Polybutylene terephthalate and method for production thereof, and composition comprising the same and film

A technology of polybutylene terephthalate and polybutylene phthalate, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of acceleration, heat resistance deterioration, poly Problems such as high concentration of butylene phthalate metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

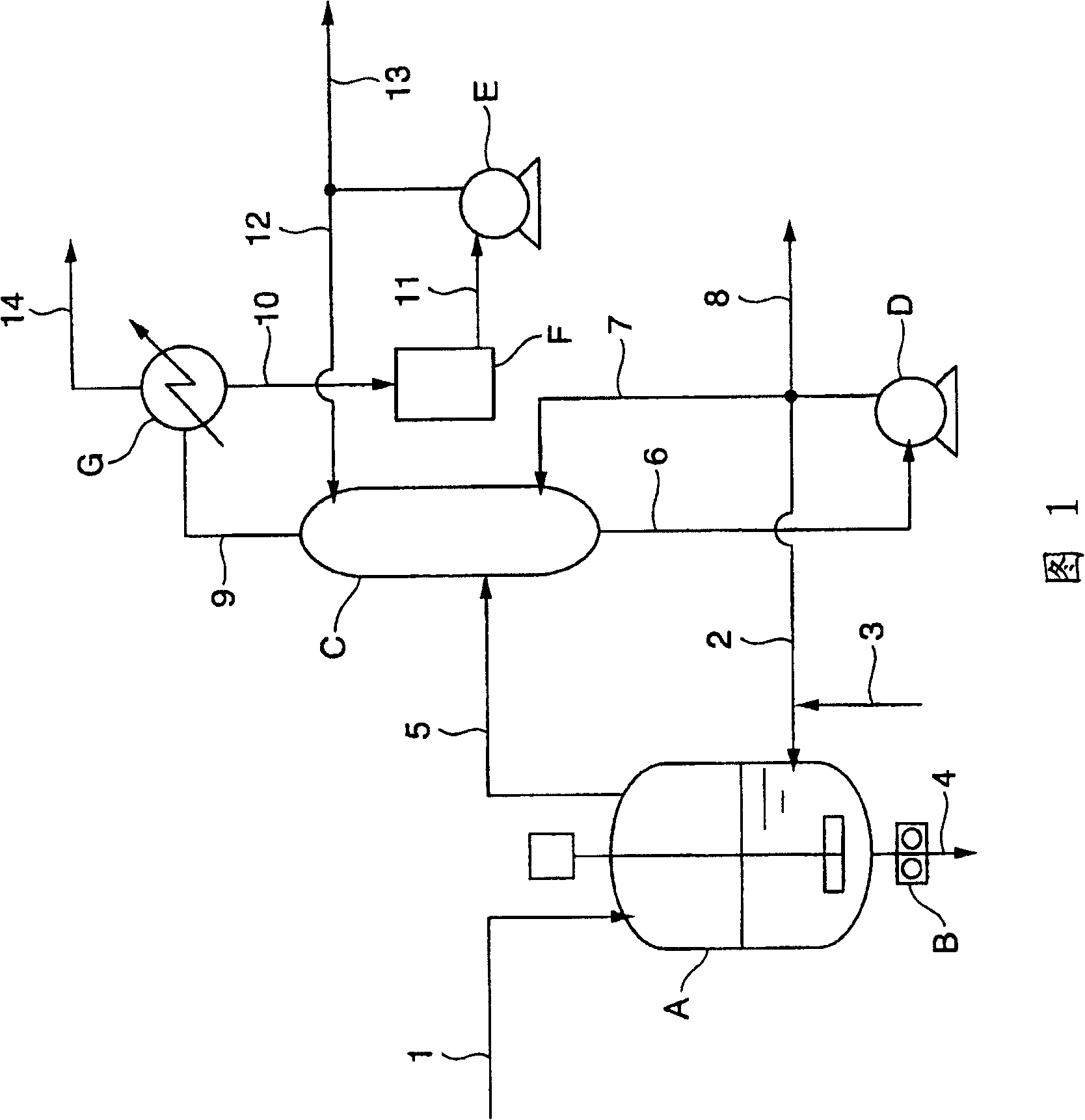

[0343] Through the esterification step shown in FIG. 1 and the polycondensation step shown in FIG. 6, PBT was produced in the following manner. First, a 60°C slurry in which 1,4-butanediol was mixed at a ratio of 1.80 mol with respect to 1.00 mol of terephthalic acid was continuously supplied at 41 kg / h to In the esterification reaction tank (A) which had the helical type agitator and filled the PBT oligomer of esterification rate 99% beforehand. At the same time, the bottom component of the rectification column (C) at 185° C. is supplied at 17.2 kg / h from the recirculation line (2), and tetrabutylene at 65° C. as a catalyst is supplied at 97 g / h from the catalyst supply line (3). 6.0% by weight of 1,4-butanediol solution (30 ppm relative to the theoretical polymer yield) of the base titanate. The moisture in this solution was 0.20% by weight.

[0344] The internal temperature of the reaction tank (A) is 230°C and the pressure is 78kPa. The generated water, tetrahydrofuran a...

Embodiment 2

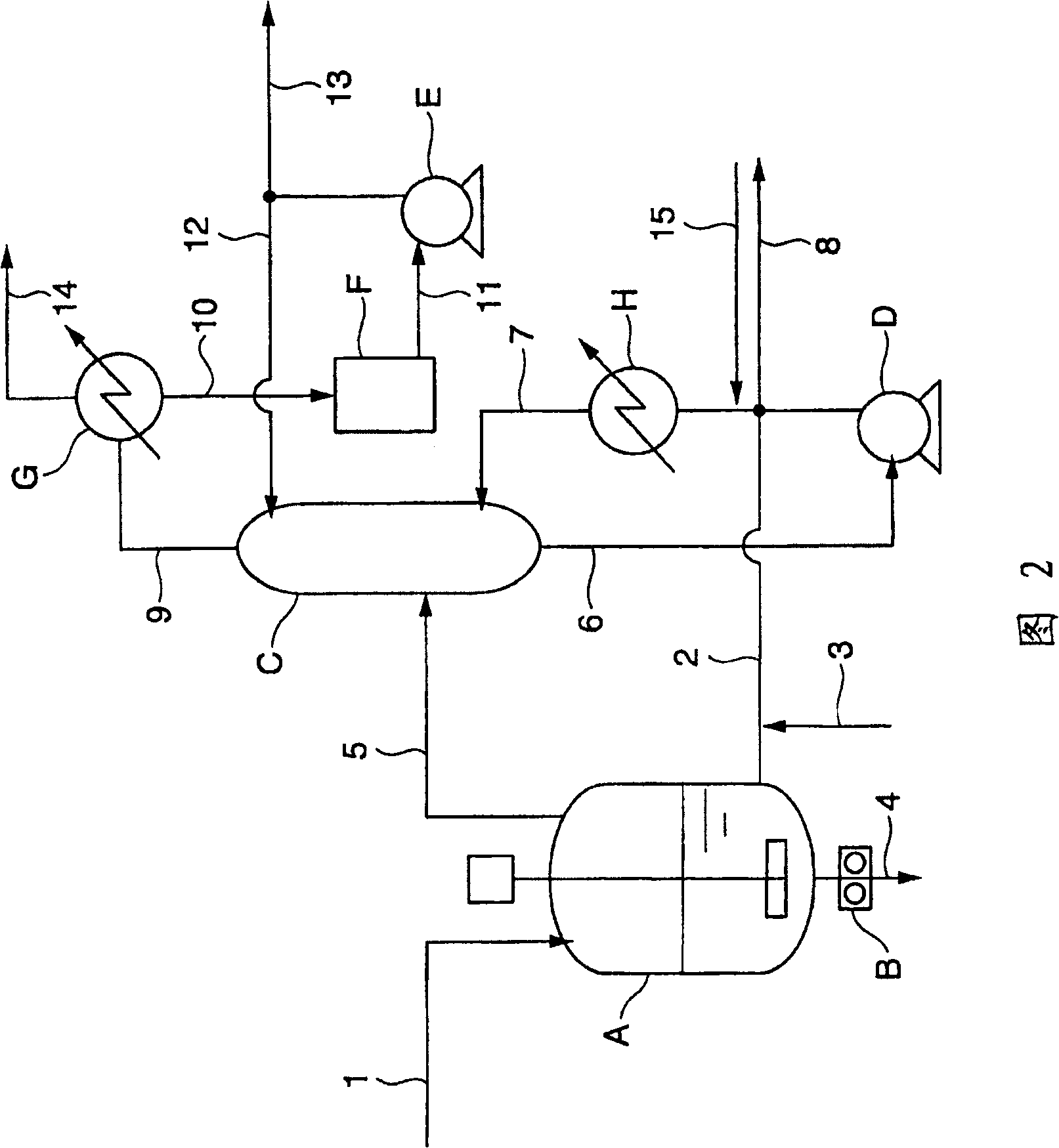

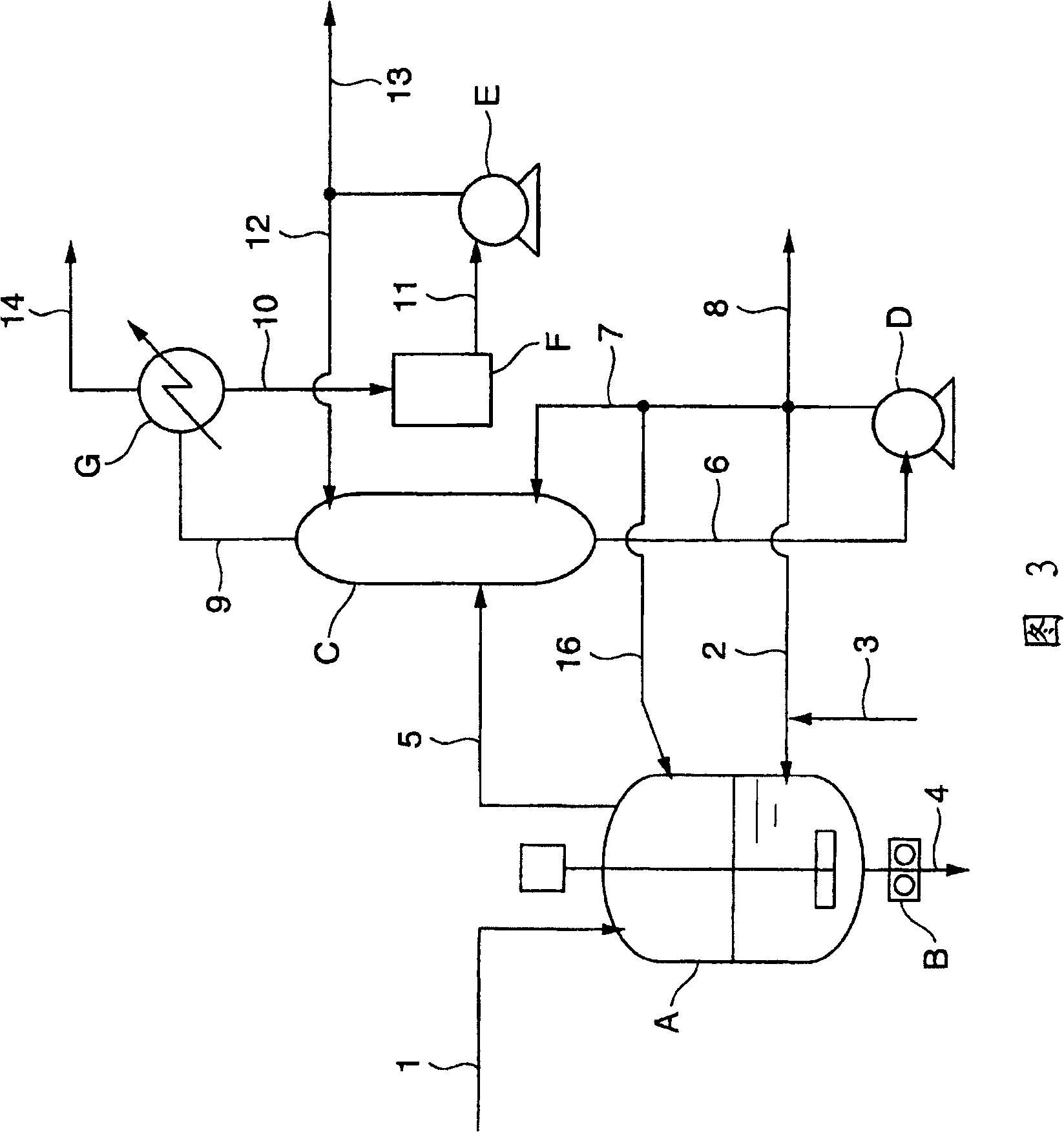

[0350] In Example 1, it carried out similarly to Example 1 except having adopted the polycondensation process shown in FIG. As the filter (f) in the polycondensation step shown in FIG. 7 , a pleated cylindrical filter made of metal nonwoven fabric and having an absolute filtration accuracy of 20 μm was used. Compared with Example 1, the PBT which reduced foreign matter was obtained. The analytical values are summarized in Table 1.

Embodiment 3 and Embodiment 4

[0352] In Example 1, except that the supply of tetrabutyl titanate was adjusted so that the titanium content in the polymer was as shown in Table 1, and the pressure of the second polycondensation reaction tank (d) was 100 Pa, the same method as in the implementation Example 1 was performed in the same manner. It is possible to obtain PBT with less foreign matter, excellent color tone, good transparency, and excellent thermal stability. The analytical values are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com