Method for producing polyethylene resin film

A polyethylene-based resin, polyethylene resin technology, which is applied to flat products, other household appliances, household appliances, etc., can solve the problems of easy scarring, pollution of the periphery of the film processing device, and decrease in heat sealing strength, and achieves the appearance and durability. Excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

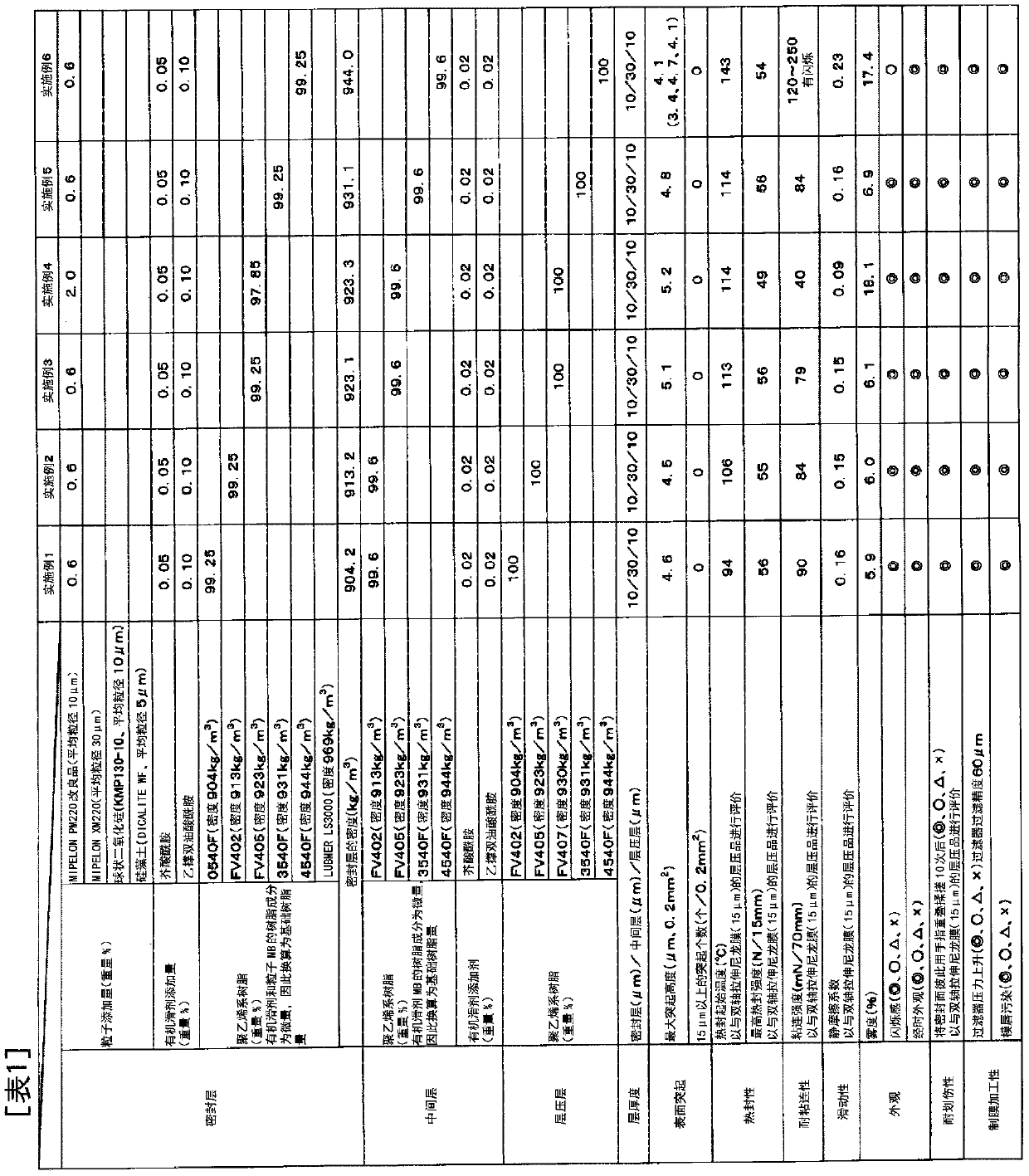

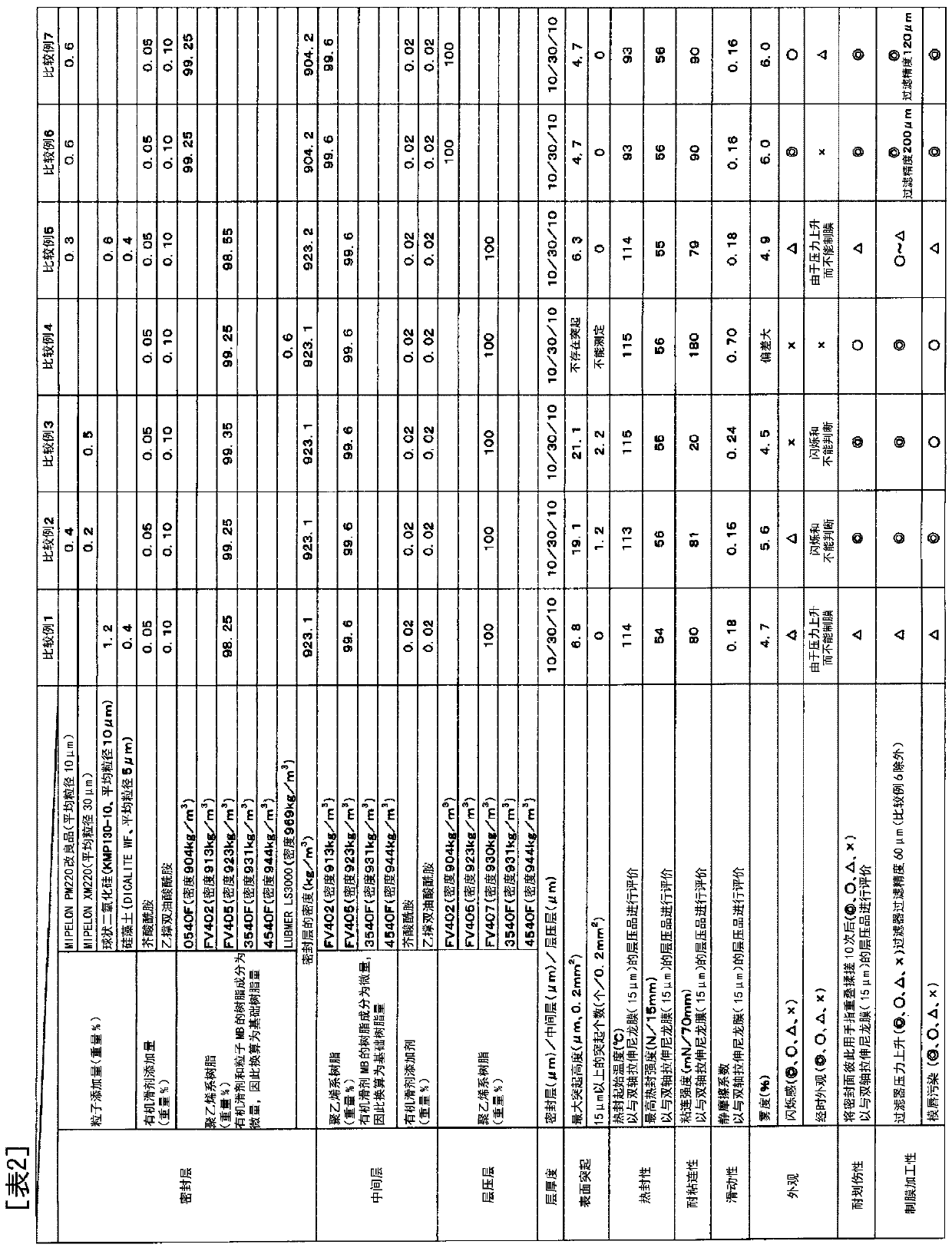

[0223] The resins and additives shown in Table 1 were used as the raw materials for the sealing layer, laminate layer, and intermediate layer. Three extruders were used to melt them at 240°C. After filtering with a sintered filter with a filtration accuracy of 60 μm, The T die was co-extruded into a sheet, and the thickness ratio of the sealing layer, the intermediate layer, and the laminate layer was melted and extruded at a ratio of 1:3:1. After cooling and solidifying with a cooling roll at 30°C, the thickness of the obtained sheet The surface of the laminated layer was subjected to corona discharge treatment, and then wound into a roll at a speed of 150 m / min to obtain a polyethylene resin film with a thickness of 50 μm and a wetting tension on the surface of the laminated layer of 45 N / m.

[0224] The polyethylene resin films obtained in Examples 1 to 5 are excellent in heat sealability, the measured values of blocking resistance and friction coefficient vary little between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com