A kind of conductive polypropylene composite powder for selective laser sintering and its preparation method

A composite powder and laser sintering technology, which is applied in the field of 3D printing technology and plastic processing, to achieve the effects of preventing adhesion, good dispersion and fluidity, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

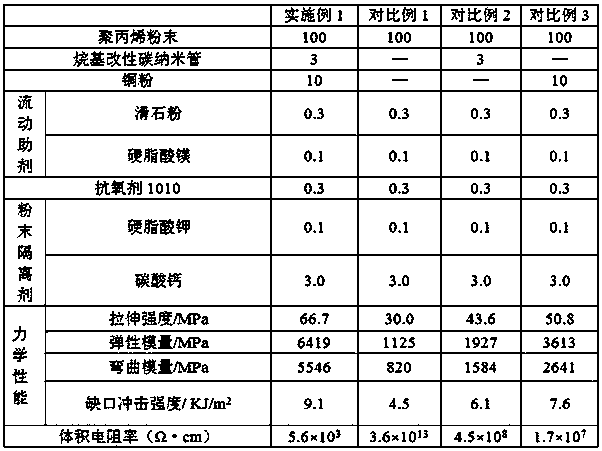

[0038] The conductive polypropylene composite powder for selective laser sintering of this embodiment is made of the following raw materials in parts by weight: polypropylene powder 100, alkyl modified carbon nanotubes 3, copper powder 10, flow aid (talc powder 0.3, magnesium stearate 0.4), antioxidant 1010 0.3 and powder release agent (magnesium stearate 0.1, calcium carbonate 3.0). The polypropylene powder is spherical / quasi-spherical, the particle size range is 20~100μm, and the particle size distribution is D10=45μm, D50=80μm, D90=110μm. The melt index of polypropylene powder is 49 g / 10min measured at 190°C under a load of 2.16kg; the copper powder is spherical / spherical, with a particle size range of 10-120 μm and a particle size distribution of D10=32 μm, D50=95 μm, D90=125μm.

[0039] The preparation method of the conductive polypropylene composite powder for selective laser sintering of the present embodiment is characterized in that it comprises the following steps: ...

Embodiment 2~6

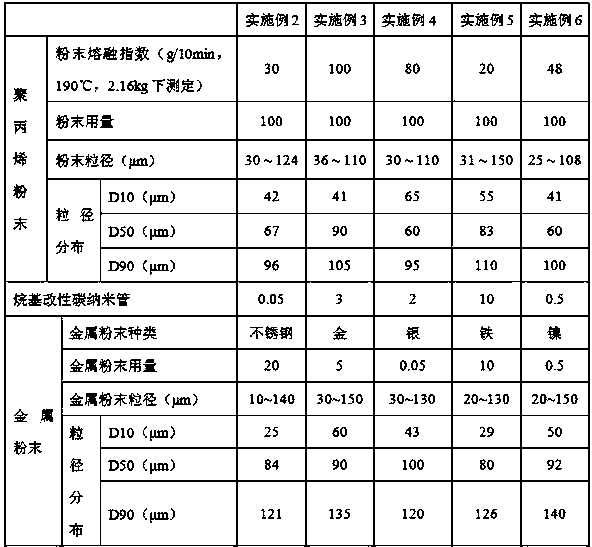

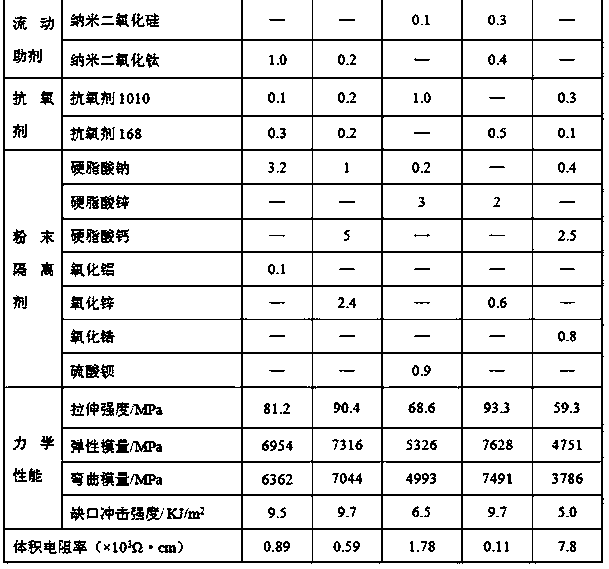

[0049] Table 2 shows the specific formulation of the conductive polypropylene composite powder for selective laser sintering prepared in Examples 2-6 and the test results of the mechanical properties and electrical conductivity of the sample formed by selective laser sintering. The preparation method of the conductive polypropylene composite powder for selective laser sintering in Examples 2-6 is the same as that in Example 1.

[0050] Table 2 Material formula (weight / part) and performance measurement results of Examples 2-6

[0051]

[0052]

[0053] It can be seen from Table 2 that the conductive polypropylene composite powder for selective laser sintering prepared within the scope of the components of the present invention has better mechanical properties and excellent electrical conductivity after selective laser sintering, which meets the electronic requirements. Or the requirements for polypropylene powder materials in the electrical field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com