Film scraping technology in molecular distillation equipment

A technology of molecular distillation and film scraping, which is applied in the field of film forming technology of molecular distillation equipment, and can solve problems such as insufficient film forming area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

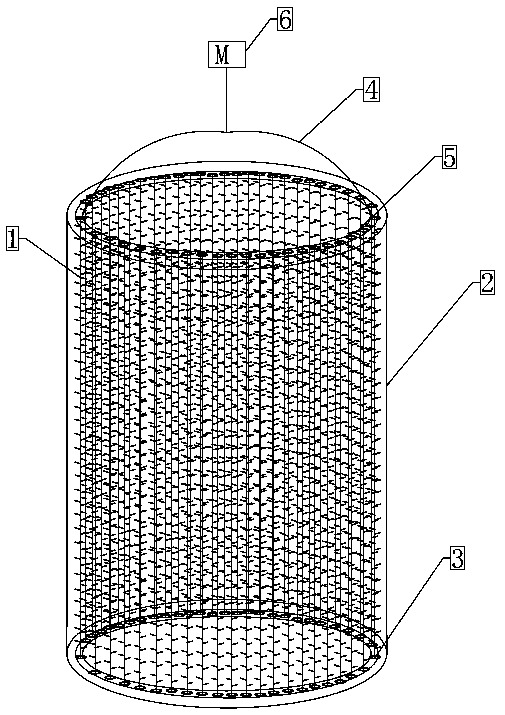

[0009] The first embodiment of the present invention relates to a scraping film technology in molecular distillation equipment, see figure 1 As shown, it includes: film scraping brush (1), connecting plate (4), connecting plate and film scraping brush are connected by bearing (3), cage-shaped cover composed of film scraping brush, bearing and connecting plate ( 5), the cylinder body (2), which is located outside the cage-shaped cover and has a certain gap with the scraping brush, drives the motor (6) of the scraping brush. The film-scraping brush and the cylinder keep a certain distance and do not touch each other to prevent the abrasion of the film-scraping brush; the elastic bristles of the film-scraping brush are dense, which can increase the area of the liquid film, thereby increasing the material handling capacity; the film-scraping brush The elastic bristles are bent towards the side away from the rotation direction of the film scraper, which can increase the contact a...

Embodiment 2

[0012] The cage-shaped cover composed of scraping film brush, rotating bearing and connecting plate is fixed, and the cylinder rotates under the drive of the motor. The liquid material enters the molecular distillation equipment, and the material flows down the inner wall of the cylinder at a uniform speed through the liquid distributor. There is resistance when the liquid in the body wall and the scraping brush move relative to each other, which drives the movement of the scraping brush. The movement of the scraping brush can continuously refresh the liquid film, increase the area of the liquid film on the bristles, and increase the material handling capacity .

Embodiment 3

[0014] The film scraping brush is connected to the connection plate, and the connection plate and the film scraping brush form a cage-shaped cover body, and the cage-shaped cover body is connected to the motor. There is a certain distance between the film-scraping brush and the inner wall of the cylinder. The difference from the first embodiment is that There is no rotating bearing connecting the scraping film brush and the connecting disc. The film-scraping brush is driven by the motor to make a turnover movement. There is resistance between the brush and the liquid on the inner wall of the cylinder, which can make the film-scraping brush rotate. While the brush is constantly updating the liquid film on the inner wall of the cylinder, it is also updating during rotation. The liquid film on the brush increases the evaporation of the liquid and has a strong material handling capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com