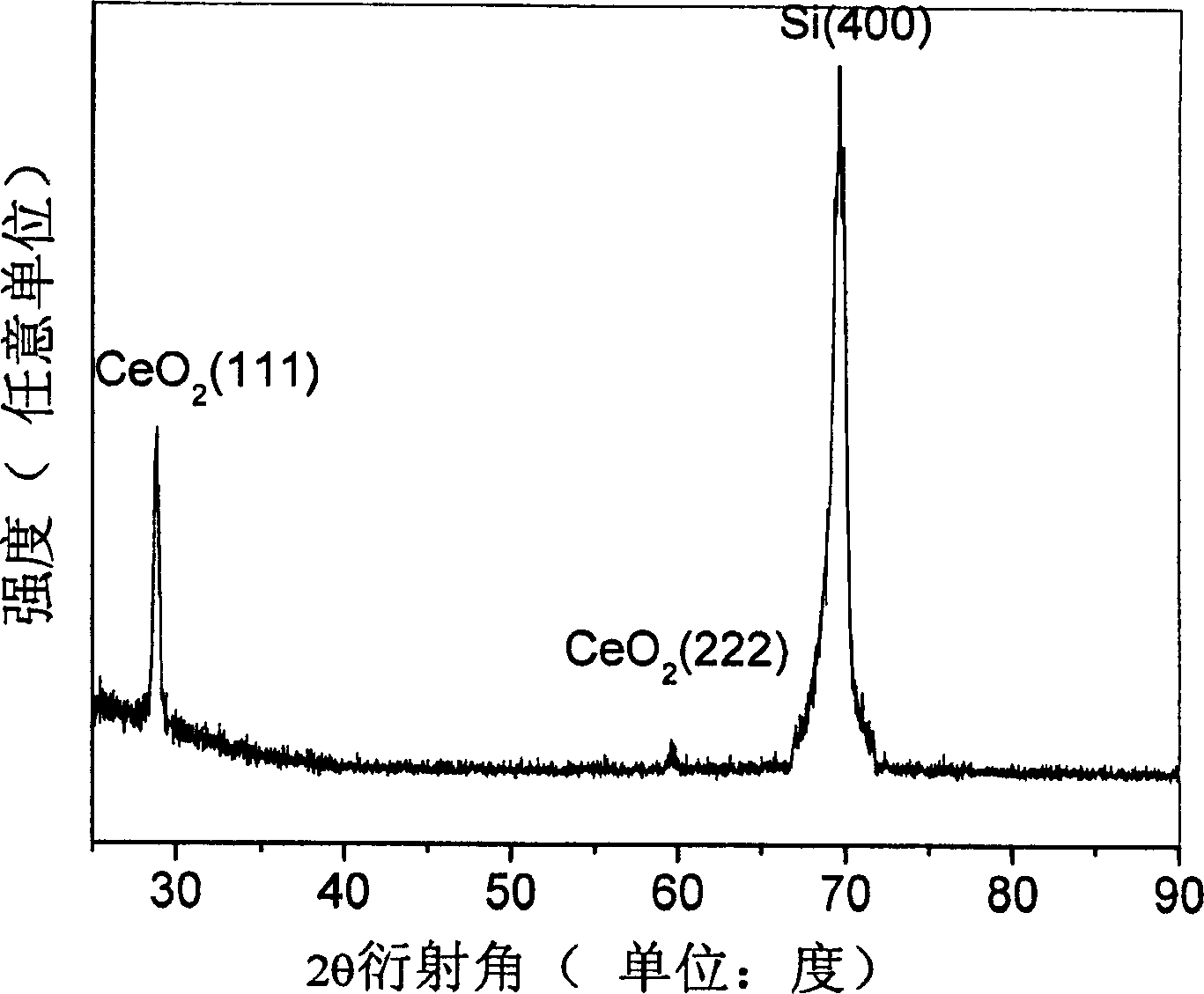

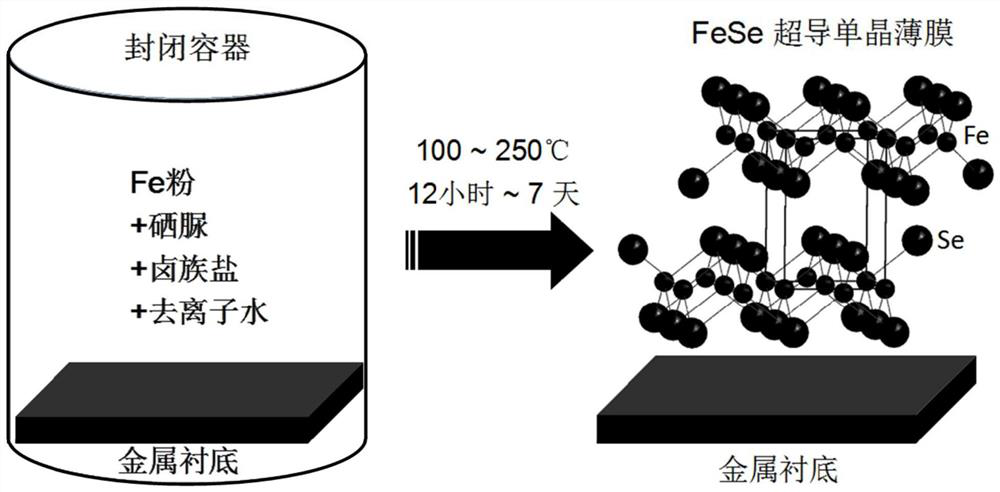

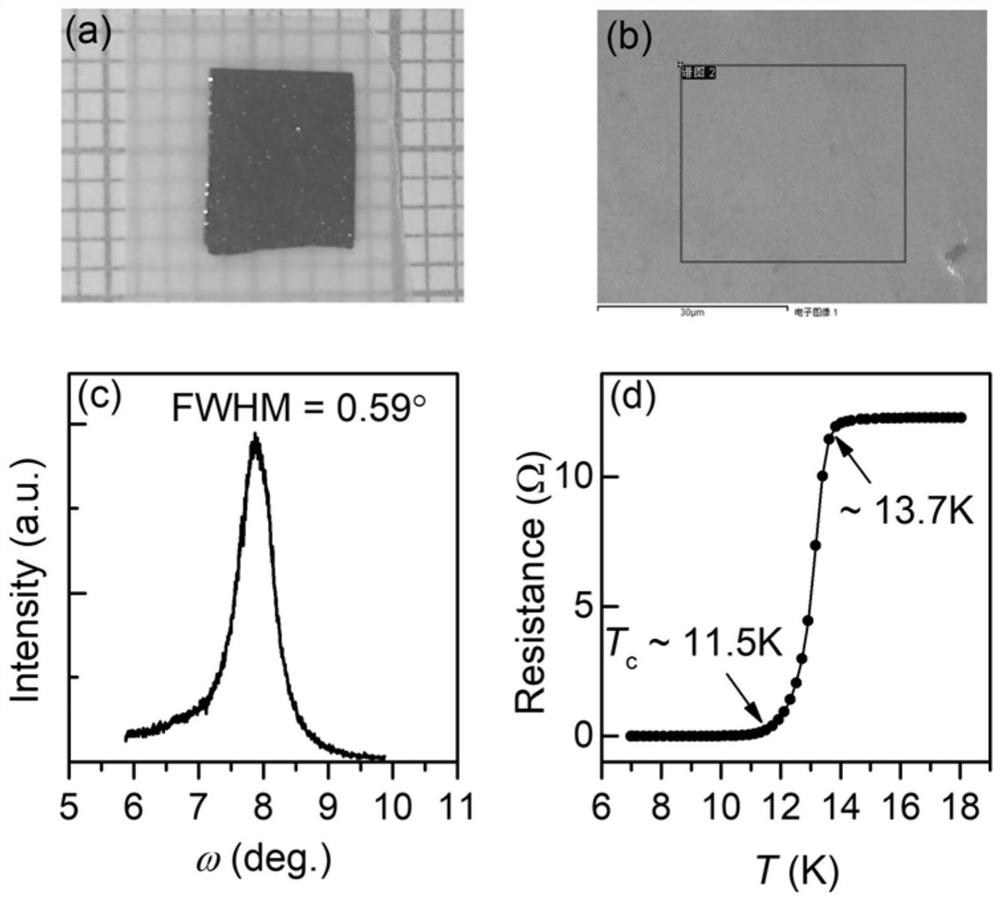

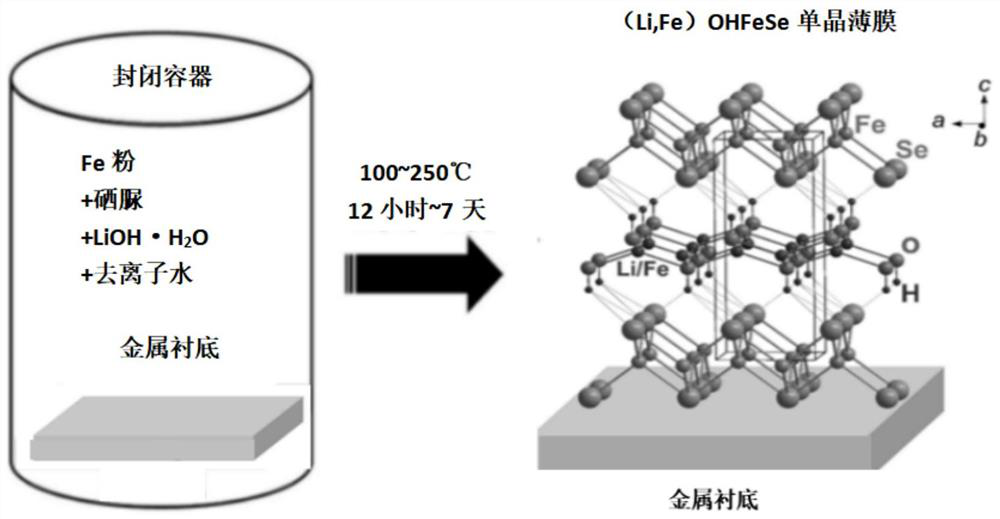

Hydrothermal preparation method of superconducting single crystal film and product thereof

ActiveCN111607826AReduce energy consumptionLow costPolycrystalline material growthFrom normal temperature solutionsMetallurgySource material

The invention provides a preparation method of a superconducting single crystal film, which is a hydrothermal method and comprises the following steps: (1) putting reactants and deionized water into asealable heating container, fully stirring and mixing, and putting a metal substrate in; (2) sealing the sealable container, and heating for reaction; and (3) after the reaction is finished, openingthe sealable container, taking out the metal substrate, and repeatedly cleaning with deionized water to obtain the superconducting single crystal film capable of realizing epitaxial growth. The methoddisclosed by the invention is low in energy consumption, low in cost and low in pollution, and does not need physical high-temperature and ultrahigh-vacuum equipment or high-valence organic source material and organic matter post-treatment required by the existing method. A metal substrate can be used, the shape and size of the substrate are not limited, and the method is simple, efficient and easy to popularize.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for preparing plasma-oriented tungsten coating used in fusion reactor by using tungsten carbonyl as precursor

InactiveCN102140625AHas a purifying effectHigh activityChemical vapor deposition coatingPorosityGas phase

The invention provides a method for preparing a plasma-oriented tungsten coating used in a fusion reactor by using tungsten carbonyl as precursor and using a plasma-enhanced metal organic chemical vapor deposition method. During a deposition reaction, the interlayer of a reactor is cooled through always introducing cooling water to the interlayer, the pressure is constant to be 150-250Pa, and thetemperature of a base is controlled to be 200-600 DEG C; saturated tungsten carbonyl vapor of which the purity is 99.9% is introduced, wherein the air flow is controlled to be 1.0-3.0ml / s, and the temperature ranges from 70 to 140 DEG C; and the deposition is carried out for 5-12 hours, and thermal diffusion annealing is carried out 3-6 hours after constant heat insulation. The method disclosed by the invention can be used for preparing tungsten coatings having high bonding strength with a base, and the coatings are less than 5mm in thickness and have the characteristics of low porosity, highpurity, smooth surface and the like. The method is relatively simple in process, has high reliability and can prepare large-area tungsten coatings, thereby being widely applied to a fusion reactor experimental facility and the first wall of a future fusion reactor.

Owner:JINGDEZHEN CERAMIC UNIV

Gas-phase continuous preparation method and special device for single-walled carbon nanotube film

The invention relates to a preparation method of single-walled carbon nanotubes by a floating catalyst chemical vapor deposition process and a film continuous collection technology thereof, and specifically relates to a gas-phase continuous preparation method of a single-walled carbon nanotube film and a special device. The preparation method comprises the steps of depositing the single-walled carbon nanotubes synthesized by the floating catalyst chemical vapor deposition process onto the surface of a microporous filter membrane moving at a uniform speed by utilizing a gas-phase suction filtration device under normal-pressure and room-temperature conditions, controlling the movement speed of the microporous filter membrane, and regulating and controlling the gas flow balance to obtain a large-area, uniform and density-controllable single-walled carbon nanotube film. According to the gas-phase continuous film-forming technology of the single-walled carbon nanotubes, provided by the invention, the large-scale preparation of the large-area, uniform and density-controllable single-walled carbon nanotube film is realized under the normal-pressure and room-temperature conditions, the preparation method has important significance in promoting the progress of the single-walled carbon nanotube film in the field of large-scale preparation and application of optoelectronic devices, and the film has application in the field of large-scale preparation of the optoelectronic devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

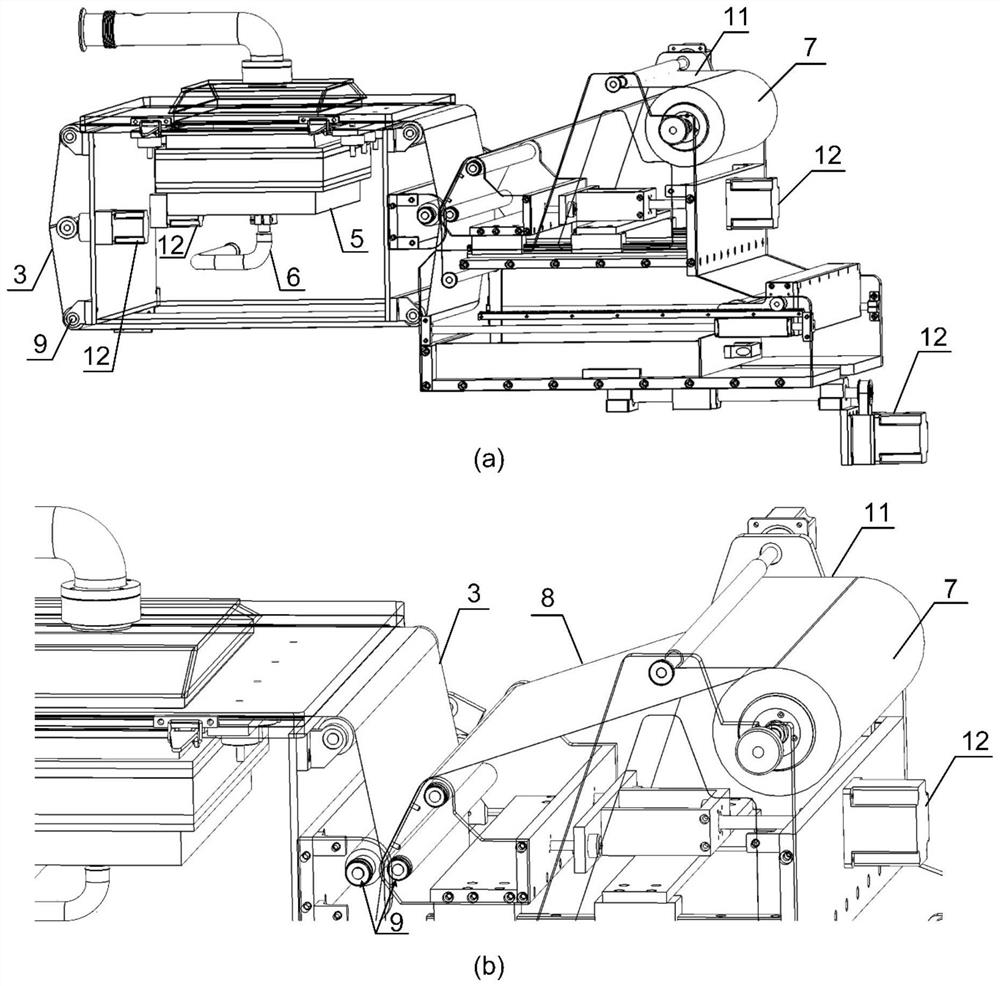

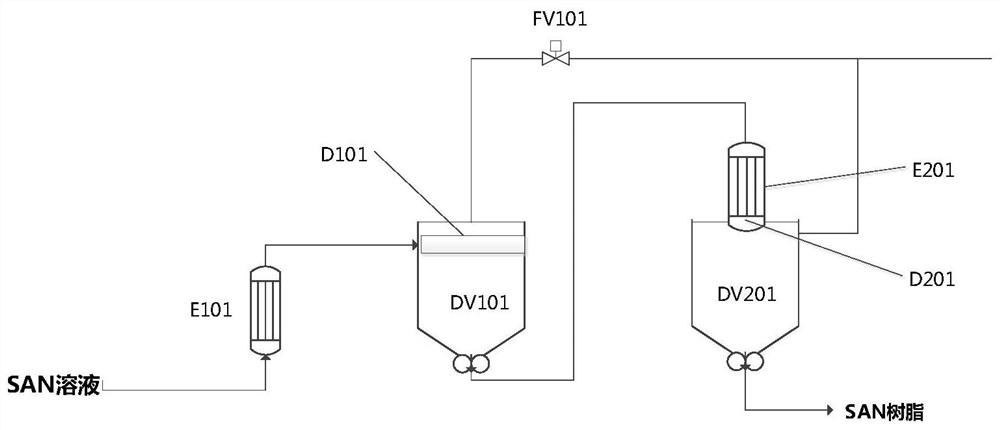

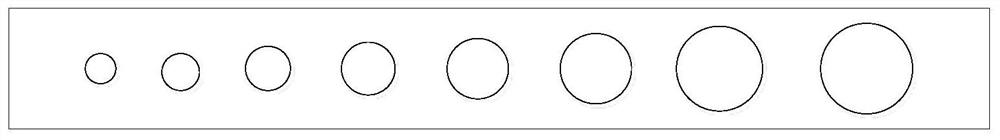

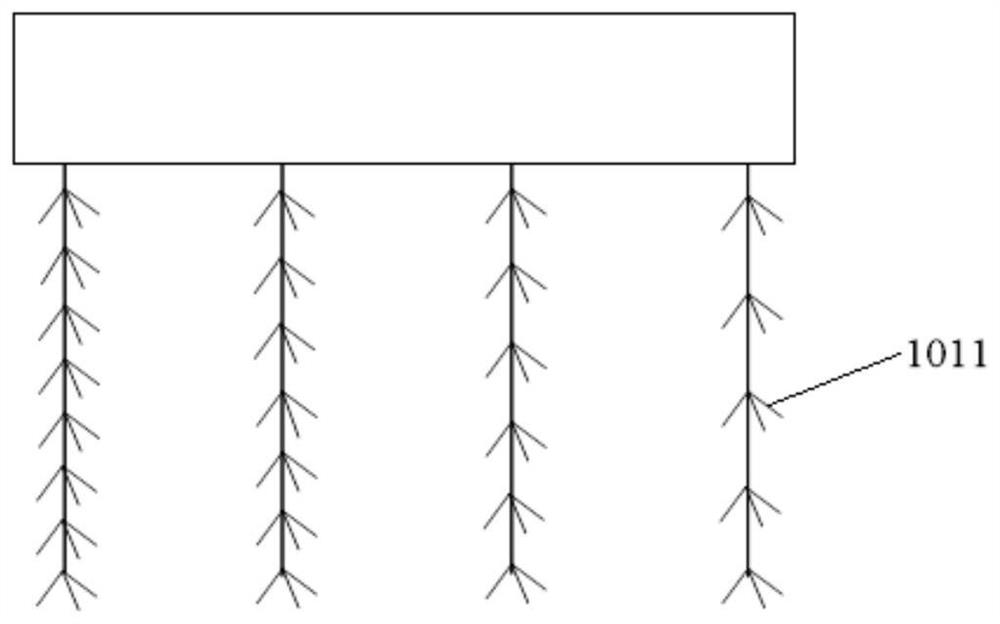

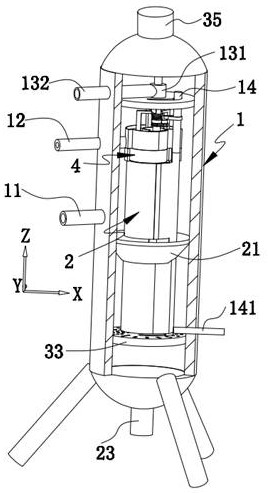

Devolatilization device and SAN (Styrene Acrylonitrile) resin devolatilization process

ActiveCN113304709AAvoid interferenceLarge film forming areaChemical/physical/physico-chemical processesFeed devicesPolymer scienceAcrylonitrile

The invention discloses a devolatilization device and an SAN resin devolatilization process. A material distributor is arranged at a material inlet of the devolatilization device, a plurality of holes are formed in the material distributor, flow guide wires are arranged at the holes, and barbs are arranged on the flow guide wires. According to the devolatilization process, the two-stage series devolatilization device is adopted for removing volatile components, the devolatilization device is adopted for devolatilization, the film forming property of the material is good, the volatile component content of the obtained material is small, and the devolatilization efficiency is high.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

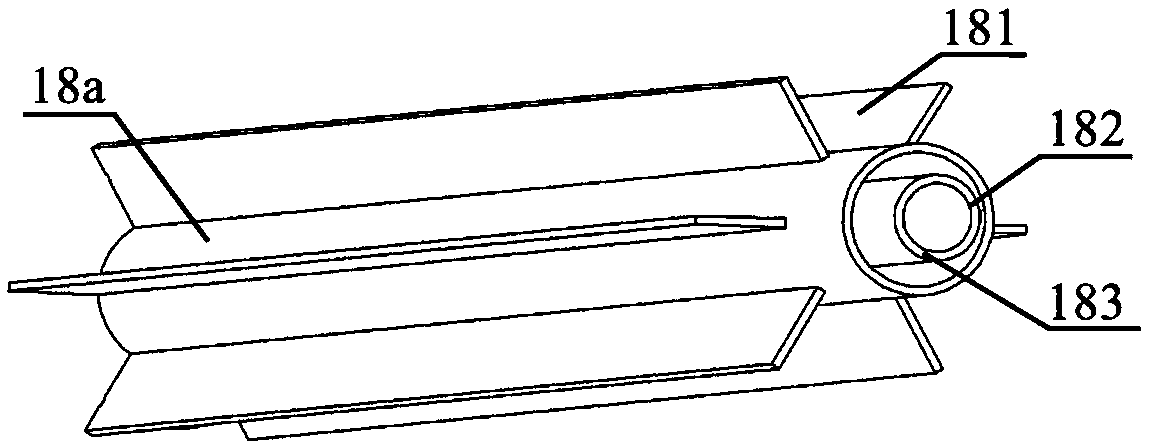

Falling film type devolatilizer and falling film element thereof

PendingCN110639461AEasy to adjust residence timeEasy to control liquidityChemical/physical/physico-chemical stationary reactorsPolymer sciencePolymer chemistry

The invention relates to a falling film type devolatilizer and a falling film element thereof. The falling film type devolatilizer comprises a vertical shell, a seal head connected with the upper endof the vertical shell, and a bottom shell connected with the lower end of the vertical shell; a material box body and at least one falling film element are arranged in the devolatilizer; the falling film element is provided with a plurality of falling film flow channels; a bottom plate of the material box body is a film distribution plate; and film distribution structures are distributed on the film distribution plate for all the falling film flow channels. The devolatilizer has the advantages of large film forming area, controllable film forming form, wide flow regulation range and the like,and is suitable for devolatilization processes such as high-viscosity polymer production, spinning solution deaeration, solution concentration and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Chemical method for rapidly synthesizing silver sulfide film at normal temperature

InactiveCN111533462AAchieve preparationQuick responseVacuum evaporation coatingSputtering coatingAmmonium sulphideThin membrane

The invention relates to a chemical method for rapidly synthesizing a silver sulfide film at normal temperature. The method comprises the following steps of: enabling a substrate deposited with an elemental silver film to react with an ammonium polysulfide aqueous solution under the conditions of normal temperature and normal pressure to prepare a silver sulfide semiconductor film material on thesurface of a substrate material in situ. According to the method, under the conditions of normal temperature and normal pressure, the ammonium polysulfide reacts with the elemental silver thin film, the reaction speed is high, preparation of the silver sulfide thin film can be rapidly achieved under the condition that the reaction time is shorter than 1 min, and the obtained silver sulfide thin film is high in compactness and good in stability. And the thickness of the silver sulfide film can reach 300-1000 nm.

Owner:XUCHANG UNIV

Method and device for preparing rare earth doped gallium nitride light-emitting film

InactiveCN100594255CBind and extend motion trajectoriesLow deposition temperatureVacuum evaporation coatingSputtering coatingDielectricRare earth

The invention discloses a preparing method of gallium nitride luminous film doped by rare earth, which is characterized by the following: controlling the substrate temperature within 0-500 Deg C; adopting nitrogen or composite gas of nitrogen and argon as splashing gas; proceeding magnetic control splashing for metal gallium of doped rare earth powder in the vacuum; sedimenting rare earth doped gallium nitride luminous film on the substrate of target position. The invention also provides magnetic control splashing device to prepare the product, which contains vacuum chamber; the rotary substrate rack with substrate and 3-5 magnetic targets are set in the vacuum chamber; the magnetic control target is set on the substrate, which makes substrate bottom parallel the magnetic control target; each magnetic control target connects DC anode directly; the cooling chamber is set in the magnetic control target, which possesses cooling dielectric inlet an outlet.

Owner:WUHAN UNIV

LED chip base using diamond film as heat sink material and preparation method

InactiveCN101465399BDistribute as soon as possibleImprove luminous efficiencySemiconductor devicesHeat sinkMaterials science

Owner:JILIN UNIV

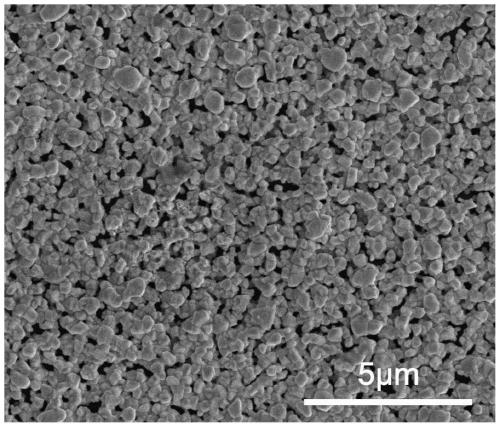

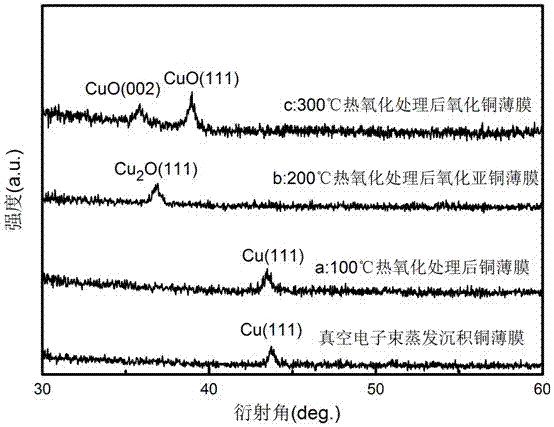

Preparation method for single-phase P type cuprous oxide thin film

InactiveCN107130215AIncrease deposition rateLarge film forming areaVacuum evaporation coatingSputtering coatingMuffle furnaceSingle phase

The invention discloses a preparation method for a single-phase P type cuprous oxide thin film. A washed quartz base is fixed to a film-coating fixture at a room temperature by adopting a vacuum electron beam evaporation method, and a metallic copper thin film is deposited under 5.0 * 10<-4> - 7 * 10<-4> Pa; and then the quartz base deposited with the metallic copper thin film is placed in a muffle furnace, thermal oxidation treatment is conducted in an atmospheric environment, and the single-phase P type cuprous oxide thin film is acquired, wherein the optimized thickness of the thin film is 50-150 nm. According to the preparation method for the single-phase P type cuprous oxide thin film, the vacuum electron beam evaporation method and the precise control of the temperature of the follow-up thermal oxidation treatment are combined together, the cuprous oxide thin film prepared by the preparation method is single phase, high in deposition rate and large in film-forming area, the uniform growth of the thin film is achieved, and the thin film can serve as a photocatalytic oxidizing material with a very high application prospect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

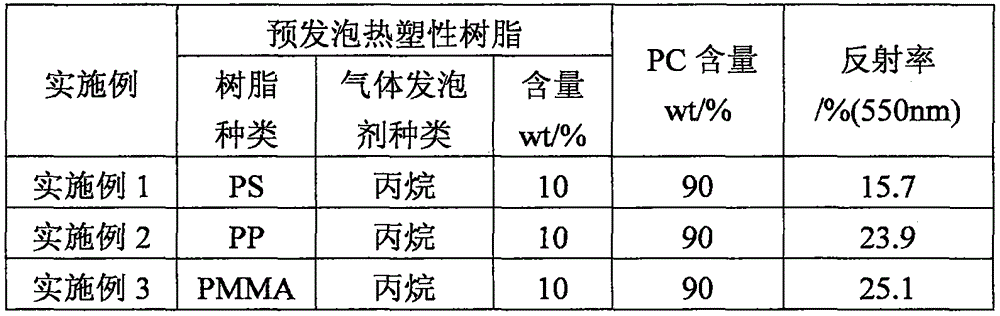

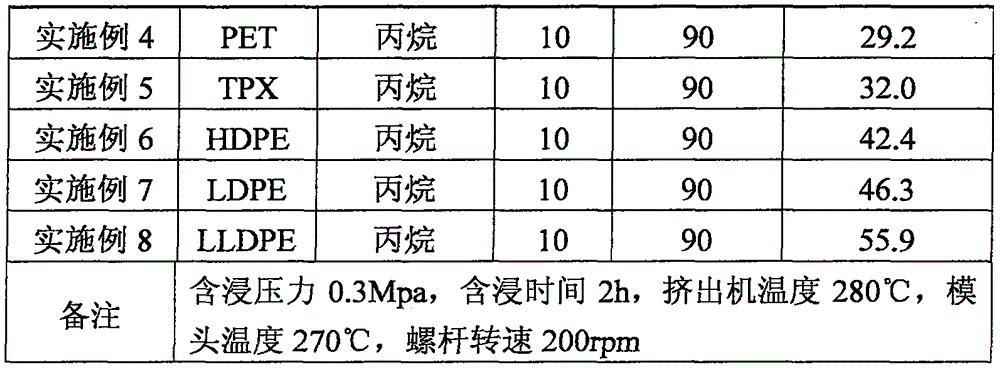

Micro-foaming and light-reflecting PC film material and preparation method thereof

InactiveCN105219055AIncrease the number of reflectionsImprove reflectivityFoaming agentLight reflection

The invention discloses a micro-foaming and light-reflecting PC film material and a preparation method thereof. The preparation method of the micro-foaming and light-reflecting PC film material comprises the following steps: (1) preparing pre-foamed thermoplastic resin particles: putting the thermoplastic resin particles into a high-pressure kettle containing a gas foaming agent and impregnating for 1-3.5 hours under the pressure of 0.20-0.45MPa to obtain the pre-foamed thermoplastic resin particles; (2) preparing the micro-foaming and light-reflecting PC film material by uniformly mixing the pre-foamed thermoplastic resin particles prepared by the step (1) with PC resin through a high-speed mixer, extruding the particles through a twin-screw extruder, and prilling, wherein the temperature of a homogenizing section of the extruder is 275-290 DEG C, the temperature of a die head is 265-280 DEG C, and the rotation rate of screws is 100-500rpm; cooling and drying the particles to obtain the micro-foaming and light-reflecting PC film material. The micro-foaming and light-reflecting PC film material has the advantages of high visible light reflection rate, light weight, low cost, simple preparation process and simple equipment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Tube alignment type condensation polymerization reaction kettle

The invention discloses a tube alignment type condensation polymerization reaction kettle. According to the kettle, tube plates (4) are arranged inside a vertical casing (8); the tube plates (4) are connected with a tube alignment (5); material distributors (6) are arranged on the upper end tube openings of the tube alignment (5); annular gaps (7) are arranged between the upper end tube openings of the tube alignment (5) and the material distributors (6); the top end of the vertical casing (8) is provided with a material inlet (1), and the lower end of the vertical casing (8) is provided witha material outlet (10); the lower part of the side surface of the vertical casing (8) is provided with a heating medium inlet tube (2), the upper part of the side surface of the vertical casing (8) is provided with a heating medium outlet tube (3), and the middle-lower part of the side surface of the vertical casing (8) is provided with a vacuum pumping port (9). According to the present invention, material naturally flows downward by gravity, if the tube alignment is large, the film forming of the inner wall of tube alignment is sufficient, such that the blocking problem can not be generated; the tube alignment type condensation polymerization reaction kettle of the present invention has characteristics of good film forming effect, reliable use, and high work efficiency, and can be used for productions of PET and other high viscosity polymers. In addition, a plurality of the tubes can be aligned in the tube alignment.

Owner:ZHEJIANG UNIFULL IND FIBER

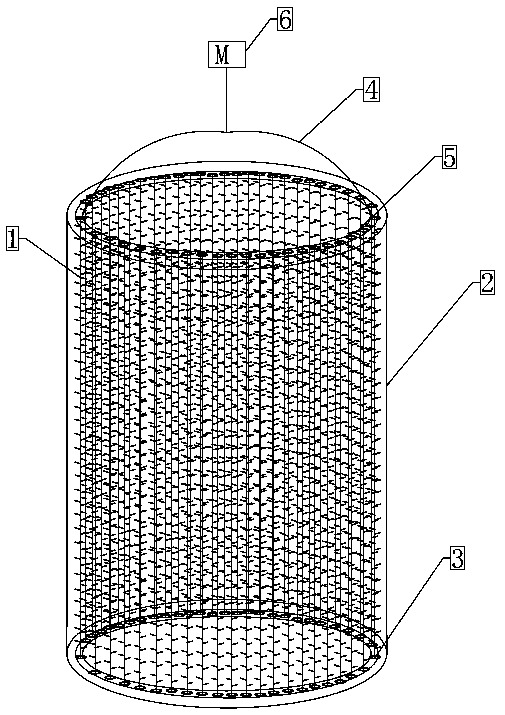

Film scraping technology in molecular distillation equipment

InactiveCN110237556AImprove fluencyAvoid contaminationMolecular distillationProduction rateDistillation

The invention relates to a film scraping technology, comprising a film scraping brush and a connecting tray, wherein the film scraping brush is connected with the connecting tray by means of a bearing. The film scraping technology also comprises a film forming barrel, a cage-shaped cover body and a motor, wherein the cage-shaped cover body is connected with the connecting tray and the motor; the film scraping brush is positioned in the barrel, and a certain gap is reserved between the film scraping brush and the barrel. The film scraping technology has the greatest advantage that the film scraping brush can revolve on the self axis depending on a certain resistance of a material while being driven to rotate by the motor, so that the film forming area is greatly enlarged, and the material treatment speed is greatly accelerated; when being used in industrial production, the technology can remarkably increase the production rate.

Owner:福建钰融科技有限公司

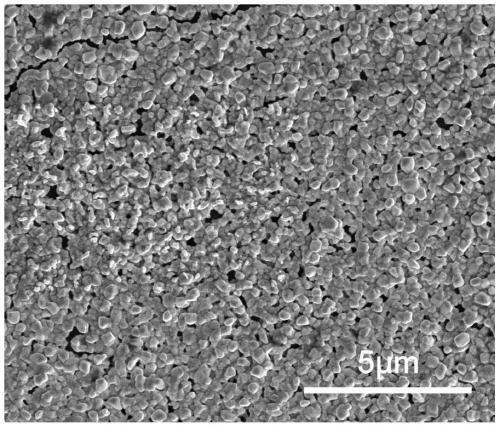

N-VO2/p-NiO-based heterogeneous structure and preparation method thereof

InactiveCN108428736AQuality improvementLow costSemiconductor/solid-state device manufacturingSemiconductor devicesOptical storageTin

The invention relates to an n-VO2 / p-NiO-based heterogeneous structure and a preparation method thereof. The n-VO2 / p-NiO-based heterogeneous structure comprises a TiN film, a first AZO transparent conductive film, a VO2 film, a p-NiO film, a second AZO transparent conductive film and a flexible stainless steel substrate which are sequentially distributed from top to bottom, wherein the p-NiO film is a buffer layer, the TiN film is a protective layer, and the first AZO transparent conductive film and the second AZO transparent conductive film both serve as a conductive electrode and a slowing layer. With the preparation method adopted, the n-VO2 / P-NiO heterostructure can be combined with a flexible stainless steel material, a flexible high-power device can be prepared; the device has a bright application prospect in high-power photoelectric switches, high-power and low-cost optical storage devices, and the like; and the device can be low in power and long in service life.

Owner:SHENYANG INST OF ENG

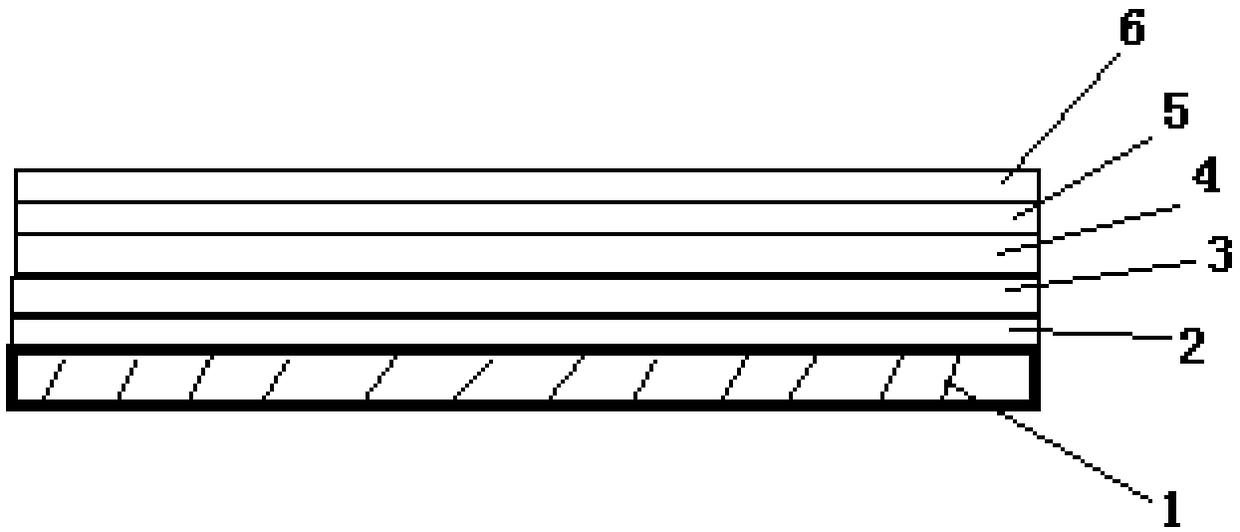

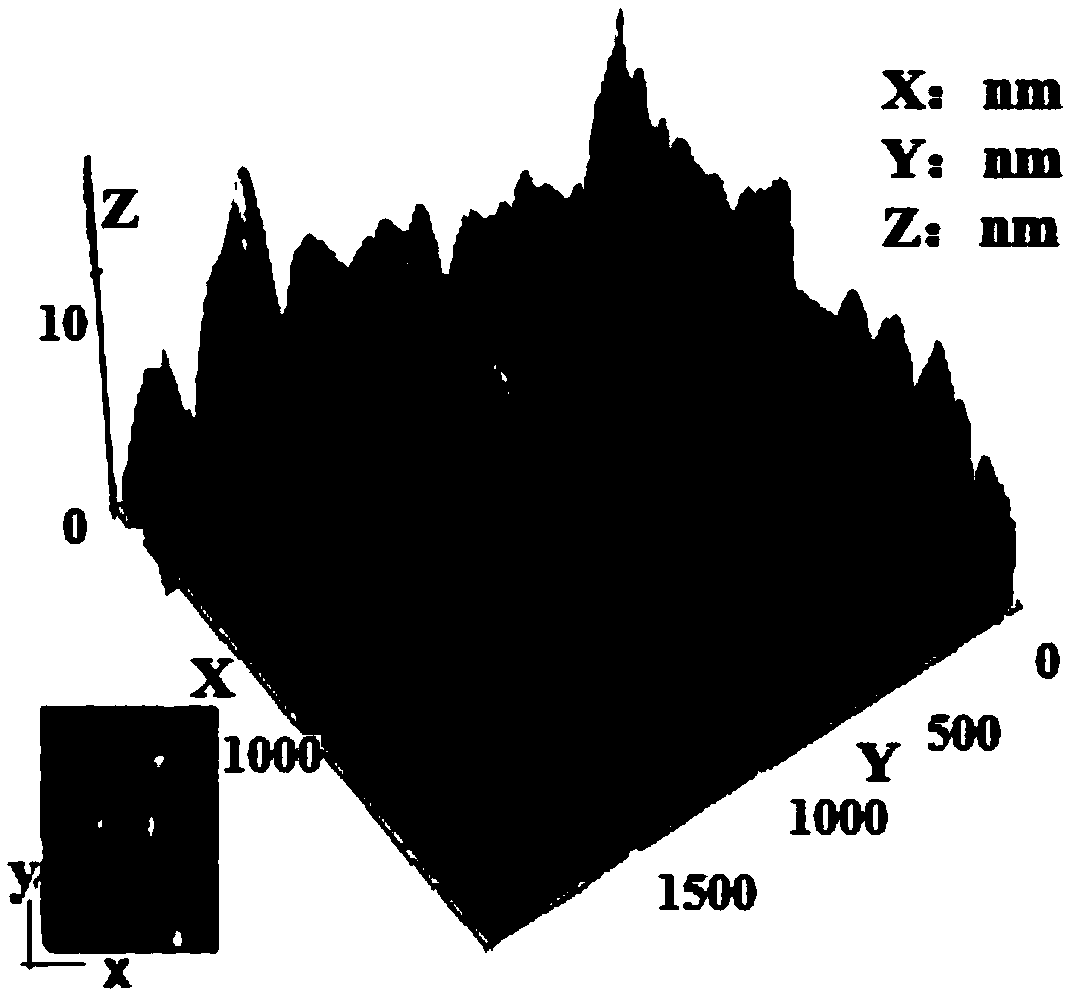

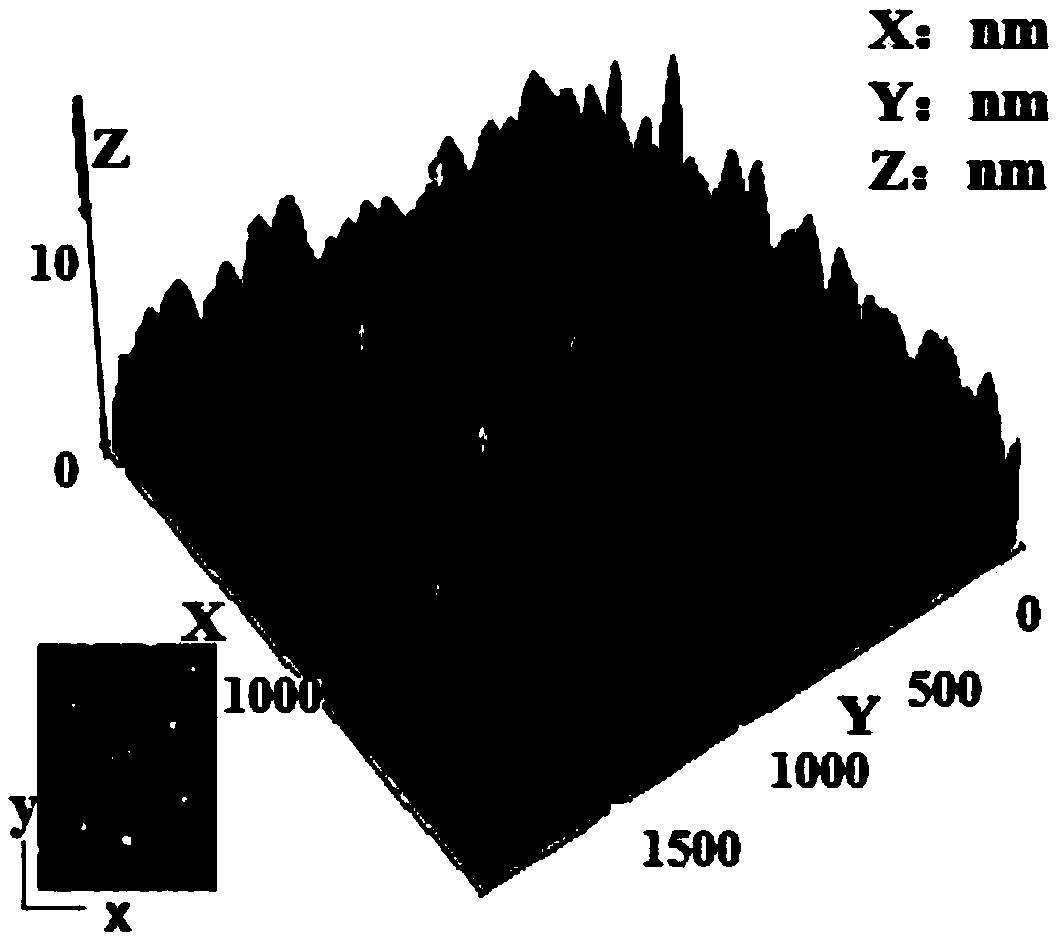

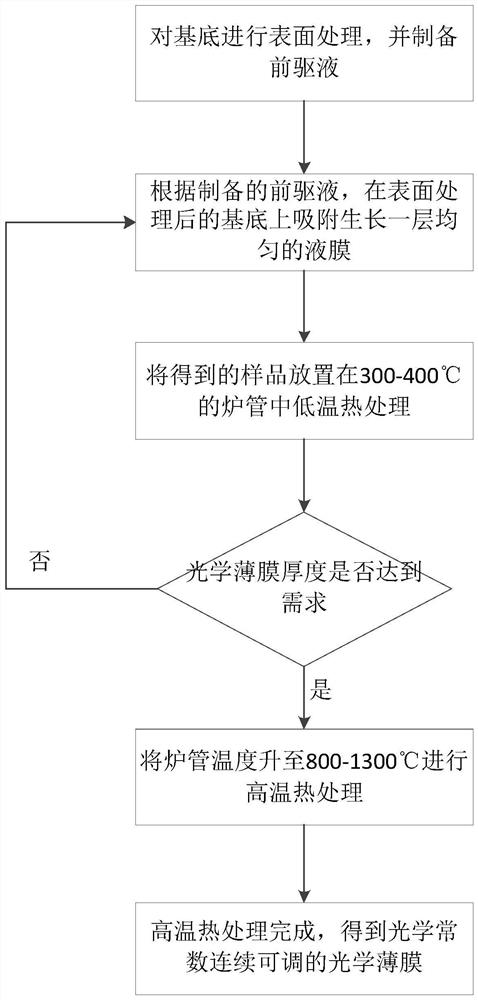

Method for growing thin film with continuously adjustable optical constants

PendingCN114277363AOptical constants are continuously adjustableLarge film forming areaLiquid/solution decomposition chemical coatingOptical elementsThin membraneChemistry

The invention belongs to the field of film growth, and particularly relates to an optical constant continuously adjustable film growth method which comprises the following steps: preparing a precursor solution; performing surface treatment on the substrate; after the treatment is completed, a layer of uniform liquid film is adsorbed and grown on the substrate; placing the substrate on which the layer of uniform liquid film is adsorbed and grown in a furnace tube at 300-400 DEG C for low-temperature heat treatment; in order to improve the efficiency and the film quality, after the low-temperature heat treatment is completed, the operations of liquid film growth and low-temperature heat treatment can be repeated to obtain a thicker film layer; the temperature of the furnace tube is increased to 800-1300 DEG C for high-temperature heat treatment, and then the optical thin film with the continuously adjustable optical constant is obtained; by changing the components of the precursor solution, the film deposition condition and the heat treatment condition, the optical constant is continuously adjustable, so that the film system structure of the filter film can be greatly simplified, and the process time and cost are shortened.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Melt polycondensation method, special reactor and falling-film elements

ActiveCN103360587BImprove quality stabilityImprove quality uniformityChemical/physical/physico-chemical stationary reactorsPolytetramethylene terephthalatePolymer science

The invention discloses a melt polycondensation method. Melted monomer blends or prepolymers slide down along the outer walls of tubular falling-film elements so as to be subjected to polycondensation, melts on all the falling-film elements gather at the bottom of a polycondensation reactor so as to be further stirred for reaction and mixed uniformly, and materials are discharged after the reaction finishes. The polycondensation reactor for implementing the method comprises a vertical shell, an end enclosure on the upper end, a bottom shell on the lower end, the falling-film elements, a heat transfer system, a film distributor and a helical ribbon stirrer, wherein the falling-film elements are corrugated pipes with optimized structural parameters. The polycondensation reactor has the advantages of simple structure, sufficient heat exchange, large film forming area, uniform reaction temperature and high polycondensation efficiency, guarantees the laminar flow in the process and can be used for the melt polycondensation of polyethylene glycol terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, polyamide and polycarbonate.

Owner:ZHEJIANG SCI-TECH UNIV

Polycondensation vacuum reaction system for flame-retardant slice production and production process

PendingCN114797732AIncrease film forming areaHigh film forming efficiencyChemical/physical/physico-chemical stationary reactorsPressure/vacuum vesselsReaction rateCoil spring

The invention relates to the technical field of flame-retardant slice production, in particular to a condensation polymerization vacuum reaction system for flame-retardant slice production and a production process. The hollow coil spring is arranged in the kettle body; the feeding pipe extends into the kettle body and is used for conveying materials to the upper end of the hollow coil spring so as to enable the materials to flow downwards along the side wall of the hollow coil spring; the first pipe and the second pipe are respectively communicated with two ends of the hollow coil spring and are matched to drive the hollow coil spring to contract and contract so as to promote heat exchange between fluid in the hollow coil spring and materials; the device has the advantages of high heat exchange efficiency, high polymerization reaction rate, high byproduct discharge rate and high product yield.

Owner:浙江安吉骏逸新材料科技有限公司

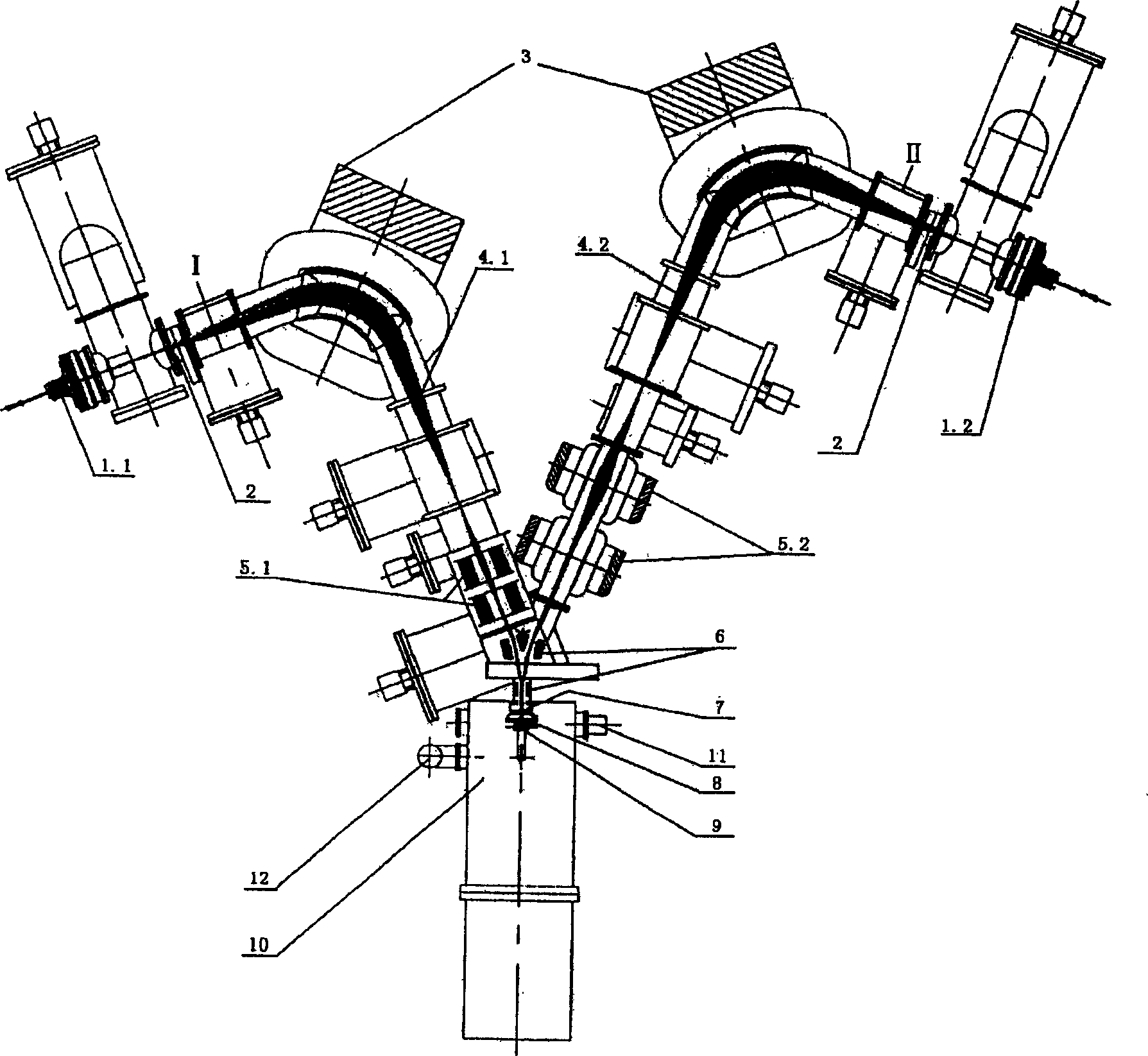

Method for preparing thin film material of binary rare earth compounds

InactiveCN1796595AEfficient growth and high qualityImprove uniformityVacuum evaporation coatingSputtering coatingUltra-high vacuumFilm material

This invention provides a preparation for binary rare earth compound thin films. A low-energy double ion beam deposition apparatus is adopted for its function of mass separation and characteristics of energetic ion deposition, and rare earth chlorides of which purity is not highly required serve as raw materials for I beam of Bonus solid ion source to give out an isotopic pure low-energy rare earth ion beam, which with another isotopic pure low-energy ion from II beam of Bonus gaseous ion source is deposited alternately in ultravacuum cultivation room. By exactly controlling the energy of the isotopic pure low-energy ions, beam shape, beam flux, beam proportion and growing temperature, deposition and low-temperature epitaxy of binary rare earth compounds which have high temperatures and are difficult to purify and easy to oxidized can be realized. A wide variety of rare earth thin films can be prepared according to this invention and the technique is convenient to modulate and optimized, which is economical to manufacture rare earth thin films used in semiconductor technology and some other fields.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

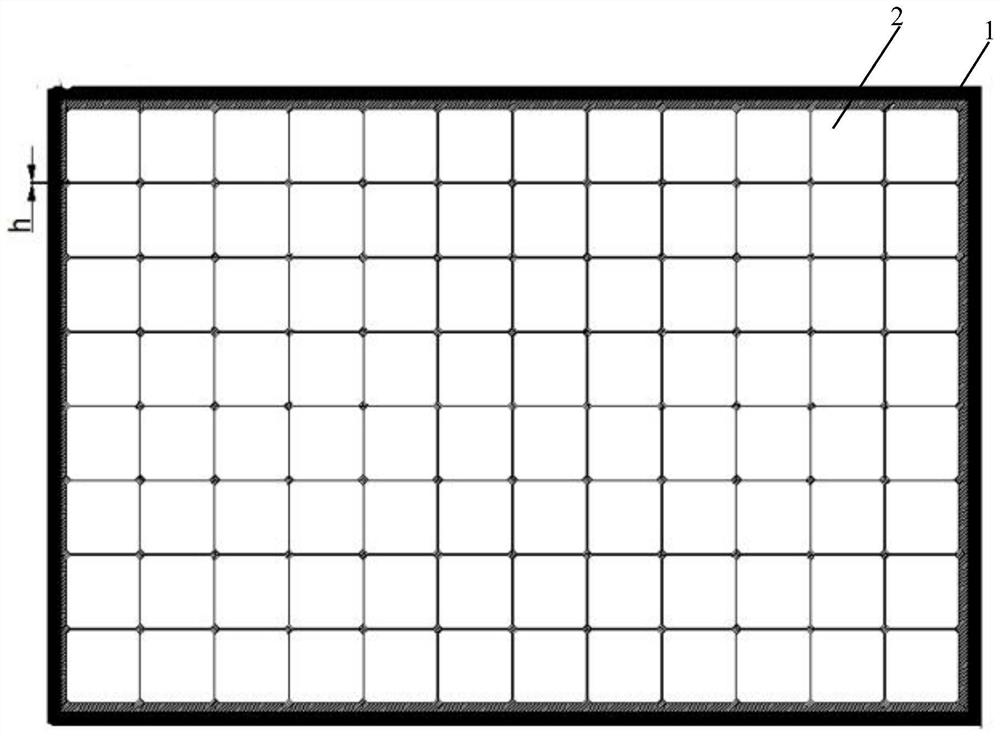

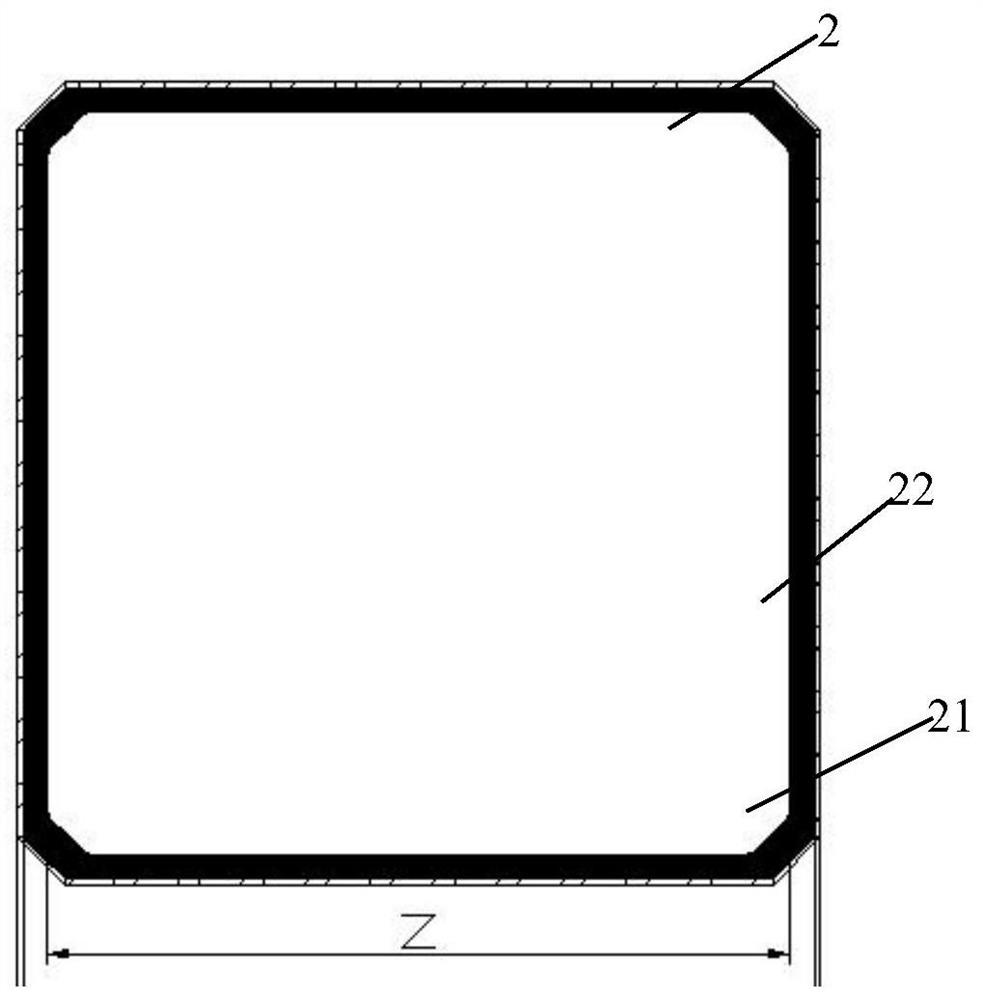

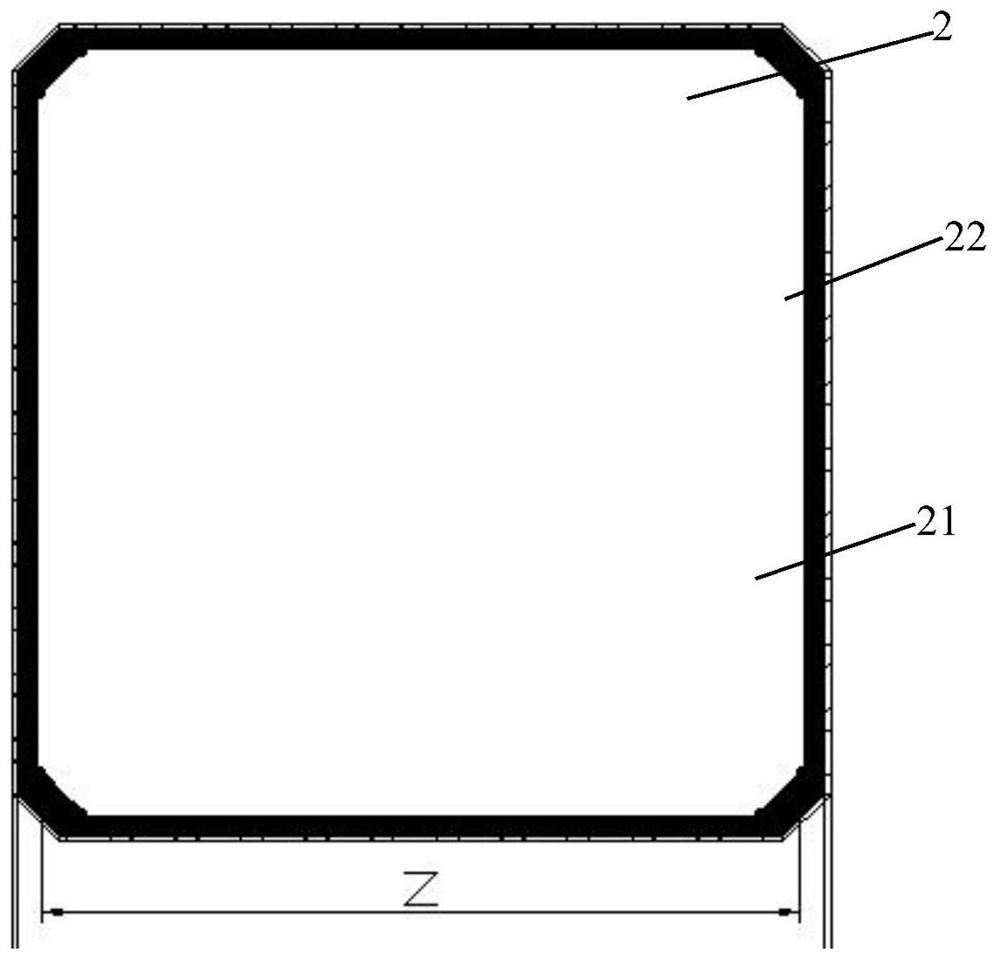

Coating carrier and method for increasing TCO coating area of heterojunction solar cell by using same

PendingCN113611640ALarge film forming areaImprove conversion efficiencyFinal product manufactureVacuum evaporation coatingPhysicsThin membrane

The invention discloses a film coating carrier which comprises a carrier body and a plurality of placing parts for containing silicon wafers, wherein the placing parts are evenly distributed in the longitudinal direction and the transverse direction of the carrier body; each placing part comprises a first frame body and a second frame body, and the first frame body is arranged on the outer side of the second frame body; a plurality of supporting points are oppositely arranged on the inner side wall of the second frame body; the invention also discloses a method for increasing the TCO coating area of the heterojunction solar cell. The method comprises the following steps: (1) texturing and cleaning a crystal silicon wafer; (2) preparing a double-intrinsic amorphous silicon layer on the front surface of the crystal silicon wafer, and then preparing a double-doped amorphous silicon layer; (3) placing the prepared silicon wafer of the double-doped amorphous silicon layer on the placing part of the coating carrier, and then preparing a conductive thin film layer and a mask region on the double-doped amorphous silicon layer respectively; (4) forming a metal electrode on the conductive film layer in a silk-screen printing manner. When the coating carrier is applied to a subsequent coating method, the TCO coating area can be increased.

Owner:晋能光伏技术有限责任公司 +1

Falling film melt polycondensation reaction method and reactor between rows of tubes

ActiveCN106000250BGood dispersionEnhanced mixing processChemical/physical/physico-chemical stationary reactorsPolymer sciencePolyethylene terephthalate glycol

Owner:ZHEJIANG SCI-TECH UNIV

Hydrothermal preparation method and product of superconducting single crystal film

ActiveCN111607826BReduce energy consumptionLow costPolycrystalline material growthSuperconductors/hyperconductorsUltra-high vacuumSource material

The invention provides a method for preparing a superconducting single crystal film, the method is a hydrothermal method, and the preparation method comprises the following steps: (1) putting reactants and deionized water into a sealable heating container, (2) Then seal the closed container and heat the reaction; (3) After the reaction, open the closed container to take out the metal substrate, and wash it repeatedly with deionized water to obtain epitaxial growth Superconducting single crystal film. The method of the invention has low energy consumption, low cost and low pollution, and does not need physical high temperature, ultra-high vacuum equipment or high-priced organic source materials and post-treatment of organic matter required by the existing method. The metal substrate can be used, the shape and size of the substrate are not limited, and the method is simple, efficient and easy to promote.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

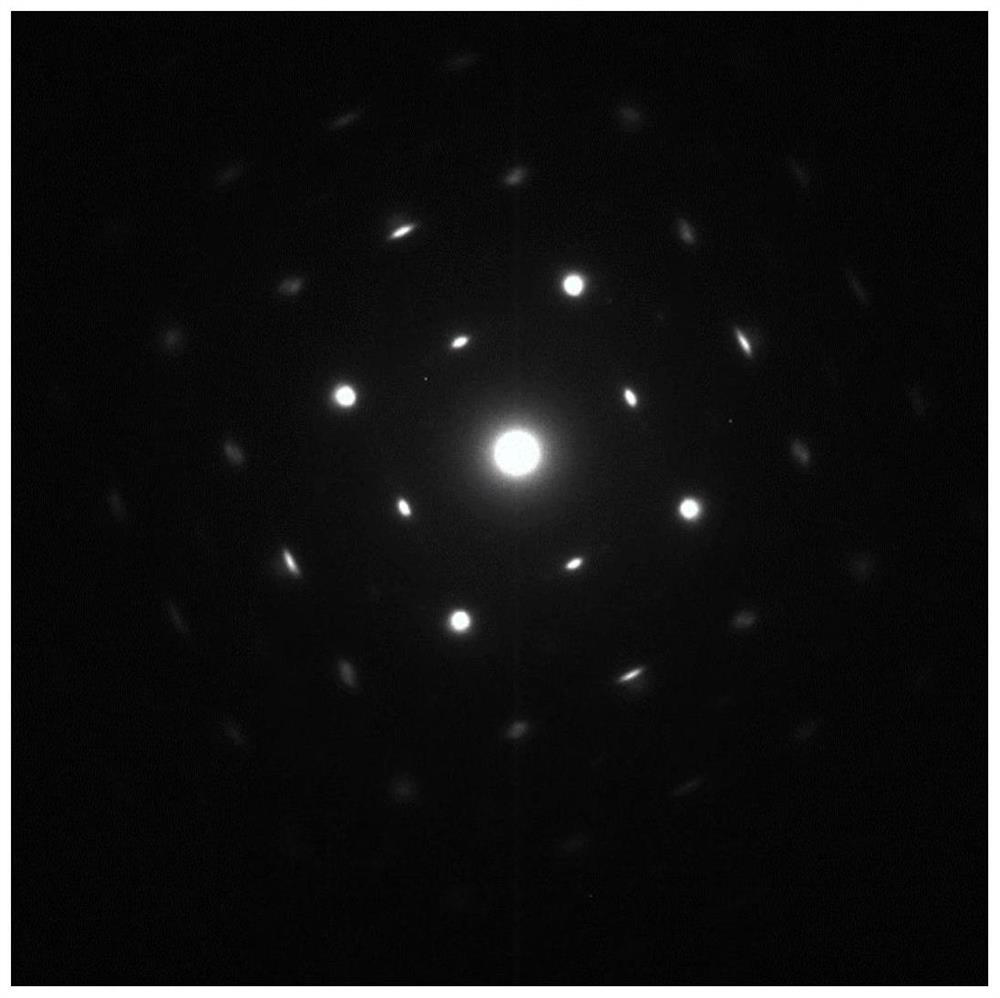

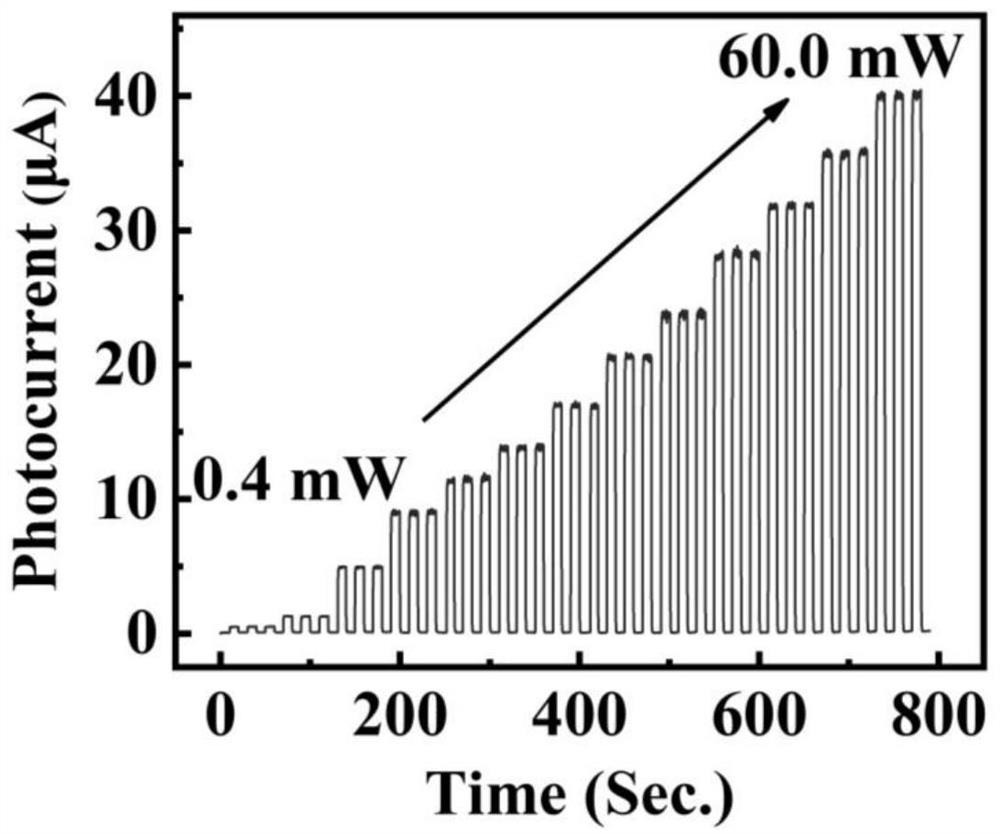

Flexible single crystal film photoelectric detector and preparation method thereof

PendingCN114300571AImprove crystal qualityHas a single crystal structurePolycrystalline material growthVacuum evaporation coatingEngineeringSingle crystal

The invention belongs to the related technical field of micro-nano manufacturing and photoelectric detection devices, and discloses a flexible single crystal film photoelectric detection device and a preparation method thereof, and the preparation method comprises the following steps: (1) preparing a single crystal film material on the surface of a NaCl crystal through employing a DC magnetron sputtering technology; (2) stripping the film from the surface of the NaCl crystal; (3) preparing an electrode structure on the flexible plastic substrate; and (4) transferring the stripped and fallen single crystal thin film to the plastic substrate forming the electrode structure to finish the preparation. The invention has the advantages of simple process, green and environment-friendly production process and product, high rate of finished products, low manufacturing cost, capability of realizing broadband detection, high response rate, high flexibility and the like, is suitable for large-scale industrial production, and has wide application prospects in the fields of photoelectric detection, wearable equipment and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A method for manufacturing a large-area zinc oxide nano-micro generator

ActiveCN104037320BSynthesis temperature is lowOptimizing Process ParametersPiezoelectric/electrostrictive device manufacture/assemblyMicro nanoNanogenerator

A method for manufacturing large-area ZnO nano-microgenerators, depositing Au electrodes on the substrate; spin-coating photoresist to form a photoresist nano-micron line structure in the Y direction; etching away the remaining photoresist through ion beam etching Protect the Au electrode material, then deposit the hard mask material aluminum oxide, and etch away the aluminum oxide material on the side wall to expose the photoresist; use acetone to peel off the photoresist and the Al2O3 on it, and use the sol-gel method to deposit ZnO Thin film; photoresist stripping using ion beam etching and acetone to form ZnO nanowires; spin-coating photoresist, exposing the ZnO nanowires at both ends after exposure and molding; using electron beam evaporation to deposit Pt electrodes; using acetone to strip off the light Resist, etching to remove Al2O3, and the piezoelectric nanogenerator structure is exposed; the piezoelectric nanogenerator is exposed to the vibration source to produce piezoelectric conversion and nano-micro piezoelectric power generation. Achieve large-area controllable production and processing of low-cost, high-mechanical-electrical energy conversion nanogenerators.

Owner:NANJING YIDEGUAN ELECTRONICS TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com