Flexible die and production method for manufacturing flexible printed circuit boards

A technology for flexible circuit boards and flexible molds, applied in chemical/electrolytic methods to remove conductive materials, printed circuit manufacturing, printed circuits, etc., can solve high costs, complicated flexible mold preparation processes, and increased production costs of flexible circuit boards. problem, to achieve the effect of reducing production cost, reducing graphic deformation, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The invention provides a method for preparing a flexible mold for making a flexible circuit board, which at least includes the following steps:

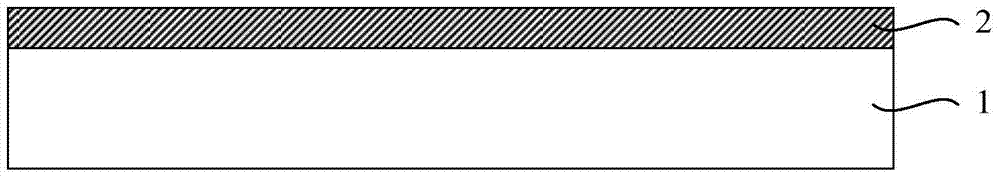

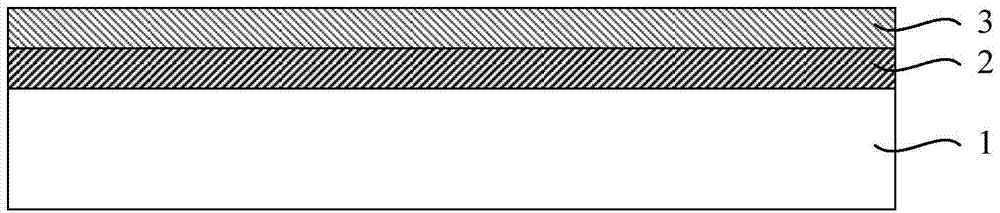

[0049] See first figure 1 , providing a flexible substrate 1 whose surface is covered with a metal layer 2 .

[0050]Specifically, the flexible substrate 1 includes but not limited to PI substrate, PTFE substrate or PET substrate. Among them, PI (Polyimid, polyimide) substrate is widely used in the field of flexible circuit boards, and is a traditional soft board material; PTFE (polytetrafluoroethylene, polytetrafluoroethylene film) has excellent performance in chemical corrosion resistance, and has excellent Flexibility; PET (Polyethylene terephthalate, polyethylene terephthalate) substrate is a highly transparent insulating material and is a common flexible substrate.

[0051] The material of the metal layer 2 includes but not limited to one or more of Au, Ag, Cu, Al, that is, the metal layer 2 can be a single metal or an ...

Embodiment 2

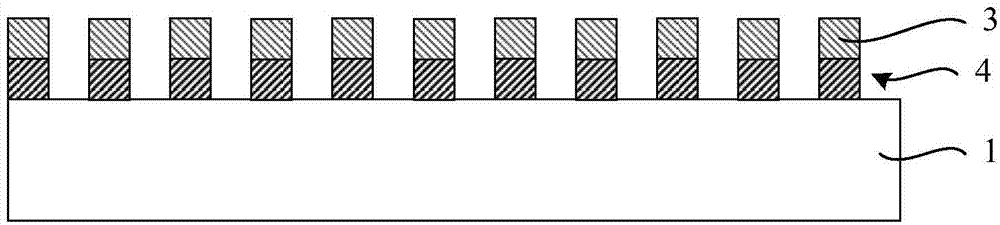

[0062] The present invention also provides a flexible mold for making flexible circuit boards, please refer to Figure 4 , the flexible mold includes a flexible substrate 1 and a metal circuit pattern 4 sequentially from bottom to top.

[0063] Specifically, the flexible substrate includes but not limited to PI substrate, PTFE substrate or PET substrate, and the material of the metal circuit pattern includes but not limited to one or more of Au, Ag, Cu, Al.

[0064] In this embodiment, the flexible substrate 1 is preferably a PI substrate, and the material of the metal circuit pattern 4 is preferably Cu. The line width range of the metal circuit pattern 4 is 20-800 μm, which can meet the requirement of making highly integrated flexible circuit boards.

[0065] In another embodiment, the bottom of the gap of the metal circuit pattern 4 does not reach the flexible substrate 1, such as Figure 5 shown. Since the bottom of the metal circuit is still connected by metal, it can e...

Embodiment 3

[0069] The method that adopts flexible mold of the present invention to make flexible circuit board is as follows:

[0070] See first Figure 6 , providing a flexible substrate. It should be pointed out that at least one of the flexible substrate 1 used in the flexible mold and the flexible substrate must have high transparency, so as to facilitate the penetration of ultraviolet light in the subsequent ultraviolet curing process. In this embodiment, it is preferable to use a flexible mold in which the flexible substrate 1 is a PI substrate and the metal circuit pattern 4 is Cu. Since the transparency of the PI substrate is not high, the flexible substrate takes the highly transparent PET film 5 as an example.

[0071] see next Figure 7 , coating a layer of UV glue 6 on the surface of the PET film 5 .

[0072] then see Figure 8 , align and contact the flexible mold with the PET film 5 coated with UV glue 6 on the surface, and then form the UV glue in the embossed area th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com