Gas phase epitaxy method

A vapor phase epitaxy and epitaxy technology, applied in chemical instruments and methods, electrical components, chemically reactive gases, etc., to achieve the effect of suppressing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

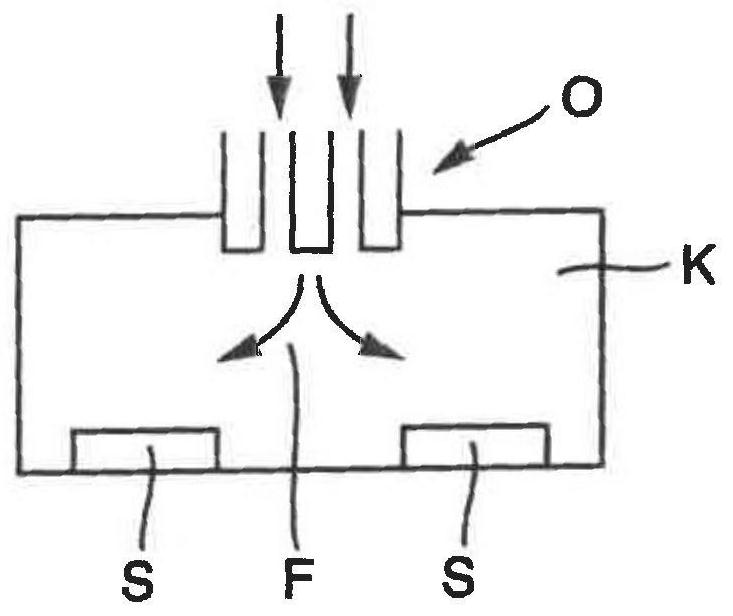

[0059] figure 1 A cross-section of a reaction chamber K of a vapor phase epitaxy facility is schematically shown. A substrate S is arranged on the bottom of the reaction chamber K. Furthermore, the reaction chamber K has a gas inlet part O through which the epitaxial flow F is introduced into the reaction chamber K.

[0060] The epitaxial flow F has a carrier gas, at least one first metal-organic precursor for elements of main group III (e.g. trimethylgallium, TMGa), a second precursor for elements of main group V (e.g. arsenic Hydrogen, Arsin) and a third precursor for the n-dopant (eg silane).

[0061] The gas inlet part O has a plurality of conduits terminating in the reaction chamber K, through which a component or components of the epitaxial gas flow F are each led to the reaction chamber K.

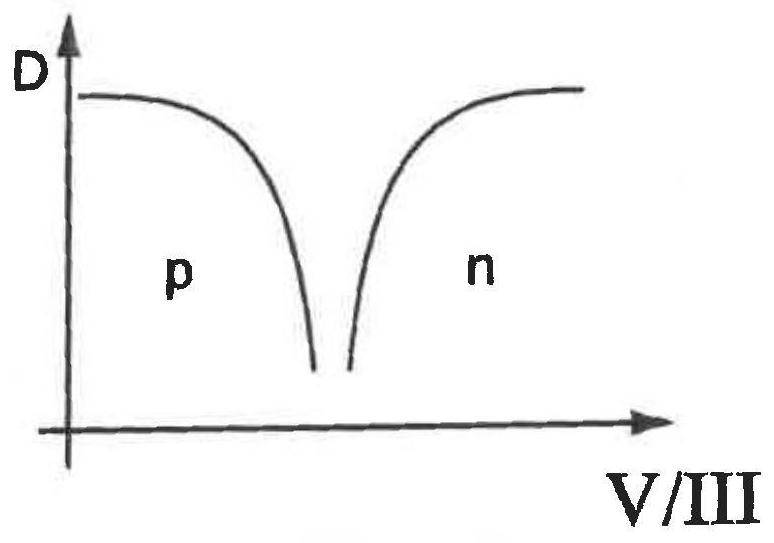

[0062] exist figure 2 The doping is plotted in a graph as a function of the amount ratio of the elements of the V. main group and the III. main group. In particular, not only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com