Laminated film

A laminated film and thin film technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of dust adhesion, dust adhesion, etc., and achieve the effect of less foreign matter and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

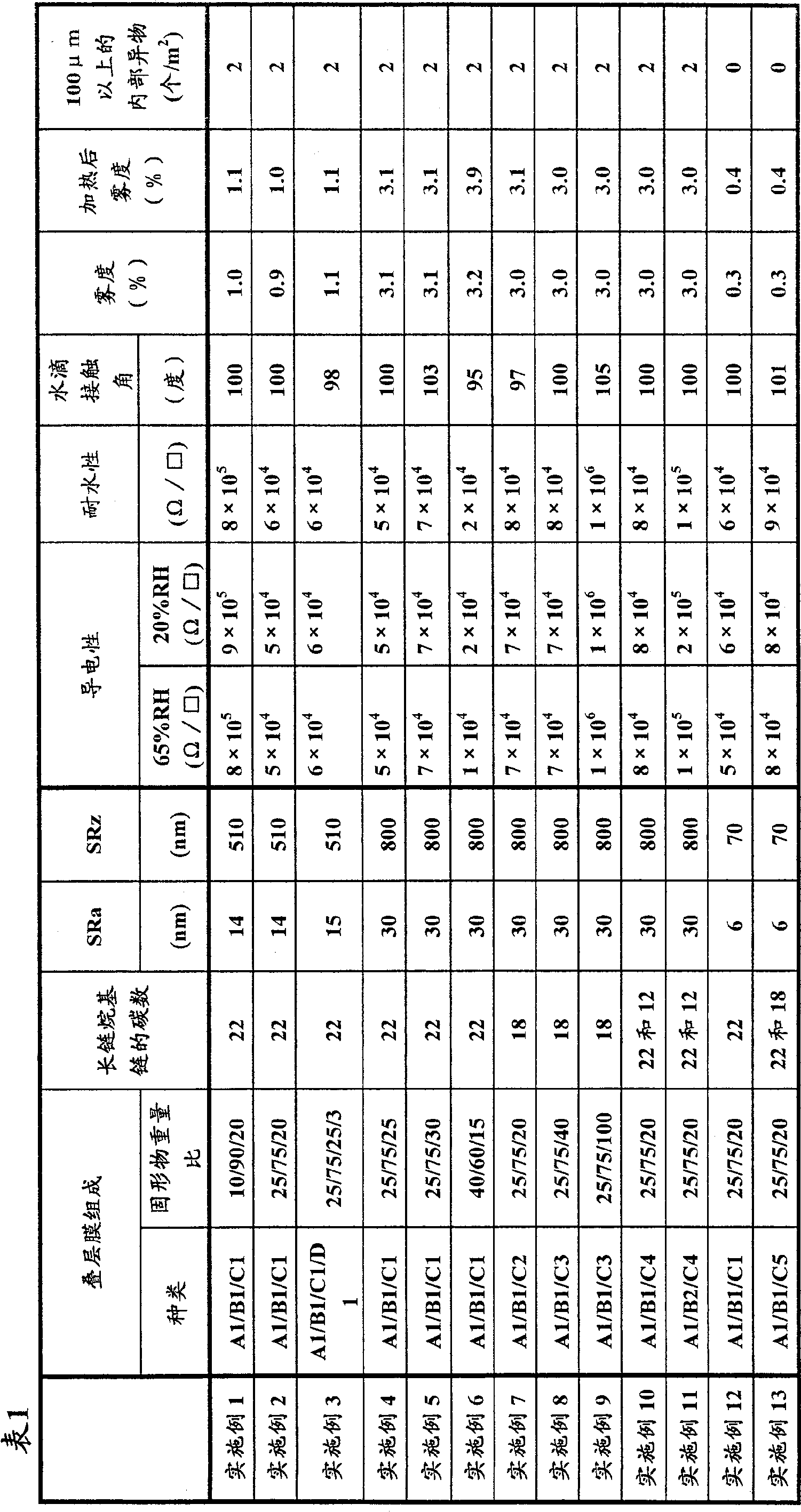

Embodiment 1

[0186] Slurry containing 45 kg of ethylene glycol relative to 100 kg of high-purity terephthalic acid was sequentially supplied over 4 hours to a tank to which approximately 123 kg of bis(hydroxyethyl) terephthalate had been added and kept at a temperature of 250°C, Pressure 1.2×10 5 In the esterification reaction tank under Pa. After completion of supply, esterification reaction was carried out over another 1 hour, and this esterification reaction product was transferred to a polycondensation tank. Next, 0.01 part by weight of ethyl diethylphosphonoacetate, 0.04 part by weight of magnesium acetate tetrahydrate, and antimony trioxide as a polymerization catalyst were added to the above-mentioned polycondensation reaction tank to which the product of the esterification reaction was transferred. (manufactured by Sumitomo Metal Mining Co., Ltd.), and the obtained polyester was adjusted to 400 ppm in terms of antimony atoms. Furthermore, as an additive, silica particles with an ...

Embodiment 2

[0203] A laminated PET film was obtained in the same manner as in Example 1 except that the following laminated film-forming coating liquid was used instead of the laminated film-forming coating liquid used in Example 1.

[0204] "Laminated Film Formation Coating Solution"

[0205] The coating liquid A1, the coating liquid B1, and the coating liquid C1 used the same coating liquid as Example 1.

[0206] The above-mentioned coating liquid A1 and coating liquid B1 are mixed according to the ratio of solid matter weight ratio of coating liquid A1 / coating liquid B1=25 / 75, and aged at room temperature for 5 days (referred to as aging for short). Coating solution 2). Then, the aged coating solution 2 and the coating solution C1 were mixed according to the solid weight ratio of the mature coating solution 2 / coating solution C1 = 100 / 20, and the resulting mixed solution was used as a laminated film forming coating. cloth liquid. The results are shown in Table 1. It is excellent in...

Embodiment 3

[0208] A laminated PET film was obtained in the same manner as in Example 1 except that the following laminated film-forming coating liquid was used instead of the laminated film-forming coating liquid used in Example 1.

[0209] "Laminated Film Formation Coating Solution"

[0210] The coating liquid A1, the coating liquid B1, and the coating liquid C1 used the same coating liquid as Example 1.

[0211] Coating solution D1:

[0212] Aqueous coating solution of colloidal silica with an average particle diameter of 45 nm.

[0213] The above-mentioned coating solution A1 and coating solution B1 are mixed according to the solid weight ratio of coating solution A1 / coating solution B1=25 / 75, and the mixed solution is aged at room temperature for 5 days (referred to as aging coating cloth liquid 2). Then, the aging coating liquid 2, coating liquid C1 and coating liquid D1 are mixed according to the ratio of solid matter weight ratio of aging coating liquid 2 / coating liquid C1 / coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com