Double-station press with upper dies and lower dies for producing glass products

一种双工位、模具的技术,应用在玻璃生产、玻璃的压制、玻璃制造设备等方向,能够解决压床操作工多、限制产量、产品表面异物、灰点多等问题,达到解决操作空间有限、减少碎渣的产生、避免外观损伤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

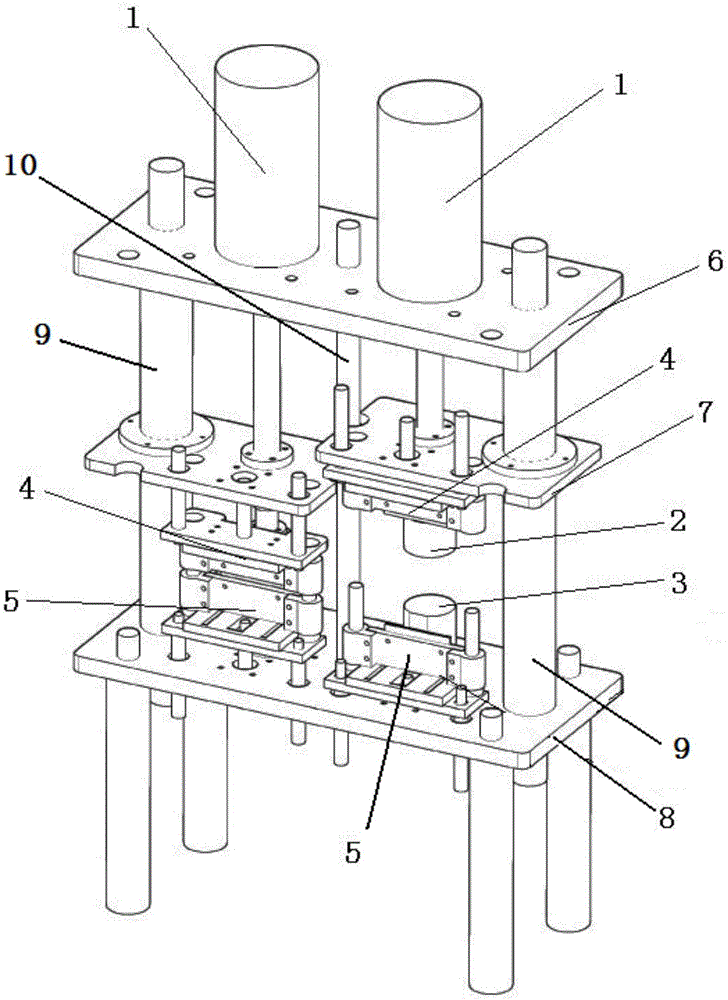

[0024] See figure 1 , the double-station press machine for glass product production provided in this embodiment includes: an upper table 6 and a lower table 8 fixedly arranged up and down, and a pair of hydraulic cylinders 1 (or air cylinders) are arranged on the upper table 6, and the pair of hydraulic cylinders 1 The lower ends of the piston rods of the piston rods are respectively connected with a movable table 7, the bottom surface of each movable table 7 is provided with an upper mold 2, and the lower table 8 is provided with a lower mold 3 coaxial with each upper mold 2 and relatively arranged up and down, each movable table 7 One side of each upper knife rest 4 is provided with an upper knife rest 4, and each upper knife rest 4 is provided with a lower knife rest 5, and upper and lower knife rests are respectively provided with cutting knives suitable for cooperating up and down.

[0025] The upper end of each movable table 7 is provided with an upper cylinder for contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com