Polycarbonate-resin manufacturing method

A technology of polycarbonate resin and manufacturing method, applied in the field of polycarbonate resin, can solve the problems of low photoelastic coefficient, low birefringence, inability to adapt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

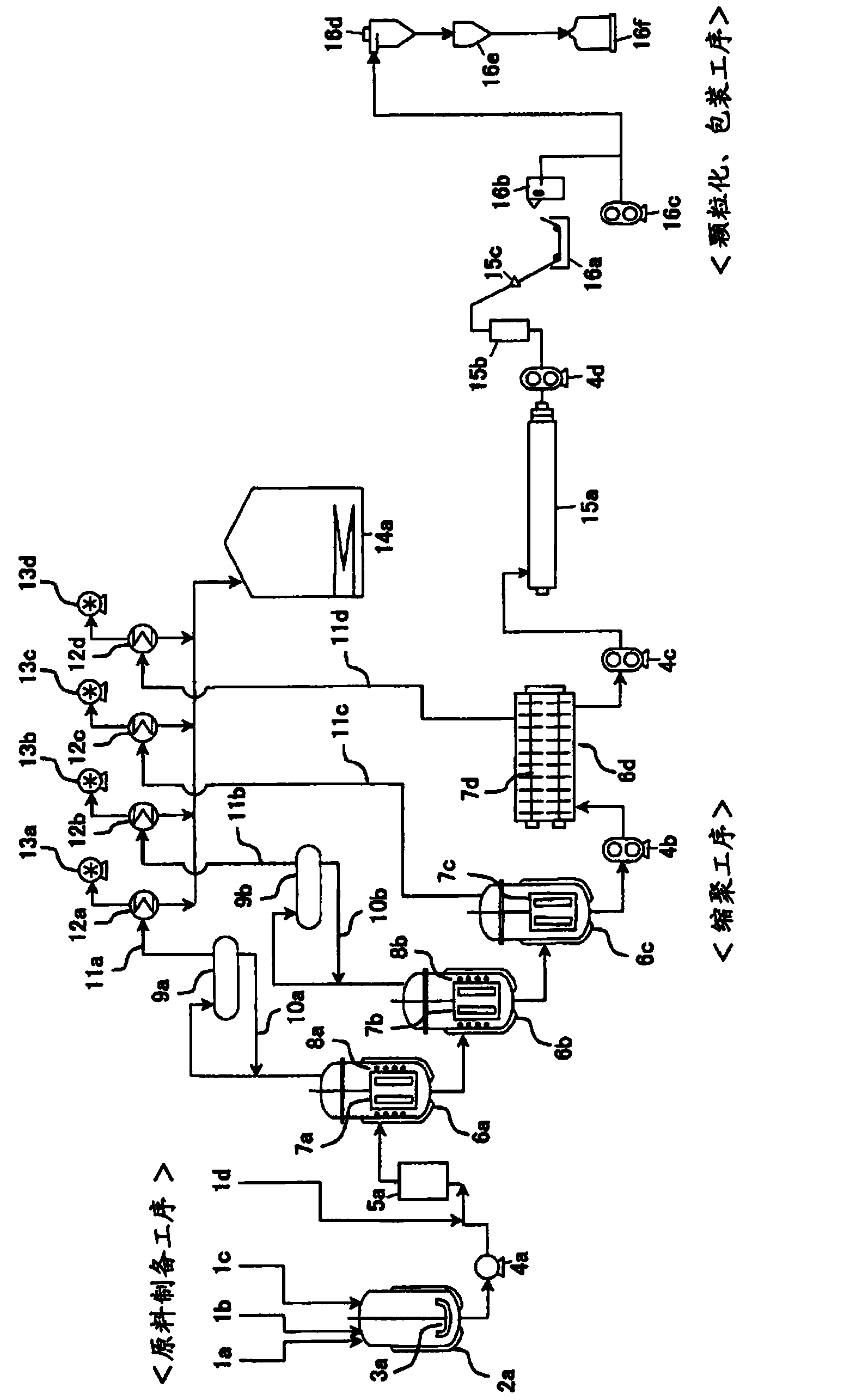

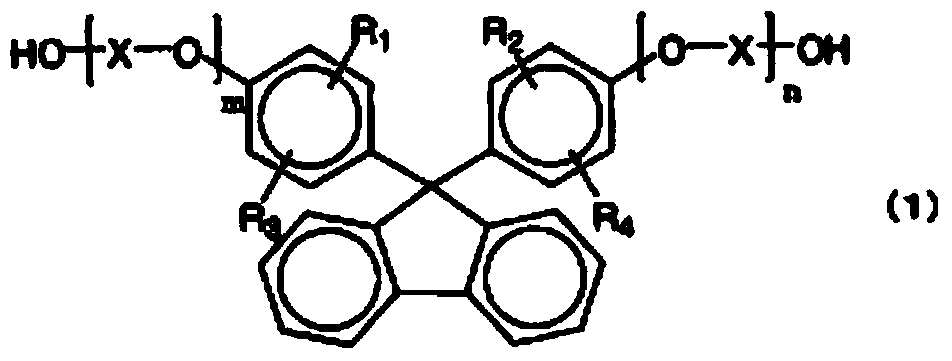

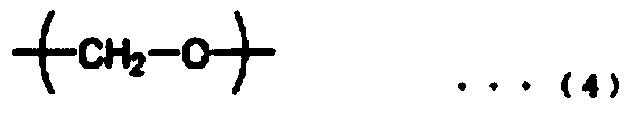

[0343] In the raw material preparation tank fully subjected to nitrogen substitution (oxygen concentration 0.0005% to 0.001% by volume), a certain amount of raw material is continuously supplied to the first polymerization reactor, and at the same time, it is continuously fed through the catalyst supply pipe connected to the raw material supply pipe. Supply the magnesium acetate tetrahydrate that has been made into the aqueous solution so that it reaches 19×10 per 1 mol of all dihydroxy compounds. -6 mol (converted into magnesium metal atoms), the raw material is prepared in such a way that the molar ratio of BHEPF / ISB / PEG (average molecular weight 1000) / DPC is 43.2 / 55.6 / 1.2 / 99, and the first polymerization reactor has : Heat medium jacket with oil as heat medium, heat medium internal coil, stirring paddle, distillation tube connected with vacuum pump, and condenser. After the raw material and the catalyst aqueous solution are mixed in the piping, two pleated cylindrical raw m...

Embodiment 2

[0347] Except that pentaerythritol tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] and tris(2,4-di-tert-butylphenyl) phosphite were not added, the same Example 1 was performed in the same manner. The results are shown in Table 1.

Embodiment 3

[0349] The raw materials were prepared in such a way that the molar ratio of BHEPF / ISB / PEG (average molecular weight 1000) / DPC was 40.3 / 59.4 / 0.3 / 99, the internal temperature of the first polymerization reactor was set to 194°C, and the pressure was set to 27.8kPa, Set the internal temperature of the second polymerization reactor to 208°C, set the pressure to 25.8kPa, set the internal temperature of the third polymerization reactor to 221°C, and set the pressure to 23.0kPa, set the inlet of the fourth polymerization reactor to The internal temperature near the outlet is set to 225°C, the internal temperature near the outlet is set to 239°C, the pressure is set to 1.3kPa, the screw speed of the extruder, the extrusion amount of polycarbonate resin / the cross-sectional area of the barrel , The heater setting temperature of the filter, and the molten resin linear velocity on the filter surface were changed as shown in Table 1, and the procedure was carried out in the same manner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com