Method for preparing novel flexible conductive fabric by using micro-sphere self-assembly technology

A self-assembly technology, flexible and conductive technology, applied in textiles and papermaking, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve the problems of limited bonding force between conductive polymers and fabrics, difficult weaving process, complicated preparation methods, etc. Achieve the effect of good moisture permeability and air permeability, light density and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

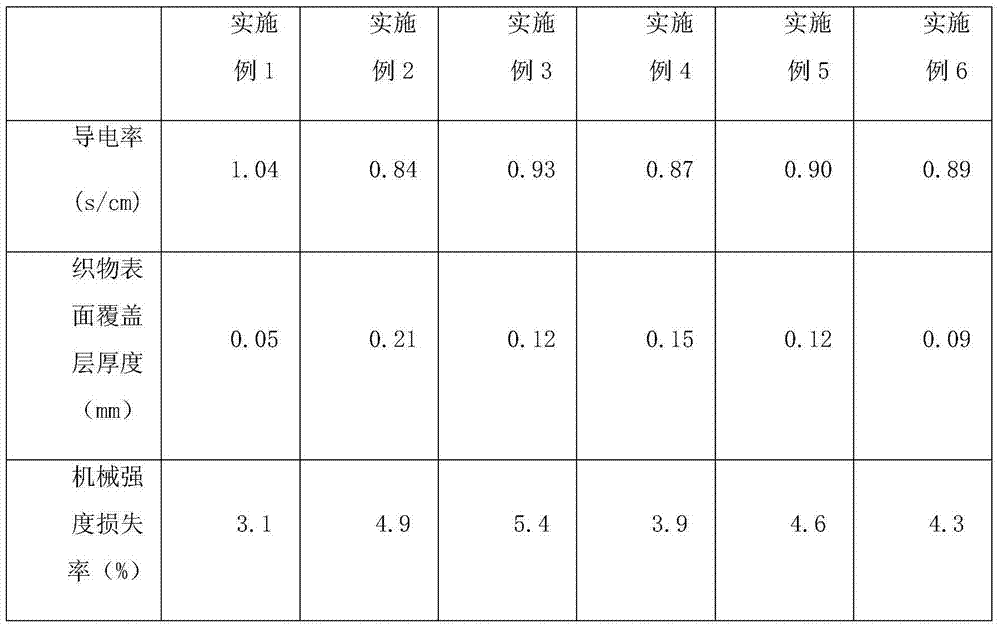

Embodiment 1

[0027] (1) Disperse the polyaniline composite hollow microspheres containing ferric oxide in distilled water containing 1.2% nonionic surfactant, magnetically stir for 50 minutes, and ultrasonically disperse for 15 minutes to obtain a microsphere suspension with a mass fraction of 0.1%. .

[0028] (2) After the fabric is cleaned, put it into a plasma processor for pretreatment, adjust the vacuum degree to 5Pa, use air as the gas atmosphere, and treat it at 100W for 5min, take it out, and use a concentration of 15g / L Polymer The sodium styrene sulfonate solution is sprayed on the surface of the fabric for 30 seconds, washed with water and dried to obtain a sulfonated fabric.

[0029] (3) Immerse the sulfonated fabric in the microsphere suspension at a bath ratio of 1:30, shake at a constant temperature at 25°C for 5 minutes, dry and solidify under an infrared lamp for 10 minutes, wash and dry, and obtain a weight gain of 0.1%. Novel flexible conductive fabrics based on microsp...

Embodiment 2

[0031] (1) Disperse polyaniline composite hollow microspheres containing ferric oxide in distilled water containing 3.5% nonionic surfactant, magnetically stir for 60 minutes, and ultrasonically disperse for 15 minutes to obtain a microsphere suspension with a mass fraction of 3%. .

[0032] (2) After the fabric is cleaned, put it into a plasma processor for pretreatment, adjust the vacuum degree to 5Pa, use air as the gas atmosphere, and treat it at 300W for 15min, take it out, and use a concentration of 15g / L Polymer The sodium styrene sulfonate solution is sprayed on the surface of the fabric for 60 seconds, washed with water and dried to obtain a sulfonated fabric.

[0033] (3) Immerse the sulfonated fabric in the microsphere suspension with a bath ratio of 1:40, shake it at a constant temperature for 10 minutes at 20°C, dry and solidify it under an infrared lamp for 15 minutes, wash and dry it with water, and the weight gain rate is 0.4%. Novel flexible conductive fabric...

Embodiment 3

[0035] (1) Disperse the polyaniline composite hollow microspheres containing ferric oxide in distilled water containing 1.5% nonionic surfactant, magnetically stir for 55 minutes, and ultrasonically disperse for 15 minutes to obtain a microsphere suspension with a mass fraction of 0.3% .

[0036] (2) After the fabric is cleaned, put it into a plasma processor for pretreatment, adjust the vacuum degree to 5Pa, use air as the gas atmosphere, and treat it at 150W for 10min, take it out, and use a concentration of 15g / L poly The sodium styrene sulfonate solution is sprayed on the surface of the fabric for 50 seconds, washed with water and dried to obtain a sulfonated fabric.

[0037] (3) Immerse the sulfonated fabric in the microsphere suspension with a bath ratio of 1:35, shake it at a constant temperature for 8 minutes at 23°C, dry and solidify it under an infrared lamp for 12 minutes, wash and dry it with water, and obtain a weight gain of 0.2%. Novel flexible conductive fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com