Patents

Literature

58results about How to "Meet the requirements of electrical conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special-purpose low temperature solidification silver migration resistance laser etching conductive silver paste for handset touch screen and preparation method thereof

InactiveCN106158065AStrong printabilityStable storageNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteLaser etching

The invention relates to a special-purpose low temperature solidification silver migration resistance laser etching conductive silver paste for a handset touch screen and a preparation method thereof. The conductive silver paste mainly comprises silver powder content 40-75%, high-molecular carrier content 20-50% and additive content 3-15%. The preparation method of the conductive silver paste comprises steps of high-molecular resin carrier preparation, conductive silver paste preparation and conductive silver paste post-treatment. The conductive silver paste has excellent silver migration resistance capability, the silver migration rate under the wet environment is greatly reduced, the conductive silver paste has excellent laser etching performance, intelligible patterns with line-width / line-space of 30mum / 30mum can be acquired through etching, the silver paste has excellent adhesive force on PET, ITO films, ITO glass and common glass, pencil hardness is above 4H, a lowest block resistance value can reach 20mohm / square@1mil, and the silver paste has excellent compatibility with insulation oil ink and a peelable blue plastic protective layer. The conductive silver paste molded through sintering under the low temperature is advantaged in that production cost is low, energy resources are saved, and the conductive silver paste without halogen is further environmental friendly.

Owner:NANO TOP ELECTRONICS TECH

Special ultralow temperature cured laser etching conductive silver paste for mobile phone touch screen

ActiveCN108022669AAchieve solidificationStable storageNon-conductive material with dispersed conductive materialMetal/alloy conductorsSilver pasteLaser etching

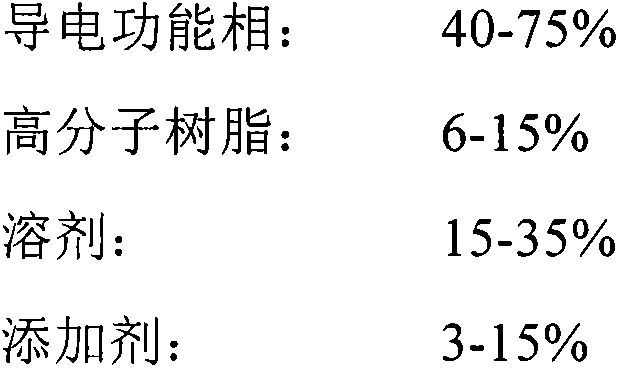

The invention relates to a special ultralow temperature cured laser etching conductive silver paste for a mobile phone touch screen. The conductive silver paste mainly comprises the following components: 40%-75% of a conductive function phase, 6-15% of macromolecule resin, 15-35% of a solvent and 3-15% of an additive. The preparation of the silver paste comprises the steps of macromolecule regioncarrier preparation, conductive silver paste preparation and conductive silver paste post-processing. The conductive silver paste can be completely cured under the condition of an ultralow temperatureof 80-110 DEG C, the temperature is reduced by 20-50 DEG C compared with a curing condition of 130 DEG C of the existing conductive silver paste, and shrinkage, folding and deformation of a substratemembrane material during high-temperature curing are reduced. The paste has excellent laser etching performance, and a clear pattern with the line width / line spacing being 30 microns / 30 microns can be etched; the paste has good adhesion on PET, an ITO film, a silver nanowire conductive film, TIO glass and ordinary glass, the pencil hardness is above 2H, and the square resistance can reach up to 20m[Omega] / square@1mil. In addition, the conductive silver paste is sintered and molded at an ultralow temperature, low in production cost, energy-saving and free of halogen, thereby being an environment-friendly product.

Owner:NANO TOP ELECTRONICS TECH

Copper clad steel wire and production method thereof

The invention discloses a method for producing a copper clad steel wire. The method comprises the following steps of: acid washing and rust-proof treatment of a steel wire, first drawing treatment, first heat treatment, copper plating, second drawing treatment, second heat treatment and surface protection. According to the copper clad steel wire, the consumption of copper is greatly reduced on the premise of meeting the electrical conductivity, and the special requirement of an electronic product for the mechanical property is met at the same time; and in the presence of an iron core, convenience is brought to the flow process of the electronic product. The copper clad steel wire is used for leads and connecting wires of the electronic product and substitutes a pure copper wire, so the copper clad steel wire has wide application.

Owner:NANTONG HONGYANG METAL PRODS

Flexible die and production method for manufacturing flexible printed circuit boards

ActiveCN104519666AQuality improvementReduce manufacturing costConductive material chemical/electrolytical removalHardnessPrinted circuit board

The invention provides a flexible die and a production method for manufacturing flexible printed circuit boards. The production method includes the steps of providing a flexible substrate having a metal layer covering the surface thereof; attaching a dry film to the surface of the metal layer, patterning the dry film, and using the patterned dry film as a mask to perform etching on the metal layer so as to obtain a metal circuit pattern; removing the dry film to obtain the flexible substrate and a flexible die of the metal circuit pattern from top to bottom. The production method has the advantages that the process is simple, die cost is low, and the requirement of the flexible printed circuit board industry for conductivity of the flexible printed circuit boards can be met when the production method is applied to the production of the flexible printed circuit boards. The flexible die is composed of the flexible substrate and the metal circuit pattern; the flexible substrate meets the requirement for uniformity of nanoimprinting on a large-area substrate; the metal circuit pattern is of high hardness, pattern deformation can be decreased during imprinting, and quality of the flexible printed circuit boards produced by nanoimprinting is improved.

Owner:SHANGHAI LIANGZI HUIJING ELECTRONICS CO LTD

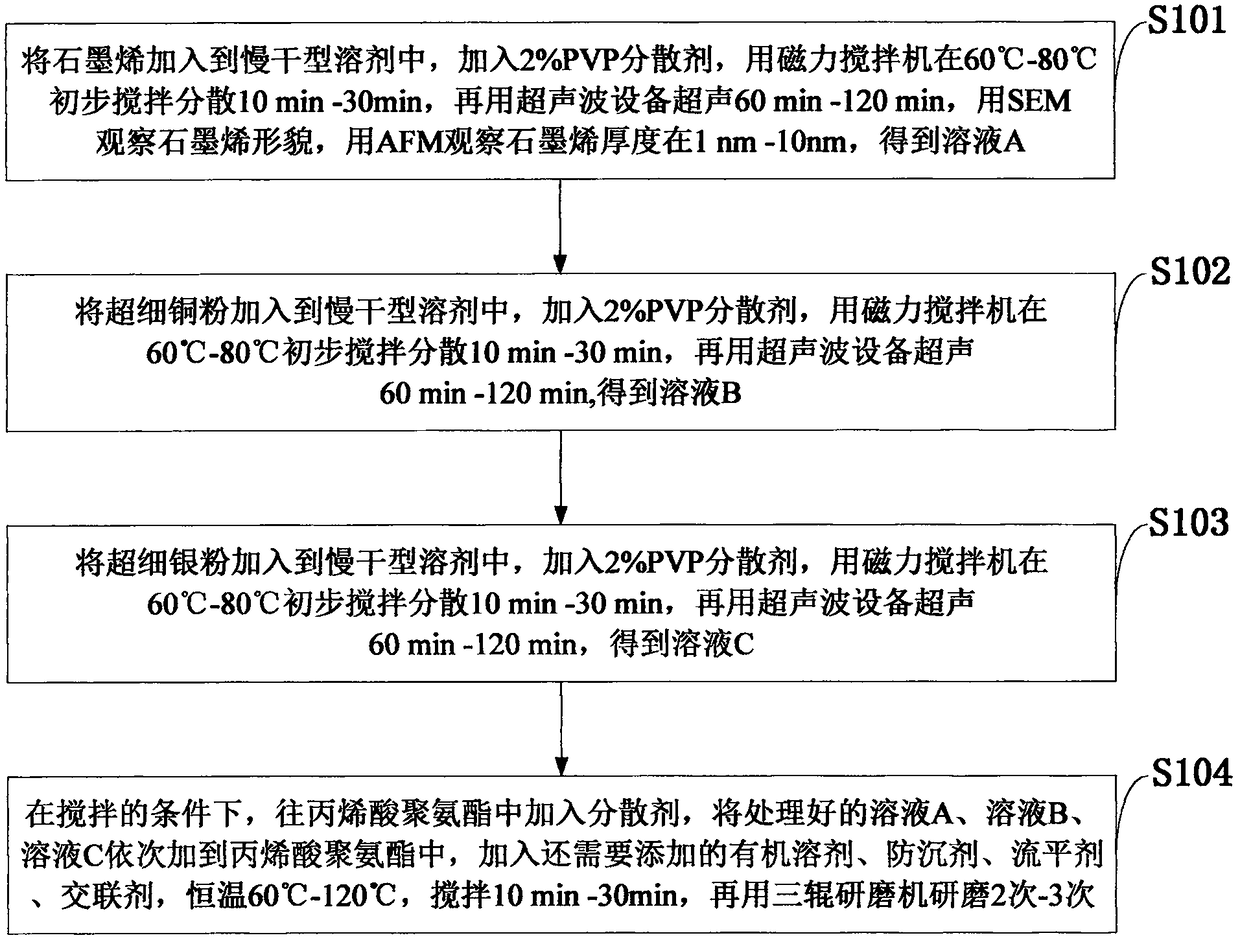

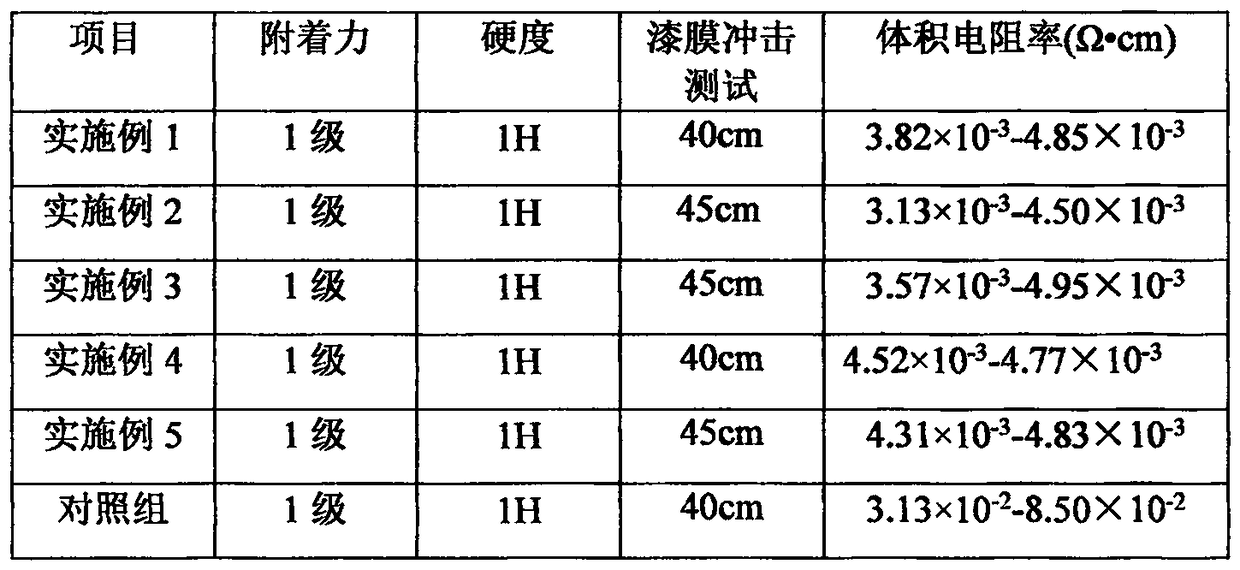

Graphene composite conductive coating as well as preparation method and application thereof

InactiveCN108129977APrevent oxidationLow costPolyurea/polyurethane coatingsElectrically-conductive paintsCross-linkUltra fine

The invention belongs to the technical field of conductive coatings, and discloses a graphene composite conductive coating as well as a preparation method and application thereof. The coating is composed of the following materials: 5-80% of resin, 0.1-5% of graphene, 2.5-20% of copper powder, 7.2-30% of silver powder, 0.55%-3.0% of a dispersant, 17-40% of an organic solvent, 0.3-1% of an anti-settling agent, 0.3-1% of a levelling agent and 0.1-1% of a cross-linking agent; and the preparation method comprises the following steps: adding the graphene into a slowly-drying solvent, adding the dispersant, performing stirring, and performing ultrasonication; adding the ultra-fine copper powder into a slowly-drying solvent, adding the dispersant, performing stirring, and performing ultrasonication; adding the ultra-fine silver powder into a slowly-drying solvent, adding the dispersant, performing stirring, and performing ultrasonication; and adding the dispersant into acrylate polyurethane, adding the treated solutions into the acrylate polyurethane in sequence, adding the organic solvent, the anti-settling agent, the levelling agent and the cross-linking agent, performing stirring, and performing grinding. The coating provided by the invention meets the requirements of conductive performance, avoids the single use of silver, reduces costs, and has a high price / performance ratio.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD

Method for preparing compound conductive layer on surface of epoxy resin

InactiveCN102808177AEasy to useImprove conductivityLiquid/solution decomposition chemical coatingSuperimposed coating processEpoxyChemical plating

The invention discloses a method for preparing a compound conductive layer on the surface of epoxy resin. The silver-nickel compound conductive layer is formed on the surface of the epoxy resin by chemical silver plating and nickel electroplating. The method comprises the steps as follows: 1, carrying out chemical silver plating, wherein the chemical silver plating process comprises the following concrete sub-steps of removing stress, removing oil, roughening, neutralizing, reducing, sensitizing and chemically plating silver, and forming a conductive silver layer on the surface of the epoxy resin; and 2, carrying out nickel electroplating on the epoxy resin with the conductive silver layer to obtain the silver-nickel conductive layer on the surface of the epoxy resin at last. Compared with the conventional chemical plating, the used time of the compound conductive layer prepared by the method is greatly shortened and the obtained compound conductive layer has the characteristics of bright and flat surface and strong bonding force; in addition, the nickel has the advantages of corrosion resistance and good conductivity, and the epoxy resin as a basis material has the advantages of high mechanical property, good process property and excellent chemical drug resistance, so that the usability of the whole material is greatly enhanced.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

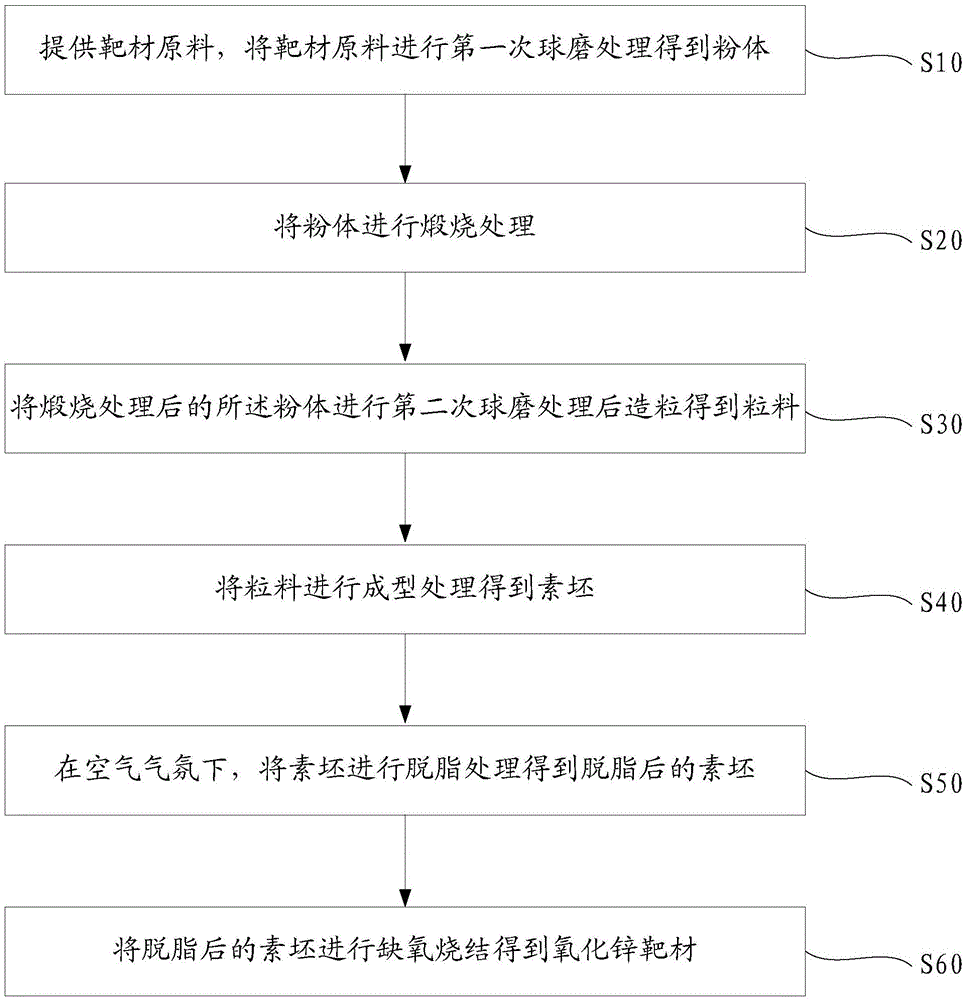

Preparation method of zinc oxide target and preparation method of zinc oxide film

ActiveCN105565798AImprove conductivityMeet the requirements of electrical conductivityAir atmosphereHigh resistance

The invention discloses a preparation method of a zinc oxide target and a preparation method of a zinc oxide film. The preparation method of the zinc oxide target comprises the following steps: providing a target raw material, and ball milling the target raw material for the first time to obtain powder; calcining the powder; ball milling the calcined powder for the second time and then granulating to obtain particles; forming the particles into a biscuit; degreasing the biscuit in air atmosphere to obtain a degreased biscuit; and anaerobically sintering the degreased biscuit to obtain the zinc oxide target. The zinc oxide target prepared by the preparation method of the zinc oxide target has good electrical conductivity. The conductive target may be made into a zinc oxide film high in resistivity and transparency by means of direct-current magnetron sputtering and oxygen atmospheric coating. The target prepared in the invention can meet the requirements for direct-current magnetron sputtering and high-resistance zinc oxide film preparation.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

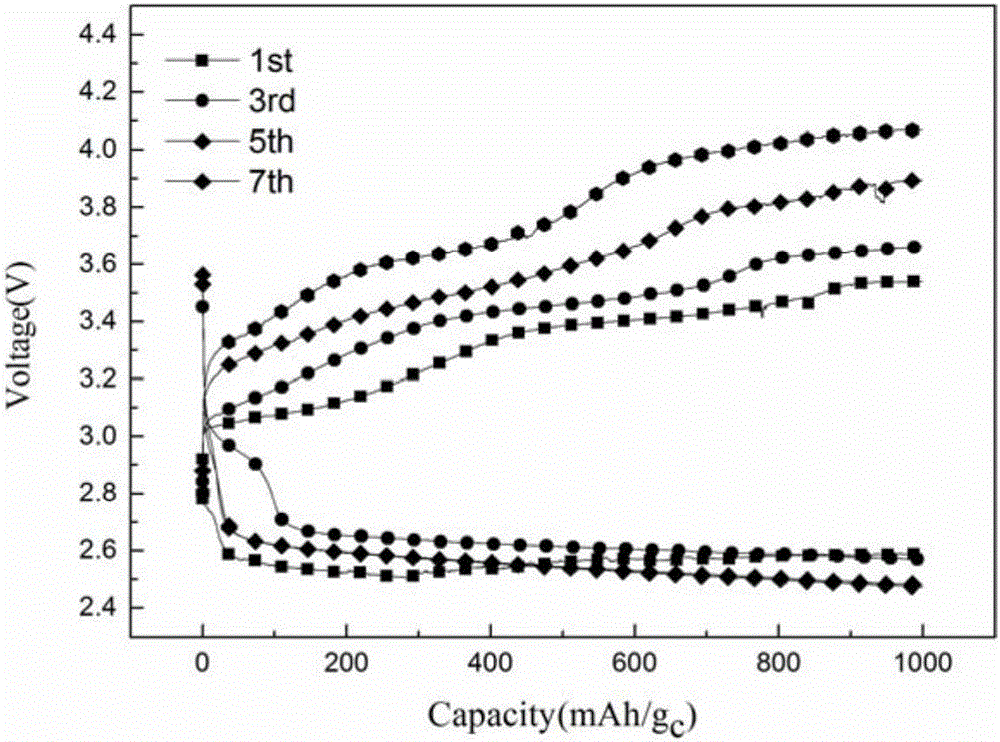

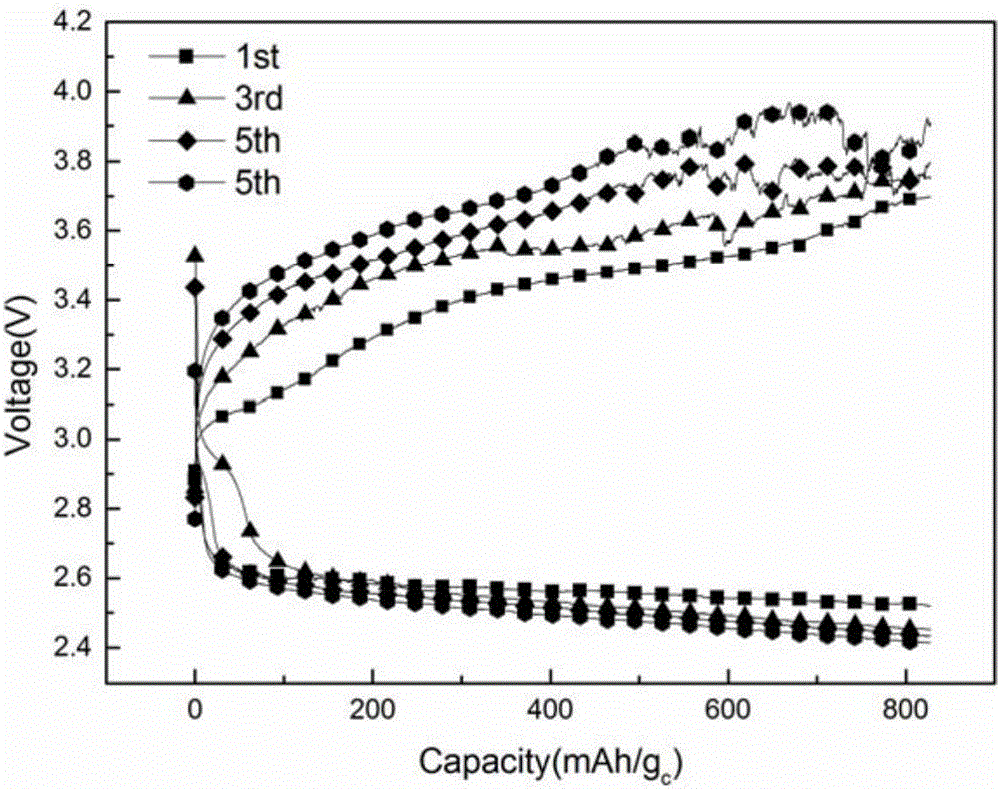

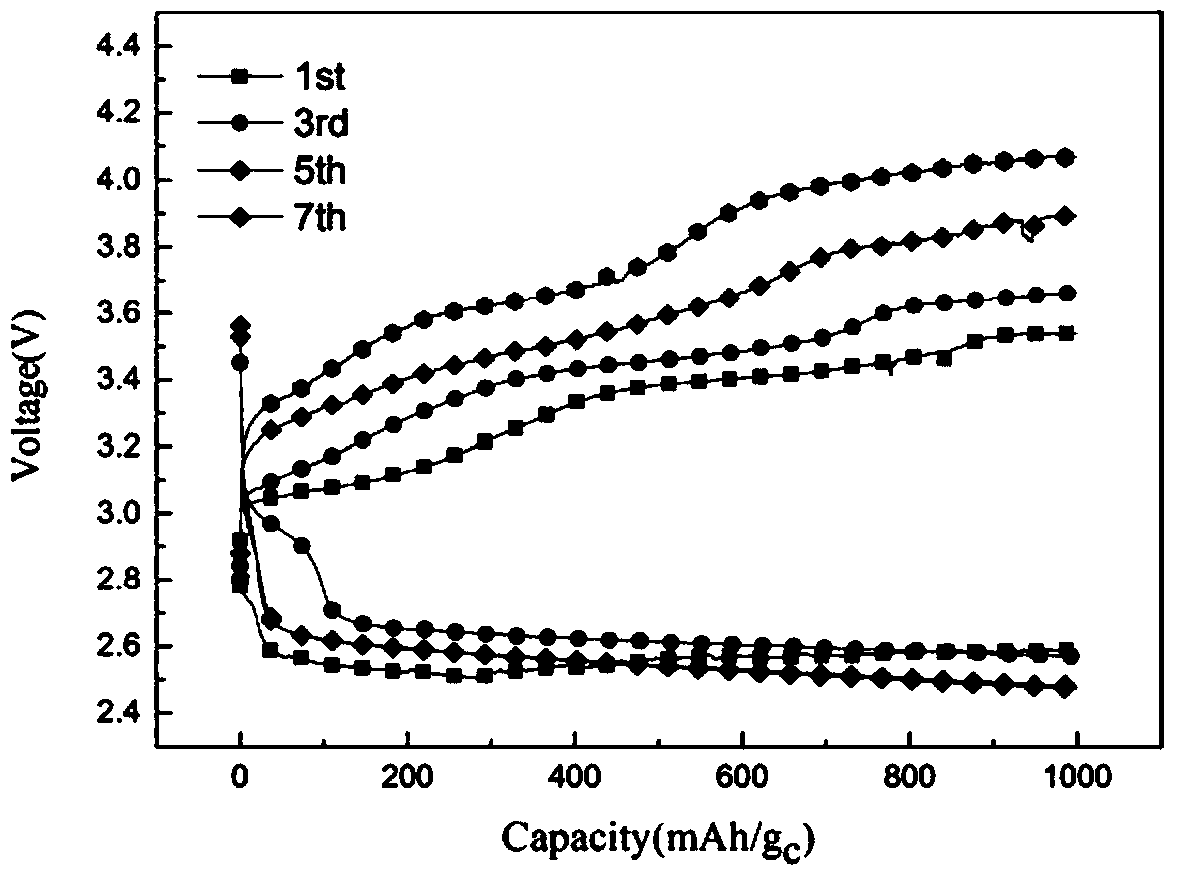

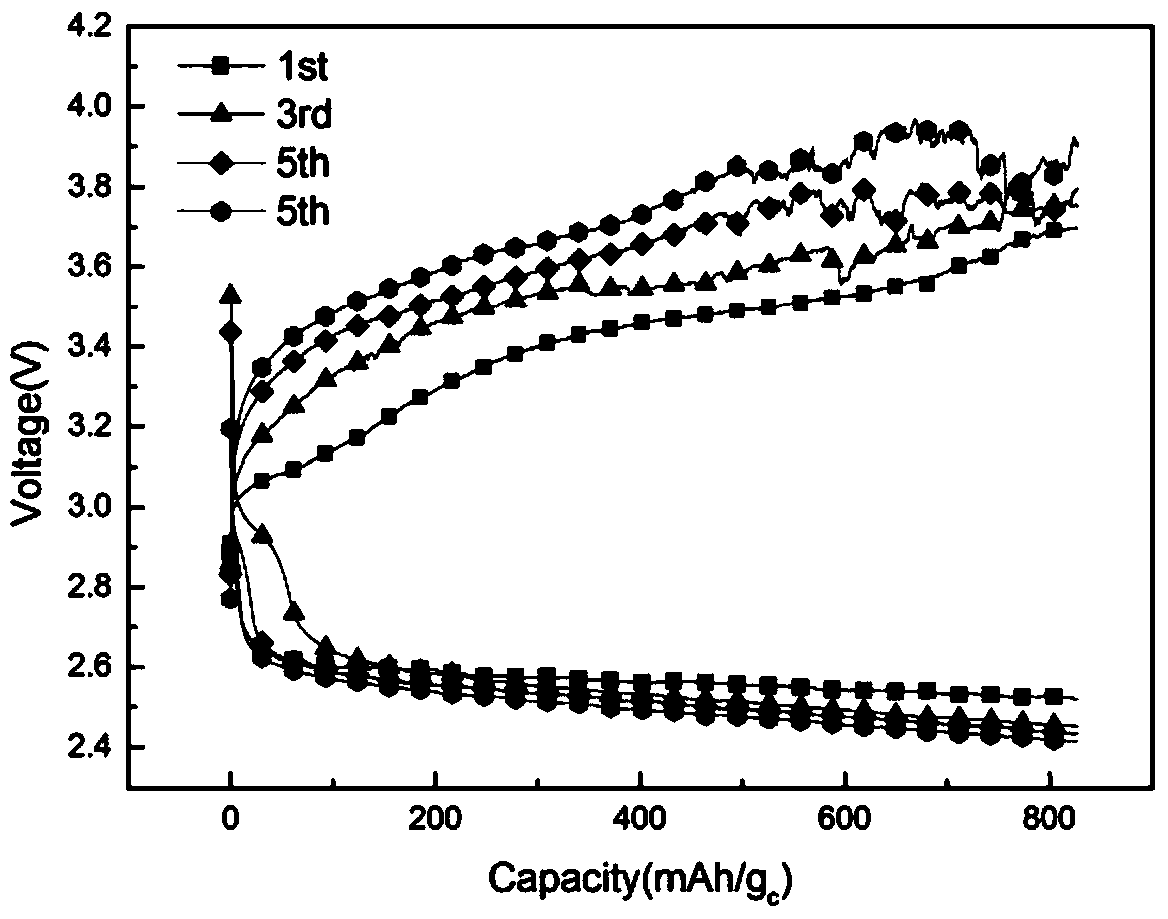

All-solid-state lithium-air battery composite positive electrode material and all-solid-state lithium-air battery

ActiveCN105870449APromote decompositionSolve conductivity problemsFuel and primary cellsCell electrodesAll solid stateMicro nano

The invention discloses an all-solid-state lithium-air battery composite positive electrode material and an all-solid-state lithium-air battery. The composite positive electrode material comprises a conductive carbon material, a micro-nano frame structure, a lithium-conducting polymer and a redox mediator, wherein the composite positive electrode material has the characteristics of good conductivity and high oxygen permeability; a discharge product can be oxidized in a positive electrode region; and the all-solid-state lithium-air battery with high circulation capability and high safety performance can be obtained on the basis of a positive plate prepared from the composite positive electrode material.

Owner:CENT SOUTH UNIV

Method using glass beads to treat anti-rust paint layer of steel aviation part

ActiveCN104353599AMeet the requirements of electrical conductivityReduce distortionPretreated surfacesSpecial surfacesAdhesion forceAviation

The invention relates to a method using glass beads to treat an anti-rust paint layer of a steel aviation part, and belongs to the technical field of surface treatment of a paint layer material. The method comprises the following steps of surface preparation, protection of non-paint spraying surfaces, sand blasting, paint spraying, baking and curing, middle inspection and reworking, treatment by the glass beads, and final characteristic inspection. The method has the advantages that the surface of the paint layer material is treated by the glass beads according to proper parameters, the conductivity of the paint layer material is less than 15 ohms per 125mm, the property requirement on conductivity by the aviation middle-temperature aluminum anti-corrosive paint layer is completely met, the curing temperature is lowered from 560 DEG C to 300 DEG C, and the part deformation is controlled; the adhesion force of the paint layer treated by the glass beads is good, the excessive paint layer material with poor surface adhesion force can be removed from a part edge with easy warpage in the glass bead blasting process, and the risk of excessive matters in the working condition of an engine is avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

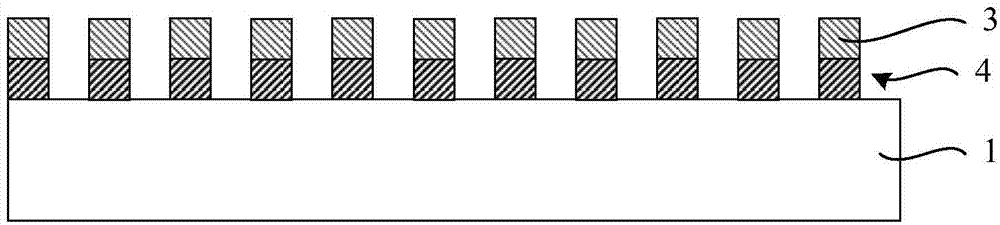

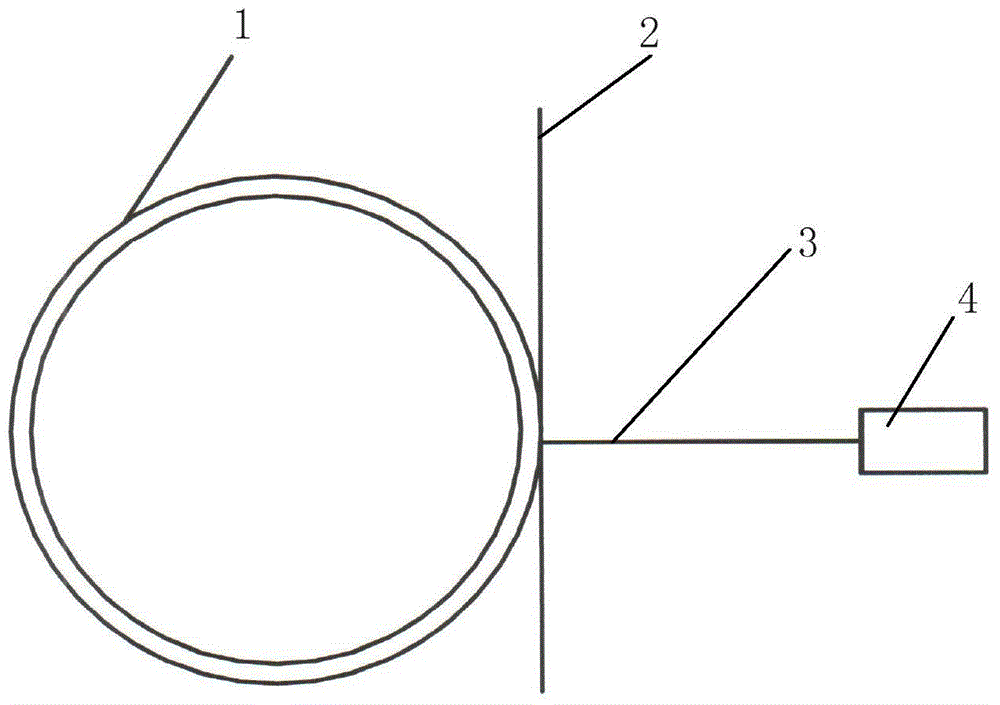

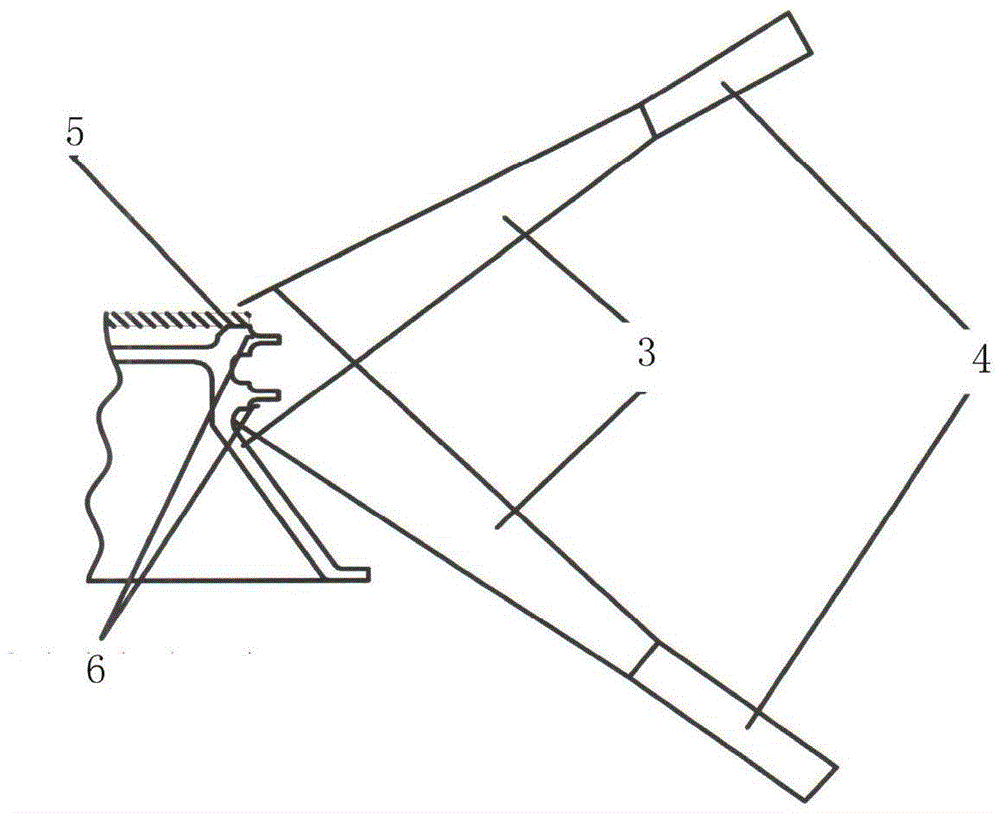

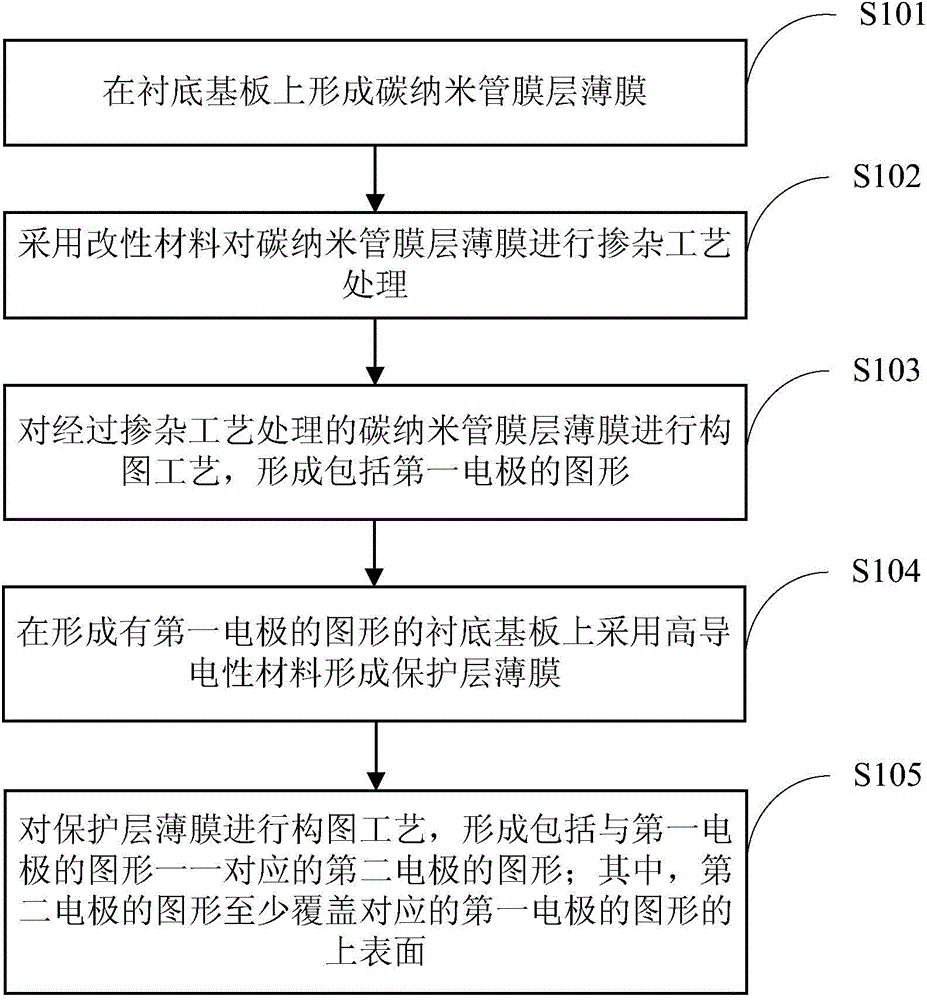

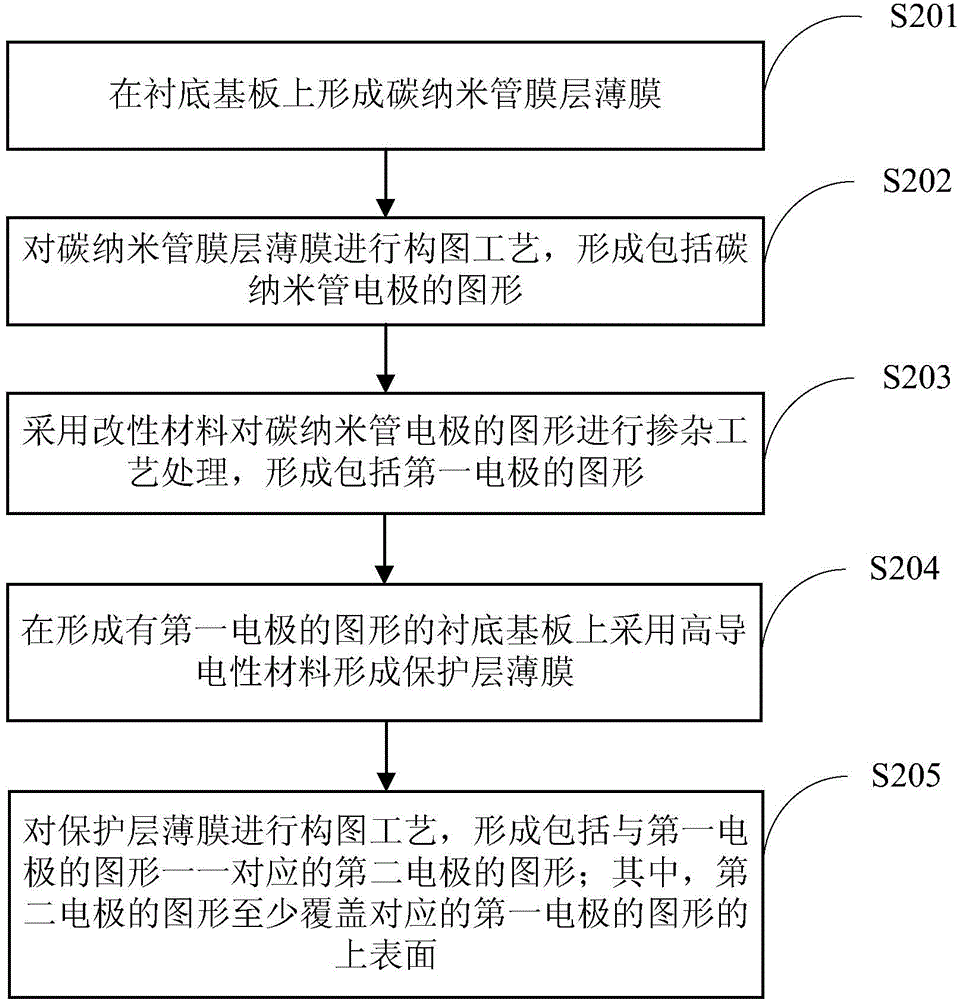

Electrode structure, manufacturing method thereof, display substrate and display device

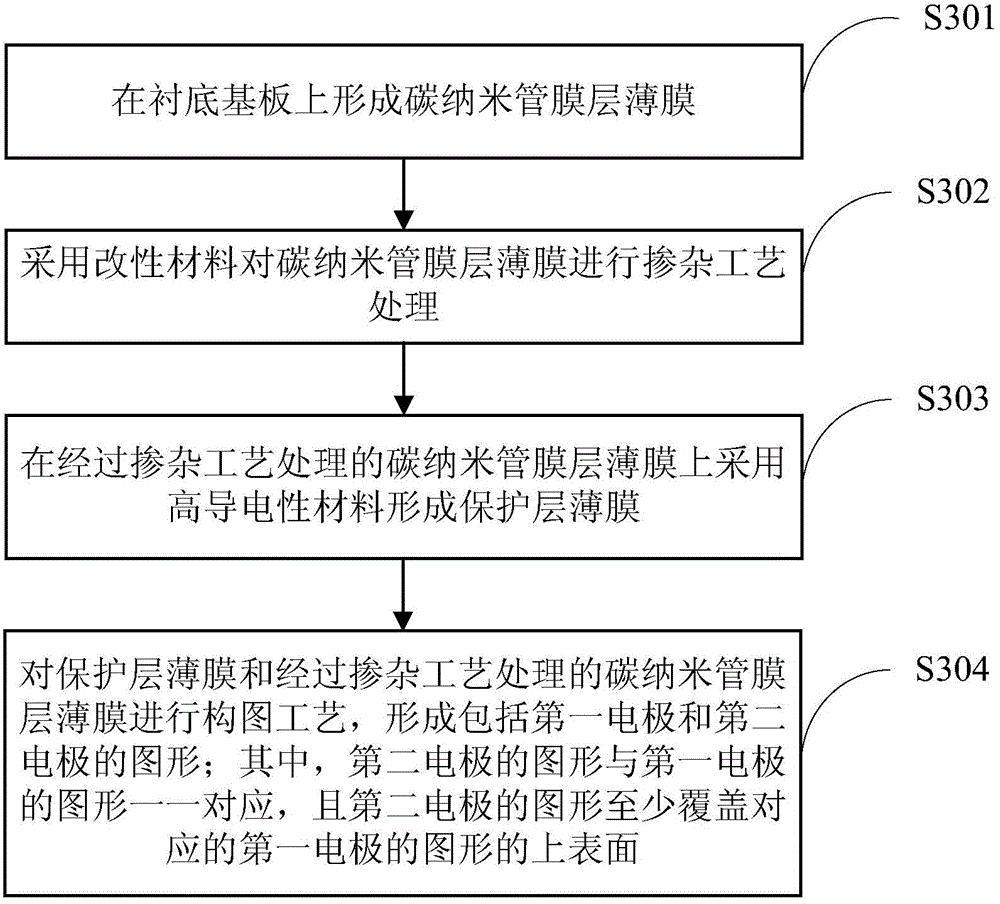

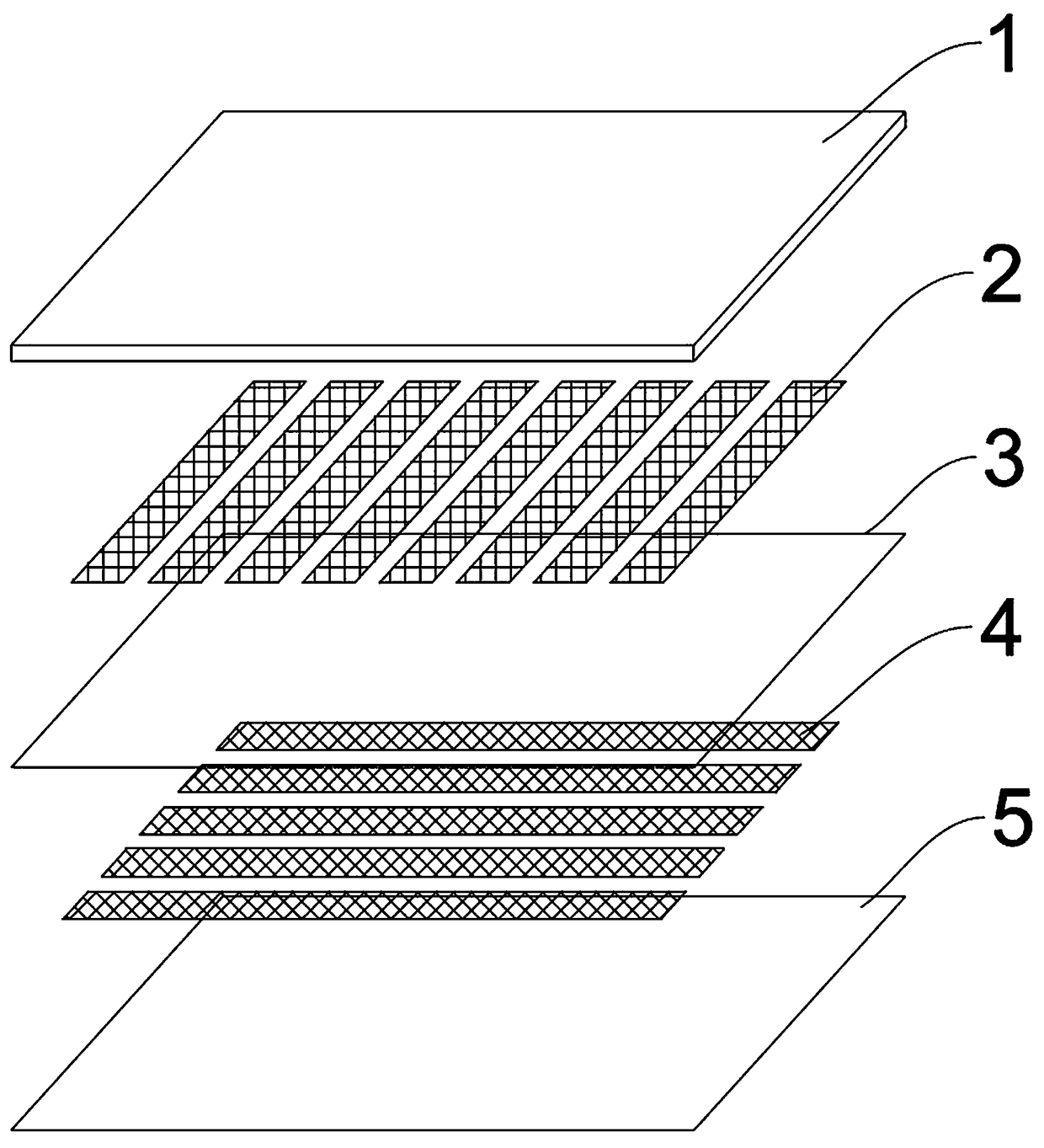

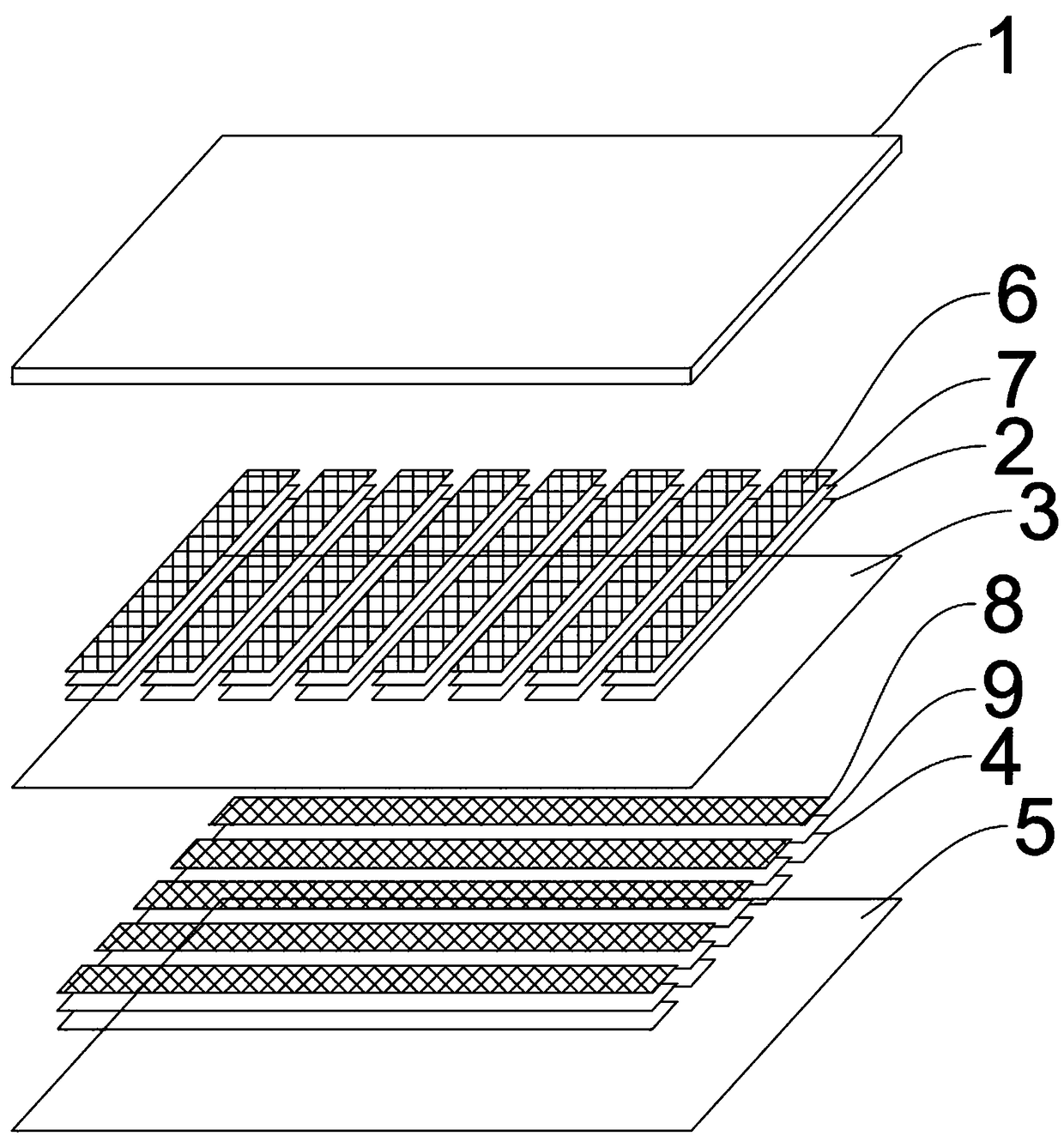

InactiveCN104576321ALow square resistanceMeet the requirements of electrical conductivitySemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeDisplay device

The invention discloses an electrode structure, a manufacturing method thereof, a display substrate and a display device. The manufacturing method of the electrode structure includes: forming a carbon nano tube film on a substrate; using modified materials to perform a doping process on the carbon nano tube film, performing pattern composition on the doped carbon nano tube film to form a pattern including a first electrode, or performing pattern composition on the carbon nano tube film to form a pattern including a carbon nano tube electrode, using modified materials to perform a doping process on the carbon nano tube electrode so as to form a pattern including the first electrode. Due to the fact that the modified materials are doped into the carbon nano tube materials, the formed first electrode is low in resistance, and the conductivity, required by flexible display, of the flexible electrode can be satisfied.

Owner:BOE TECH GRP CO LTD +1

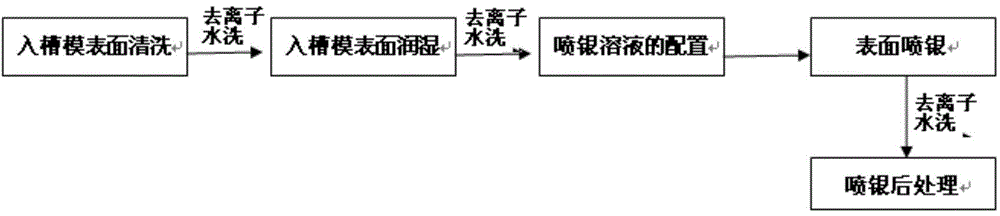

Conductive treatment method for inlet groove mould surface of slush moulding mould

InactiveCN104674202AImprove conductivityNot easy to fall offLiquid/solution decomposition chemical coatingReducing agentMaterials science

The invention belongs to the field of automobile instrument panels, and relates to a conductive treatment method for an inlet groove mould surface of a slush moulding mould. The conductive treatment method comprises the following steps: 1, cleaning the inlet groove mould surface by using a mixed solution of deionized water and washing powder; 2, rinsing the residual cleaning solution by spraying the deionized water through a spray gun; 3, wetting the inlet groove mould surface by using a mixed solution of isopropanol and a hydrophillic treatment agent HYDRO310; 4, rinsing the residual wetting solution by spraying the deionized water through the spray gun; 5, preparing a diaminesilver solution A and a reducing agent solution B; 6, silvering the inlet groove mould surface by using a double-head spray head; 7, cleaning the inlet groove mould surface by spraying the deionized water through the spray gun. In the conductive treatment method, a sensitization process is avoided, and in the preparation process of the diaminesilver solution, an alkaline solution is not used, and a silver mirror can be directly sprayed on the cleaned and wetted surface, so that the conductive treatment method is simple and low in cost; a formed silver layer is bright, dense, good in conductivity and unlikely to shed off, so that the requirement on conduction of the inlet groove mould surface of the large-sized slush moulding mould can be met.

Owner:刘子睿

Copper-coated steel wire and method for manufacturing same

InactiveCN103177819AReduce usageMeet special requirements for mechanical propertiesMetal/alloy conductorsCable/conductor manufactureCopper wireElectroplating

The invention discloses a method for manufacturing a copper-coated steel wire. The method includes steps of acid-washing and rustproof treatment for a steel wire; primary drawing treatment; primary heat treatment; copper electroplating; secondary drawing treatment; secondary heat treatment; and surface protection. The method has the advantages that the usage amount of copper of the copper-coated steel wire is greatly reduced under the condition of meeting the requirement on electrical conductivity, special requirements of electronic products on the mechanical performance of the copper-coated steel wire are met, and the copper-coated steel wire brings convenience for line production of the electronic products owing to an iron core; and the copper-coated steel wire can be used as a lead or a connecting wire for the electronic products, replaces a pure copper wire and is wide in application.

Owner:NANTONG HONGYANG METAL PRODS

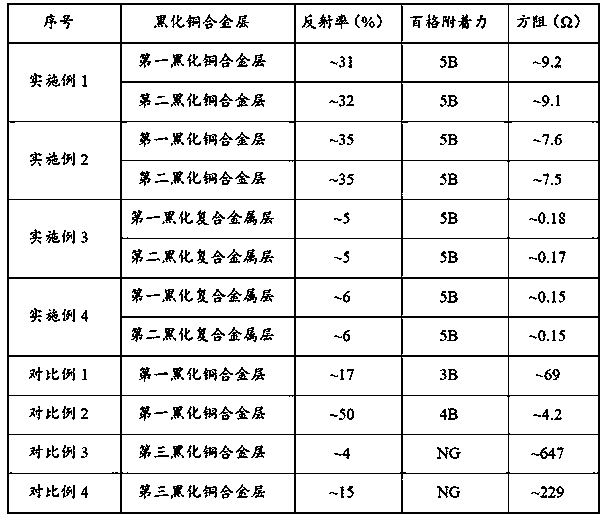

Metal grid touch screen and preparation process thereof

PendingCN108762578AMeet the requirements of electrical conductivityReduce reflectivityInput/output processes for data processingCopper oxideHigh reflectivity

The invention provides a metal grid touch screen and a preparation process thereof. According to the metal grid touch screen and the preparation process thereof, blackened CU alloy grid layers which contain copper oxide, copper nitride and other oxides are adopted, so that the requirement for conductivity is satisfied, and low reflectivity is realized; due to the presence of the other oxides, thereliability of film layers and the adhesive power between the film layers and substrates are improved; through adding alloyed elements in the copper, uniform mechanical property, corrosion resistanceand conductivity of Cu alloy grids can be ensured; by adoption of blackened layer and conductive layer integrated process design, the problem of high reflectivity caused by the reason that the blackened layers caused by side corrosion cannot completely cover the metal grids and the problem bad display effect can be effectively avoided; and the making process is simple, the cost is relatively low,the adhesive power between the metal grids and the substrates is good, the etching process is relatively simple, so that the production efficiency and yields of products can be effectively improved.

Owner:TRULY OPTO ELECTRONICS

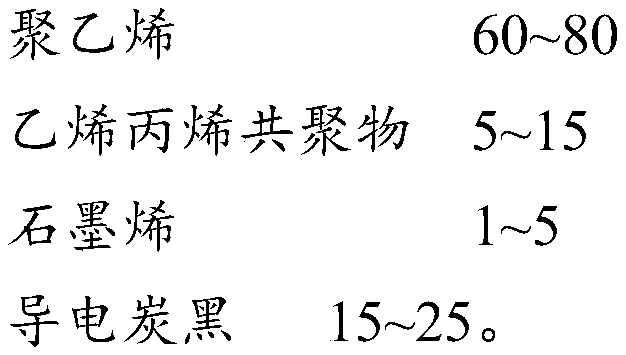

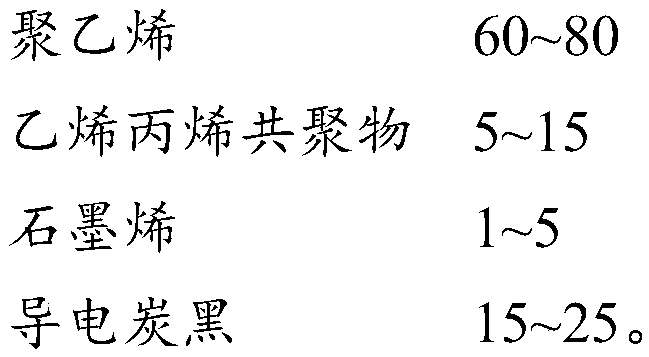

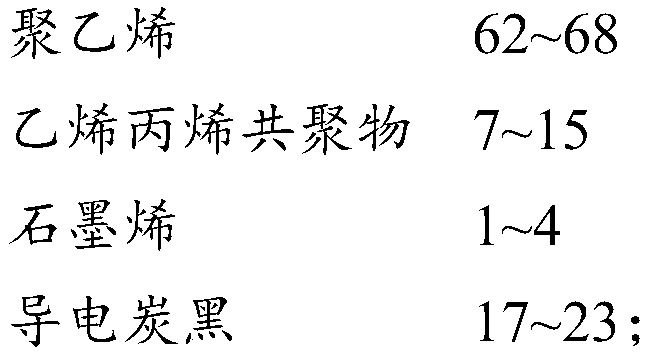

Conductive polyethylene, and preparation method and use thereof

The embodiment of the invention discloses a conductive polyethylene. The conductive polyethylene is mainly prepared from, by weight, 60-80 parts of polyethylene, 5-15 parts of an ethylene-propylene copolymer, 1-5 parts of graphene and 15-25 parts of conductive carbon black. After an inner liner prepared from the conductive polyethylene is used in a chemical raw material barrel, the chemical raw material is in direct contact with the inner liner and is not in direct contact with the sidewall of the chemical raw material barrel in the use process in order to avoid the direct pollution of the chemical raw material barrel, so the treatment cost of hazardous wastes is greatly reduced.

Owner:DONGGUAN DECHENG PLASTIC TECH

Static conducting internal wall paint

ActiveCN102372972AImprove antistatic performanceWith moisture absorption functionElectrically-conductive paintsIron powderLong lasting

The invention discloses a static conducting internal wall paint which creatively uses a mixture of diatomite, palygorskite, conductive mica powder, nano-iron powder and talcum powder as the composite conductive filler. Therefore, the prepared paint has long-lasting conductivity, good stability and excellent paint comprehensive performance. An economical and environmentally-friendly solution is provided for the indoor antistatic problem of the building.

Owner:5ELEM HI TECH CORP

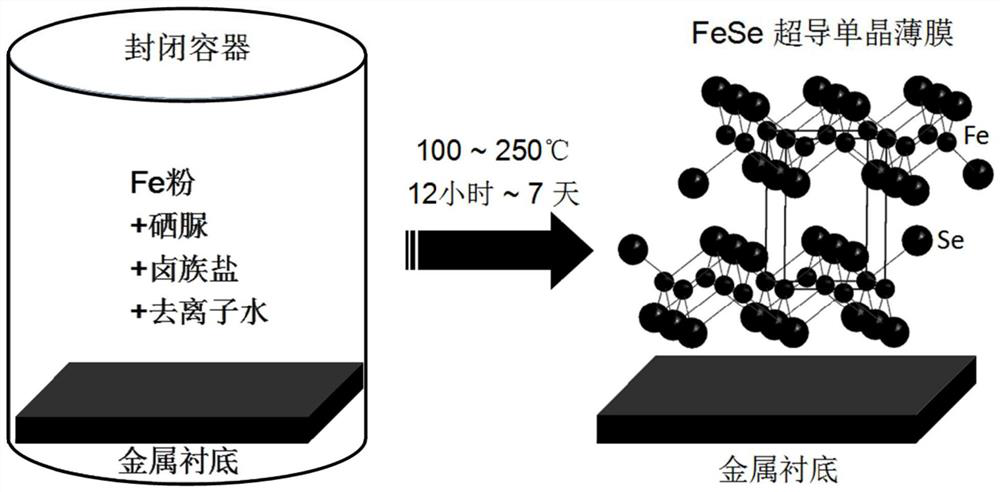

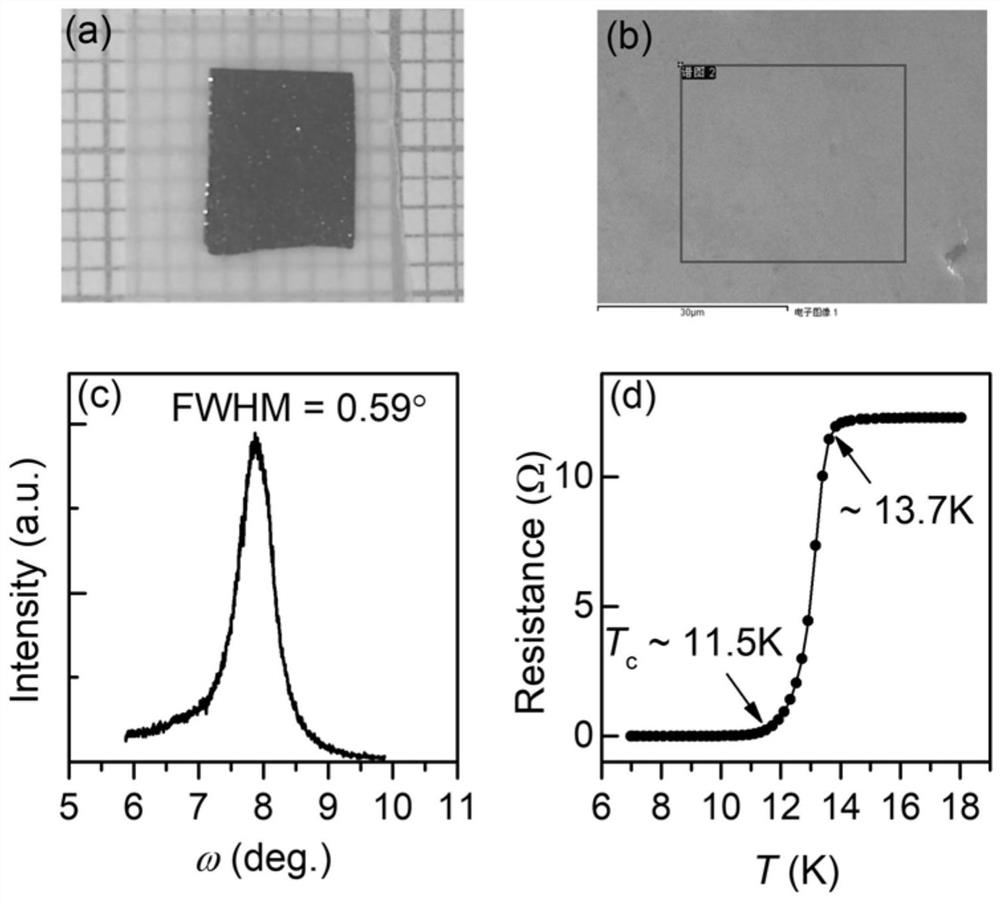

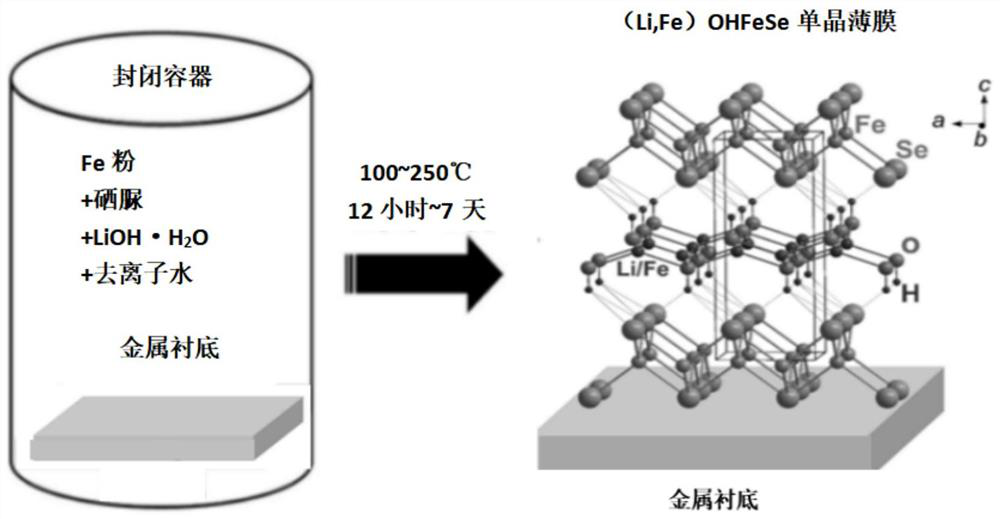

Hydrothermal preparation method of superconducting single crystal film and product thereof

ActiveCN111607826AReduce energy consumptionLow costPolycrystalline material growthFrom normal temperature solutionsMetallurgySource material

The invention provides a preparation method of a superconducting single crystal film, which is a hydrothermal method and comprises the following steps: (1) putting reactants and deionized water into asealable heating container, fully stirring and mixing, and putting a metal substrate in; (2) sealing the sealable container, and heating for reaction; and (3) after the reaction is finished, openingthe sealable container, taking out the metal substrate, and repeatedly cleaning with deionized water to obtain the superconducting single crystal film capable of realizing epitaxial growth. The methoddisclosed by the invention is low in energy consumption, low in cost and low in pollution, and does not need physical high-temperature and ultrahigh-vacuum equipment or high-valence organic source material and organic matter post-treatment required by the existing method. A metal substrate can be used, the shape and size of the substrate are not limited, and the method is simple, efficient and easy to popularize.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

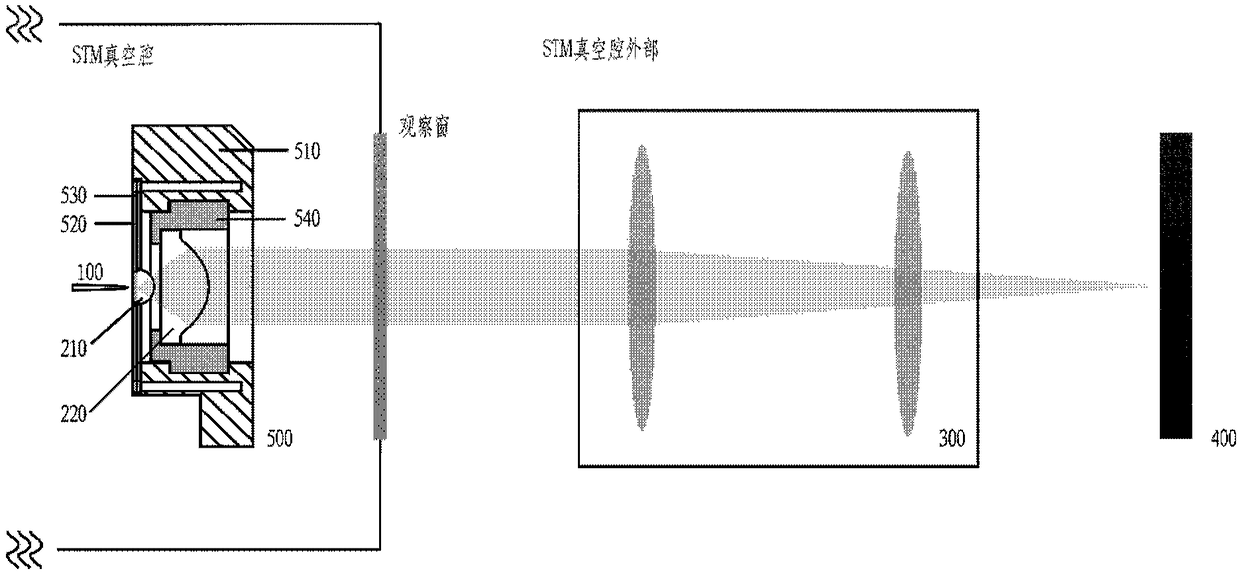

Back focal plane imaging device combined with low-temperature ultra-high vacuum scanning tunneling microscope

PendingCN109387669AAvoid reflectionsLarge numerical apertureColor/spectral properties measurementsScanning probe microscopyUltra-high vacuumScanning tunneling microscope

The invention provides a back focal plane imaging device combined with a low-temperature ultra-high vacuum scanning tunneling microscope. The device comprises a to-be-measured sample, an optical imaging assembly, an integrated support, an extra-cavity lens group of the scanning tunneling microscope and an optical detector. A metal electrically excites the surface of the to-be-measured sample to generate a surface plasmon, and the optical imaging assembly collects a large-angle optical signal of the radiation leakage formed in the propagation process of the surface plasmon and converts the large-angle optical signal into parallel optical signals for output. The extra-cavity lens group of the scanning tunneling microscope receives the parallel optical signals for convergence and / or imaging and then outputs the signal, and the optical detector performs spectral measurement and / or back focal plane imaging of the received optical signal. The device facilitates imaging of the feature of theback focal plane of the sample illumination and the measurement of associated spectrums in a low-temperature ultra-high vacuum environment.

Owner:UNIV OF SCI & TECH OF CHINA

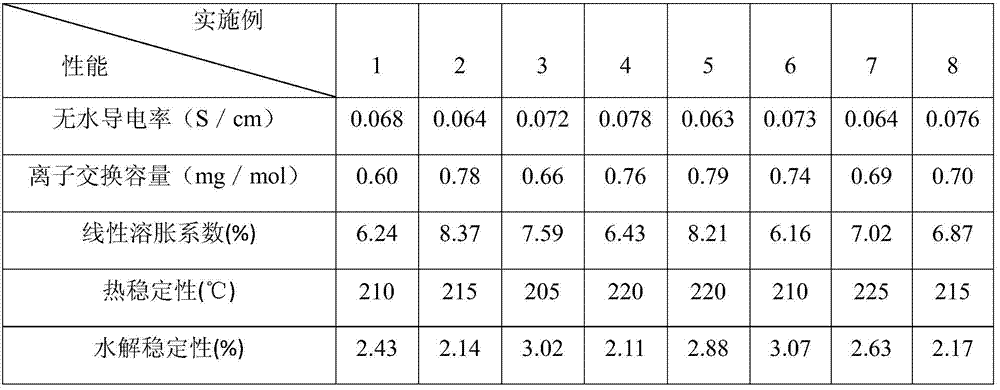

Bis phosphonic acid functional organosilicon high temperature proton conductor and preparation method thereof

InactiveCN104900896AImprove hydrolytic stabilityAvoid formingSolid electrolyte fuel cellsElectrolyte immobilisation/gelificationSilanesHYDROSOL

The invention relates to a bis phosphonic acid functional organosilicon high temperature proton conductor and a preparation method thereof, the preparation method of the proton conductor is as follows: (1) hydroxyethylidene bis-phosphonic acid tetrasodium salt and tetrahydrofuran are added into a four-mouth flask, completely dissolved, then heated to 45-60 DEG C, and then slowly added dropwise with isocyanate propyl trimethoxy silane, after the reaction is completed, bis phosphonic acid trimethoxy silane can be obtained; (2) the bis phosphonic acid trimethoxy silane as a main hydrolysis precursor, amino propyl trimethoxy silane and tetraethoxysilane as auxiliary hydrolysis precursors, ethanol as a solvent, and a suitable amount of hydrochloric acid as a catalyst are stirred at room temperature to obtain a sol; (3) the sol is dried, demoulded, and soaked with hydrochloric acid for post-processing to obtain the bis phosphonic acid functional organosilicon high temperature proton conductor. The bis phosphonic acid functional organosilicon high temperature proton conductor prepared by the method has high conductivity, good hydrolysis stability and thermal stability.

Owner:WUHAN UNIV OF TECH

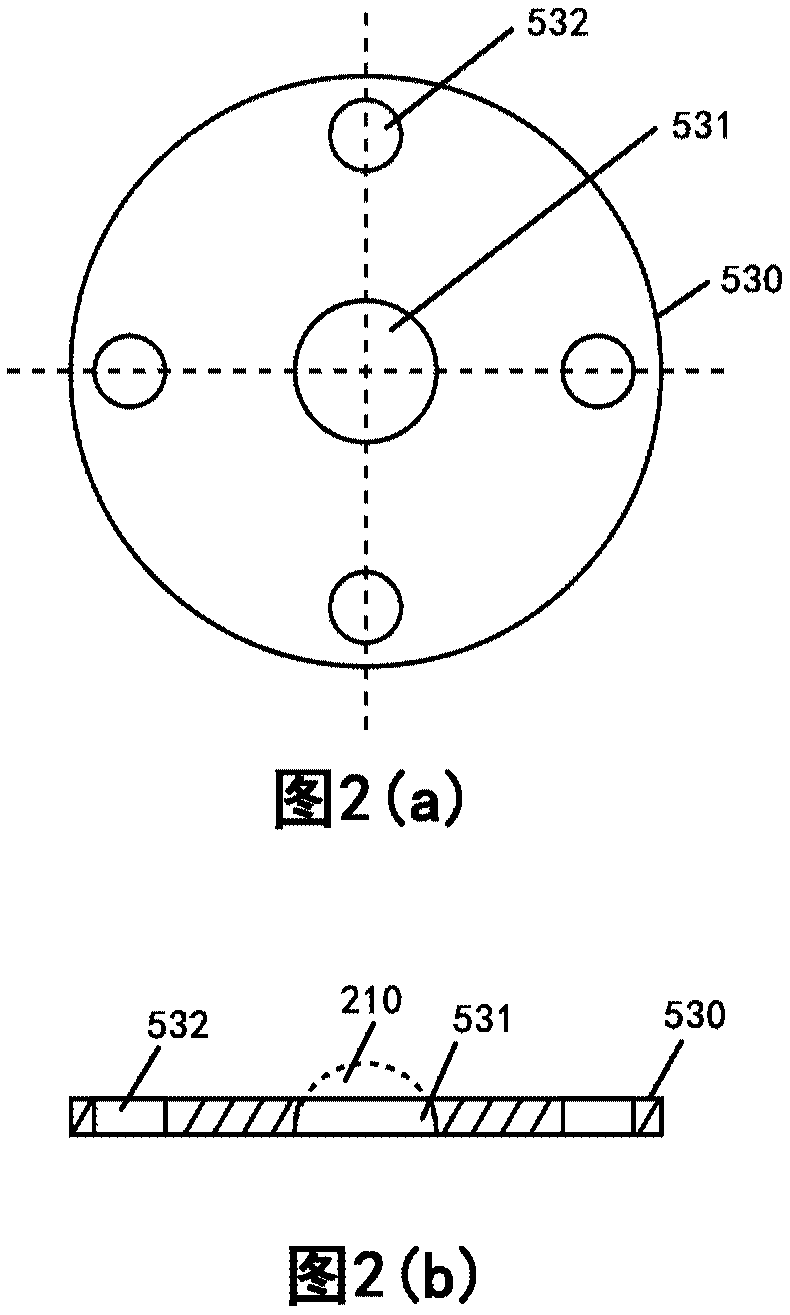

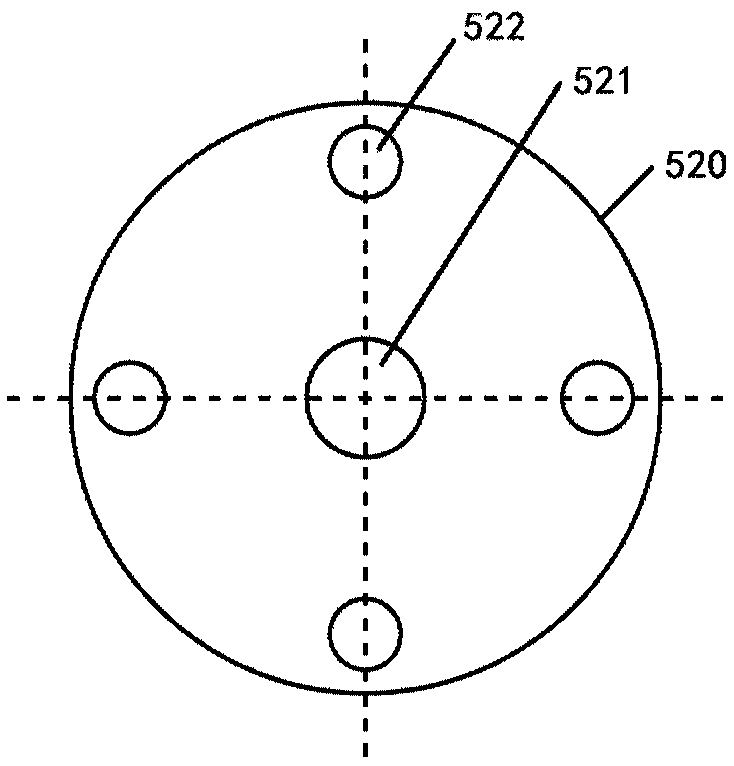

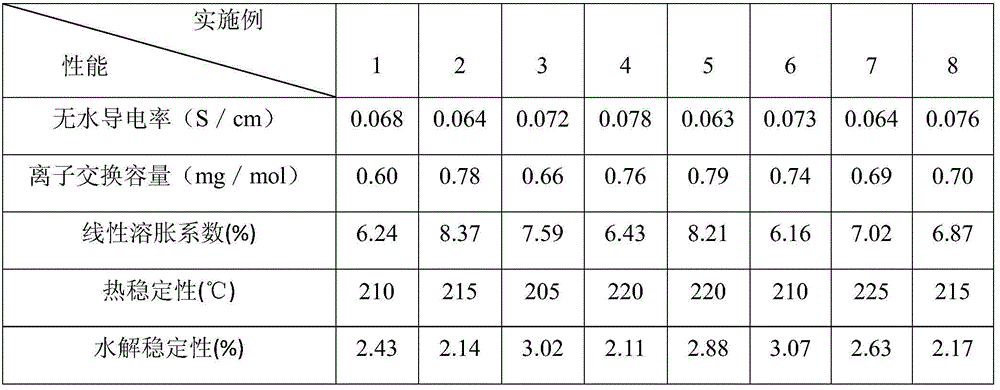

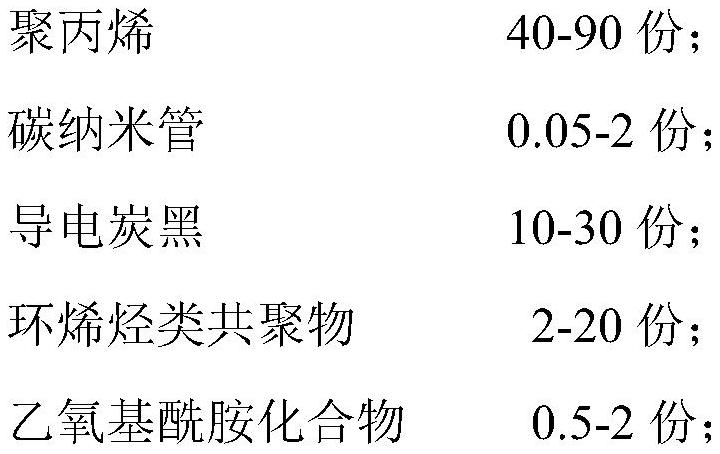

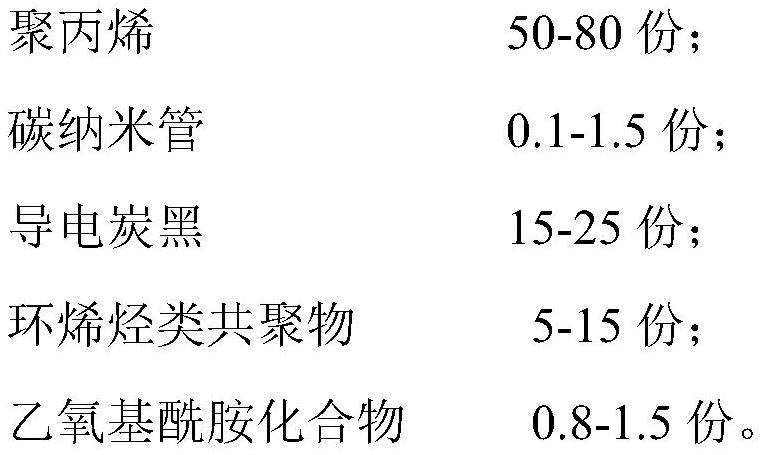

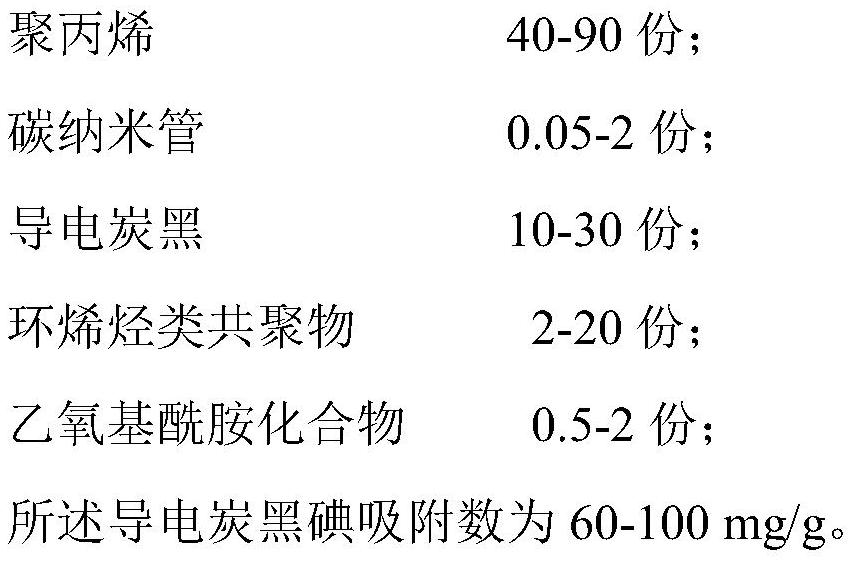

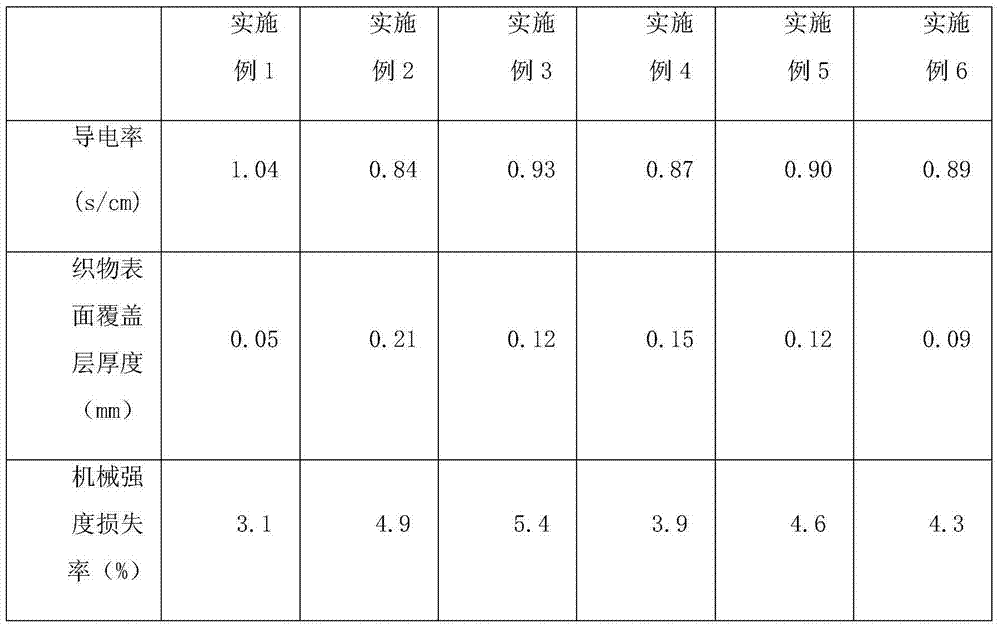

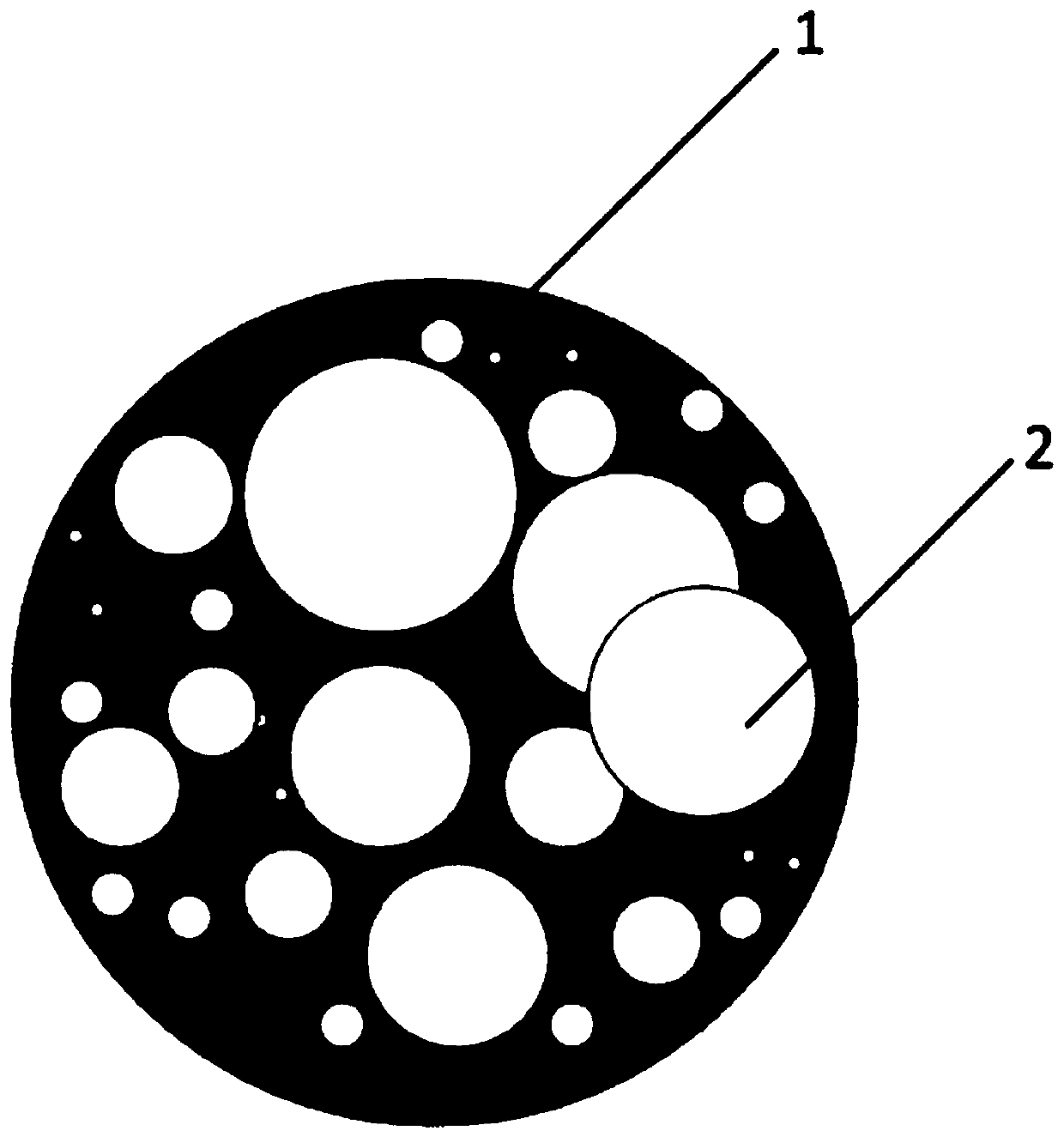

Conductive thermoplastic resin composition as well as preparation method and application thereof

PendingCN114230927AReduce sheddingImprove the problem of a large increase in resistancePolymer scienceCycloalkene

The invention relates to a conductive thermoplastic resin composition as well as a preparation method and application thereof. The composition comprises the following components in parts by weight: 40-90 parts of polypropylene; 0.05 to 2 parts of a carbon nano tube; 10 to 30 parts of conductive carbon black; 2 to 20 parts of a cycloolefin copolymer; and 0.5 to 2 parts of an ethyoxyl amide compound. The composition is high in resistance retention rate, high in tensile strength and small in carbon black shedding amount after being subjected to stretching processing.

Owner:KINGFA SCI & TECH CO LTD

Cast aluminum alloy for high-voltage power control assembly and preparation method of cast aluminum alloy

ActiveCN104745896AMeet the requirements of electrical conductivityImprove conductivityRare-earth elementElectrical conductor

The invention provides a cast aluminum alloy for a high-voltage power control assembly and a preparation method of the cast aluminum alloy. The cast aluminum alloy contains Si, B, Mg, La and the balance of Al and inevitable impurities. The dosage of the Si element is controlled, so that the requirements of the high-voltage power control assembly on the electrical conductivity can be met while the mechanical properties are improved. Secondly, the B element is added to react with the impurity elements capable of reducing the electrical conductivity in the alloy, and then the distortion of the internal crystal lattices of an aluminum conductor can be reduced, and furthermore, the crystal lattice defects can be reduced and the electrical conductivity can be improved. In addition, the rare earth element La is added to achieve certain effects of removing hydrogen, refining, purifying and altering, and therefore, the electrical conductivity of the aluminum alloy can be improved. The results of experiments indicate that the prepared cast aluminum alloy under a cast condition has the electrical conductivity of greater than or equal to 55% IACS, the tensile strength of 189-194MPa and the yield strength of 128-136Mpa, and has excellent electrical conductivity and mechanical properties.

Owner:NONFERROUS METALLIC OF HEBEI NEW LIZHONG GRP CO LTD

A kind of electrolytic aluminum cathode steel-aluminum fusion brazing welding method

ActiveCN108723534BMeet the requirements of electrical conductivityEasy to operateSoldering apparatusEconomic benefitsUltimate tensile strength

The invention discloses an electrolytic aluminum cathode steel-aluminum melting and brazing welding method. The method aims at solving the problems that in the production process of electrolytic aluminum, steel-aluminum welding efficiency is low, and a welding joint is poor in electrical conductivity. According to the method, a layer of welding flux with the thickness ranging from 80 microns to 150 microns is uniformly applied to each welding workpiece with a surface oxidation layer removed, and the generation amount of brittle compounds at the welding joint is reduced, so that mechanical performance of the welding joint is improved. The method that melting welding is conducted on the aluminum welding workpiece, and brazing welding is conducted on the steel welding workpiece is adopted; after preheating treatment is conducted, the aluminum welding workpiece and the steel welding workpiece are welded through welding wires. The method is low in cost, great in operability and uniform in welding composition; performance test results indicate that the pressure drop, formed after welding, at the welding joint can be lowered by 25 mV or more; the tensile strength can reach 110-150 Mpa; the shearing strength can reach 100-140 Mpa; electrical conductivity and mechanical performance are obviously superior to the traditional explosion welding mode; and economical benefits are remarkable.

Owner:ZHENGZHOU JINGWEI TECH & IND

Method for preparing novel flexible conductive fabric by using micro-sphere self-assembly technology

ActiveCN104746346ALow densityLarge specific surface areaUltrasonic/sonic fibre treatmentWater vapor permeabilityPlasma technology

The invention provides a method for preparing a novel flexible conductive fabric by using a micro-sphere self-assembly technology. The method comprises the following steps: by adopting hollow conductive micro-spheres as conductive materials, finishing the fabric surface by adopting a plasma technology, densely and regularly arranging the hollow conductive micro-spheres on the fabric surface by utilizing the self-assembly technology, and forming dense conductive micro-sphere layers on the fabric surface. According to the method, the preparation method is simple and convenient, the materials do not need to be alternatively arranged layer by layer, the time and the labor are saved, the conductivity, mechanical strength and other performances of conductive preparation can be regulated by controlling the layer number of the hollow conductive micro-spheres, and the controllability is high. The wire fabric prepared by the method is high in flexibility, high in conductivity, good in strength and water vapor permeability and air permeability and high in comfort level, and the wearing performance change of the fabric is slight.

Owner:广东樱兰智能服装有限公司

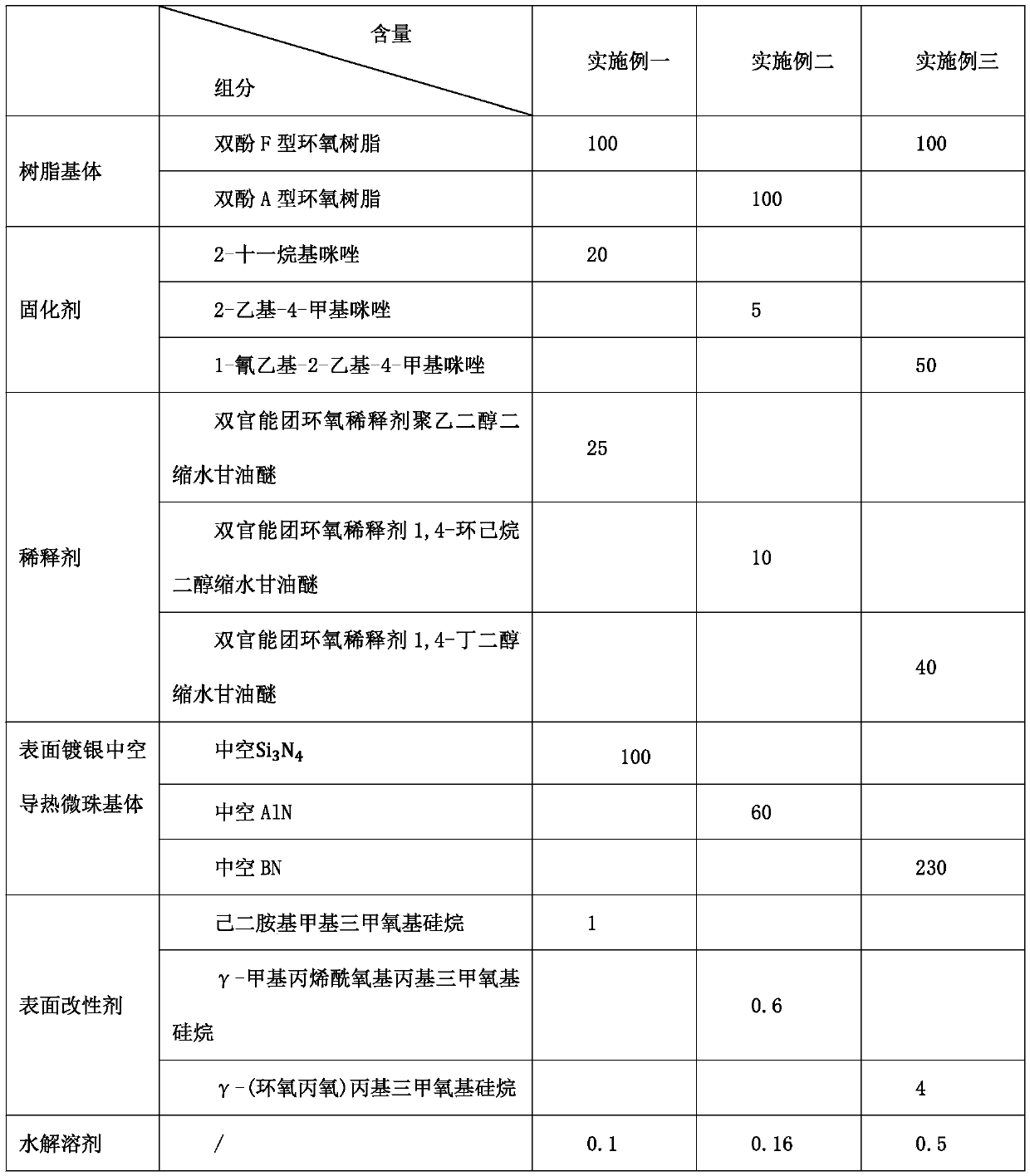

Preparation method of novel conductive silver adhesive with high heat conductivity coefficient and conductive silver adhesive

ActiveCN111518501ALow priceIncrease volume fractionNon-macromolecular adhesive additivesVacuum evaporation coatingAdhesiveMicrosphere

The invention discloses a preparation method of a novel conductive silver adhesive with a high heat conductivity coefficient and the conductive silver adhesive. The preparation method comprises the following steps: plating silver on the surfaces of hollow heat-conducting microspheres to prepare silver-plated microbeads; preparing the silver-plated microbeads into a component A; preparing a component B; adding the component A into the component B, and performing vacuum defoaming and mixing to form a mixed product; subjecting the mixed product to vacuum filling to obtain the conductive silver adhesive. The density of conductive particles in any layer of the conductive silver adhesive of a multifunctional plate prepared by the method is close to that of a resin matrix, the problem of conductive particle sedimentation in mixing, stirring and processing use is thoroughly avoided, so that a more effective and reliable conductive network is introduced, and the batch consistency and the quality reliability are higher.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Electrolytic aluminum cathode steel-aluminum melting and brazing welding method

ActiveCN108723534AStrong maneuverabilityGood electrical conductivitySoldering apparatusSurface oxidationAluminium

The invention discloses an electrolytic aluminum cathode steel-aluminum melting and brazing welding method. The method aims at solving the problems that in the production process of electrolytic aluminum, steel-aluminum welding efficiency is low, and a welding joint is poor in electrical conductivity. According to the method, a layer of welding flux with the thickness ranging from 80 microns to 150 microns is uniformly applied to each welding workpiece with a surface oxidation layer removed, and the generation amount of brittle compounds at the welding joint is reduced, so that mechanical performance of the welding joint is improved. The method that melting welding is conducted on the aluminum welding workpiece, and brazing welding is conducted on the steel welding workpiece is adopted; after preheating treatment is conducted, the aluminum welding workpiece and the steel welding workpiece are welded through welding wires. The method is low in cost, great in operability and uniform in welding composition; performance test results indicate that the pressure drop, formed after welding, at the welding joint can be lowered by 25 mV or more; the tensile strength can reach 110-150 Mpa; the shearing strength can reach 100-140 Mpa; electrical conductivity and mechanical performance are obviously superior to the traditional explosion welding mode; and economical benefits are remarkable.

Owner:ZHENGZHOU JINGWEI TECH & IND

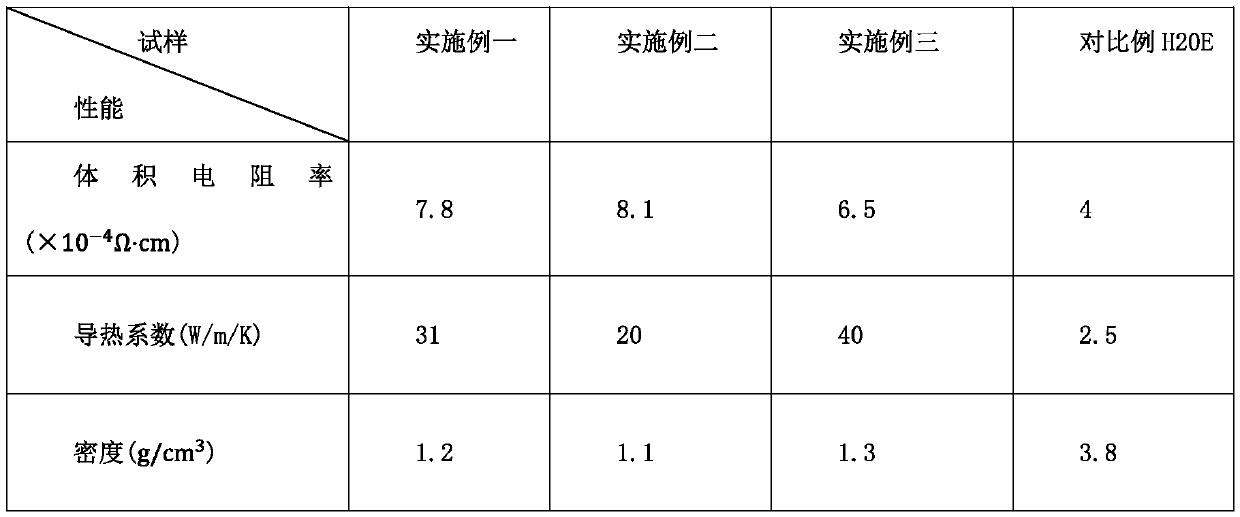

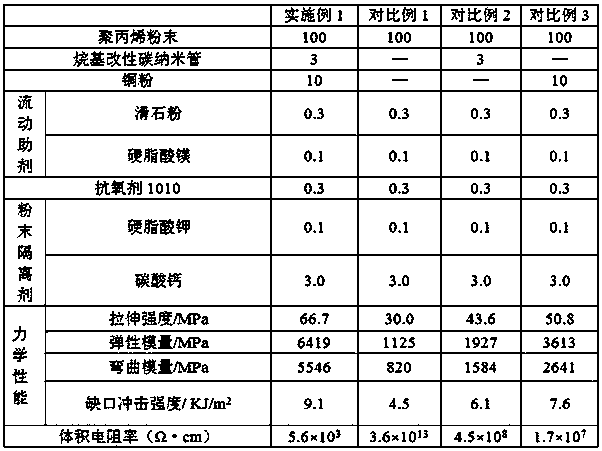

A kind of conductive polypropylene composite powder for selective laser sintering and its preparation method

ActiveCN105754224BImprove performanceReduce polarityAdditive manufacturing apparatusPolypropylene compositesSelective laser sintering

Owner:HENAN INST OF ENG

A method for treating antirust paint layer of steel aviation parts with glass pellets

ActiveCN104353599BMeet the requirements of electrical conductivityReduce distortionPretreated surfacesCoatingsAviationAdhesion force

The invention relates to a method using glass beads to treat an anti-rust paint layer of a steel aviation part, and belongs to the technical field of surface treatment of a paint layer material. The method comprises the following steps of surface preparation, protection of non-paint spraying surfaces, sand blasting, paint spraying, baking and curing, middle inspection and reworking, treatment by the glass beads, and final characteristic inspection. The method has the advantages that the surface of the paint layer material is treated by the glass beads according to proper parameters, the conductivity of the paint layer material is less than 15 ohms per 125mm, the property requirement on conductivity by the aviation middle-temperature aluminum anti-corrosive paint layer is completely met, the curing temperature is lowered from 560 DEG C to 300 DEG C, and the part deformation is controlled; the adhesion force of the paint layer treated by the glass beads is good, the excessive paint layer material with poor surface adhesion force can be removed from a part edge with easy warpage in the glass bead blasting process, and the risk of excessive matters in the working condition of an engine is avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A kind of diphosphonic acid functionalized organosilicon high temperature proton conductor and its preparation method

InactiveCN104900896BImprove hydrolytic stabilityAvoid formingFuel cellsElectrolyte immobilisation/gelificationSilanesHydrolysis

Owner:WUHAN UNIV OF TECH

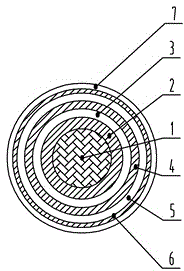

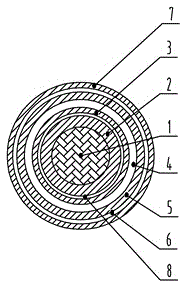

Multi-layer coated enamelled wire

InactiveCN104979041AExtended service lifeImprove energy savingFlexible cablesMetal/alloy conductorsPolyesterElectrical conductor

The invention belongs to the technical field of enamelled wires and particularly relates to a multi-layer coated enamelled wire. The multi-layer coated enamelled wire comprises a core wire as a conductor and a protective layer positioned out of the core wire, wherein the protective layer comprises inner insulating layers and an outer coating; the core wire is a poly-metal compound conductor which is composed of an aluminum core and a copper layer wrapped on the outer surface of the aluminum core; multiple insulating layers sequentially comprise a polyester layer, a polyamideimide layer, a polyurethane layer and a polyesterimide layer from inside to outside. The multi-layer coated enamelled wire provided by the invention is relatively high in corona resistance and long in anti-pulse service life, and the service life of a motor is prolonged, so that the demand on the conductive performance of an electrical apparatus element is satisfied; the metal wire core is good in flexibility, malleability and tensile property, the integral heat resistance, the insulativity, the mechanical property and the chemical resistance of an enamelled film are improved, and moreover, the multi-layer coated enamelled wire is good in straight welding performance; when the enamelled wire is welded, the film layer is not removed; the dielectric loss tangent at high frequency is relatively small, the application range is wide, and the multi-layer coated enamelled wire is suitable for being popularized and implemented.

Owner:湖州三行线缆有限公司

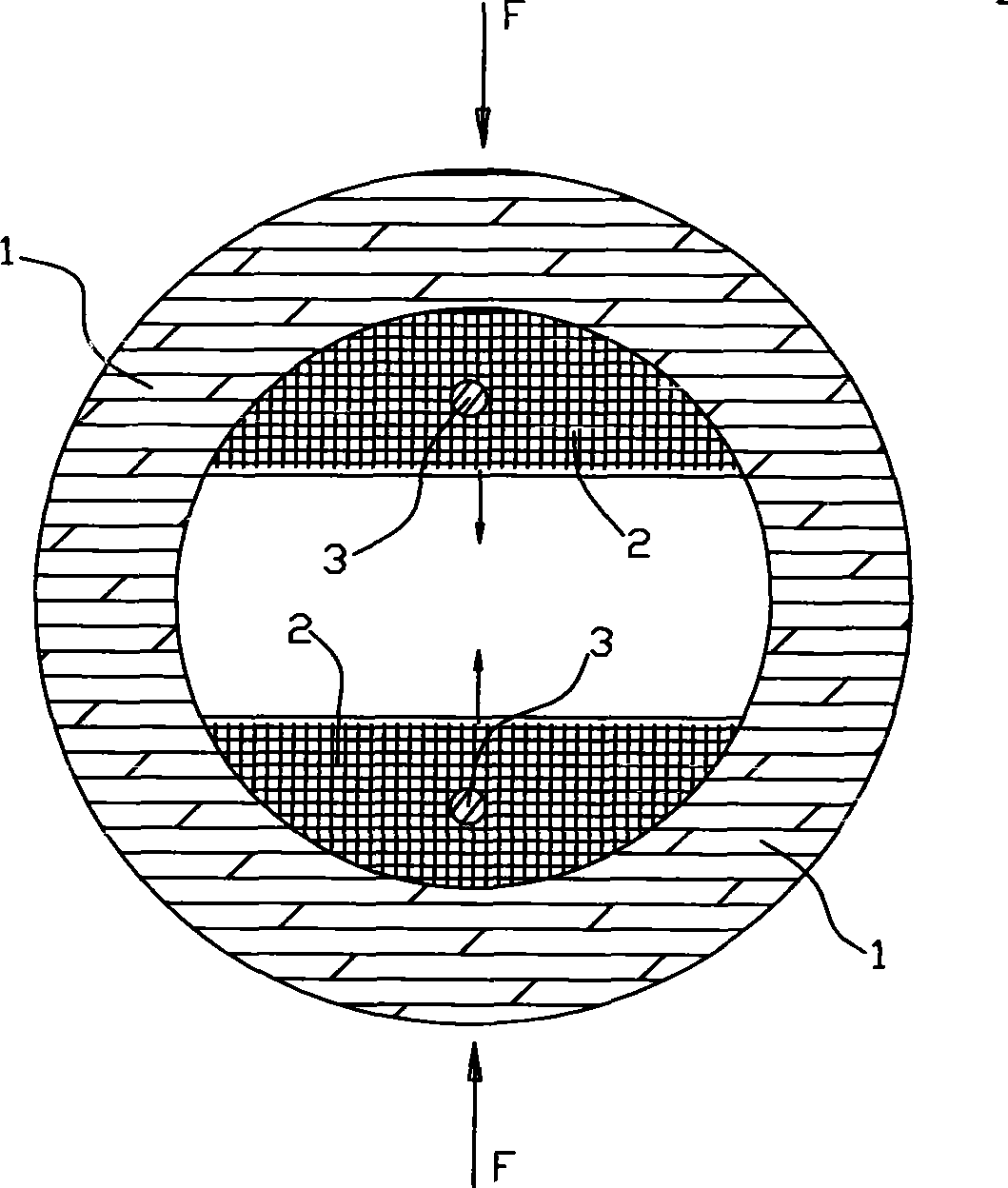

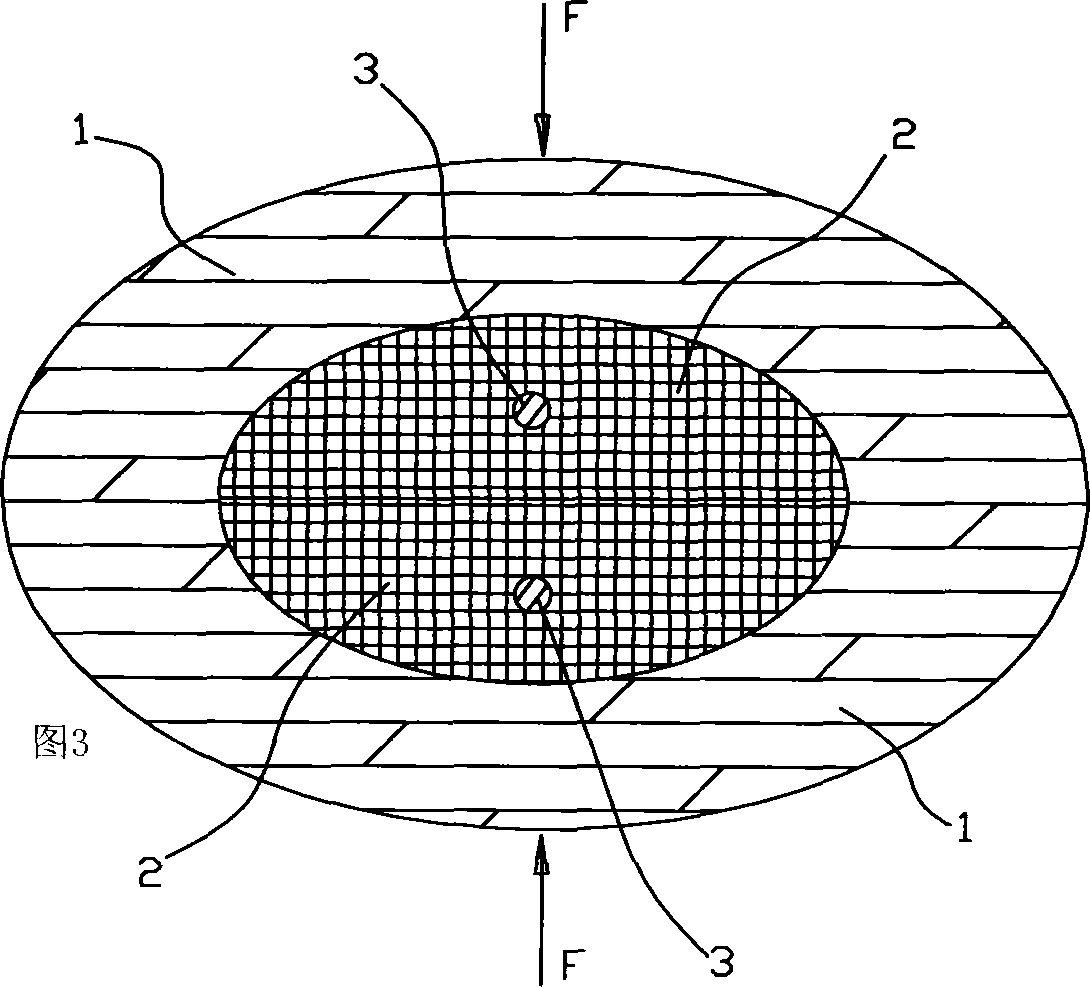

Electroconductive thermoplastic elastomer composition as well as preparation method and applications thereof

ActiveCN102604311BNo sticking phenomenonRecyclableNon-conductive material with dispersed conductive materialElastomerThermoplastic elastomer

The invention provides an electroconductive thermoplastic elastomer composition with an excellent electroconductive performance, which is formed by the mixing of the following raw materials in parts by weight: 30-50 parts of oil charge SEBS (Styrene-Ethylene / Butylene-Styrene) elastomer, 10-20 parts of PP (propene polymer) powder, 20-45 parts of electroconductive carbon black, 3-5 parts of carbon black dispersing agent, and 3-5 parts of anti-adhesive agent, wherein the oil charge SEBS elastomer is formed by blending of an SEBS elastomer and naphthenic base charge oil according to the weight proportion of 1 to 3. The electroconductive thermoplastic elastomer composition with the excellent electroconductive performance is especially suitable for an electroconductive thermoplastic elastomer in manufacturing an anti-clamping strip in an automobile door.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

A kind of all-solid-state lithium-air battery composite positive electrode material and all-solid-state lithium-air battery

ActiveCN105870449BImprove cycle performanceUniform shapeFuel and primary cellsCell electrodesMicro nanoAll solid state

The invention discloses an all-solid-state lithium-air battery composite positive electrode material and an all-solid-state lithium-air battery. The composite positive electrode material comprises a conductive carbon material, a micro-nano frame structure, a lithium-conducting polymer and a redox mediator, wherein the composite positive electrode material has the characteristics of good conductivity and high oxygen permeability; a discharge product can be oxidized in a positive electrode region; and the all-solid-state lithium-air battery with high circulation capability and high safety performance can be obtained on the basis of a positive plate prepared from the composite positive electrode material.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com