A kind of preparation method of polyester composition

A composition and polyester technology, applied in the field of polyester composition preparation, can solve the problems of limited use, decreased film quality, increased filter pressure, etc., and achieves simple preparation process, low gel rate, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

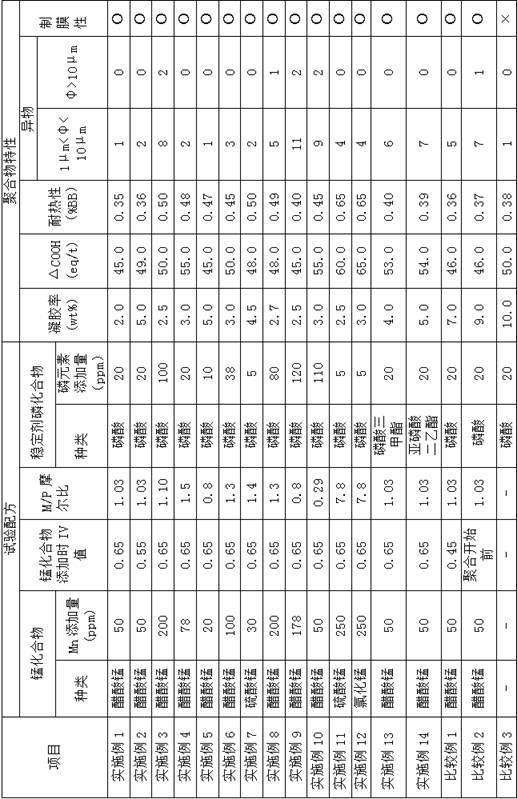

Examples

preparation example Construction

[0016]The preparation method of the present invention is prior to the esterification reaction of the aromatic dicarboxylic acid with the aliphatic diol, and then further polymerization, specifically, in the period of time before the esterification reaction begins to the polymerization Add a bismuth compound, a phosphorus-containing mine-containing or phosphorus organic compound, and a phosphate metal salt to the reaction system, and the polymerization is started, and the polymerization reaction has reached 0.5 dl / g to the polymerization reaction before the first time. The manganese compound is added to the reaction system in the polymerization reactant and the polymerization is continuously reacted until it is completed.

[0017]The manganese compound has an inhibiting oxidation, which can capture the oxygen free radicals to cause free radicals, such that hydrogen on the polyester phenyl ring is avoided to a certain extent, inhibiting the occurrence of thermal oxygen degradation. The...

Embodiment 1

[0046]Activated reaction at 250 ° C of 166 parts by weight of terephthalic acid (TPA) and 72 parts by weight of ethylene glycol (Eg) (i.e., EG and TPA of the molar ratio of 1.1%), passed by by-product water Production, the reaction rate to be reacted is more than 97%, and the prepared new p-oligate (BHT) oligomer is transferred to the polymerizer. To the polymerization, a catalyst, a catalyst, a catalyst, a catalyst (AO) having a polyester composition, a polyester composition, and 5 minutes, 5 minutes, 5 minutes, 5 minutes, 5 minutes, 5 minutes, sodium dihydrogen phosphate (NaH)2PO4· 2h2O) and the phosphorus element is equivalent to a mixture of 20 ppm of the polyester composition by the polyester composition. The end of the addition is completed, and the reduced pressure is started, the temperature is warmed, and the reaction time is 3 hours, the inherent viscosity is 0.65 dl / g. The addition of manganese or manganese or manganese acetate is added to a acetate of 50 ppm of the pol...

Embodiment 2

[0048]Activated reaction at 250 ° C of 166 parts by weight of terephthalic acid (TPA) and 72 parts by weight of ethylene glycol (Eg) (i.e., EG and TPA of the molar ratio of 1.1%), passed by by-product water Production, the reaction rate to be reacted is more than 97%, and the prepared new p-oligate (BHT) oligomer is transferred to the polymerizer. The catalysts (AO) of the polyester element were sequentially added to the polyester composition in the polyester composition, and Eg was added to 5 minutes, and 70 ppm was added to 5 minutes. 5 minutes of phosphate sodium dihydrogen (NaH).2PO4· 2h2O) mixed with a phosphoric acid phosphoric acid having a total amount of 20 ppm of the polyester composition by phosphorus element, and 5 minutes at the end of the addition end, the temperature is increased, and the reaction time is 2 hours and 30 minutes, the intrinsic viscosity is 0.55 dl / When G, a manganese acid polyester composition is added to the polyester composition in a manganese elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com