Multi-layer coated enamelled wire

An enameled wire and coating technology, applied in the field of enameled wire, can solve the problems of weak resistance to high frequency and instantaneous pulse peak voltage, inability to meet the electrical conductivity requirements of electrical components, breakdown between turns of enameled wire windings, etc. Production efficiency and the effect of small dielectric loss tangent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

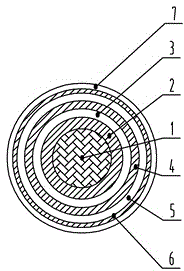

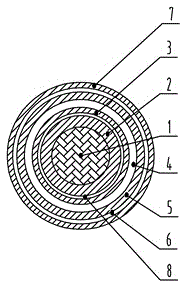

[0021] see figure 1 , among the figures, the multi-layer coated enameled wire of the present invention includes a multi-metal composite conductor core, an outer covering insulating layer and an outer coating, wherein the multi-metal composite conductor wire consists of an aluminum core 1 and a copper layer 2 coated on its outer surface The coating layer is composed of polyester layer 3, polyamideimide layer 4, polyurethane layer 5 and polyesterimide layer 6 from the inside to the outside. The outer coating layer is made of hot-melt self-adhesive paint layer 7. Heat to form the enameled wire. The ratio of the radius of the aluminum core to the thickness of the copper layer is 1:0.1, and the thickness ratio of the polyester layer, polyamideimide layer, polyurethane layer and polyesterimide layer is 1:0.9:0.9:0.3.

Embodiment 2

[0023] Present embodiment figure is not drawn. This embodiment is similar in structure to Embodiment 1, and the structurally identical parts will not be repeated here. The difference is that the ratio of the radius of the aluminum core to the thickness of the copper layer in this embodiment is 1:0.2, and the polyester layer, polyamide The thickness ratio of the imide layer, polyurethane layer and polyesterimide layer is 1:1:1:0.5.

Embodiment 3

[0025] Present embodiment figure is not drawn. This embodiment is similar in structure to Embodiment 1, and the structurally identical parts will not be repeated here. The difference is that the ratio of the radius of the aluminum core to the thickness of the copper layer in this embodiment is 1:0.4, and the polyester layer, polyamide The thickness ratio of the imide layer, polyurethane layer and polyesterimide layer is 1:1:1.1:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com