Hydrothermal preparation method of superconducting single crystal film and product thereof

A hydrothermal method and superconducting technology, applied in the field of materials, can solve the problems of high energy consumption, inability to grow high-temperature and easy-to-decompose thin film materials, high pollution, etc., and achieve low energy consumption, simple and efficient method, easy to promote, and large film-forming area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

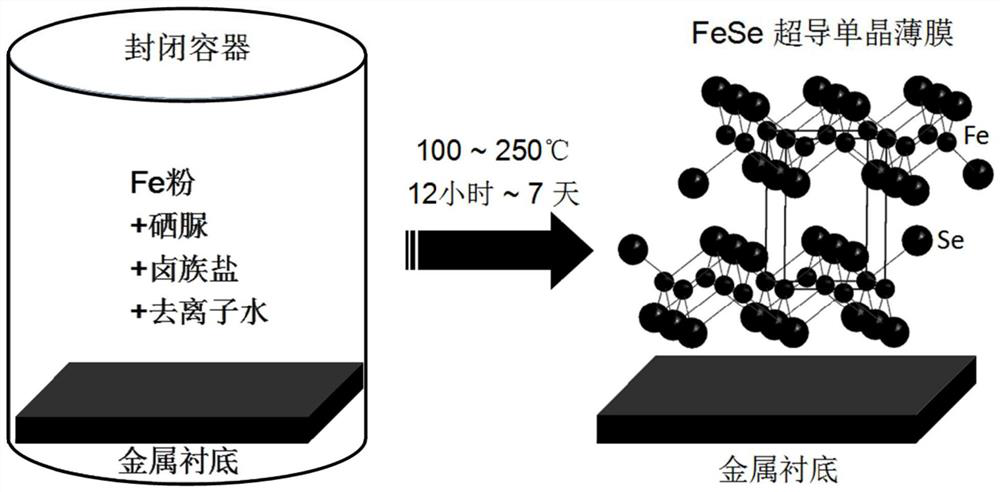

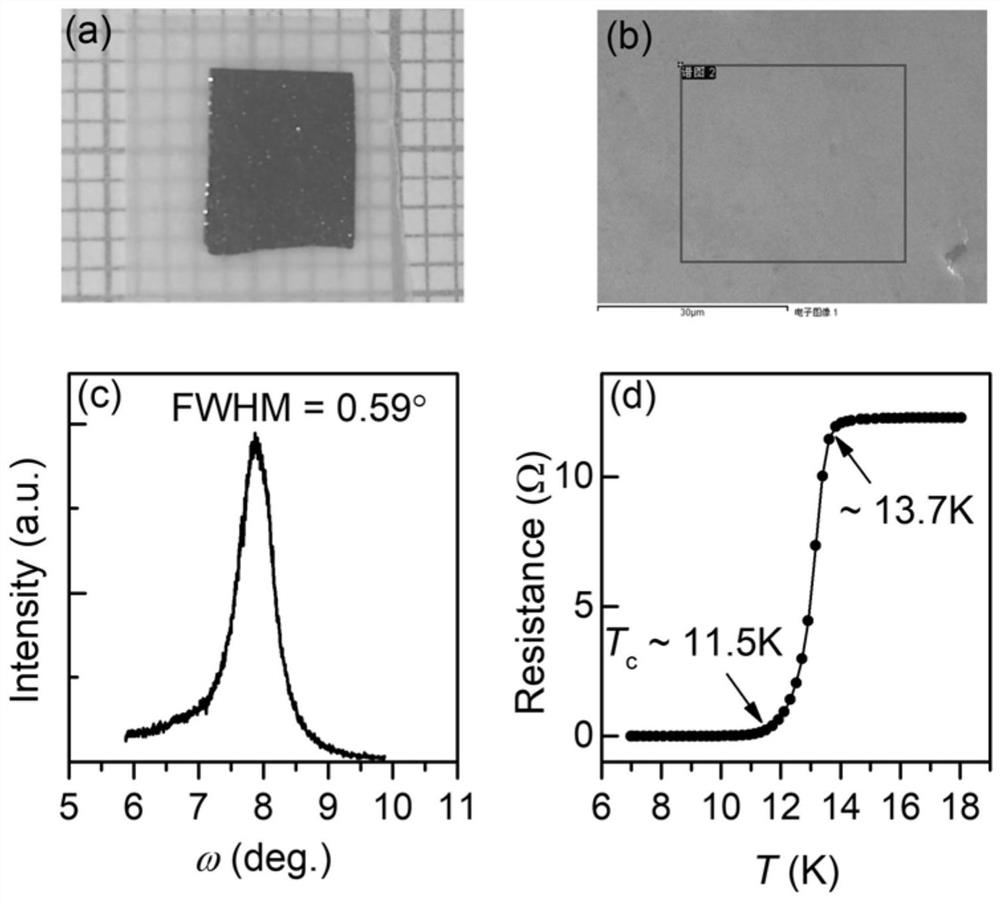

[0043] This example is used to illustrate the growth of a high-quality FeSe single crystal thin film on a metal substrate by soft chemical method.

[0044] Table 1 Reaction conditions for growing FeSe single crystal thin films

[0045]

[0046]

[0047] Specifically include the following steps:

[0048] (a) Put 0.01mol of selenourea, 0.02mol of iron powder, 0.03mol of catalyst NaF and 5ml of deionized water into a sealable heating container, stir and mix well with a glass rod, and put it into a polished metal substrate FeTe. All reagents were purchased from AlfaAesar company with a purity higher than 4N.

[0049] (b) Then seal the closed container, put it into an oven, heat it from room temperature to 130 °C at a rate of 2 °C / min, react at this temperature for 7 days, then stop the heat preservation, and cool naturally to room temperature.

[0050] (c) After the reaction, open the closed container to take out the metal substrate, and wash it repeatedly with deionized w...

Embodiment 16~27

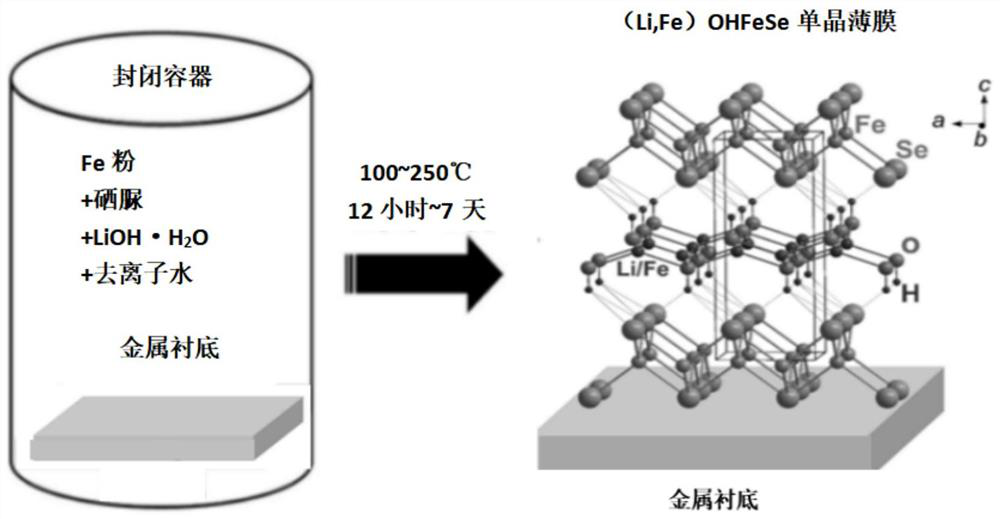

[0058] This example is used to illustrate the growth of high-quality (Li, Fe)OHFeSe single crystal thin films on metal substrates by soft chemical method.

[0059] Table 3 Reaction conditions for growing (Li,Fe)OHFeSe single crystal thin films

[0060]

[0061] (a) 0.01mol of selenourea, 0.015mol of iron powder, LiOH·H 2 O0.01mol and 5ml deionized water are put into a closed heating container, stirred and mixed fully with a glass rod, and put into a polished metal substrate FeTe. All reagents were purchased from AlfaAesar company with a purity higher than 4N.

[0062] (b) Then seal the closed container, put it into an oven, heat it from room temperature to 130 °C at a rate of 2 °C / min, react at this temperature for 7 days, then stop the heat preservation, and cool naturally to room temperature.

[0063] (c) After the reaction, open the closed container to take out the metal substrate, and wash it repeatedly with deionized water to obtain a (Li,Fe)OHFeSe superconducting si...

Embodiment 28-32

[0071] Adopt the method similar to embodiment 1-27, also can be used for growing transition metal dichalcogenide film MX 2 , where M is transition metal Ti, Nb, Ta, Mo, W; X is chalcogen element S, Se, Te, and the specific reactants and conditions are shown in Table 5.

[0072] Table 5 Transition metal dichalcogenide films MX prepared under different reaction conditions 2

[0073]

[0074]

[0075] The doping of chalcogen elements only needs to add substances that can provide the required chalcogen elements for hydrothermal reaction. It is not required to be the above reagents. The substrate can also be adjusted according to the actual situation, including various single crystals or alloys. , as long as the substrate surface is smooth and does not participate in the hydrothermal reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com