Method for refining lovastatin

A technology of lovastatin and toluene, applied in the field of lovastatin refining, can solve the problems of non-compliance with environmental protection requirements, acetone is volatile, and the price is relatively high, and the production environment and environmental protection treatment costs are low, and odor and foreign matter are reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

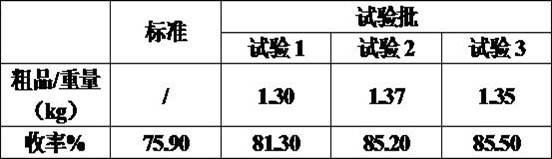

Examples

Embodiment Construction

[0053] In the embodiment of the present invention, a method for refining lovastatin, the specific steps include extraction, primary refining and secondary refining;

[0054] Described extraction specifically comprises the following steps:

[0055] S1. Put 100L of fermentation broth in the fermentation bottle into the receiving tank;

[0056] S2, detect pH after stirring, monazolic acid, lovastatin content;

[0057] S3, add water, and adjust the pH to 3.00±0.50 with 15% W / V sulfuric acid;

[0058] S4, heating up to 45-65°C;

[0059] S5. Maintain 45-65°C, and detect the pH, monazolic acid, and lovastatin contents at 0, 5, 10, 15, 17, and 19 hours respectively;

[0060] S6, add 100ml toluene;

[0061] S7. Cool down to 30-45°C, stir for 3-6h, and detect the content of lovastatin;

[0062] S8, separating the toluene layer obtained, repeating the operations of S6 and S7 until the lovastatin residual amount is ≤1.5%;

[0063] S9, washing the toluene layer with 2-4% purified wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com