Patents

Literature

51results about How to "Reduce foreign matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

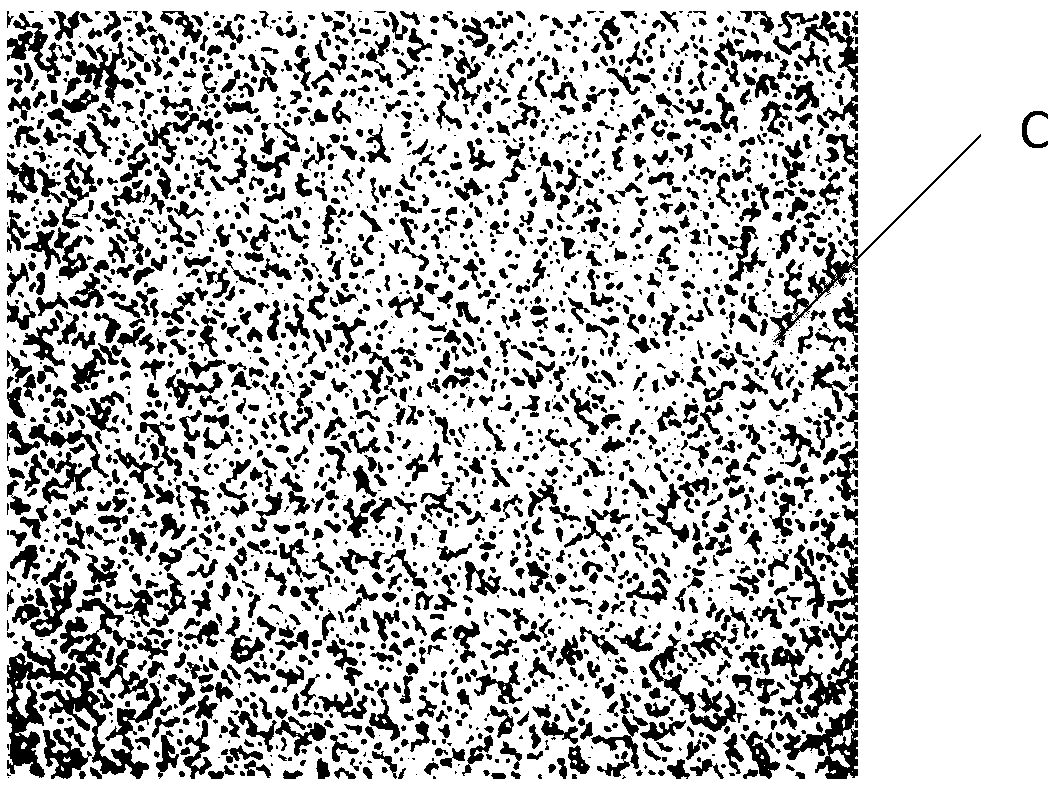

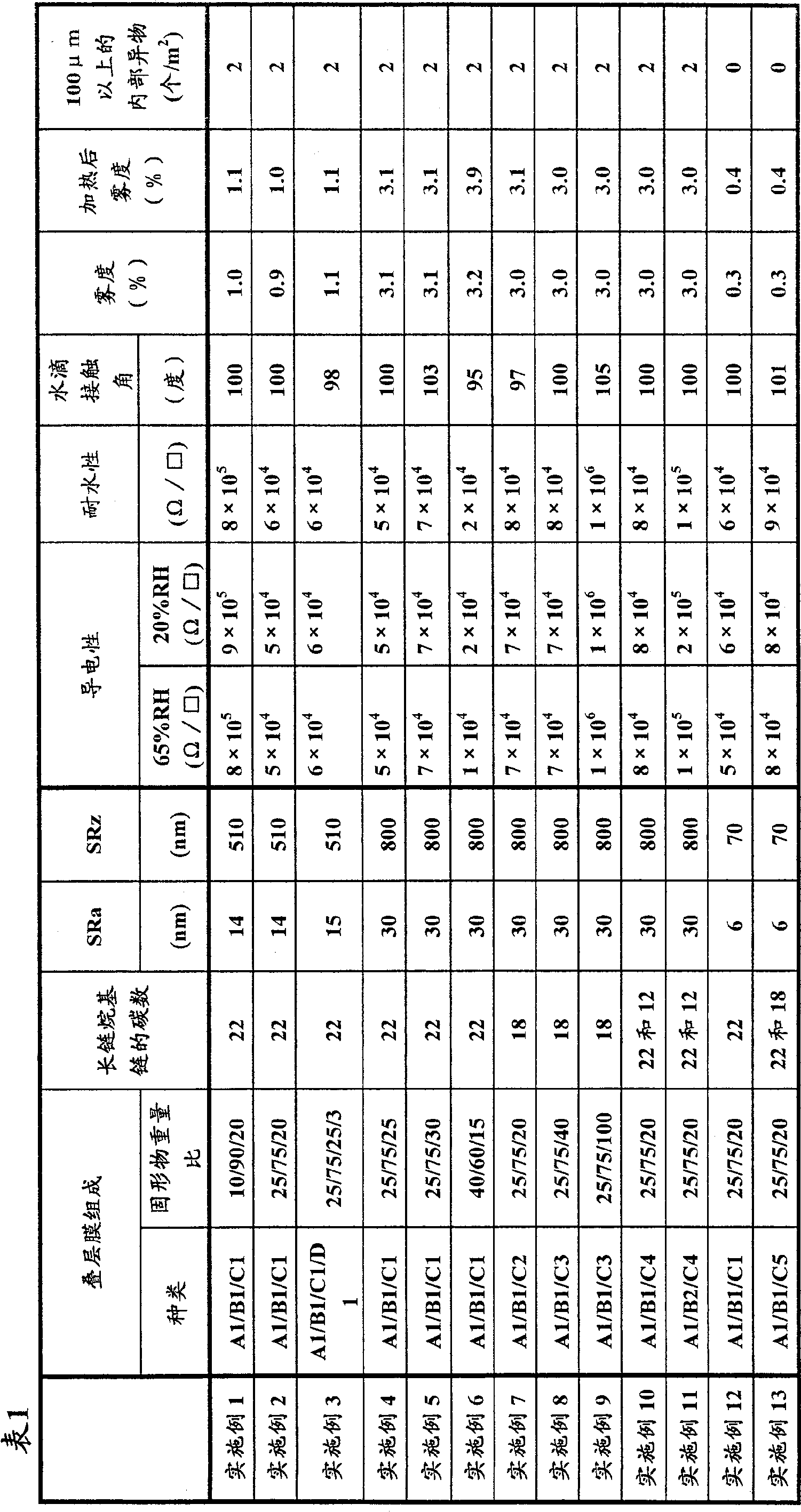

Laminated film

ActiveCN101065246AGood antifoulingGood release effectSynthetic resin layered productsForeign matterOligomer

A laminated film including a thermoplastic resin film and an laminated layer that is formed on at least one side of the thermoplastic resin film and comprises (A) a composition, (B) an epoxy crosslinking agent and (C) an acrylic resin having an alkyl chain of 18 to 25 carbon atoms is characterized in that the composition (A) is a composition containing at least a polythiophene and a polyanion and / or a composition containing a polythiophene derivative and a polyanion, the laminated layer contains 15 to 100 parts by weight of the acrylic resin (C) having an alkyl chain of 18 to 25 carbon atoms based on 100 parts by weight of the sum of the composition (A) and the cross-linking agent (B) and / or its reaction product, at least one side of the laminated film has a three-dimensional average surface roughness (SRa) of 3 to 50 nm, and the laminated film contains less than 10 internal contaminant particles with an average particle size of at least 100 mum per 1 m<2>, so that it has high level of electrical conductivity, good releasability and water resistance, and also has oligomer precipitation-preventing properties during heating.

Owner:TORAY IND INC

Polyphenylene sulfide fiber spinning technology

ActiveCN102776601AHigh crystallinityGood light stabilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentPolymer scienceVacuum drying

The invention relates to a polyphenylene sulfide fiber spinning technology which comprises the steps as follows: (1) pre-processing materials: mixing graphite powder with a silane coupling agent to obtain modified graphite, and mixing the modified graphite and polyphenylene sulfide resin at a high speed so as to obtain a mixture, and finally pre-crystallizing and drying the mixture in a vacuum drying box to obtain dried powder with less than 50 ppm of water; (2) melting and spinning: feeding the dried powder into a double-screw extruder for melting and spinning so as to obtain a melt; (3) slowly cooling and cooling: thermally forming the smelt after forming silk through a spinneret plate, and then transferring to a slow cooling area, and finally transferring to a cooling area to solidify and form; and (4) drafting and finalizing: carrying out oil applying and silk guiding on the solidified and finalized fiber, and then drafting and finalizing at three times so as to obtain the short fiber with the linear density of 11 dte x. The polyphenylene sulfide fiber spinning technology is low in cost and easy in industrial production; and the fiber material prepared via the technology has good performance.

Owner:DUNHUANG XIYU MINING & CHEM

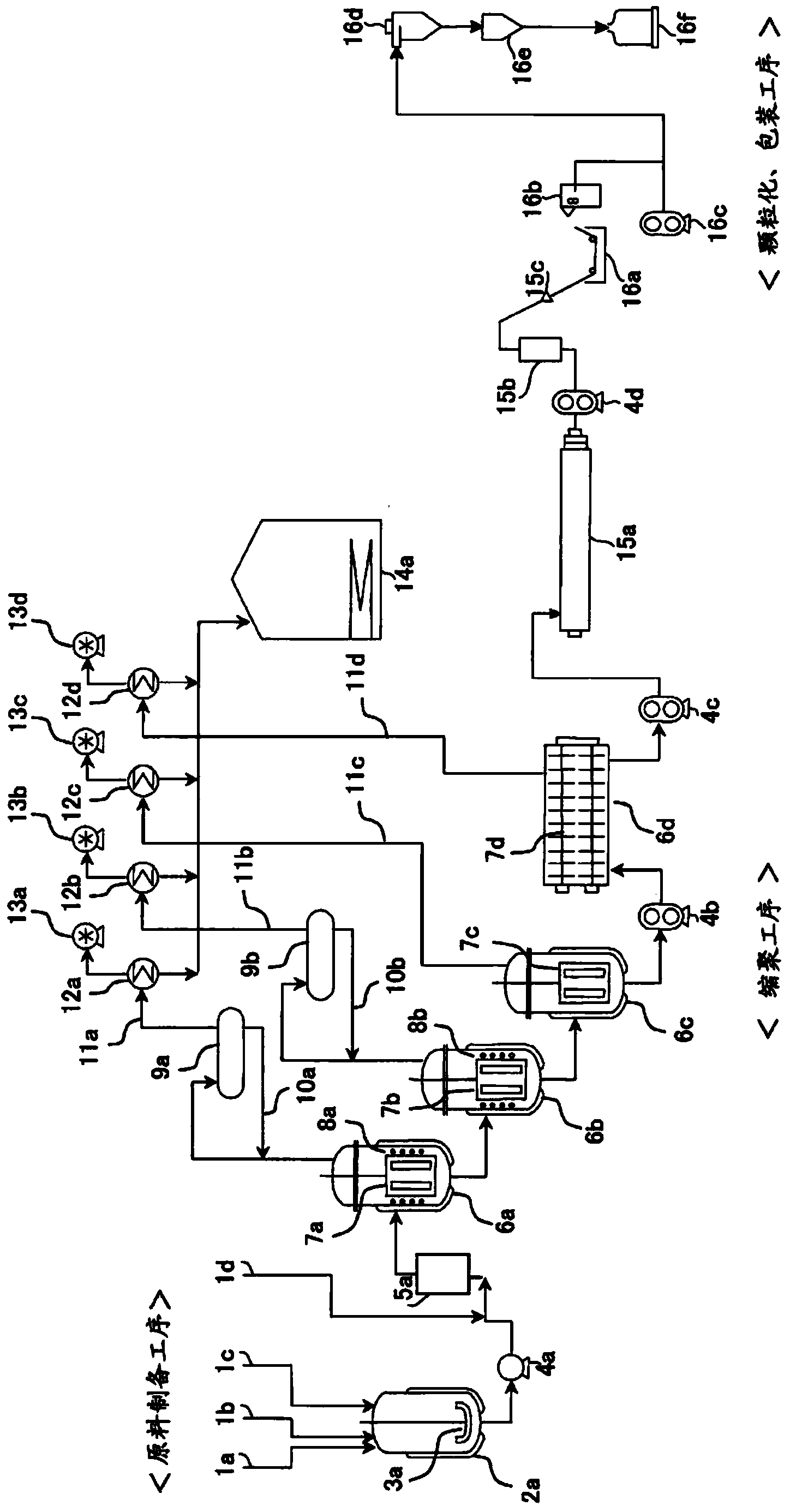

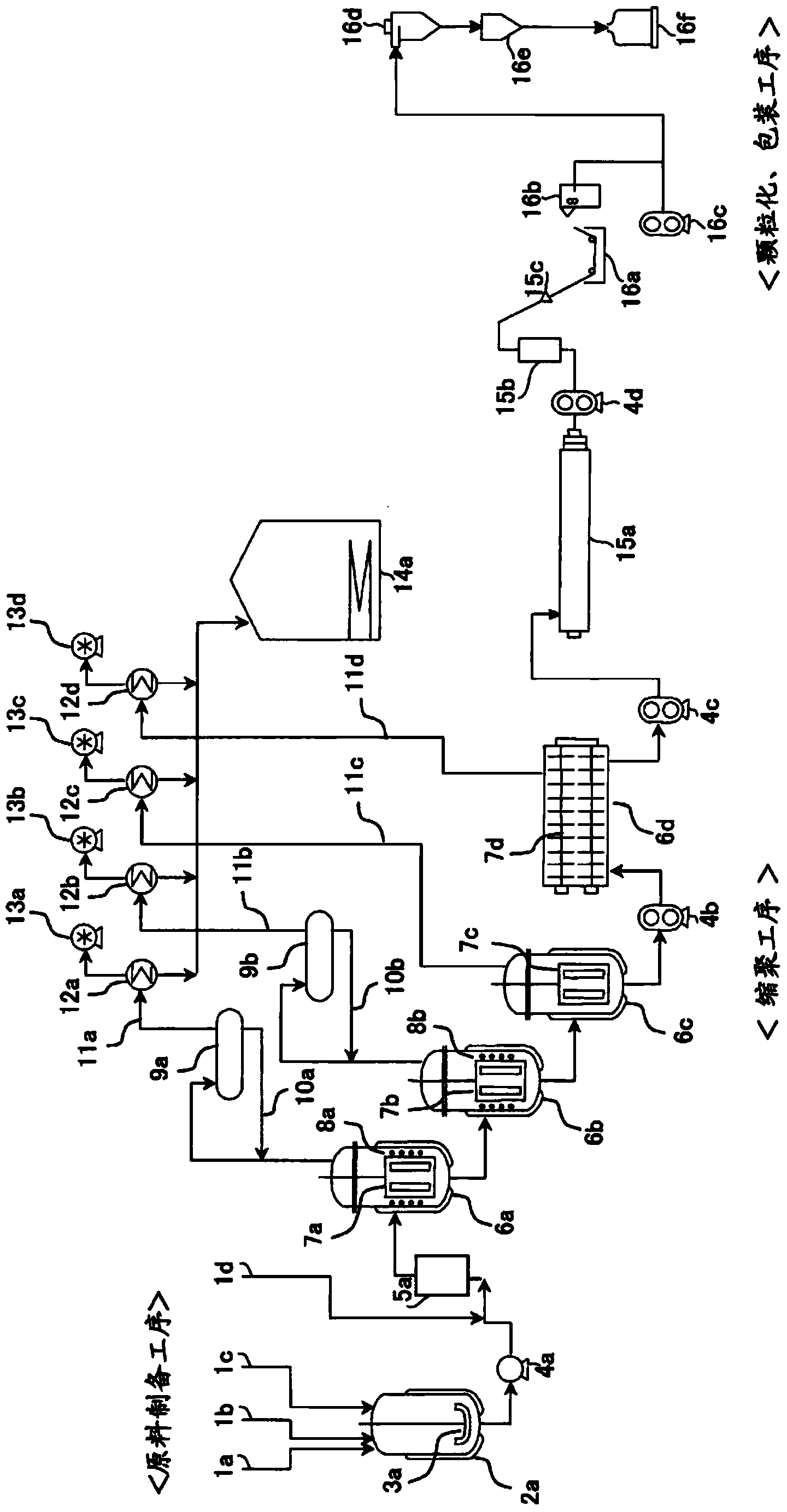

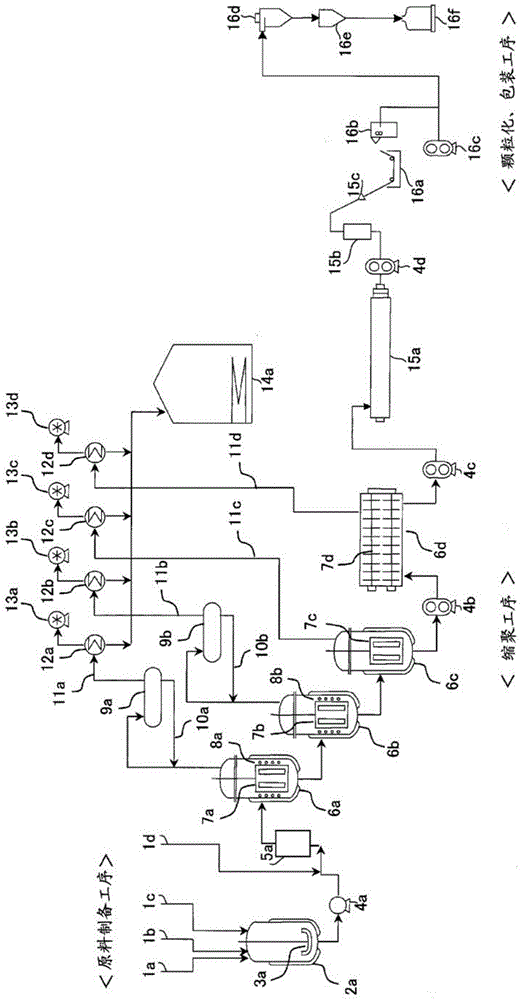

Method for manufacturing polycarbonate resin, polycarbonate resin, and methods for manufacturing polycarbonate-resin film and polycarbonate-resin pellets

ActiveCN103476561AEfficient and stable manufacturingHigh mechanical strengthThermal stabilityPolycarbonate

The present invention relates to a polycarbonate-resin manufacturing method whereby a polycarbonate resin that contains little foreign material and exhibits excellent thermal stability, hue, and mechanical strength is manufactured efficiently and stably.

Owner:MITSUBISHI RAYON CO LTD

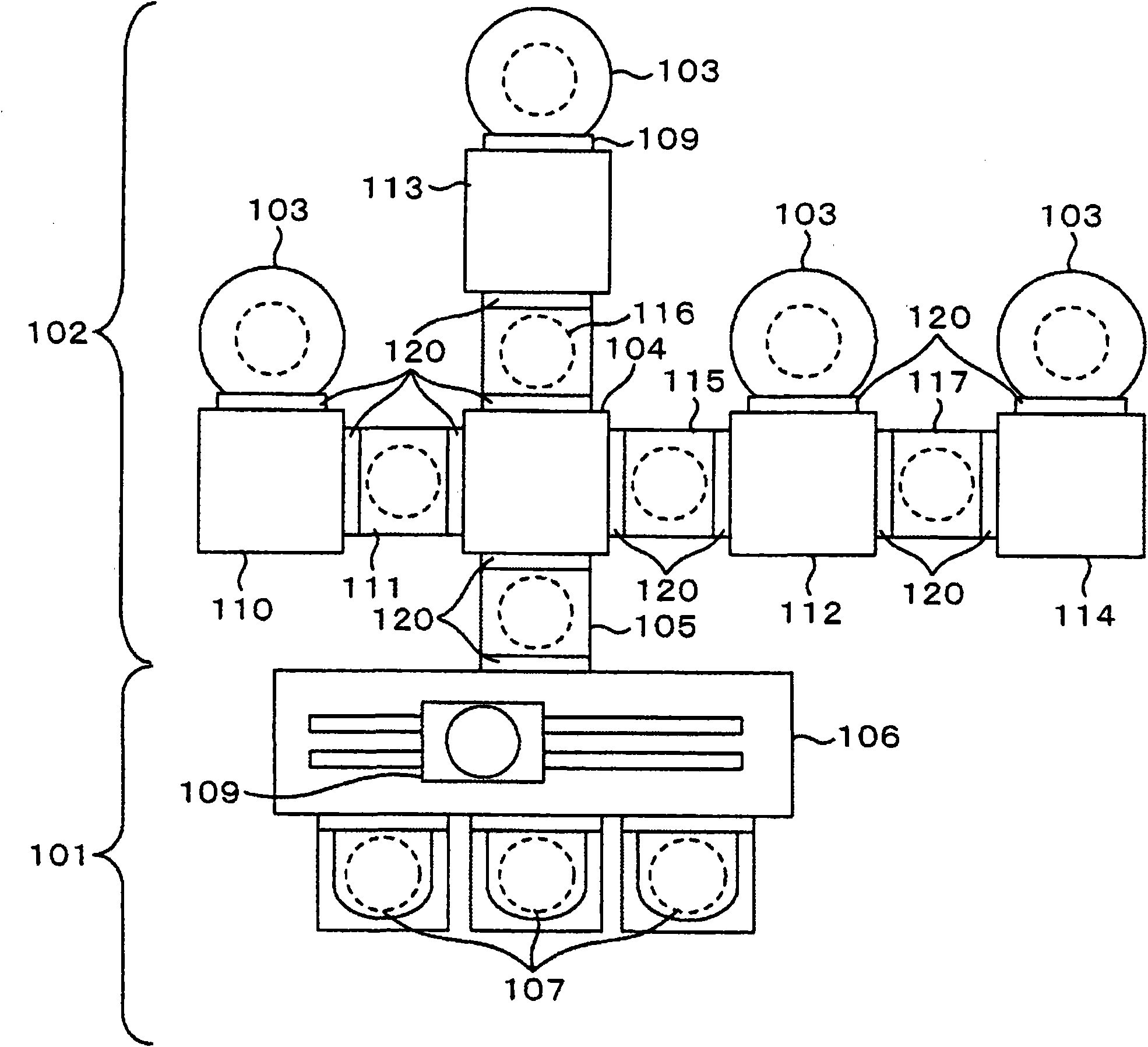

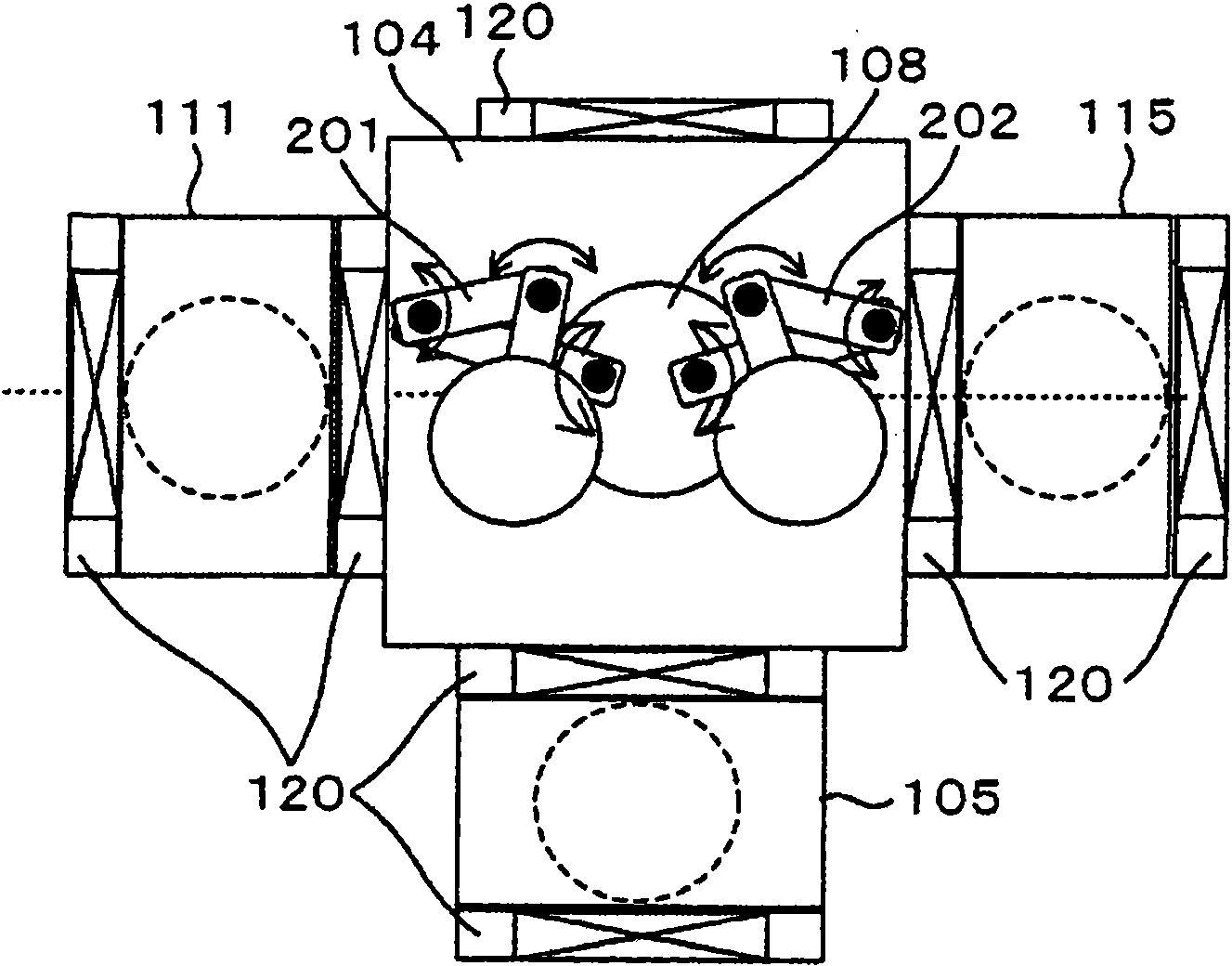

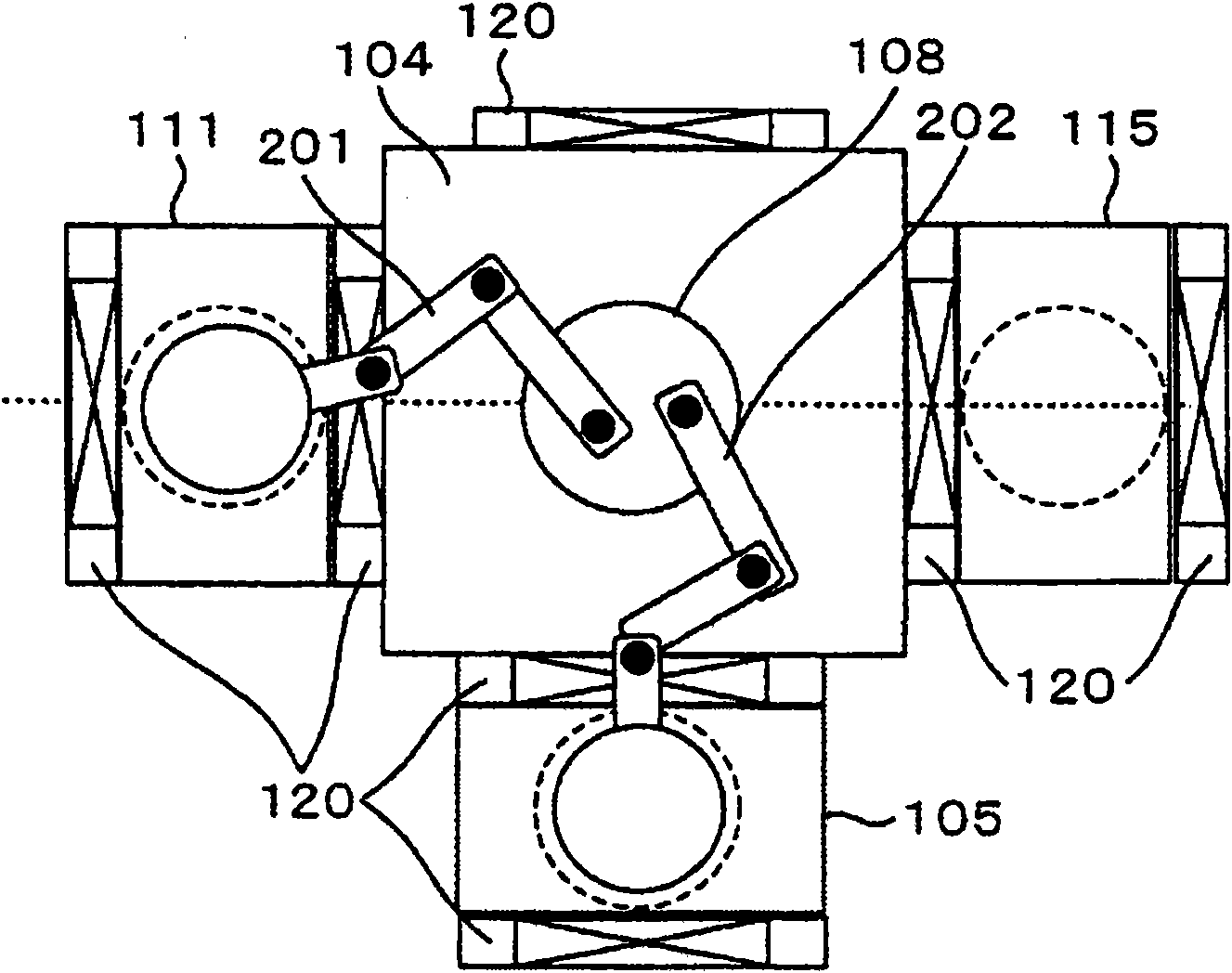

Vacuum processing system and vacuum processing method of semiconductor processing substrate

InactiveCN102064124AInhibit cross-contaminationReduce foreign matterSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Owner:HITACHI HIGH-TECH CORP

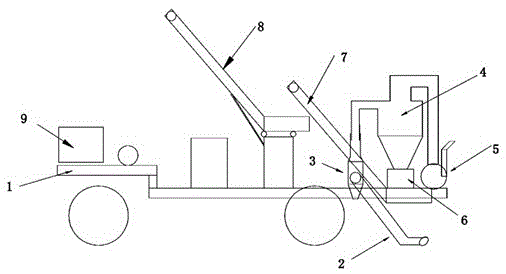

Moving type bulk pepper collecting equipment

InactiveCN105600512AReduce generationEnvironmentally friendlyGas current separationLoading/unloadingEngineeringHigh pressure

The invention discloses moving type bulk pepper collecting equipment, which comprises a carrying vehicle body, wherein a feeding pipeline, a stone removing and rotating device, a cyclone separator, a high-pressure fan, a wind closer and a chain plate conveyor are arranged on the carrying vehicle body; the outlet end of the feeding pipeline is connected with the stone removing and rotating device; the stone removing and rotating device is connected with the cyclone separator; the upper end of the cyclone separator is connected with the high-pressure fan; the lower end of the cyclone separator is connected with the wind closer; the wind closer is connected with the chain plate conveyor. The moving type bulk pepper collecting equipment has the advantages that the pepper bulk loading is realized; a woven bag is not used in the whole process; the labor consumption and the work intensity of people are reduced.

Owner:新疆晨曦椒业有限公司

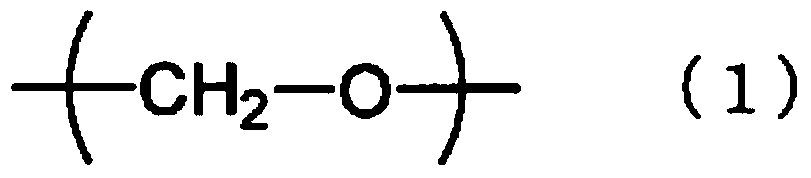

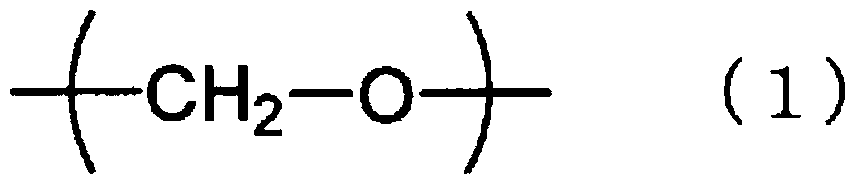

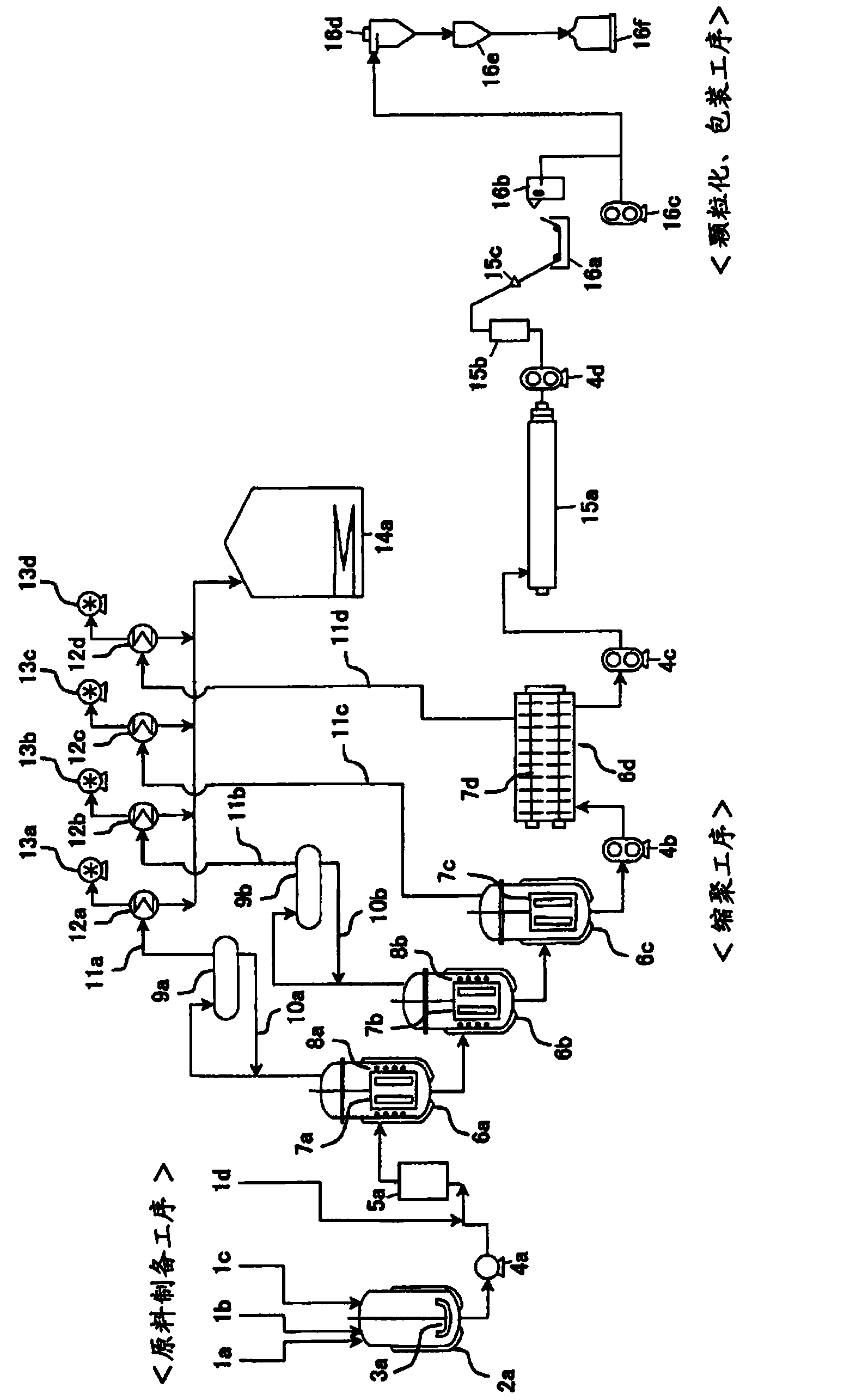

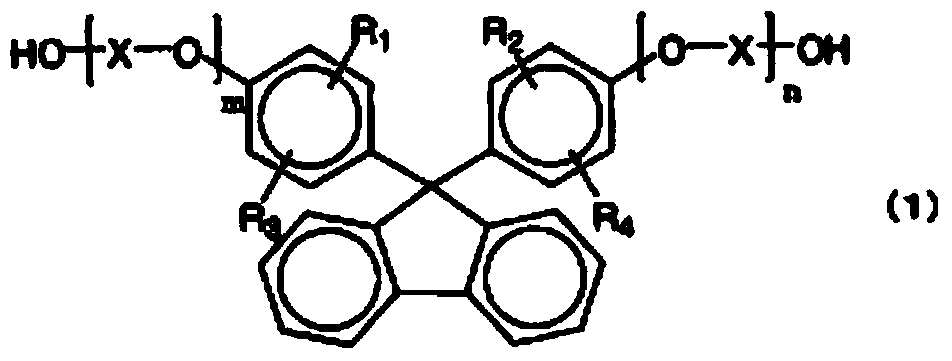

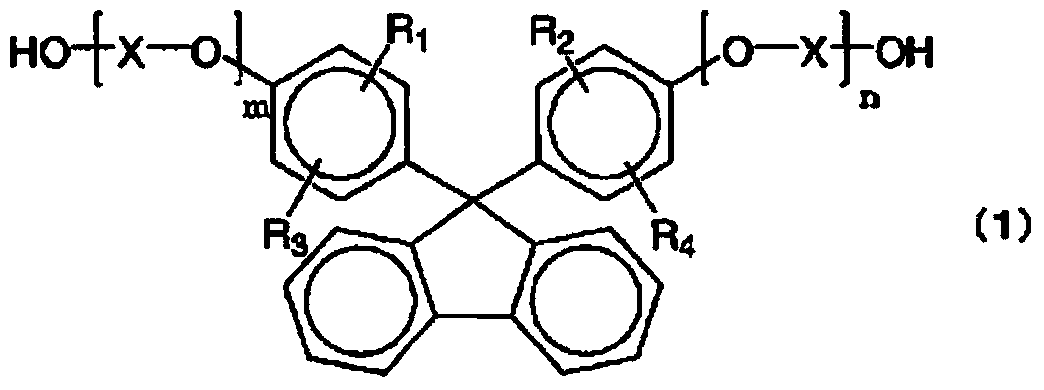

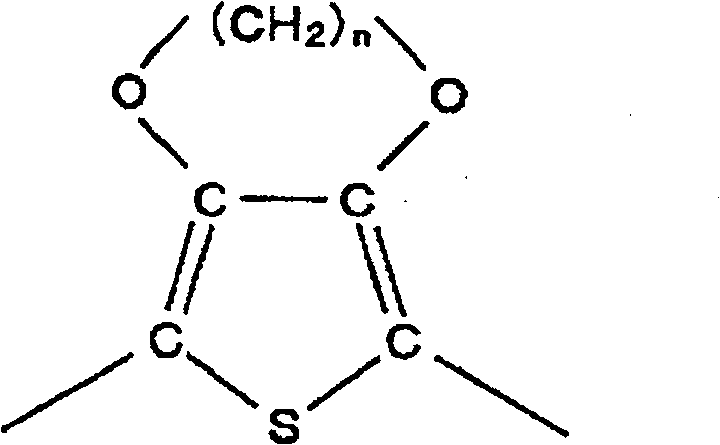

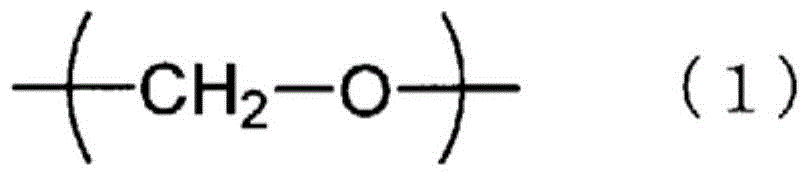

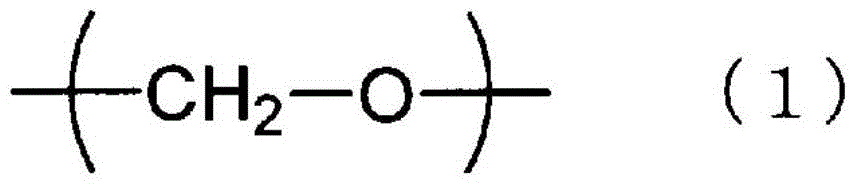

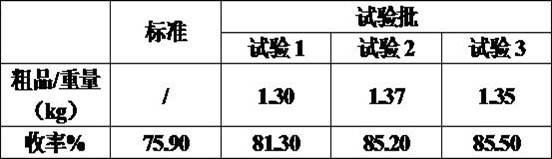

Polycarbonate-resin manufacturing method

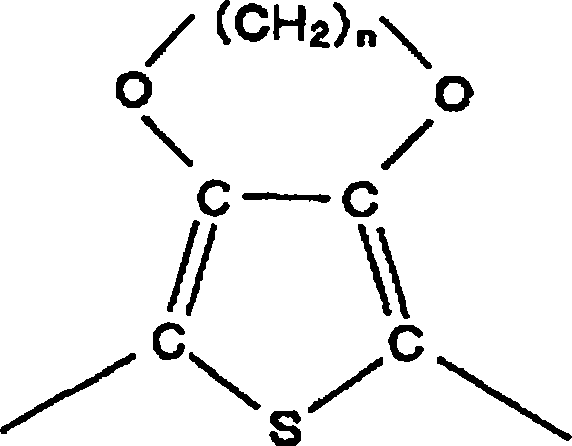

InactiveCN103476558AEfficient and stable manufacturingEffective and stable optical propertiesSquare meterUnit/Kilogram

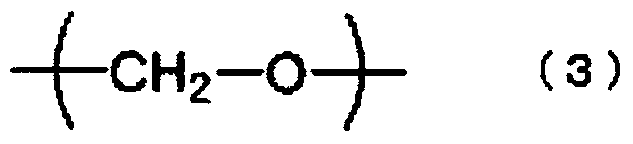

A polycarbonate-resin manufacturing method in which a polycarbonate resin is obtained by polycondensing feedstock monomers including at least a dihydroxy compound represented by general formula (1) and the resulting polycarbonate resin is supplied to an extruder, kneaded, and then discharged from a die. The weight (W) of the amount of resin extruded by the extruder per hour, in kilograms per hour, and the cross-sectional area (S) of the barrel of the extruder, in square meters, satisfy relation (2): 12,000<=W / S<=60,000...(2).

Owner:MITSUBISHI CHEM CORP

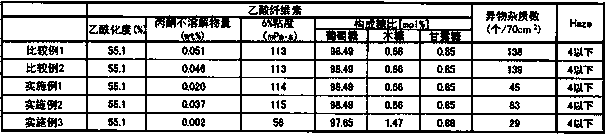

Cellulose acetate, cellulose acetate composition, molded article, and film

The purpose of the present invention is to provide a cellulose acetate with which it is possible to obtain a molded article that contains cellulose acetate having little dimpling. Cellulose acetate characterized by having a degree of acetylation of 52-59% and an acetone-insoluble matter level of 0.04% by weight or less.

Owner:DAICEL CORP

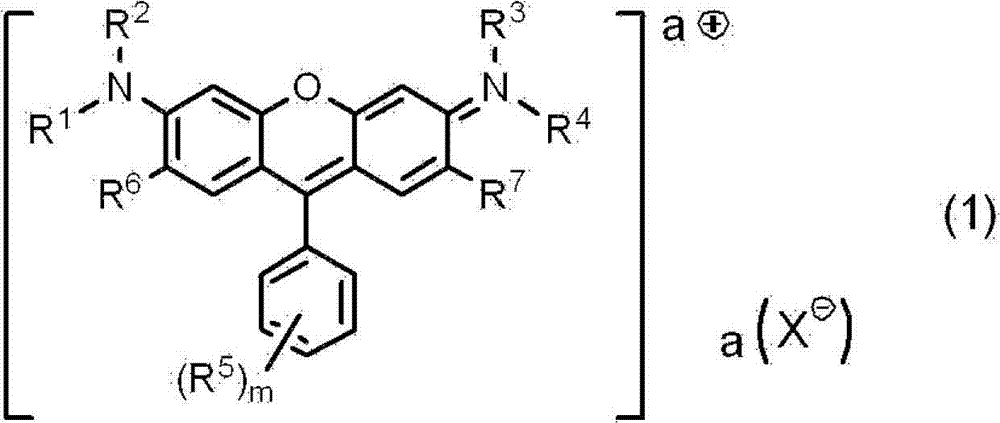

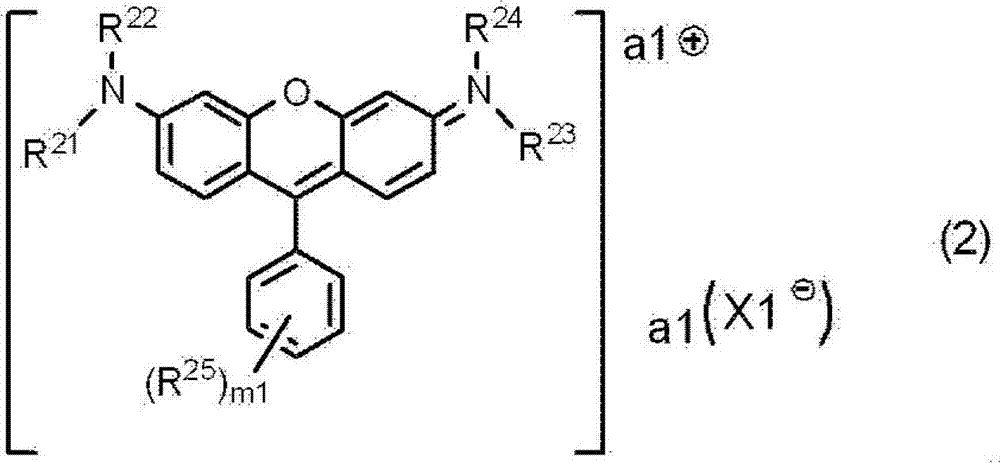

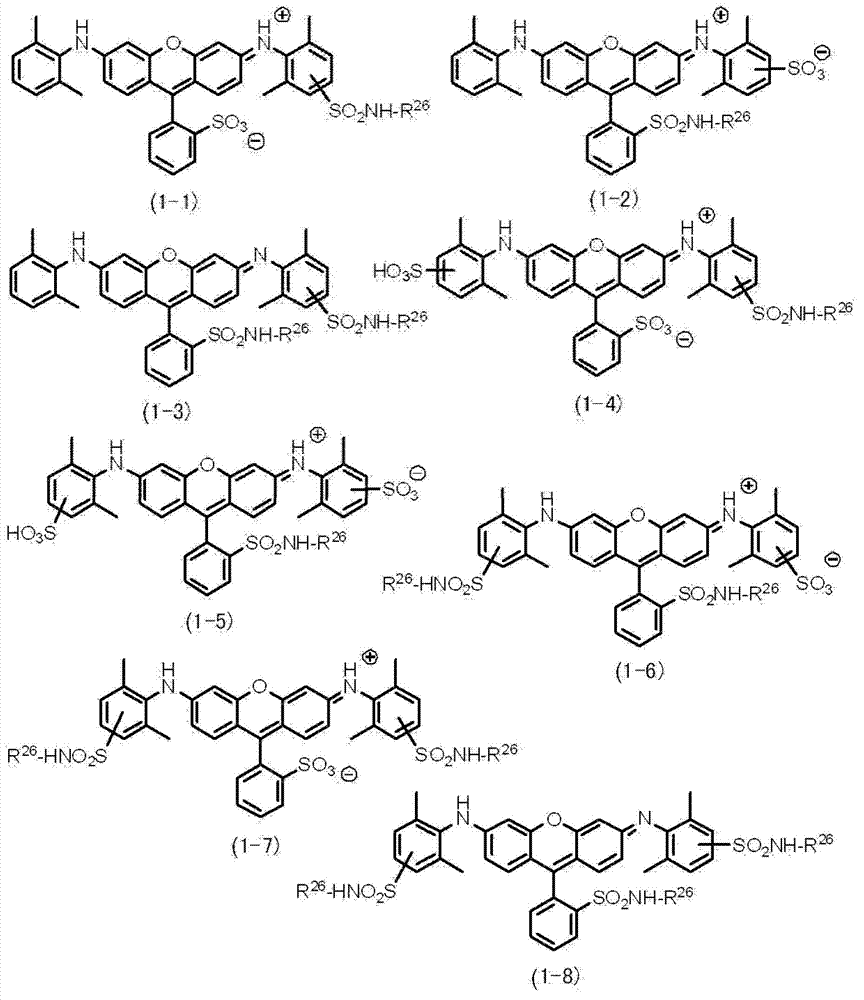

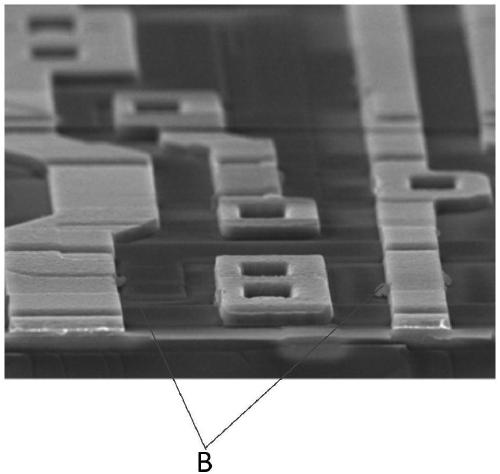

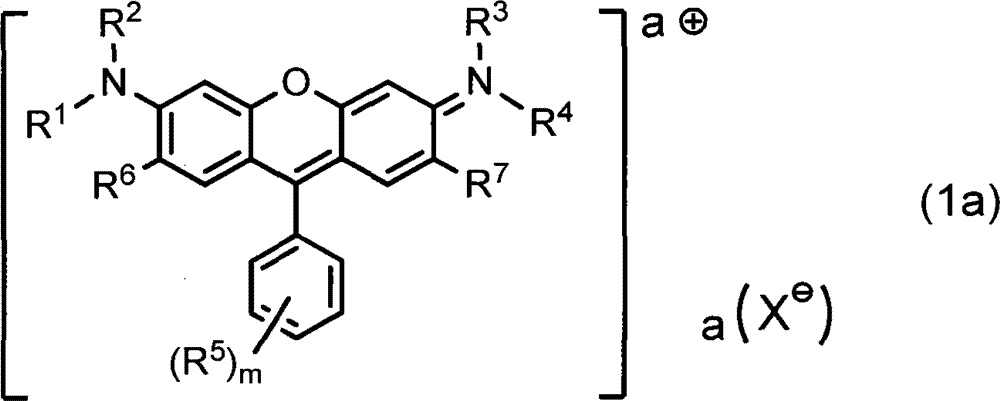

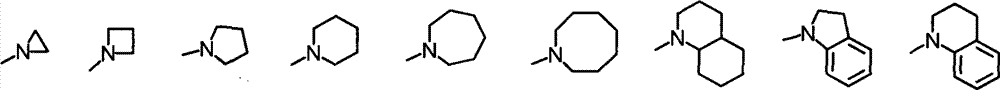

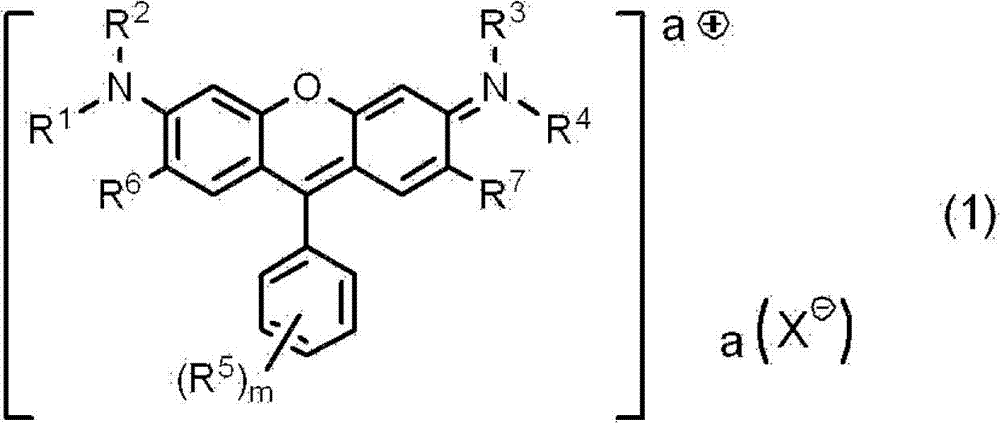

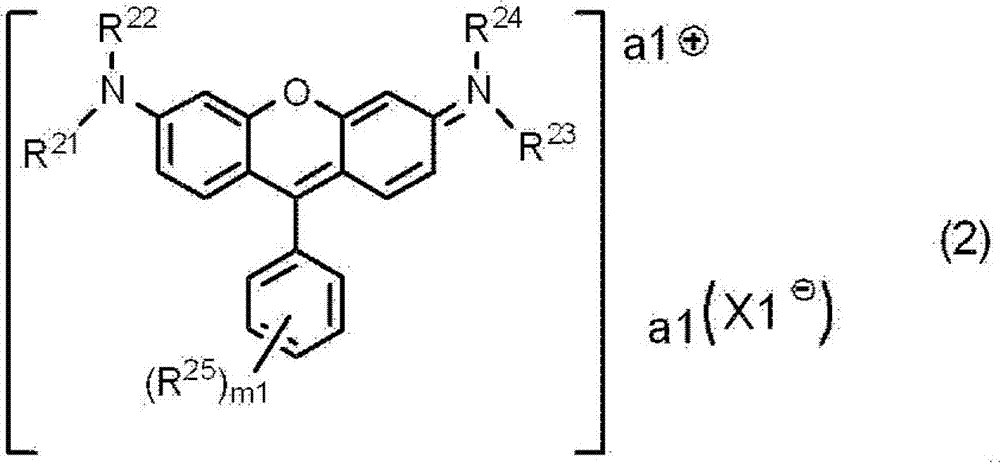

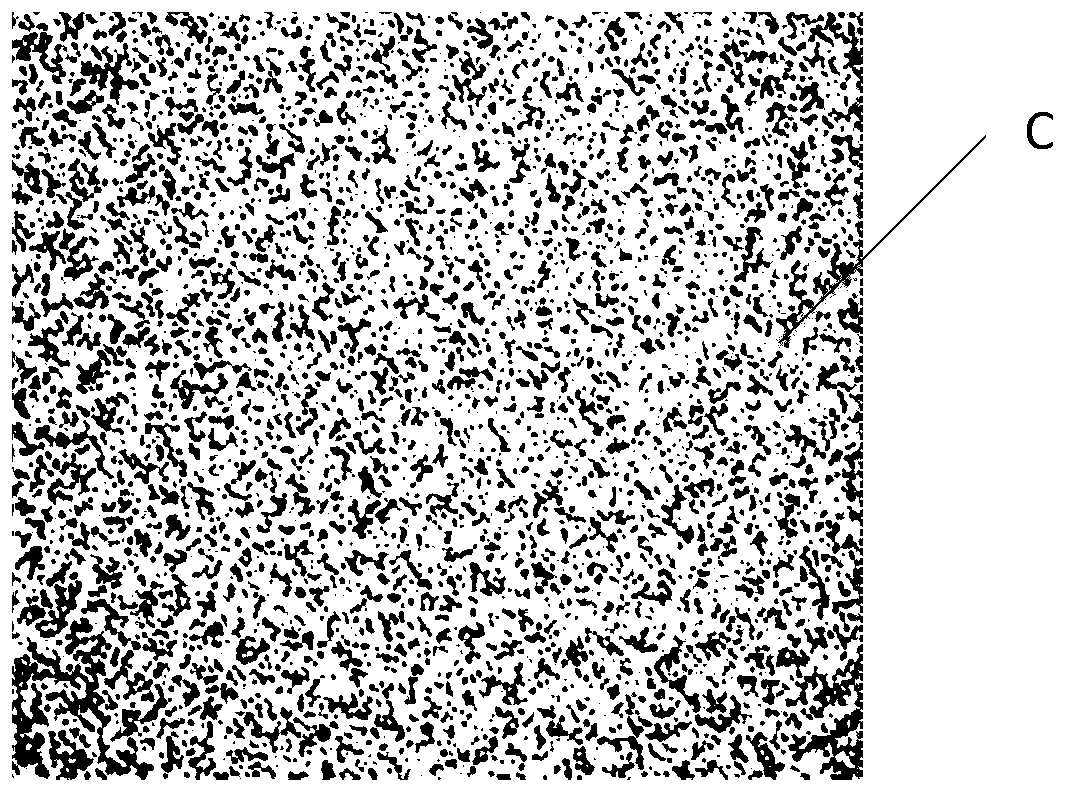

Coloring photosensitive resin composition

ActiveCN102819188APrevent peelingReduce foreign matterPhotomechanical exposure apparatusPhotosensitive materials for photomechanical apparatusCarbon numberForeign matter

The present invention provides a coloring photosensitive resin composition, which includes a dye (A), a copolymer (B1), resin (B2), polymerized compound (C) and a polymerization initiator (D). The copolymer (B1) includes: a structural unit selected from the group consisting of at least one of unsaturated carboxylic acids and carboxylic acid anhydrides, a cyclic ether structure with the carbon number of 2-4, and a single structure unit of olefinic unsaturated bonds, wherein the side chains have no carbon-carbon unsaturated double bonds. The resin has side chains with carbon-carbon unsaturated double bonds and the weight-average molecular weight of the resin is above 10000 and below 100000. The weight-average molecular weight of the polymerized compound is below 3000. According to the present invention, the stripping of one part of an unexposed part on the composition layer formed by the coloring photosensitive resin composition during developing can be restrained, and the foreign matter on the pattern can be reduced.

Owner:SUMITOMO CHEM CO LTD

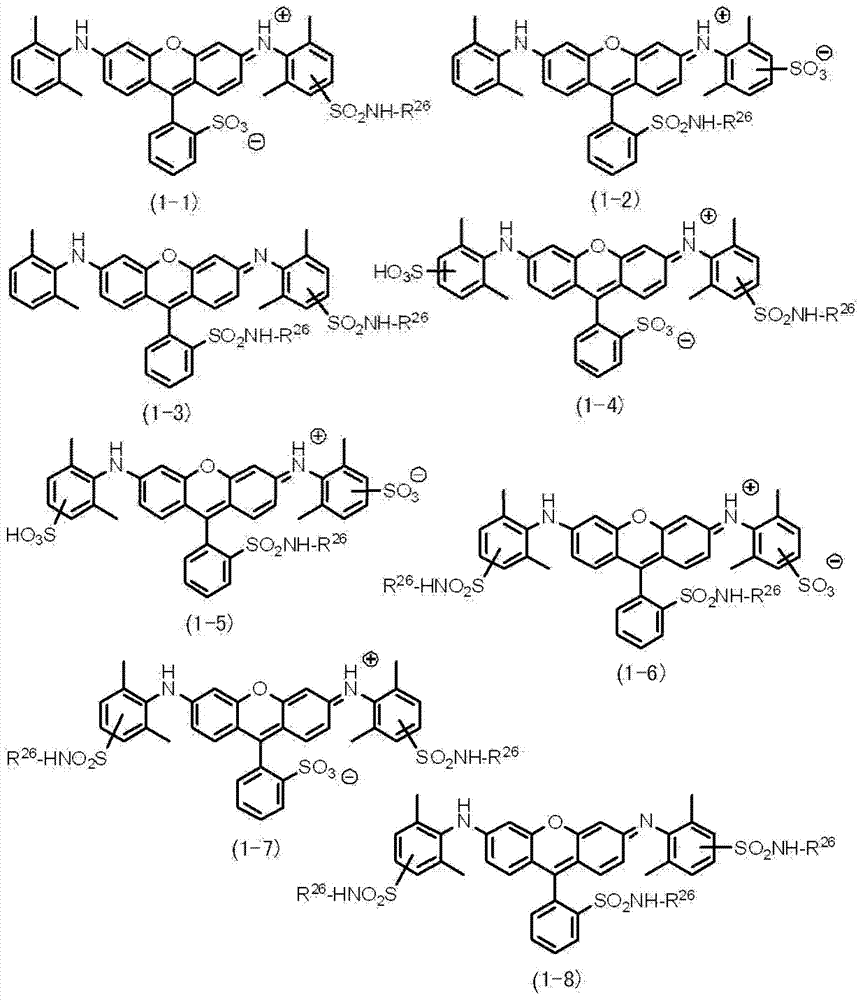

Luminescence display appliance, etching method and display device

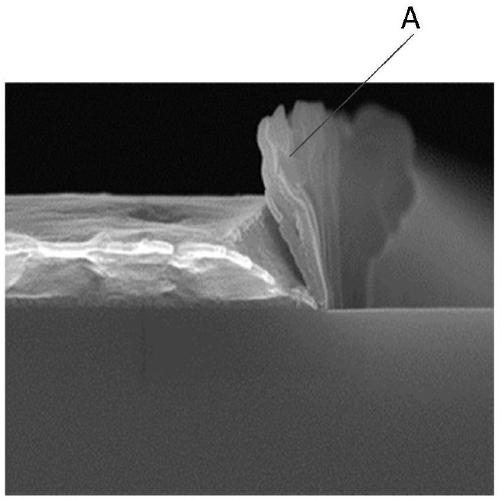

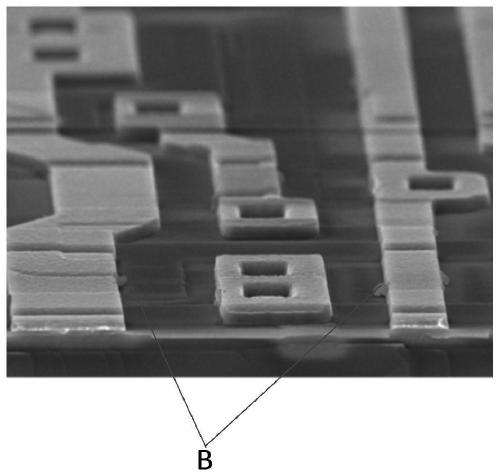

ActiveCN109338365AHigh voltageIncrease attractionSolid-state devicesSemiconductor/solid-state device manufacturingElectricityEtching

The invention discloses a luminescence display appliance, an etching method and a display device. The etching method comprises the steps: to-be-etched metal film layers are coated with photoresist, exposed and developed; the metal layers are etched through preset etching conditions; and the preset etching conditions comprise one or more of etching gas and the power of a bias power supply, whereinthe etching gas comprises boron trichloride with the flow rate being larger than 60 sccm and argon, and the power of the bias power supply is larger than or equal to 300 W. Physical etching can be enhanced through the etching conditions, etched by-products growing on the etched side walls after a reaction between chlorine and metal can be effectively removed by enhancing physical etching, thus filling of subsequent film layers is facilitated, the electrical property of the metal film layers and the film forming quality of the subsequent film layers are improved, thus the product yield is increased, and the product reliability is improved; and removing of the by-products on the side walls of the metal film layers can be further enhanced.

Owner:YUNGU GUAN TECH CO LTD

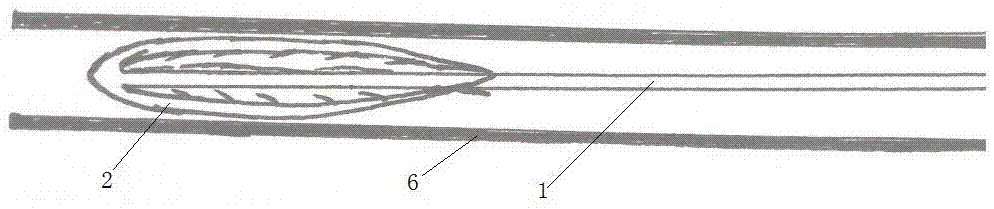

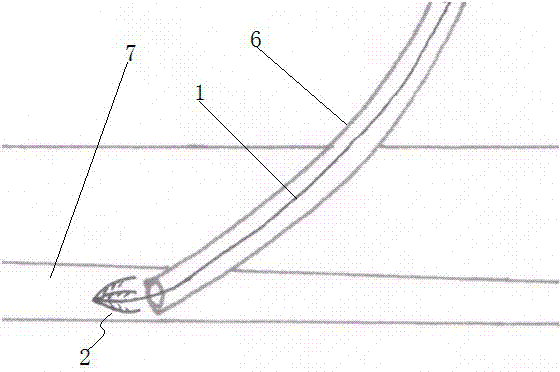

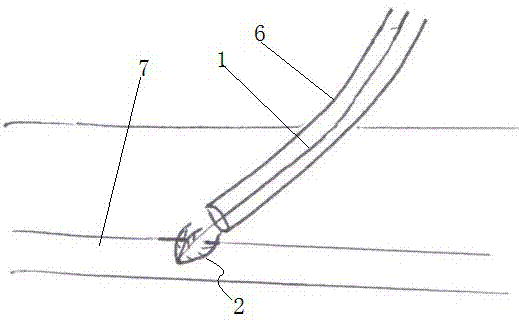

Human pathological or iatrogenic cavity blocking device

The invention discloses a human pathological or iatrogenic cavity blocking device. The device comprises a sheathing canal and a push rod, wherein an elastic anchor is connected to the front end of the push rod and comprises an anchoring base connected with the front end of the push rod, and a plurality of elastic puncturing arms connected with the anchoring base, and an acupuncturing part is arranged at the tail end of each acupuncturing arm; the elastic anchor is compressed and placed in the sheathing canal together with the push rod, and after the elastic anchor disengages from the sheathing canal, the puncturing arms rebound off to form claw-shaped anchors. The device is operated in the same way as ordinary instruments in cavities and has the advantages that operation is easy, the blocking effect is good, and the number of residues in a cavity is small.

Owner:HUNAN ZHUOSHI CHUANGSI TECH CO LTD

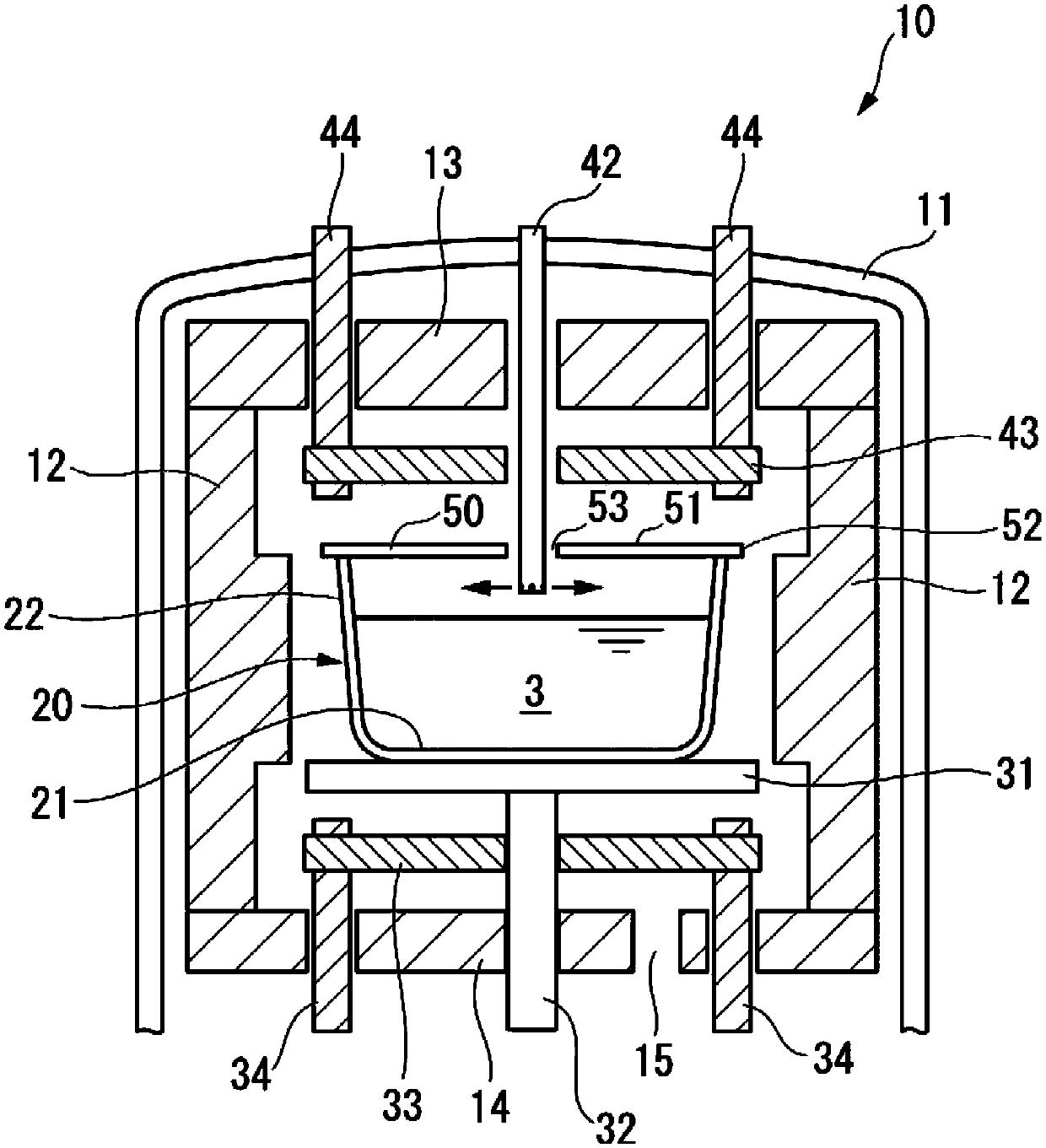

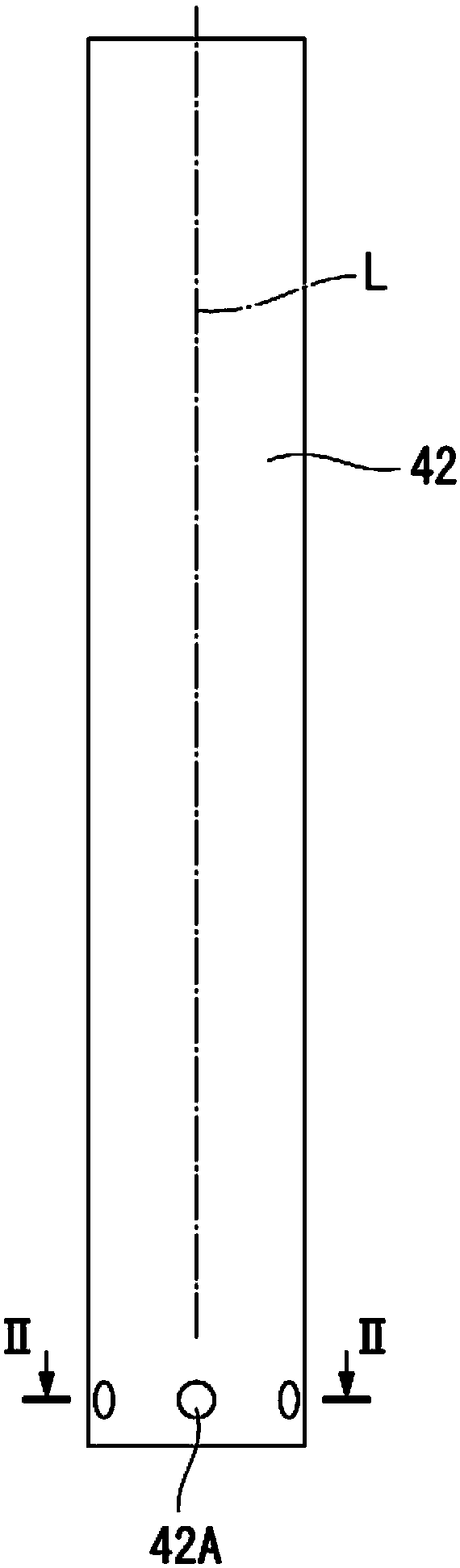

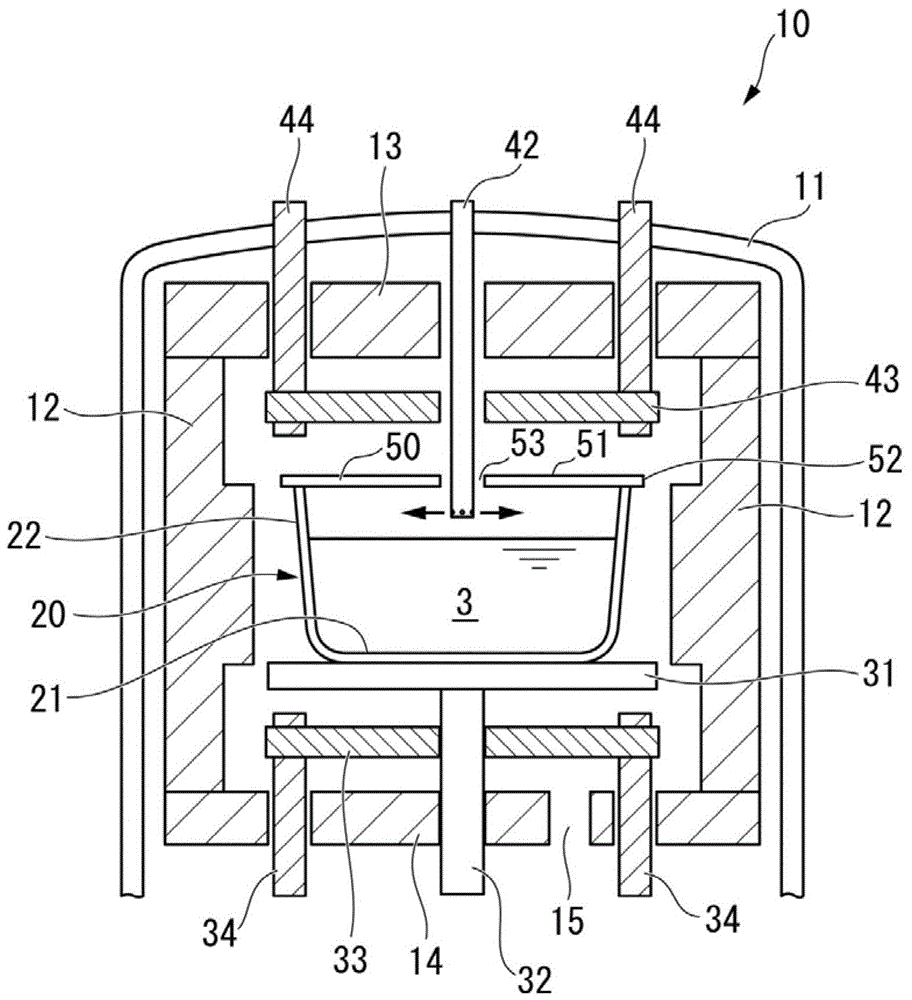

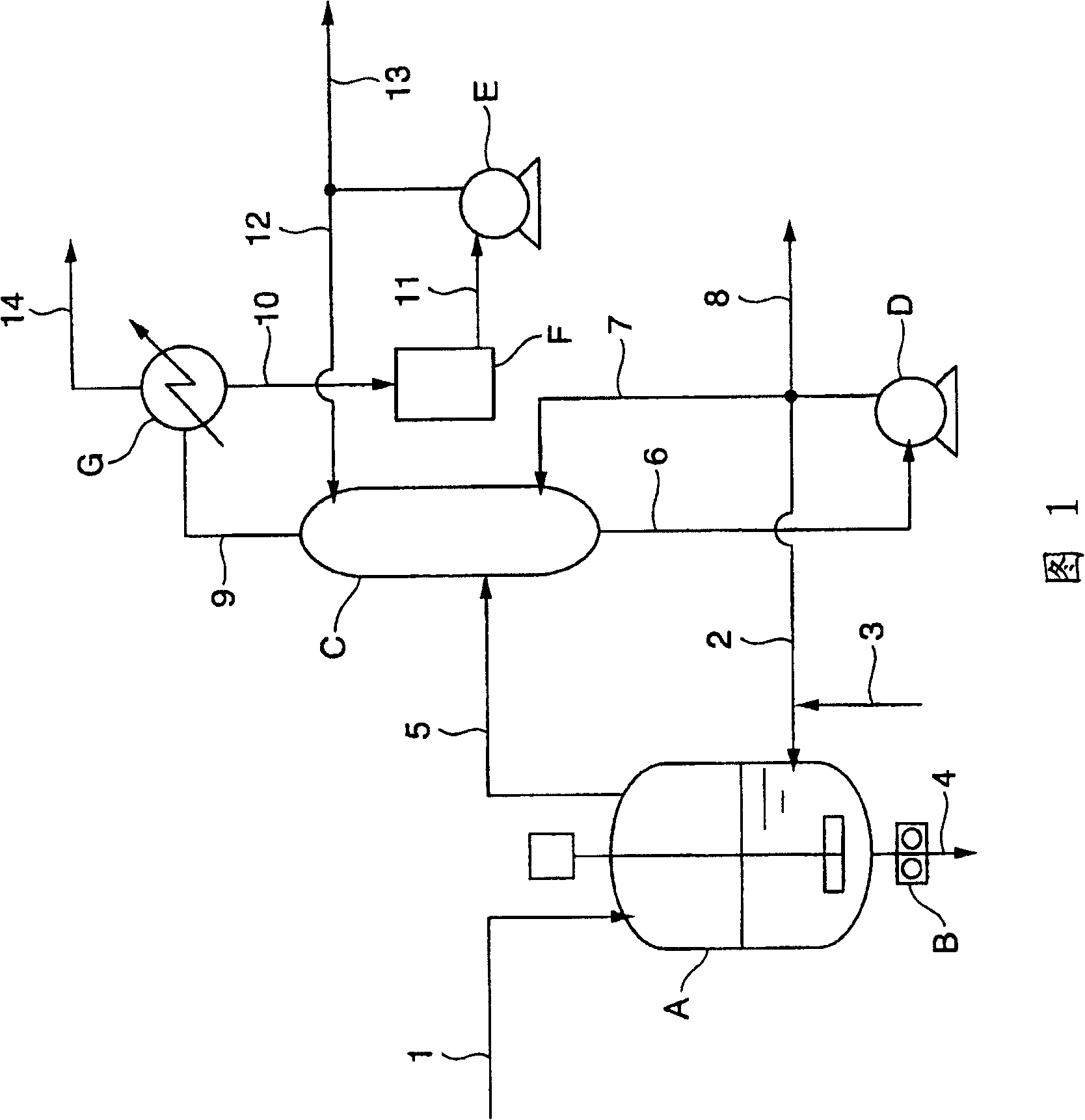

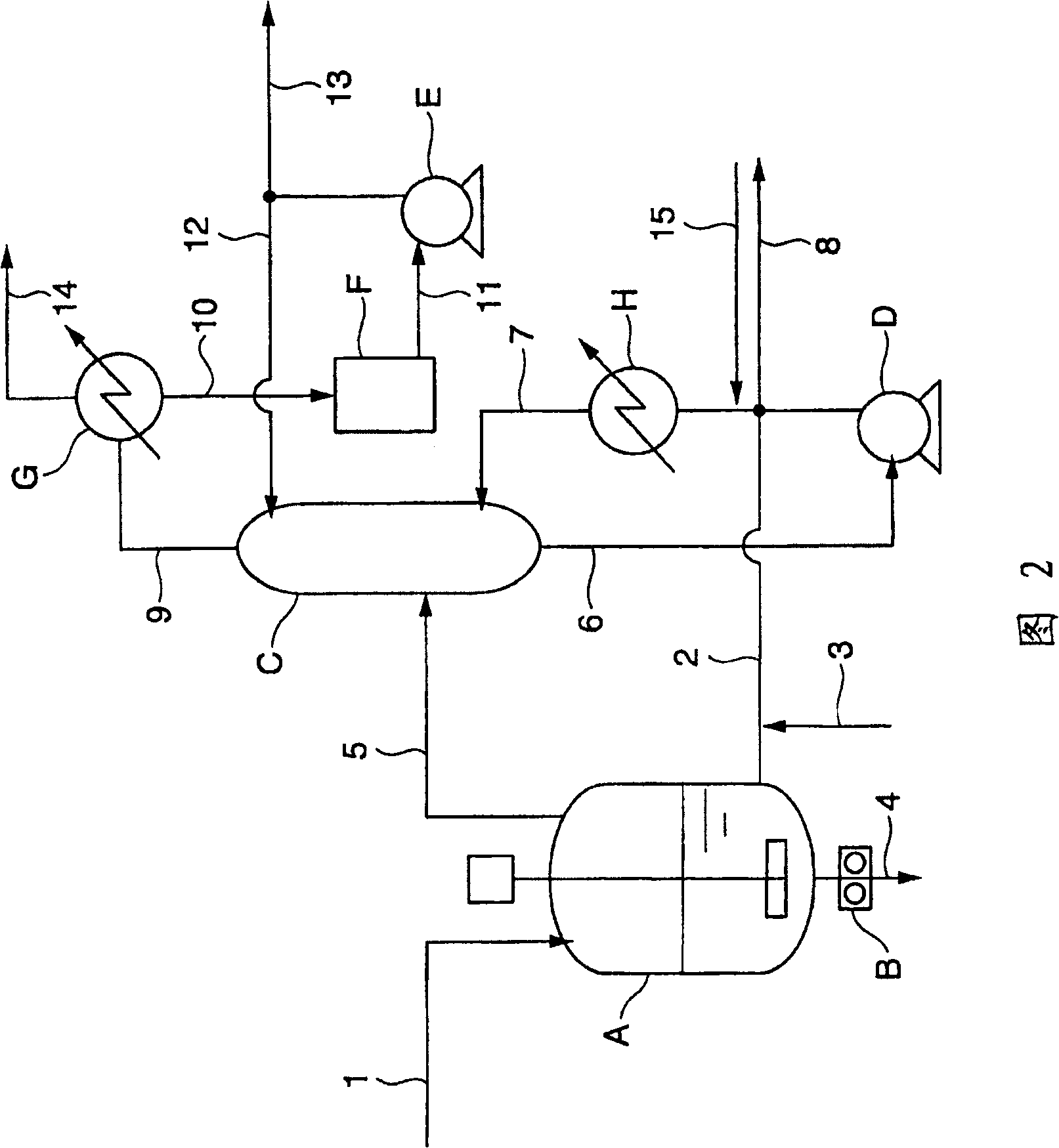

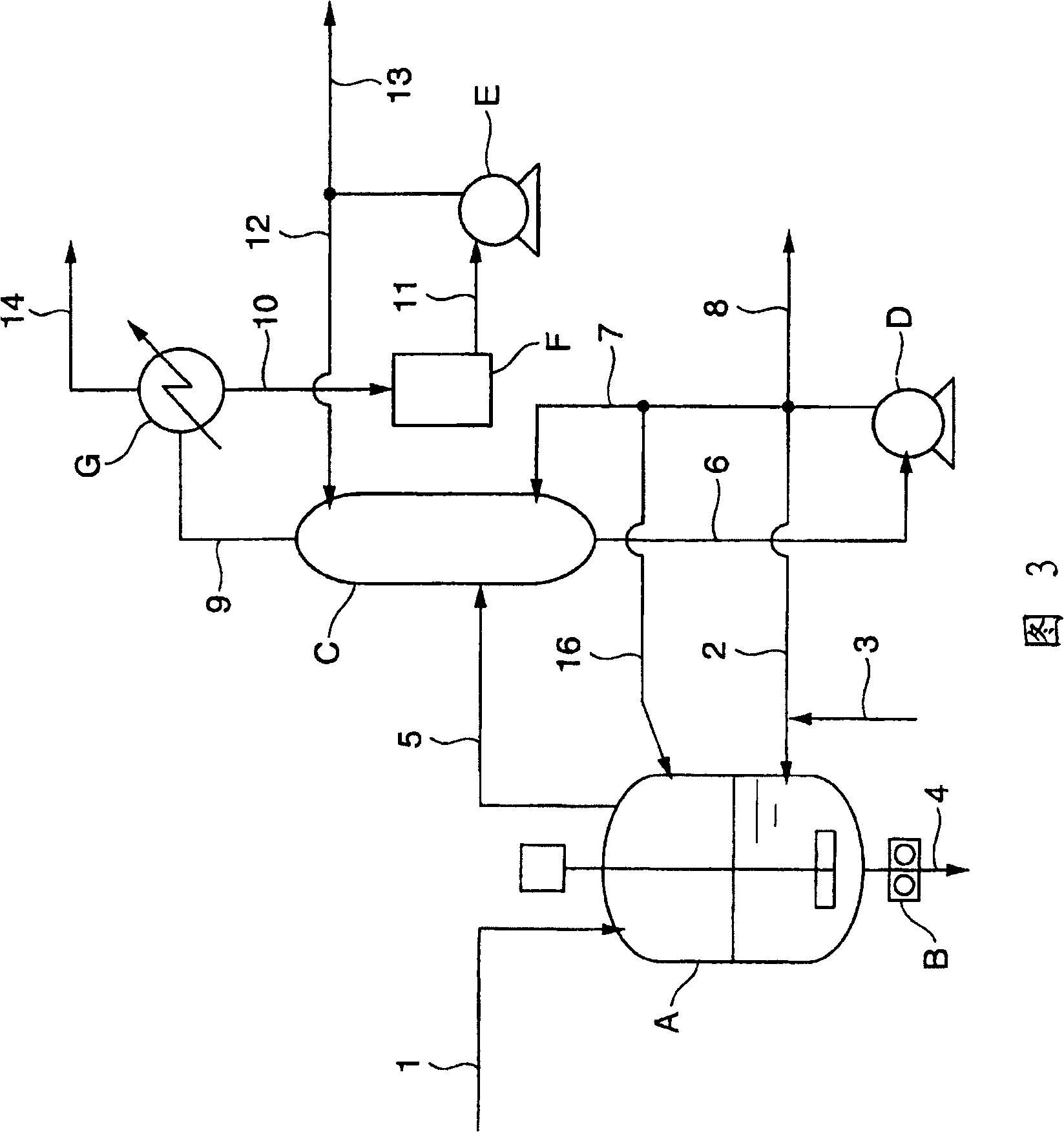

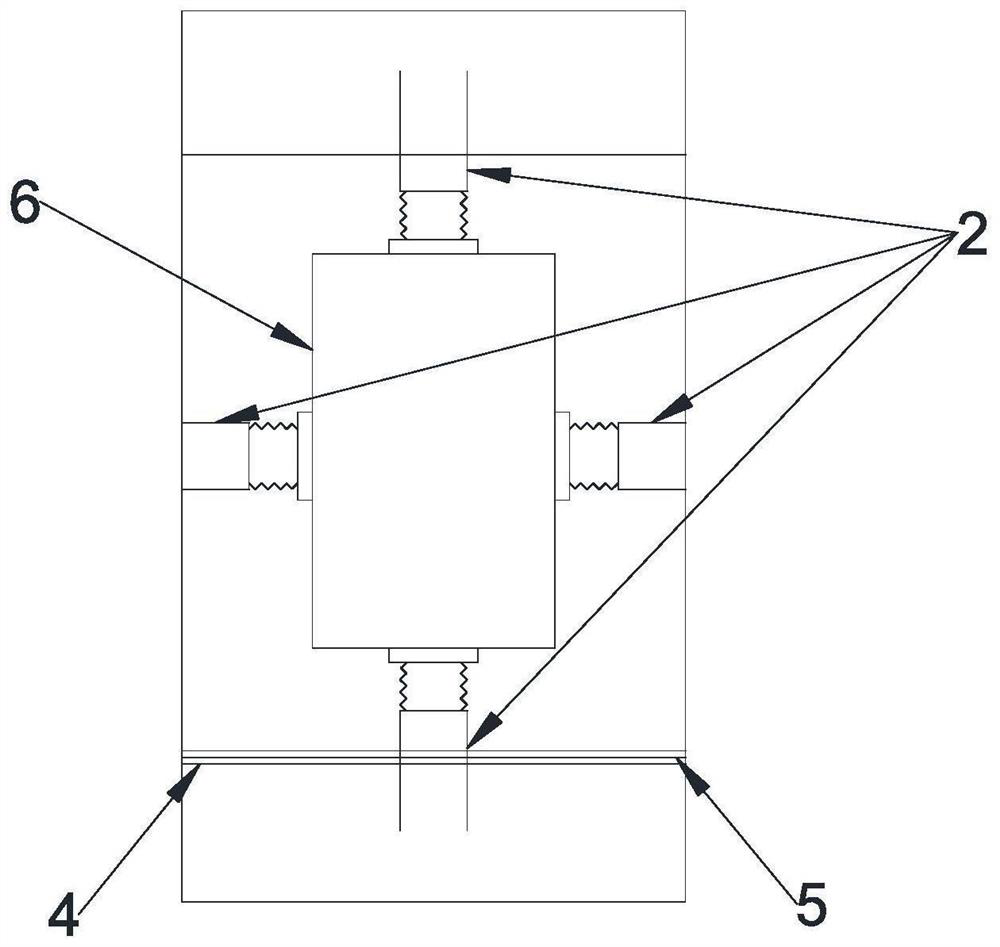

Casting apparatus and casting method

ActiveCN103498195AReduce foreign matterAvoid impuritiesMelt-holding vesselsPolycrystalline material growthCrucibleGas supply

The casting apparatus comprises a crucible (20) that stores a melt and has an opening on its upper side, a heater for heating the crucible, and a device for supplying an inert gas to an upper portion of an interior of the crucible, where the inert gas supplying device extends to the upper portion of the interior of the crucible and includes a gas flow passage and a gas discharging hole located at a distal end portion of the inert gas supply device. The gas flow passage includes a main gas supply tube placed in a distal end of upper portion of the crucible. The casting apparatus comprises a crucible (20) that stores a melt and has an opening on its upper side, a heater for heating the crucible, and a device for supplying an inert gas to an upper portion of an interior of the crucible, where the inert gas supplying device extends to the upper portion of the interior of the crucible and includes a gas flow passage and a gas discharging hole located at a distal end portion of the inert gas supply device. The gas discharge hole is provided such that a flow of the supplied inert gas from the gas discharging hole is parallel to a surface of the melt in the crucible or is inclined at a predetermined angle to the surface of the melt in the crucible. The gas flow passage includes a main gas supply tube placed in a distal end of upper portion of the crucible, and the gas discharge hole is formed in a side surface of a distal end portion of the gas supply tube. The gas flow passage further includes gas supply pipes branched from a distal end of the main gas supply pipe. The branched gas supply pipes are arranged parallel to the surface of the melt in the crucible. The gas discharge hole is provided in a distal end of the branched gas supply pipes. An independent claim is included for a casting process.

Owner:MITSUBISHI MATERIALS CORP

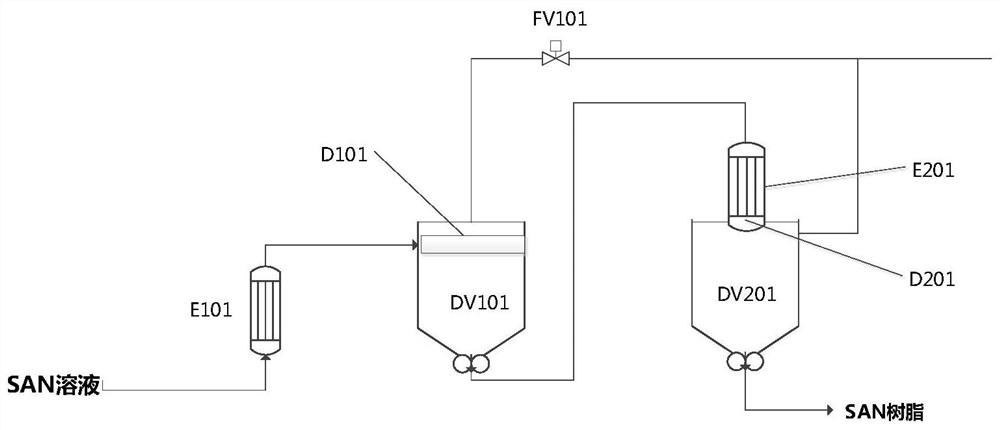

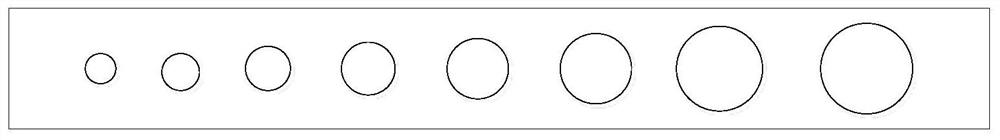

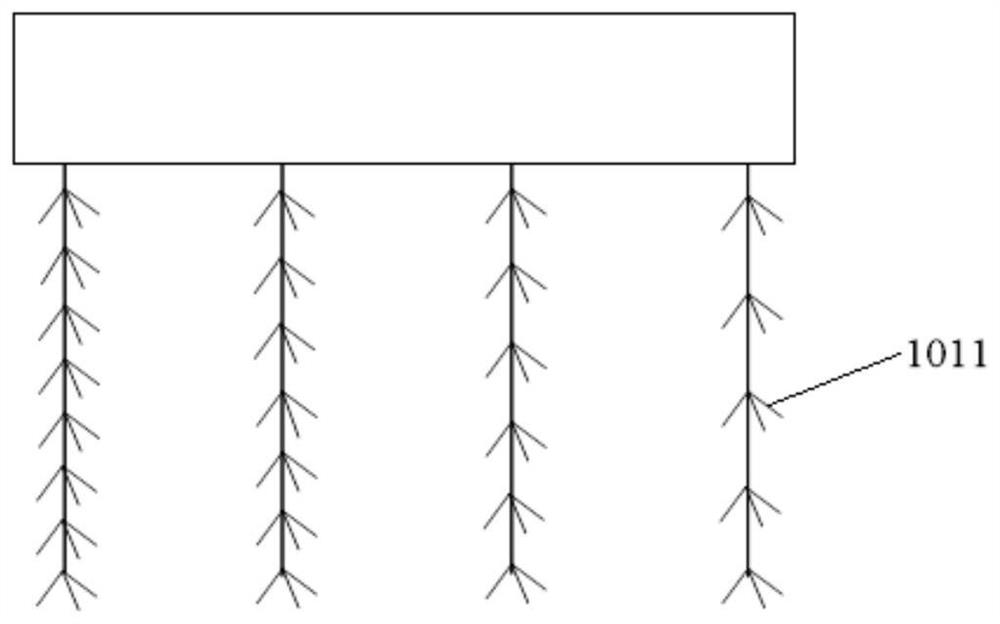

Devolatilization device and SAN (Styrene Acrylonitrile) resin devolatilization process

ActiveCN113304709AAvoid interferenceLarge film forming areaChemical/physical/physico-chemical processesFeed devicesPolymer scienceAcrylonitrile

The invention discloses a devolatilization device and an SAN resin devolatilization process. A material distributor is arranged at a material inlet of the devolatilization device, a plurality of holes are formed in the material distributor, flow guide wires are arranged at the holes, and barbs are arranged on the flow guide wires. According to the devolatilization process, the two-stage series devolatilization device is adopted for removing volatile components, the devolatilization device is adopted for devolatilization, the film forming property of the material is good, the volatile component content of the obtained material is small, and the devolatilization efficiency is high.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

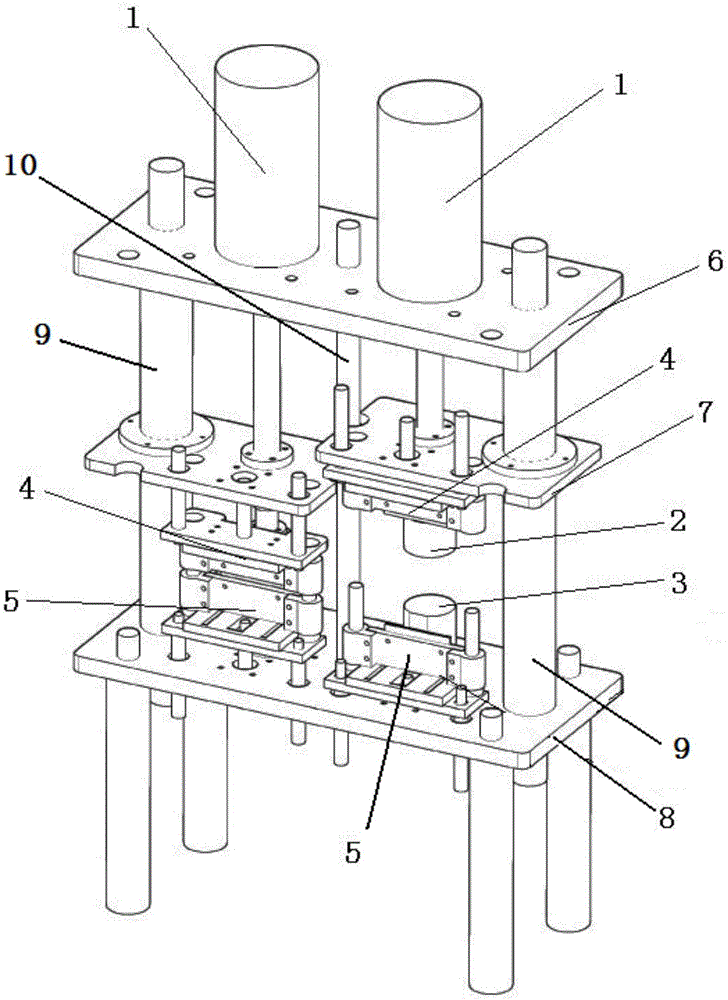

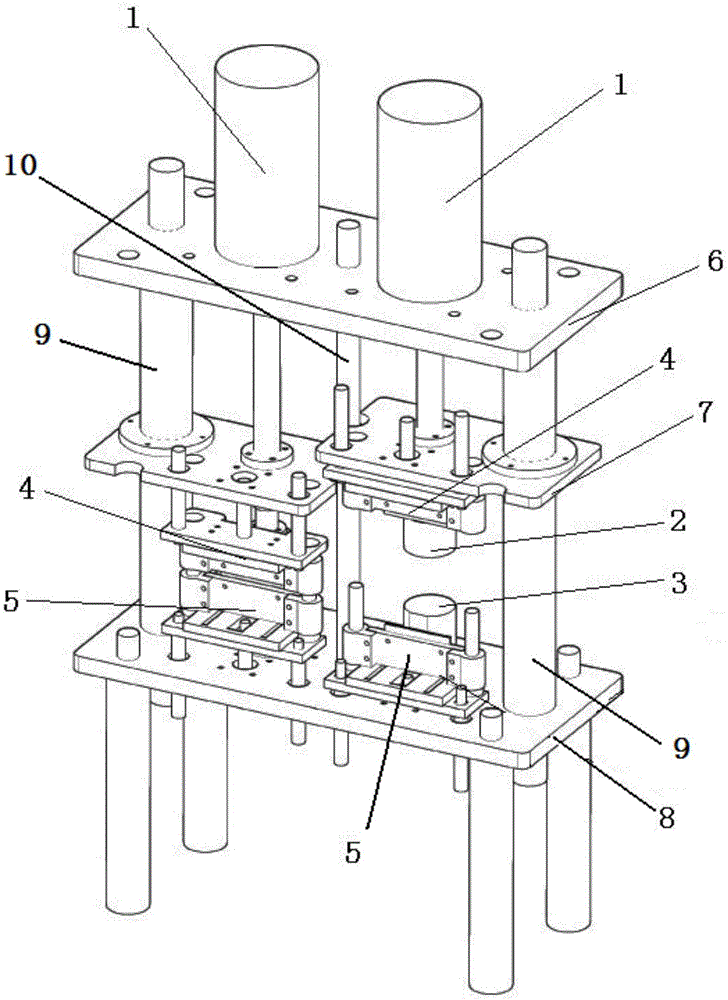

Double-station press with upper dies and lower dies for producing glass products

InactiveCN105016608AReduce adhesionReduce surface pittingGlass pressing apparatusGlass productionState of artHydraulic cylinder

The invention relates to a double-station press machine which comprises an upper table top and a lower table top that are fixedly arranged vertically, wherein a pair of hydraulic cylinders is arranged on the upper table top; lower ends of piston rods of the hydraulic cylinders are connected with moving table tops respectively; an upper mould is arranged on the bottom surface of each of the moving table tops; a lower mould which is coaxial with and opposite to each of the upper moulds is arranged on the lower table top; an upper cutter saddle is arranged on one side of each of the moving table tops; a lower cutter saddle is arranged under each of the upper cutter saddles; and cutters suitable for matching vertically are arranged on the upper and lower cutter saddles. The double-station press machine solves the problems that the product surface has break marks, wrinkles, shrinkage and deformation, the yield is low, and the operation is complicated when glasswork with high requirements, such as an optical glass lens, is produced in the prior art. With the adoption of the double-station press machine, the product qualification rate and the yield are increased and the working load is reduced. The practical data shows that the product qualification rate is increased by about 30% and the yield is increased by about 25%.

Owner:朱保生

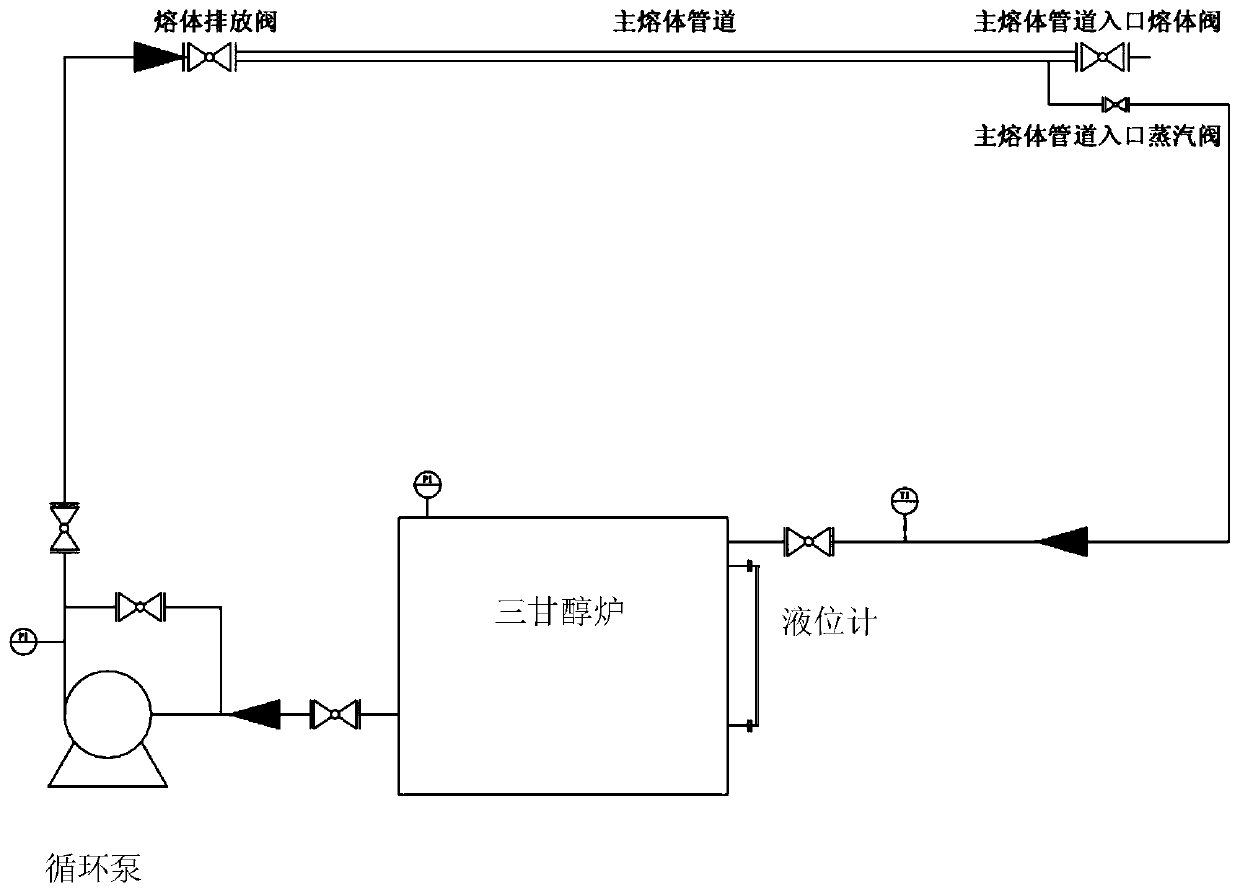

Cleaning method of melt pipeline and application

InactiveCN109940005AEfficient removalImprove qualityHollow article cleaningCirculator pumpProcess engineering

The invention provides a cleaning method of a melt pipeline and application. The cleaning method of the melt pipeline comprises the following steps of connecting the melt pipeline with a triethylene glycol furnace; arranging a circulating pump between the melt pipeline and the triethylene glycol furnace; heating triethylene glycol, then circularly cleaning the triethylene glycol in the melt pipeline through the circulating pump, and cooling after cleaning; blowing the triethylene glycol in the pipeline by using steam; and finally introducing desalted water for washing, and finishing the wholecleaning process after washing. According to the cleaning method, the triethylene glycol furnace with the heating function is only required to be connected with the pipeline for cyclic cleaning, the triethylene glycol is used for alcoholysis of material scaling on the inner wall of the melt pipeline, therefore, degradable materials adhered in the pipe wall can be effectively removed, and the product quality is improved; and the method has the advantages of being convenient, simple, and easy to operate, higher in safety and the like.

Owner:YINGKOU KANGHUI PETROCHEM

Method for manufacturing polycarbonate resin, polycarbonate resin, polycarbonate-resin film, and methods for manufacturing polycarbonate-resin pellets and polycarbonate-resin films

InactiveCN103459112AEfficient and stable manufacturingHigh mechanical strengthFlat articlesForeign matterThermal stability

The present invention relates to a polycarbonate-resin manufacturing method whereby polycarbonate-resin pellets or polycarbonate-resin films that contain little foreign material and exhibit excellent optical properties, thermal stability, hue, and mechanical strength are manufactured efficiently and stably.

Owner:MITSUBISHI CHEM CORP

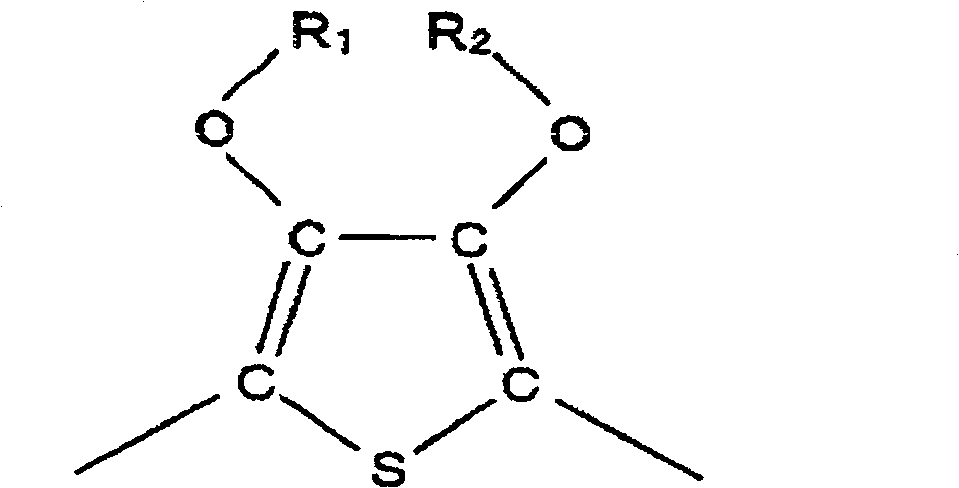

Colored photosensitive resin composition

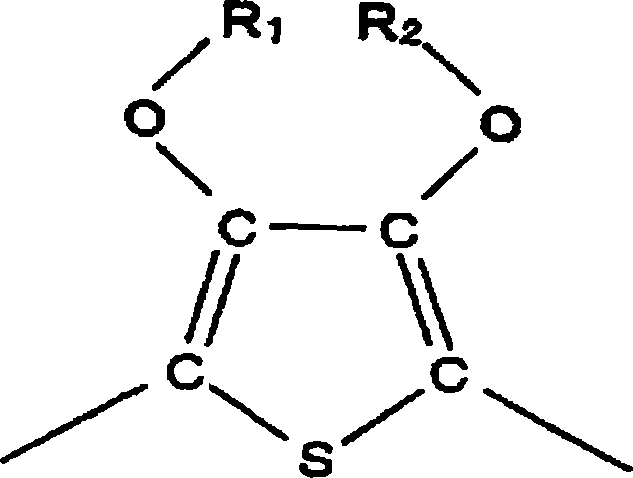

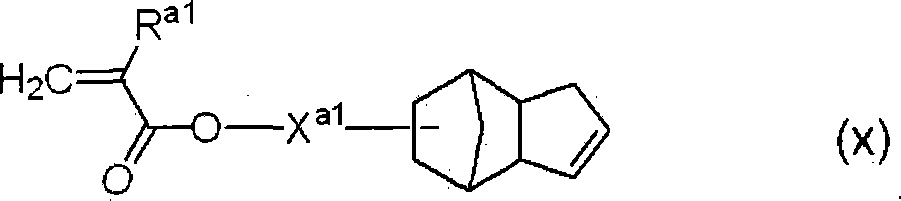

InactiveCN103034055APrevent peelingReduce foreign matterOptical filtersPhotosensitive materials for photomechanical apparatusHydrogen atomCyclic ether

The invention provides a colored photosensitive resin composition containing a colorant, resin, polymerized compounds, and a polymerization initiator; the colorant is a colorant containing a dye; the resin is resin containing a copolymer which comprises the following structure units: a structure unit derived from at least one of a group formed by compounds selected from unsaturated carboxylic acid and unsaturated carboxylic acid anhydride, a structure unit derived from monomers with cyclic ether structures with a carbon atom number of 2-4 and ethylene unsaturated bonds, and a structure unit derived from a monomer shown in formula (x); with respect to the total amount of structure units forming the copolymer, the content of the structure unit derived from the monomer shown in formula (x) is more than 0.1 mol% and less than 20 mol%. [In formula (x), Ra1 represents an alkyl with a hydrogen atom number or a carbon atom number of 1-4; Xa1 represents a single bond, -Xa2-, *-Xa2-O-, *-Xa2-S- or *-Xa2-NH-; Xa2 represents an alkylene with a carbon atom number of 1-6; * represents a bonding position with O].

Owner:SUMITOMO CHEM CO LTD

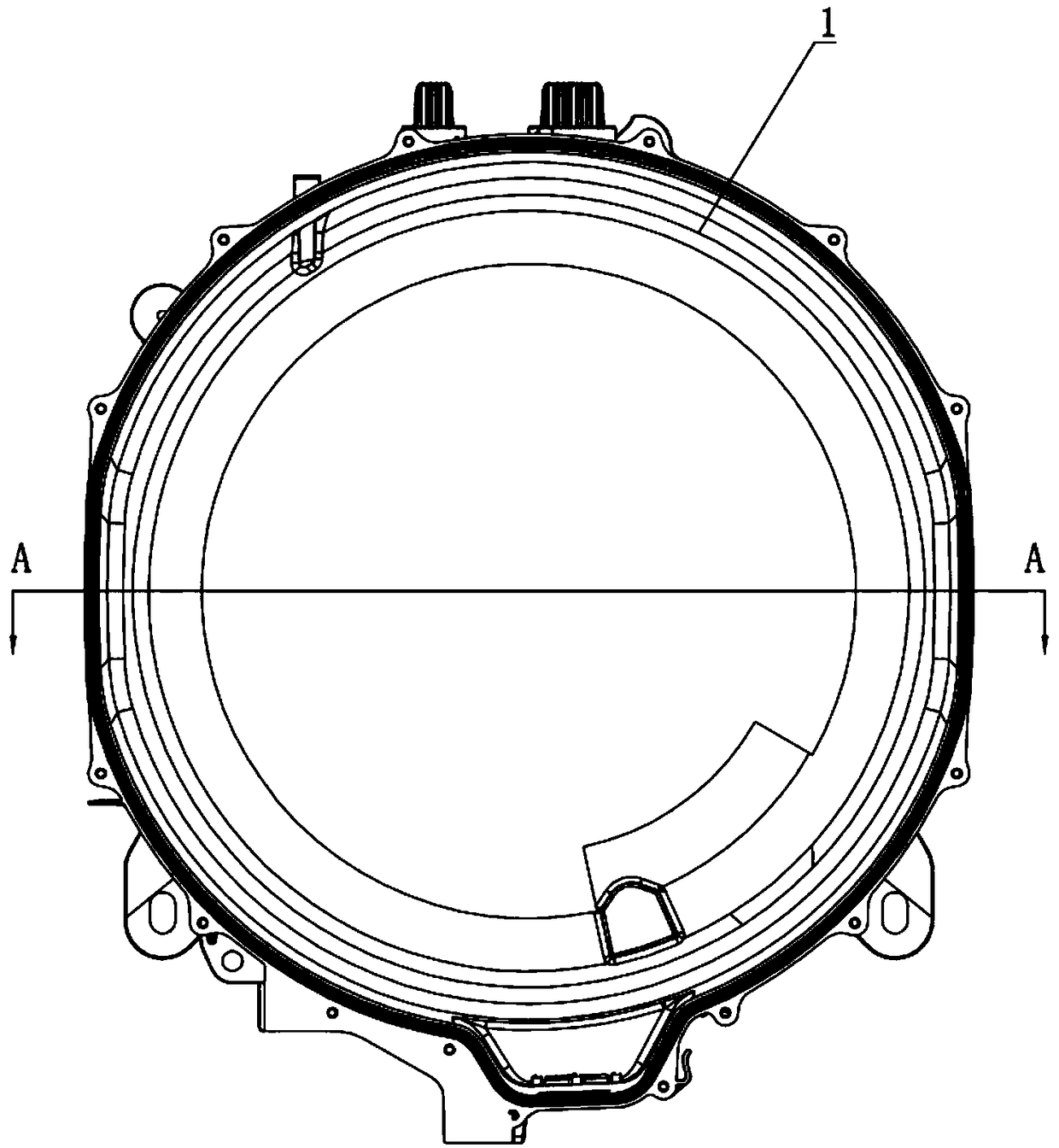

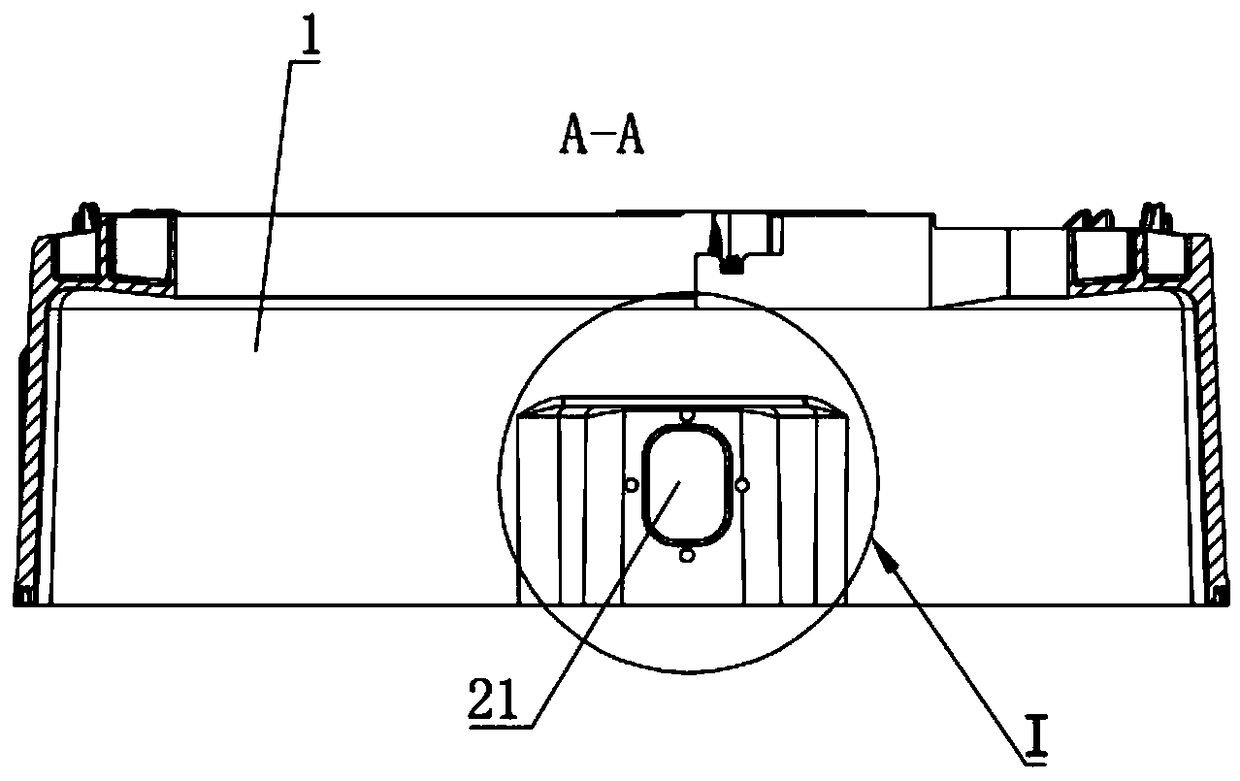

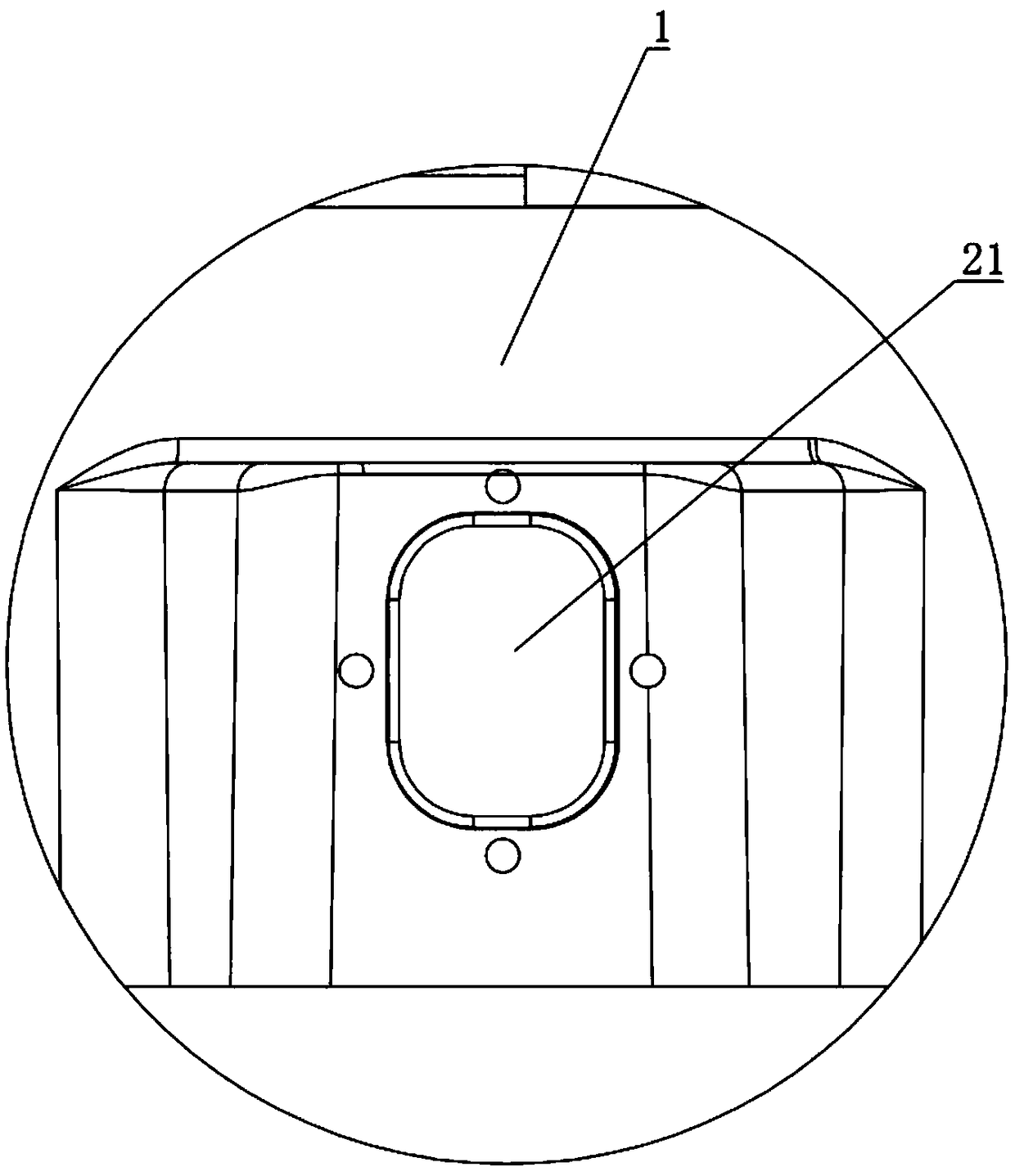

Washing machine

PendingCN108642809ACompact structureReduce foreign matterOther washing machinesTextiles and paperForeign matterHeat conducting

The invention relates to the field of washing machines, and discloses a washing machine. The washing machine comprises an outer tub, a heater connected to the outer tub and a heating base connected tothe end, outside the outer tub, of a heater body and used for heating; one end of the heater is arranged between the outer tub and an inner tub of the washing machine and connected to the heater bodyof the outer tub, the heating base is electrically connected to a controller of the washing machine, and the heater body is made of heat conducting materials. According to the heater, only one end ofthe heater body is arranged inside the outer tub, an installing support is canceled, the structure that the heater is arranged inside the outer tub is omitted, and therefore the foreign matter woundaround the interior of the outer tub of the heater body is reduced to a certain degree; the heating base for heating is arranged outside the outer tub, the heater body only has the effect of heat transfer, even when wire chips are wound around the heater body, only the heat transfer efficiency is affected, and a dry-burning problem is not caused.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

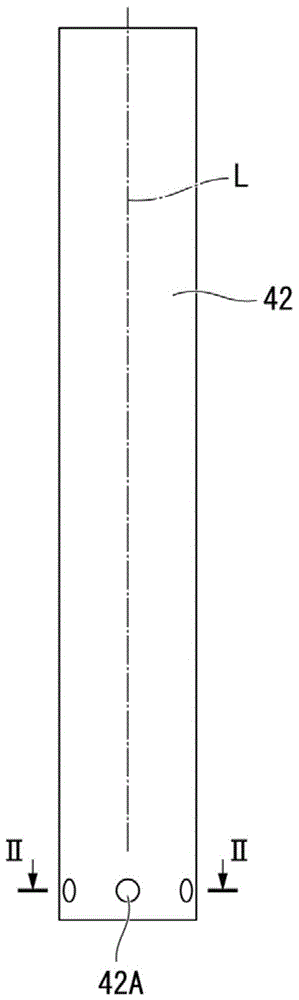

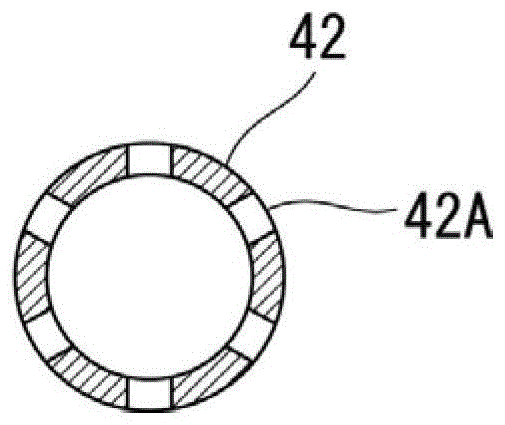

Casting device and casting method

ActiveCN103498195BSolution to short lifeReduce quality problemsPolycrystalline material growthStirring devicesCrucibleIngot

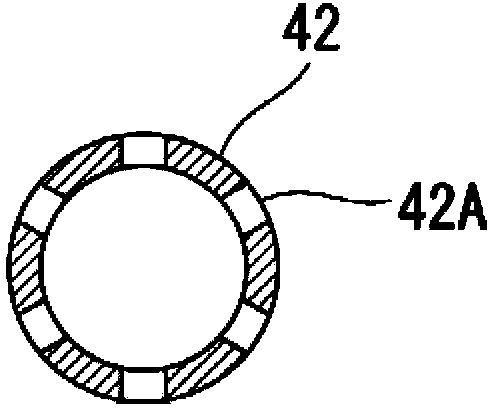

The invention relates to a casting device and a casting method, which can respectively reduce the low-life area and the amount of impurities, hardly cause the problem of slagging of the crucible, and manufacture ingots through ideal unidirectional solidification. The casting device includes a crucible (20) containing a molten material and having an opening at the top, heaters (33, 43) for heating the crucible, and an inert gas supply unit (42) for supplying an inert gas to the upper part of the crucible. The inert gas supply unit has a gas channel extending to the upper part of the crucible and provided with a gas discharge port at the front end. The gas outlet is provided so that the flow of the inert gas discharged from the gas outlet is parallel to the surface of the melt in the crucible.

Owner:MITSUBISHI MATERIALS CORP

Polybutylene terephthalate and method for production thereof, and composition comprising the same and film

ActiveCN100434452CImprove thermal stabilityHigh transparencySynthetic resin layered productsForeign matterFiber

A polybutylene terephthalate (PBT) which contains titanium and has a titanium content of 33 ppm or less; and a composition comprising the polybutylene terephthalate. In a preferred embodiment, the polybutylene terephthalate exhibits a crystallization temperature in the course of the decrease of temperature of 170 to 190 DEG C, has a concentration of a terminal vinyl group of 0.1 to 10 mueq / g, exhibits a haze of its specific solution of 10 % or less, exhibits an increase of the concentration of a terminal carboxyl group of 0.1 to 30 mueq / g after being heat-treated under specific conditions, and contains foreign particles having a size of 5 mum or larger in an amount of 50 pieces / 10 g-polymer or less. The PBT and a composition comprising the PBT are excellent in color tone, hydrolysis resistance, heat stability, transparency and processability, and is reduced in the content of foreign matter, and thus can be suitably used for a film, a monofilament, a fiber, an electric or electronic part, an automobile part or the like.

Owner:MITSUBISHI RAYON CO LTD

Double-station press for producing optical glass lenses and glassworks

InactiveCN105016607AReduce adhesionReduce surface pittingGlass pressing apparatusGlass productionHydraulic cylinderWrinkle skin

The invention relates to a double-station press machine which comprises an upper table top and a lower table top that are fixedly arranged vertically, wherein a pair of hydraulic cylinders is arranged on the upper table top; lower ends of piston rods of the hydraulic cylinders are connected with moving table tops respectively; an upper mould is arranged on the bottom surface of each of the moving table tops; a lower mould which is coaxial with and opposite to each of the upper moulds is arranged on the lower table top; an upper cutter saddle is arranged on one side of each of the moving table tops; a lower cutter saddle is arranged under each of the upper cutter saddles; and cutters suitable for matching vertically are arranged on the upper and lower cutter saddles. The double-station press machine solves the problems that the product surface has break marks, wrinkles, shrinkage and deformation, the yield is low, and the operation is complicated when glasswork with high requirements, such as an optical glass lens, is produced in the prior art. With the adoption of the double-station press machine, the product qualification rate and the yield are increased and the working load is reduced. The practical data shows that the product qualification rate is increased by about 30% and the yield is increased by about 25%.

Owner:朱保生

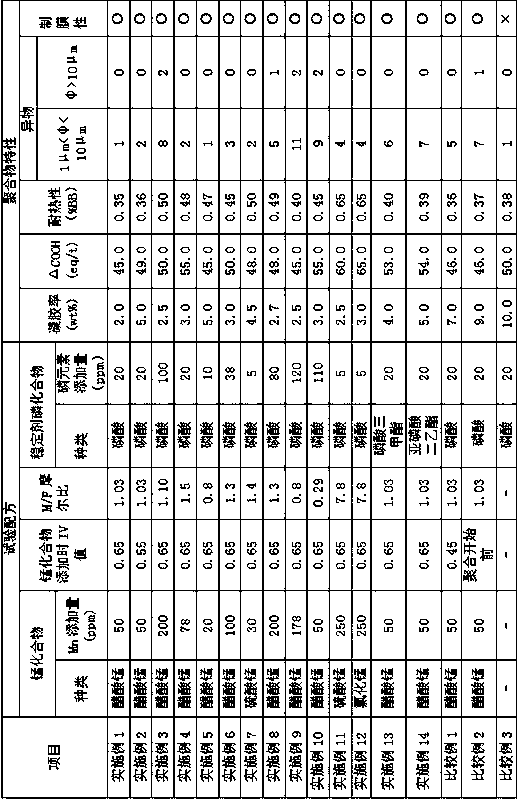

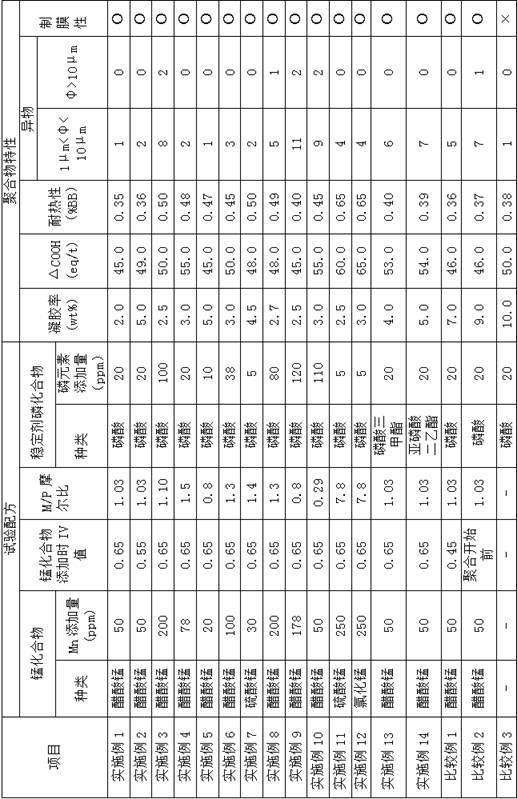

A preparing method for polyester composition

The invention discloses a preparing method for a polyester composition. An esterification reaction between aromatic dicarboxylic acid and aliphatic dihydric alcohol is firstly performed in the method;an antimony compound, an inorganic acid containing phosphorus, or an organic compound containing phosphorus and phosphoric acid alkali metal salt are added to the reaction system from the end of esterification reaction to the beginning of a polymerization reaction to begin the polymerization reaction; in the time period from the inherent viscosity of the polymerized reactant reaching 0.5dl / g to the end of the polymerization reaction, a manganese compound is added to the reaction system to the continue the polymerization reaction until the end of the polymerization reaction. The gel fraction of the polyester composition prepared through the method is under 5wt% in a N2 / O2 gas mixture (oxygen concentration is 1 vol%) after thermal treatment of 300DEG C * 6hr and the polyester composition can be used for preparing thin films and fibers with little foreign material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Polyphenylene sulfide fiber spinning technology

ActiveCN102776601BHigh crystallinityGood light stabilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentPolymer scienceVacuum drying

The invention relates to a polyphenylene sulfide fiber spinning technology which comprises the steps as follows: (1) pre-processing materials: mixing graphite powder with a silane coupling agent to obtain modified graphite, and mixing the modified graphite and polyphenylene sulfide resin at a high speed so as to obtain a mixture, and finally pre-crystallizing and drying the mixture in a vacuum drying box to obtain dried powder with less than 50 ppm of water; (2) melting and spinning: feeding the dried powder into a double-screw extruder for melting and spinning so as to obtain a melt; (3) slowly cooling and cooling: thermally forming the smelt after forming silk through a spinneret plate, and then transferring to a slow cooling area, and finally transferring to a cooling area to solidify and form; and (4) drafting and finalizing: carrying out oil applying and silk guiding on the solidified and finalized fiber, and then drafting and finalizing at three times so as to obtain the short fiber with the linear density of 11 dte x. The polyphenylene sulfide fiber spinning technology is low in cost and easy in industrial production; and the fiber material prepared via the technology has good performance.

Owner:DUNHUANG XIYU MINING & CHEM

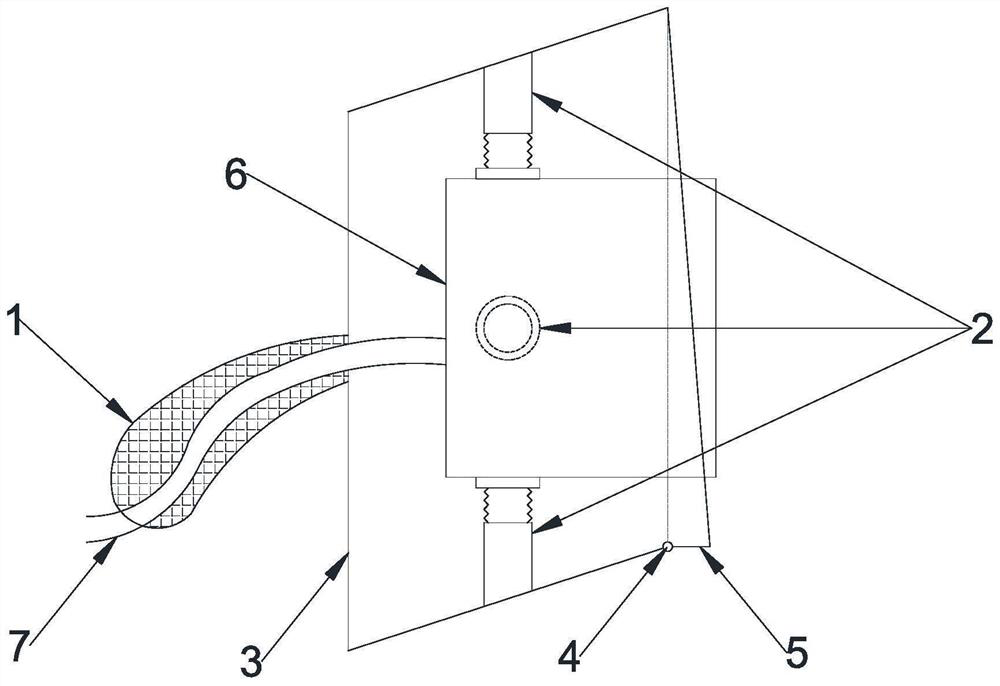

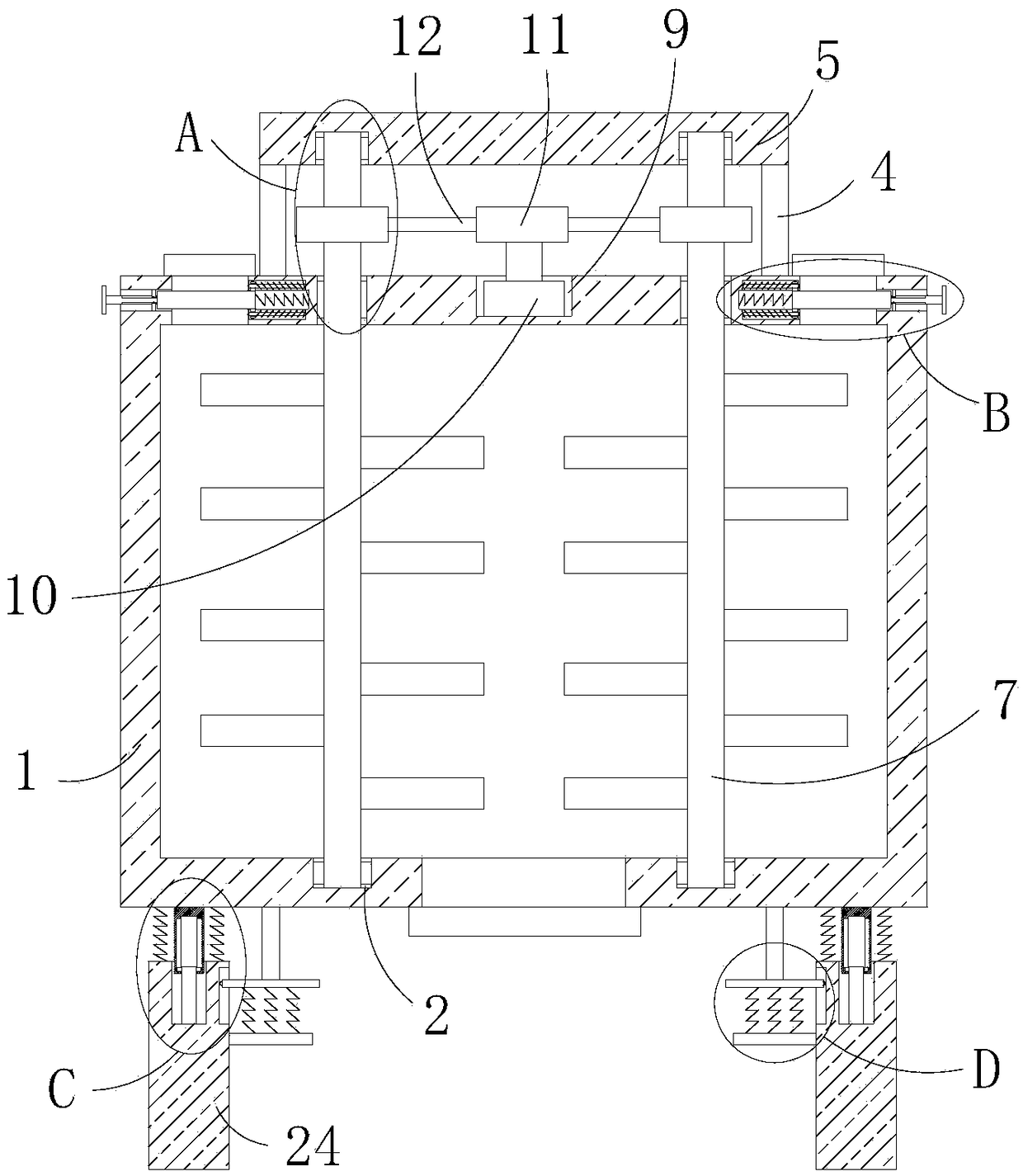

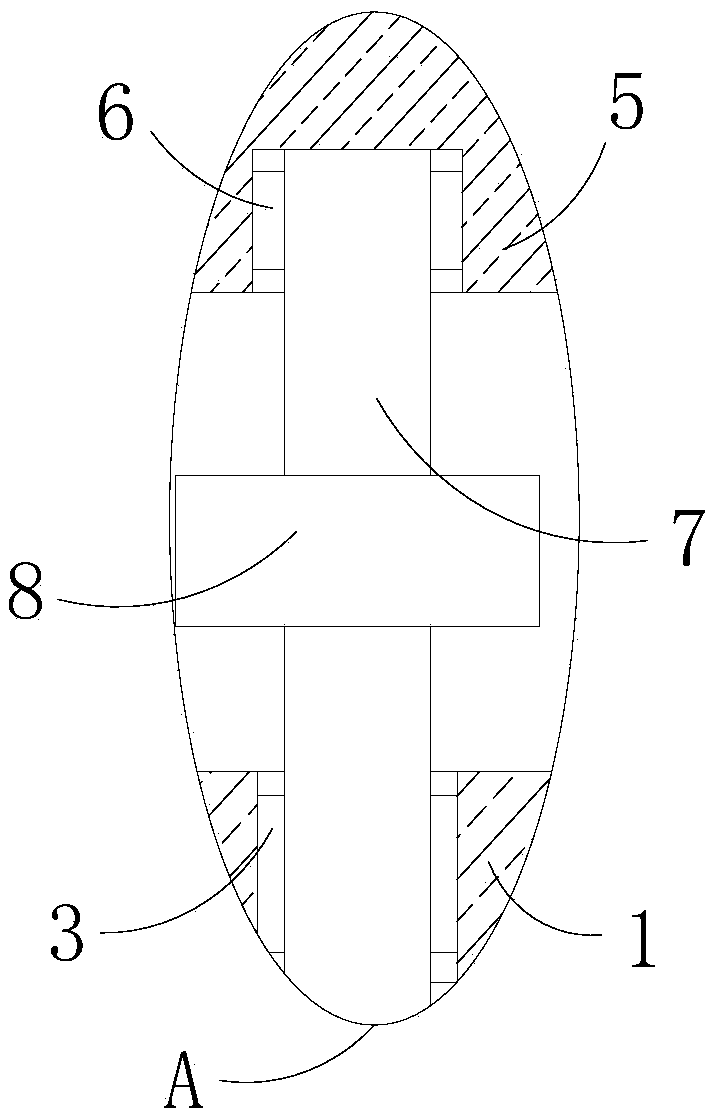

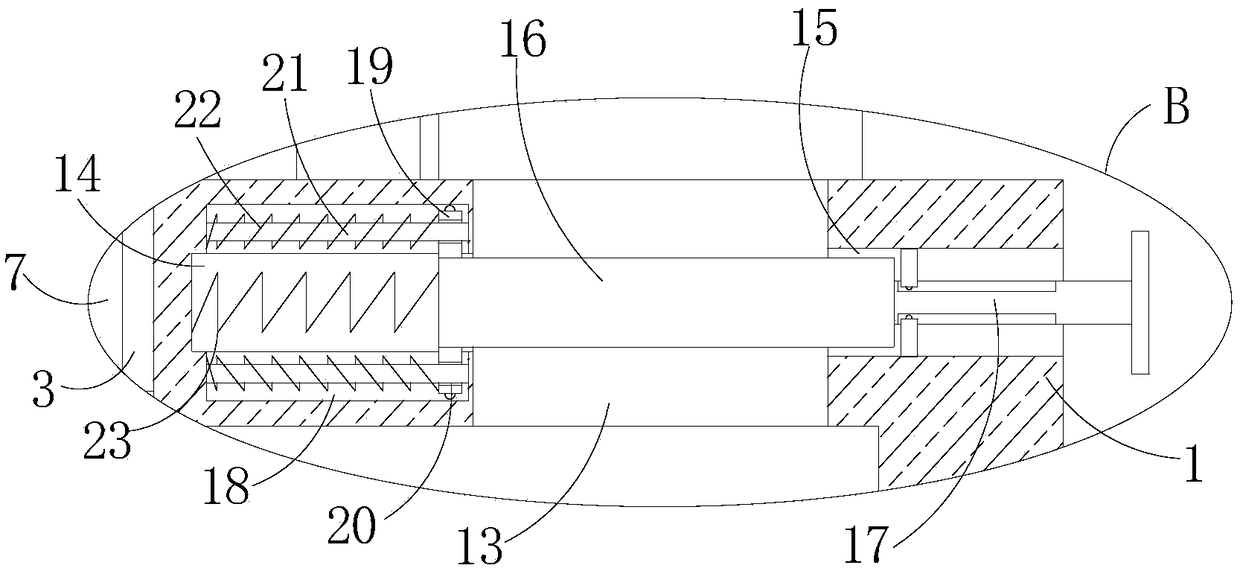

Manual ultrasonic nondestructive testing probe clamping device

PendingCN113552225AAvoid damageReduce foreign matterAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringMechanical engineering

The invention discloses a manual ultrasonic nondestructive testing probe clamping device. The manual ultrasonic nondestructive testing probe clamping device comprises a handle, a shell and an internal clamping device; and the handle is connected to the shell, a probe is arranged in the shell and connected to the inner wall of the shell through an internal clamping device, a through hole is formed in the handle, and a probe wire of the probe penetrates through the shell and the through hole of the handle to be led out. The device can be used for manual ultrasonic nondestructive testing work under most working conditions, has the telescopic property, is suitable for probes of most specifications and sizes, and is good in applicability. Problems of probe falling and hand contamination of personnel in nuclear power field application can be greatly reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Laminated film

ActiveCN100577413CGood antifoulingGood release effectSynthetic resin layered productsForeign matterOligomer

A laminated film including a thermoplastic resin film and an laminated layer that is formed on at least one side of the thermoplastic resin film and comprises (A) a composition, (B) an epoxy crosslinking agent and (C) an acrylic resin having an alkyl chain of 18 to 25 carbon atoms is characterized in that the composition (A) is a composition containing at least a polythiophene and a polyanion and / or a composition containing a polythiophene derivative and a polyanion, the laminated layer contains 15 to 100 parts by weight of the acrylic resin (C) having an alkyl chain of 18 to 25 carbon atoms based on 100 parts by weight of the sum of the composition (A) and the cross-linking agent (B) and / or its reaction product, at least one side of the laminated film has a three-dimensional average surface roughness (SRa) of 3 to 50 nm, and the laminated film contains less than 10 internal contaminant particles with an average particle size of at least 100 mum per 1 m<2>, so that it has high level of electrical conductivity, good releasability and water resistance, and also has oligomer precipitation-preventing properties during heating.

Owner:TORAY IND INC

Method for producing polycarbonate resin, polycarbonate resin, polycarbonate resin film-forming method, and method for producing polycarbonate resin pellets

ActiveCN103476561BEfficient and stable manufacturingHigh mechanical strengthForeign matterThermal stability

The present invention relates to a method for producing a polycarbonate resin capable of efficiently and stably producing a polycarbonate resin excellent in thermal stability, hue, and mechanical strength and having less foreign matter.

Owner:MITSUBISHI RAYON CO LTD

Method for refining lovastatin

The invention discloses a method for refining lovastatin. The method comprises the steps of extraction, primary refining and secondary refining. The extraction comprises the following steps: putting afermentation flask containing fermentation broth into a receiving tank; stirring, detecting the pH value and the contents of monacolin acid and lovastatin; adding water, and adjusting the pH value to3.00 + / - 0.50 by using 15% W / V sulfuric acid; S4, heating to raise the temperature to 45 to 65 DEG C; S5, maintaining the temperature at 45 to 65 DEG C, detecting pH and the contents of monacolin acid and lovastatin at 0.5, 10, 15, 17, and 19h. Toluene extraction and methanol refining are adopted, the odor is reduced, the cost is reduced, the actual purification efficiency is high, and the foreign matters in a plant area are reduced, and the actual production environment and the environmental protection treatment cost is lower.

Owner:福安药业集团烟台只楚药业有限公司

Colored photosensitive resin composition

ActiveCN102819188BPrevent peelingReduce foreign matterPhotomechanical exposure apparatusPhotosensitive materials for photomechanical apparatusForeign matterCarbon number

The present invention provides a coloring photosensitive resin composition, which includes a dye (A), a copolymer (B1), resin (B2), polymerized compound (C) and a polymerization initiator (D). The copolymer (B1) includes: a structural unit selected from the group consisting of at least one of unsaturated carboxylic acids and carboxylic acid anhydrides, a cyclic ether structure with the carbon number of 2-4, and a single structure unit of olefinic unsaturated bonds, wherein the side chains have no carbon-carbon unsaturated double bonds. The resin has side chains with carbon-carbon unsaturated double bonds and the weight-average molecular weight of the resin is above 10000 and below 100000. The weight-average molecular weight of the polymerized compound is below 3000. According to the present invention, the stripping of one part of an unexposed part on the composition layer formed by the coloring photosensitive resin composition during developing can be restrained, and the foreign matter on the pattern can be reduced.

Owner:SUMITOMO CHEM CO LTD

Light-emitting display device, etching method thereof, and display device

ActiveCN109338365BHigh voltageIncrease attractionSolid-state devicesSemiconductor/solid-state device manufacturingEtchingBoron trichloride

The invention discloses a light-emitting display device, an etching method thereof, and a display device, wherein the method includes: coating a photoresist on a metal film layer to be etched, exposing and developing; layer is etched; the preset etching conditions include: the etching gas includes boron trichloride with a flow rate greater than 60 sccm, the etching gas includes argon, and the power of the bias power supply is greater than or equal to at least one of 300W. Eclipse conditions. The above etching conditions can enhance physical etching, and enhanced physical etching can more effectively remove the etching by-products that grow on the etching sidewall after the reaction of chlorine and metal, so as to facilitate the filling of subsequent film layers and improve the electrical conductivity of the metal film layer. Performance and film quality of subsequent film layers, thereby improving product yield and reliability. The removal of sidewall by-products of the metal film layer can be further enhanced.

Owner:YUNGU GUAN TECH CO LTD

Concrete mixer with filtering function

InactiveCN109249537AImprove shock absorptionAvoid damageMixing operation control apparatusCement mixing apparatusForeign matterMixed materials

The invention discloses a concrete mixer with a filtering function. The concrete mixer comprises a mixing box arranged as a hollow structure, the inner wall of the bottom of the mixing box is providedwith two first rotating slots, the top of the mixing box is provided with two rotating holes, fixing rods are fixedly mounted on both sides of the top of the mixing box, a same fixing plate is fixedly mounted on the top of the two fixing rods, the bottom of the fixing plate is provided with two second rotating slots, and a same rotating column is rotatably mounted in the second rotating slot, therotating hole, and the first rotating slot. The concrete mixer disclosed by the invention has the advantages of high practical performance, simple structure, and convenient operation; the mixed raw material can be quickly and conveniently filtered, foreign matters in the mixed raw material are reduced, at the same time, the mixing box can be quickly and conveniently buffered and the mixed material in the mixing box can be evenly mixed, the damage of the mixing box is reduced, and needs of people are met.

Owner:罗峰

A kind of preparation method of polyester composition

The invention discloses a preparation method of a polyester composition. In the method, an aromatic dicarboxylic acid and an aliphatic dihydric alcohol are subjected to an esterification reaction, and during the period from the end of the esterification reaction to the start of the polymerization reaction Add antimony compound, phosphorus-containing inorganic acid or phosphorus-containing organic compound, and alkali metal phosphate to the reaction system to start the polymerization reaction; during the period from the time when the intrinsic viscosity of the polymerization reactant reaches 0.5dl / g to the end of the polymerization reaction , add manganese compound to the reaction system, and continue the polymerization reaction until it is completed. The polyester composition prepared by the method has a gel rate of less than 5wt% after heat treatment at 300°C×6hr under a mixed gas of nitrogen / oxygen with an oxygen concentration of 1 vol%, and less foreign matter, and can be used for making films, fibers, etc. .

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com