Colored photosensitive resin composition

A technology of photosensitive resin and composition, applied in optics, filters, optical elements, etc., can solve the problem of foreign matter, and achieve the effect of reducing foreign matter and inhibiting peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0376] Next, examples will be given to further specifically describe the present invention. In the examples, % and parts indicating the content or usage amount are based on mass unless otherwise specified.

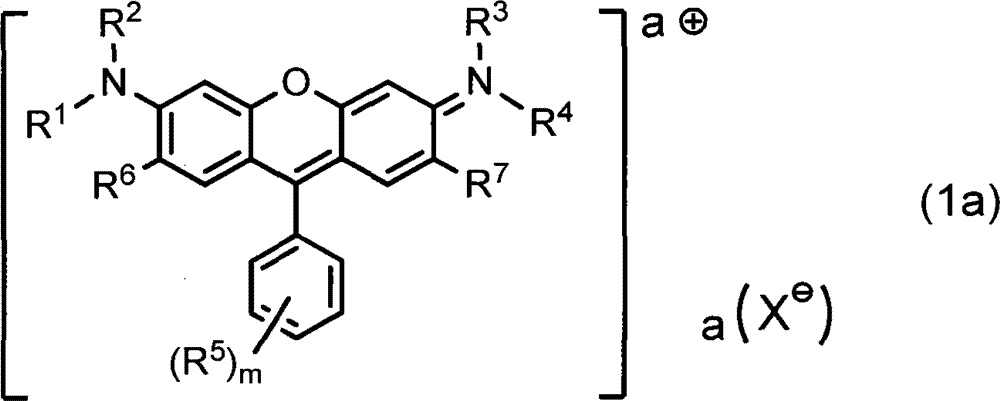

Synthetic example 1

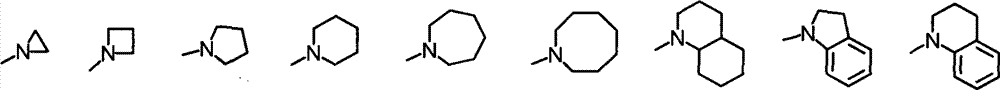

[0378] In the flask that is equipped with condenser tube and stirring device, drop into the mixture (commercial name Chugai Aminol Fast Pink R of the compound shown in formula (A1-1a) and the compound shown in formula (A1-1b) 15 parts, chloroform 150 parts and 8.9 parts of N,N-dimethylformamide were added dropwise to 10.9 parts of thionyl chloride while maintaining the temperature below 20°C under stirring. After completion of the dropwise addition, the temperature was raised to 50°C, and the reaction was maintained at the same temperature for 5 hours, and then cooled to 20°C. While maintaining the cooled reaction solution at 20° C. or lower with stirring, a mixed solution of 12.5 parts of 2-ethylhexylamine and 22.1 parts of triethylamine was added dropwise. Thereafter, the reaction mixture was stirred at the same temperature for 5 hours. Next, the solvent of the obtained reaction mixture was distilled off with a rotary evaporator, and then a small amount of methanol was adde...

Synthetic example 2

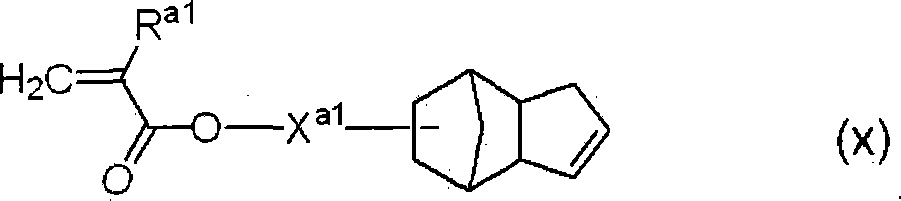

[0382] Into a flask equipped with a stirrer, a thermometer, a reflux condenser, and a dropping funnel, 0.02 L / min of nitrogen was passed through to make a nitrogen atmosphere, 268 parts of ethyl lactate were added, and the mixture was heated to 70° C. while stirring. Next, 55 parts of acrylic acid, 81 parts of N-cyclohexylmaleimide, 3,4-epoxytricyclo[5.2.1.0 2.6 ]decyl ester (the compound shown in the formula (I-1) and the compound shown in the formula (II-1) are mixed at a molar ratio of 50:50) 224 parts, and acrylic tricyclo[5.2.1.0 2. 6 ] Decen-8-yl ester (the compound represented by the formula (c-1) and the compound represented by the formula (c-2) are mixed at a molar ratio of 50:50) and 7 parts are dissolved in 140 parts of ethyl lactate to prepare A solution was formed, and the solution was added dropwise into a flask kept at 70° C. using a dropping funnel over a period of 4 hours.

[0383]

[0384] On the other hand, a solution obtained by dissolving 30 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com