Vacuum processing system and vacuum processing method of semiconductor processing substrate

A vacuum processing and vacuum processing chamber technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as insufficient consideration and loss of wafer processing capacity, and achieve high productivity, suppression of cross-contamination, and low foreign matter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

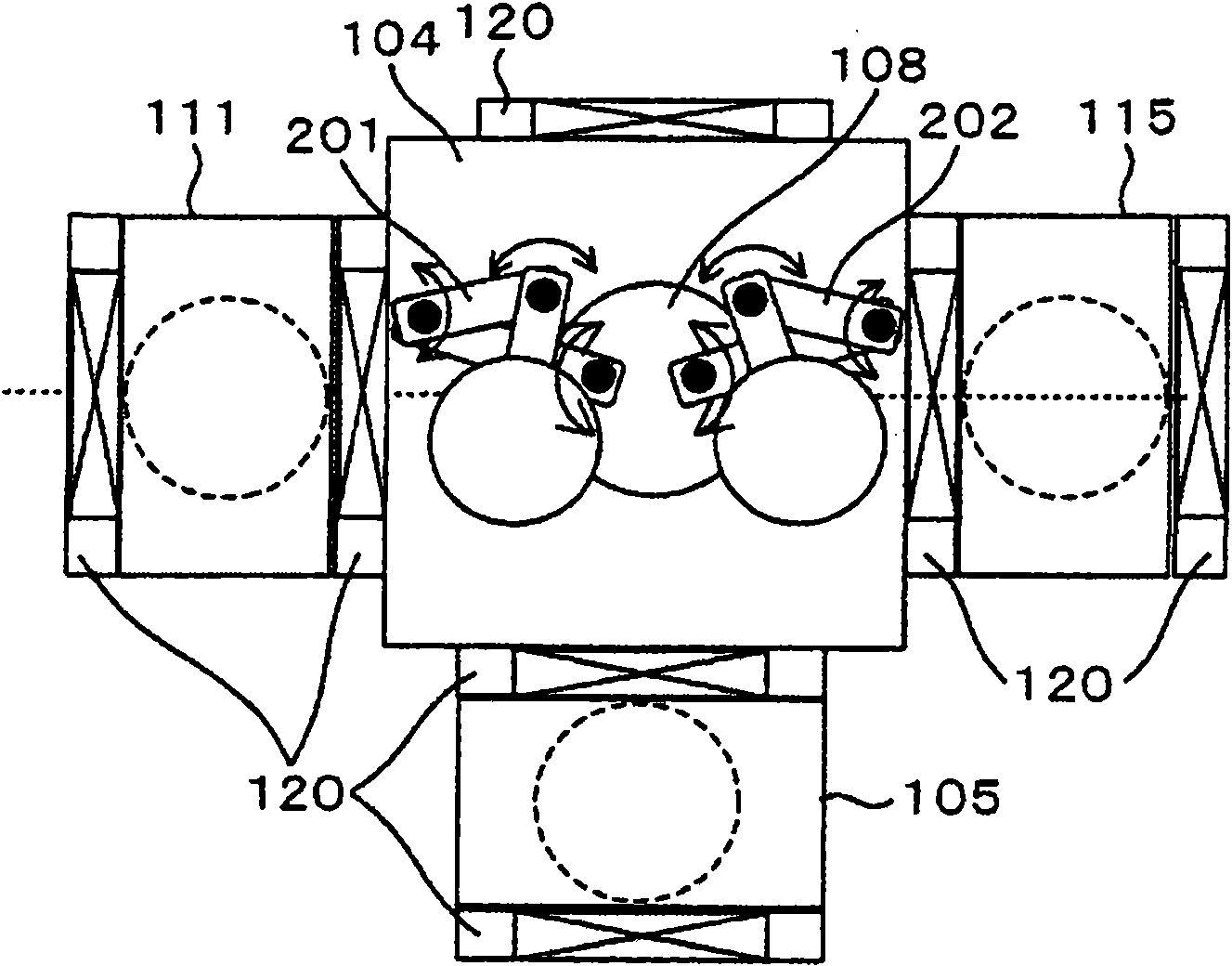

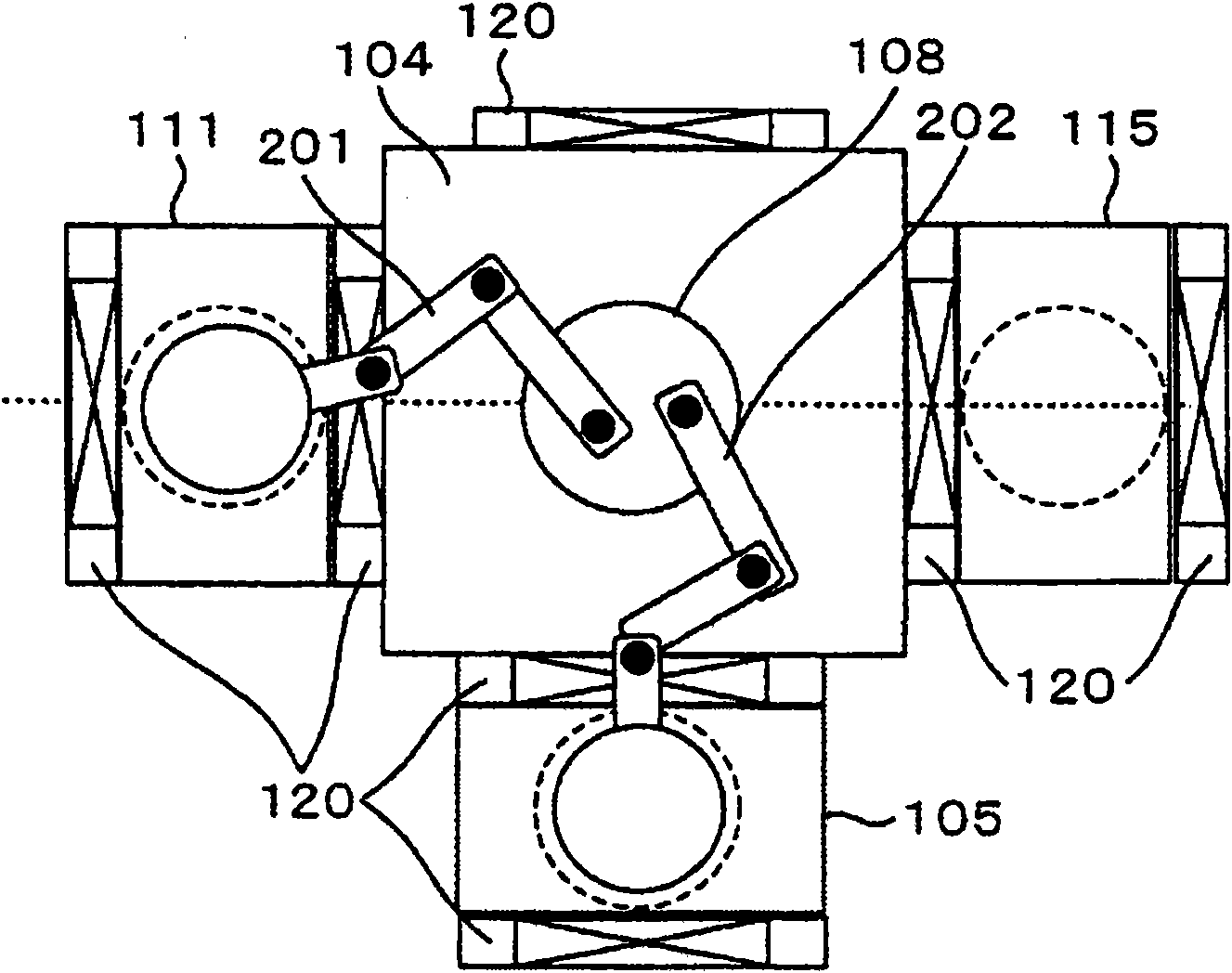

[0046] Embodiments of a vacuum processing system and a vacuum processing method for a semiconductor substrate to be processed according to the present invention will be described in detail below with reference to the drawings.

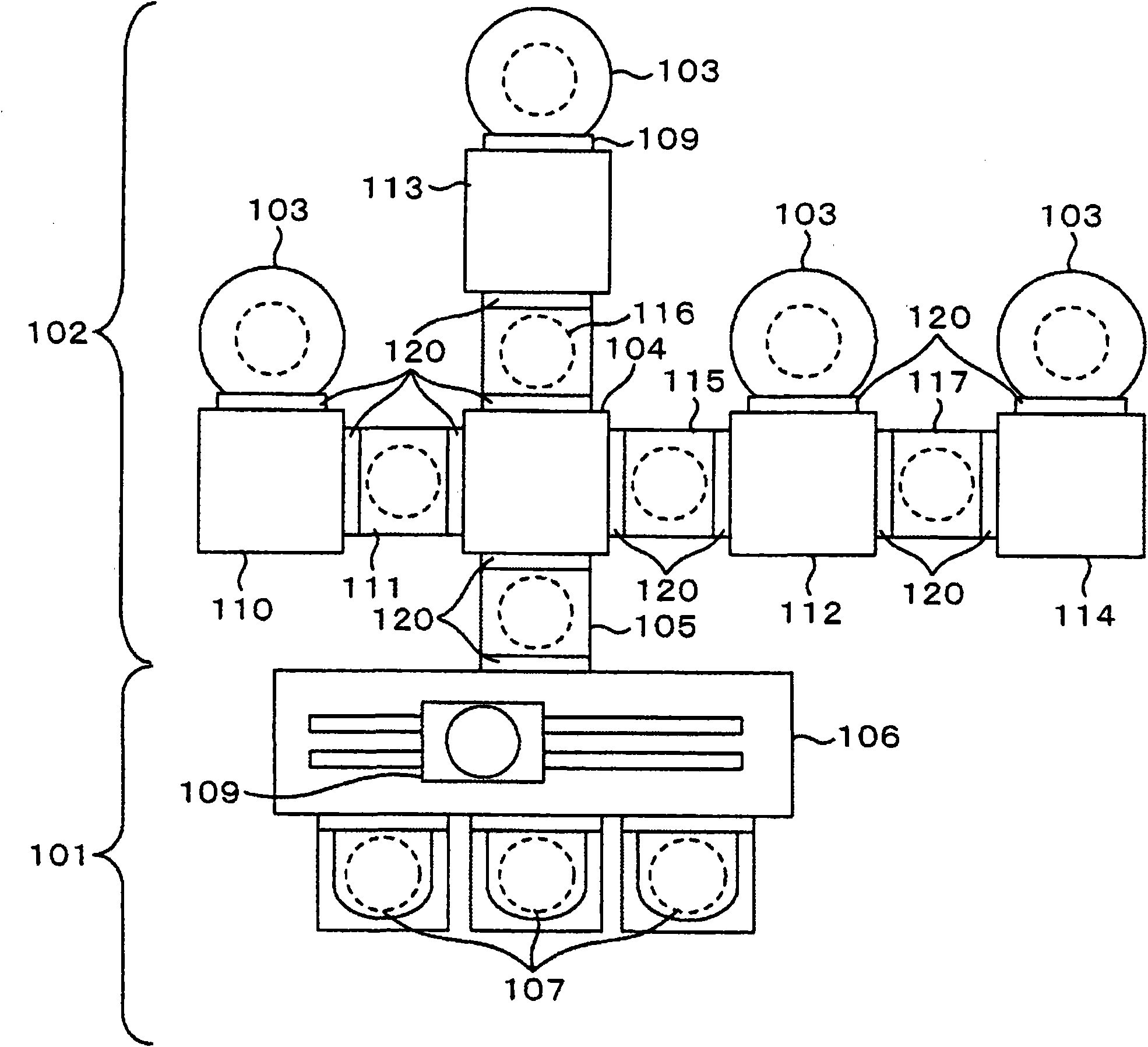

[0047] figure 1 The outline of the overall configuration of a vacuum processing system including a plurality of vacuum processing chambers 103 , 103 , 103 , 103 according to the first embodiment of the present invention will be described.

[0048] figure 1 The shown vacuum processing system 100 according to the first embodiment of the present invention including four vacuum processing chambers 103 , 103 , 103 , 103 is roughly divided into an atmosphere side module 101 and a vacuum side module 102 . The atmosphere side module 101 is a part that transports, accommodates, and locates the object to be processed, that is, semiconductor wafers, etc. under atmospheric pressure. processed modules. Furthermore, a lock chamber 105 is provided between the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com