Cellulose acetate, cellulose acetate composition, molded article, and film

一种乙酸纤维素、组合物的技术,应用在乙酸纤维素组合物,乙酸纤维素领域,能够解决不能充分减少等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Hereinafter, the present invention will be specifically described by way of examples, but the technical scope of the present invention is not limited by these examples.

[0109] The physical properties described in the examples described later were evaluated by the following methods.

[0110]

[0111] The acetylation degree of cellulose acetate is calculated|required by the measuring method of the acetylation degree in ASTM-D-817-91 (test method of cellulose acetate etc.). 1.9 g of dried cellulose acetate was precisely weighed, dissolved in 150 ml of a mixed solvent of acetone and dimethyl sulfoxide (volume ratio 4:1), and then 30 ml of 1N-sodium hydroxide aqueous solution was added, followed by saponification at 25°C for 2 hours. Phenolphthalein was added as an indicator, and excess sodium hydroxide was titrated with 1N-sulfuric acid (concentration factor: F). In addition, a blank test was carried out in the same manner as above, and the acetylation degree was calcu...

Embodiment 2

[0153] To 16 parts by weight of cellulose acetate obtained in Comparative Example 1, 80 parts by weight of dichloromethane and 4 parts by weight of methanol were added, followed by shaking for 3 hours to completely dissolve. The resulting cellulose acetate solution was pressurized (3 kg / cm 2) was passed through a filter (manufactured by Kansai Gold Network Co., Ltd., ベキポア15AL3, filtration particle size 15 μm). To the obtained cellulose acetate solution, 289 parts by weight of methanol was added, and the precipitated cellulose acetate was filtered through filter paper (Kiyama Filter Paper No. 5C 40φ, manufactured by Kiriyama, Ltd., Ltd.). 150 parts by weight of distilled water was added to the cellulose acetate, and the solution was centrifuged and dehydrated (1000 rpm, 3 minutes). Then, it was dried at 80° C. for 12 hours to obtain cellulose acetate, which was pulverized with a Makino-type pulverizer (manufactured by MAKINO MFG. CO. LTD, model: DD-2-3.7). The grinding condit...

Embodiment 3

[0157] The same procedure as in Example 1 was carried out, except that coniferous sulfite pulp with an α-cellulose content of 97.0 wt % was used, the acetylation time at 85° C. was set to 100 minutes, and the concentration of water in the reaction bath (aging water) was set to 39 mol % Cellulose acetate is obtained.

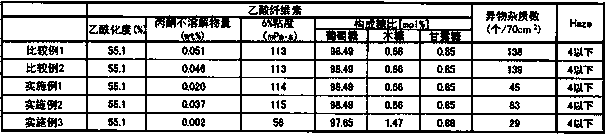

[0158] The acetylation degree, the amount of acetone insoluble matter, the 6% viscosity, and the constituent sugar ratio were measured for the obtained cellulose acetate. The results are shown in Table 1.

[0159] 100 parts by weight of the obtained cellulose acetate and 35 parts by weight of DEP (diethyl phthalate) were mixed with a Henschel mixer, dried at 80° C. for 12 hours, and fed to a biaxial extruder (cylinder temperature: 200°C). °C, die temperature: 220 °C), extruded and pelletized. Using this pellet, a film of 200 μm was formed by remelting at 230° C. with a single-screw extruder I (model: GT-25A, manufactured by Plastic Optical Laboratory Co., Ltd.)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of acetylation | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com