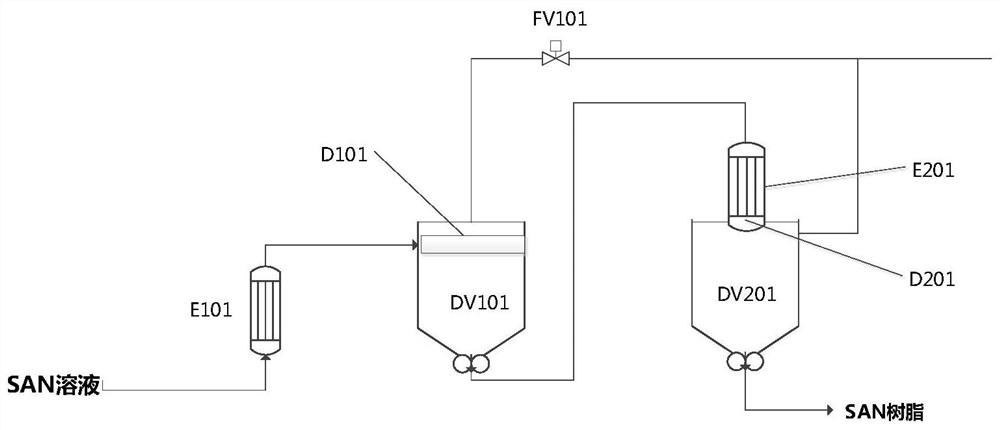

Devolatilization device and SAN (Styrene Acrylonitrile) resin devolatilization process

A devolatilization device and devolatilization technology, which is applied in feeding devices, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve problems such as excessive heating of materials, resin appearance defects, etc., and achieve enhanced melt back-mixing , The effect of promoting the surface renewal of the liquid film and enhancing the devolatilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the flow rate of the SAN solution entering the devolatilization section is 200kg / h, the solid content is 60%, and the temperature is 150°C. The primary preheater is heated by saturated steam at 185°C, the temperature of the SAN solution at the outlet of the primary preheater is 180°C, the operating temperature of the primary devolatilizer is 180°C, and the operating pressure is 37kPa(A). Open the front valve of the vacuum pump every 5 minutes. After ventilating for 1 min, close the valve and cycle.

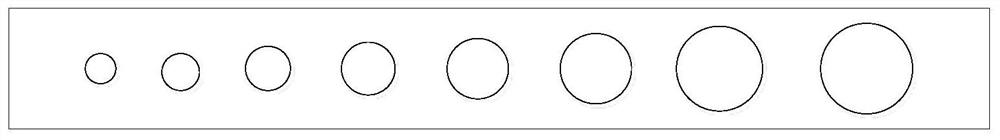

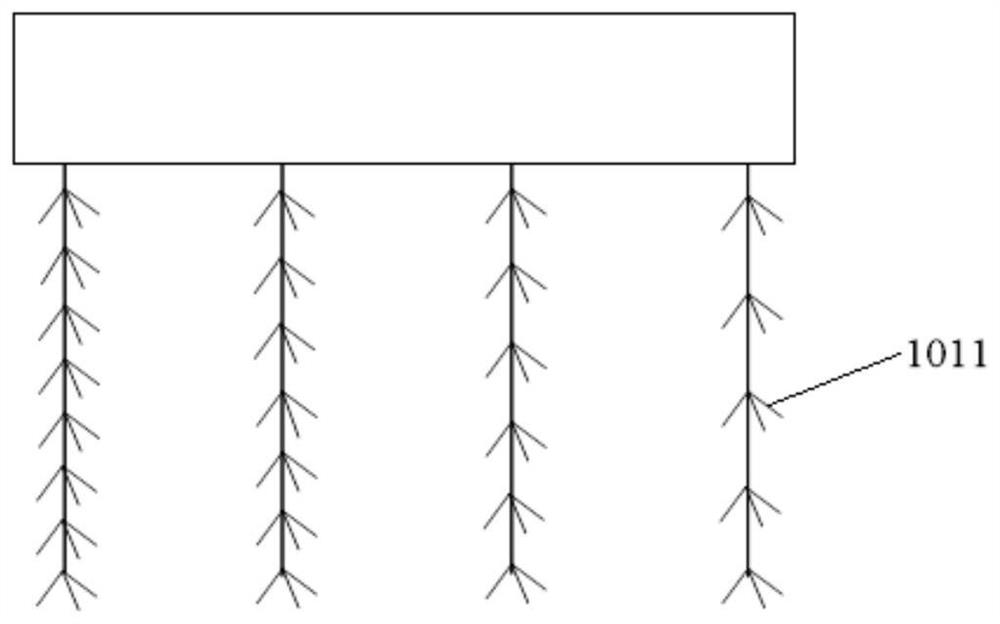

[0061] The material distribution pipe of the first-stage devolatilizer is provided with 30 openings, the size of the openings gradually increases from 6mm to 30mm, and the spacing between the holes is 10mm. A guide wire with barbs is installed vertically below the opening of the material distribution pipe. The length of the guide wire is 140mm, and the diameter of each guide wire is 0.3 times the diameter of the opening connected to it. There are multip...

Embodiment 2

[0065] In this embodiment, the flow rate of the SAN solution entering the devolatilization section is 300kg / h, the concentration is 80%, and the temperature is 120°C. The primary preheater is heated by 180°C saturated steam, and the temperature of the SAN solution at the outlet of the primary preheater is 174°C. The operating temperature of the primary devolatilization tank is 150°C and the operating pressure is 30kPa(A). The valve in front of the vacuum pump is opened every 4 minutes, and the valve is closed after 1 minute of ventilation, and the operation is cyclic.

[0066] The material distribution pipe of the first-stage devolatilizer is provided with 30 openings, the size of the openings gradually increases from 10mm to 45mm, and the spacing between the holes is 7mm. The guide wire with barbs is vertically distributed under the opening of the material distribution pipe, and the length of the guide wire is 180mm. The diameter of each guide wire is 0.2 times the diameter ...

Embodiment 3

[0070] In this embodiment, the flow rate of the SAN solution entering the devolatilization section is 500kg / h, the concentration is 60%, and the temperature is 140°C. The primary preheater is heated by 190°C saturated steam, the temperature of the SAN solution at the outlet of the primary preheater is 183°C, the operating temperature of the primary devolatilizer is 140°C, and the operating pressure is 35kPa(A). Open the front valve of the vacuum pump every 4 minutes. After ventilating for 1 min, close the valve and cycle.

[0071] The material distribution pipe of the first-stage devolatilizer is provided with 30 openings, the size of the openings gradually increases from 7mm to 35mm, and the hole spacing is 8mm. A guide wire with barbs is installed vertically below the opening of the material distribution pipe. The length of the guide wire is 260 mm, and the diameter of each guide wire is 0.4 times the diameter of the hole connected to it. There are multiple groups of barbs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com