Hemostatic cotton compress and production method therefor

A technology of compression hemostasis and manufacturing method, which is applied in the field of compression hemostatic cotton and its manufacturing, and can solve the problems of poor workability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

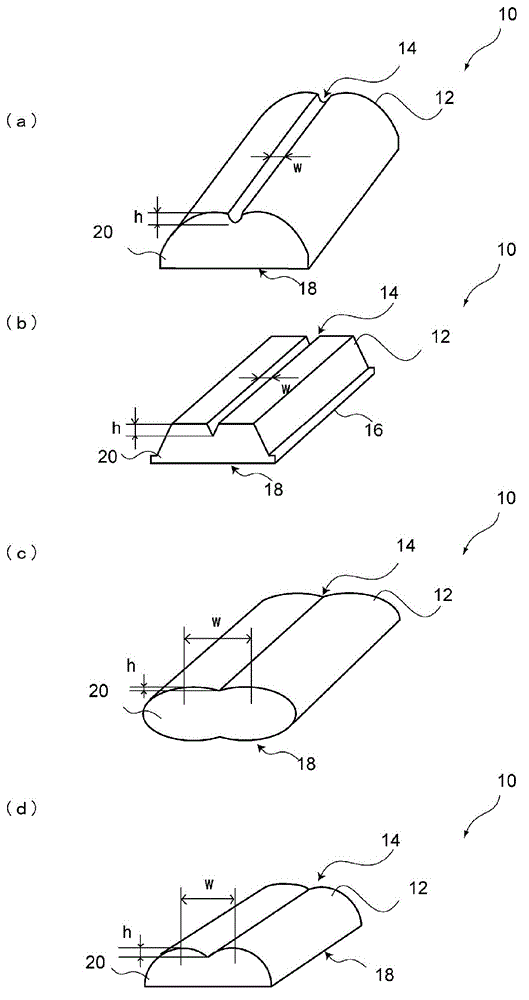

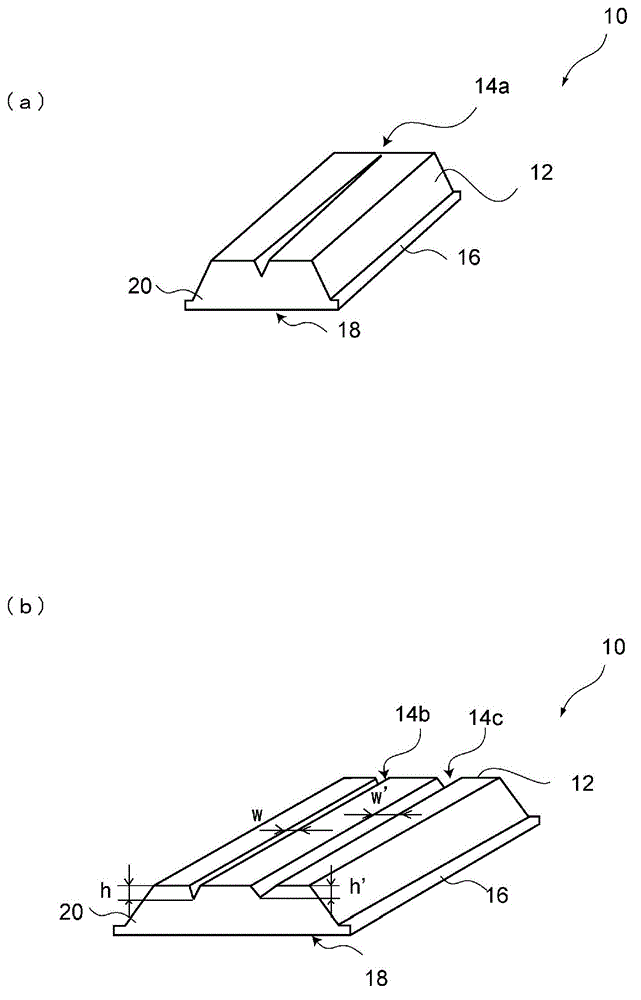

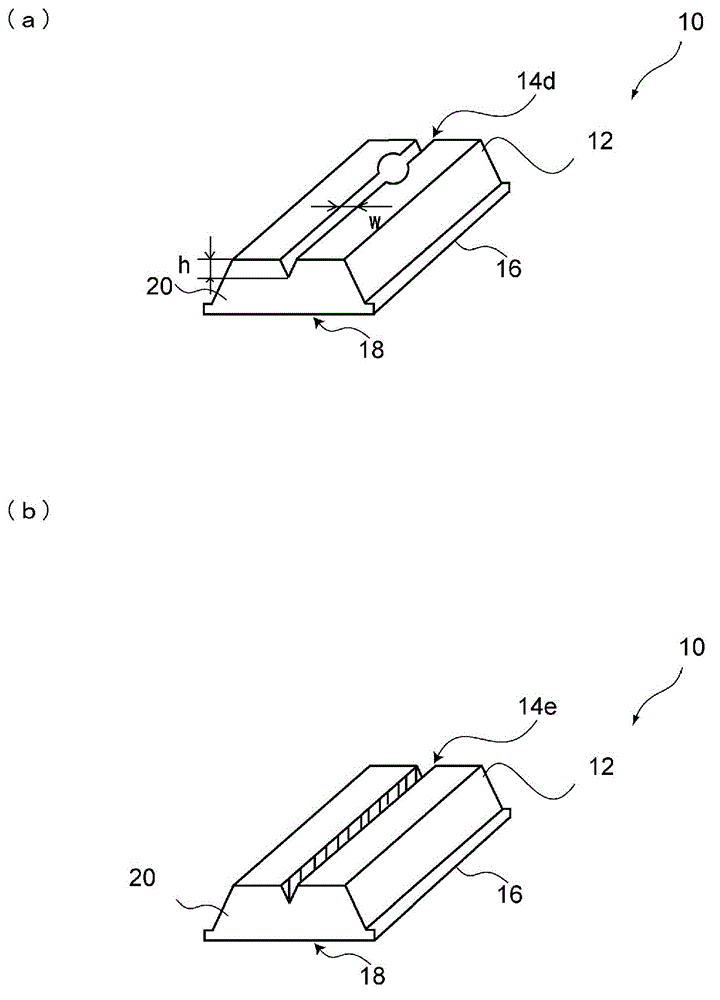

[0043] The first embodiment is a hemostatic cotton compress, which is a hemostatic cotton compress formed by integrally molding a fibrous object, has a surface for compressing a predetermined hemostatic site, and a part of the surface is made flat or curved. , and a part of the surface has a groove that engages with the injection needle or the plastic tube that accompanies it.

[0044] And, if figure 1 As shown in (a) and (b), it is characterized in that it is a hemostatic cotton compress 10 formed by integrally molding a fibrous object 20 , which includes a groove 14 , and the surface 12 with the groove is flat or curved.

[0045] Hereinafter, the first embodiment of the present invention will be specifically described with reference to the drawings as appropriate.

[0046] 1. Fibrous matter

[0047] (1) Type

[0048] The type of fibrous material constituting the hemostatic cotton is not particularly limited, and examples include rayon, polyester, cotton, polypropylene, p...

no. 2 Embodiment approach ]

[0120] The second embodiment of the present invention is a method of manufacturing hemostatic cotton compresses, which is characterized in that it is a method of manufacturing hemostatic cotton compresses formed by integrally molding fibrous objects, including the step of molding the fibrous objects into a roll shape and heating and compressing the roll-shaped fibrous material to obtain a flat or curved surface for compressing a prescribed hemostatic site, and a part of the surface is equipped with a plastic tube that is engaged with an injection needle or an accompanying plastic tube. The process of compressing the hemostatic cotton in the ditch.

[0121] Hereinafter, the manufacturing method of the hemostatic cotton compress which is 2nd Embodiment of this invention is concretely demonstrated centering on the difference from 1st Embodiment.

[0122] 1. Roll forming process

[0123] Such as Figure 4 As shown in (a), the roll forming step is a step of forming the sheet-like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com