Conductive treatment method for inlet groove mould surface of slush moulding mould

A processing method and technology for slotting molds, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of complex conductive process and poor conductive effect, and achieve good conductivity, low cost, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

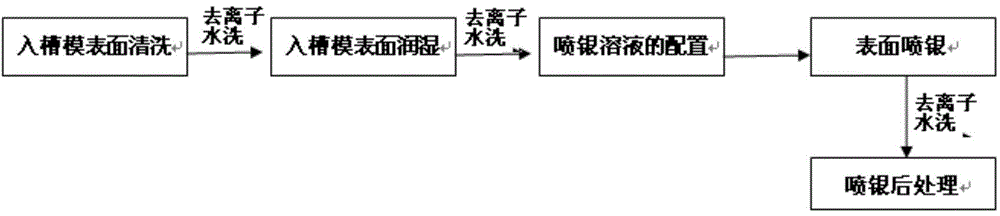

Method used

Image

Examples

Embodiment 1

[0025] First, spray the deionized aqueous solution (30g / l, solution temperature: 30℃) of the prepared washing powder evenly on the surface of the resin model with a spray gun, clean the slush mold into the slot mold, and then spray the deionized water with the spray gun to rinse the residual Cleaning solution, the temperature of deionized water is 23°C;

[0026] Next, spray a wetting solution (30°C) on the cleaned surface. The mixed solution of deisopropanol and hydrophilic treatment agent HYDRO310 is the wetting solution. After staying for 1 minute, spray deionized water with a spray gun to clean the residual wetting solution. The temperature of deionized water is 23°C;

[0027] Again, the silver ammonia solution A (silver nitrate 5g / l) that has been configured and reducing agent B liquid are simultaneously sprayed onto the surface of the groove mold after wetting with a double-headed spray gun to form a bright and dense silver layer. The spray gun pressure is 0.5 Mpa, the d...

Embodiment 2

[0029] First, spray the deionized aqueous solution (32g / l, solution temperature: 30℃) of the prepared washing powder evenly on the surface of the resin model with a spray gun, clean the slush mold into the slot mold, and then spray the deionized water with the spray gun to rinse the residual Cleaning solution, the temperature of deionized water is 23°C;

[0030] Secondly, spray wetting solution (30°C) on the cleaned surface, the mixed solution of deisopropanol and hydrophilic treatment agent HYDRO310 is the wetting solution, after staying for 2 minutes, spray deionized water with a spray gun to clean the residual wetting solution, The temperature of deionized water is 23°C;

[0031] Once again, the configured silver ammonia solution A (silver nitrate 7g / l) and reducing agent B liquid are sprayed onto the surface of the grooved mold after wetting simultaneously with a double-headed spray gun to form a bright, dense silver layer. The spray gun pressure is 0.5Mpa, the distance i...

Embodiment 3

[0033] First, spray the deionized aqueous solution (35g / l, solution temperature: 30°C) of the prepared washing powder evenly on the surface of the resin model with a spray gun, clean the slush mold into the slot mold, and then spray the deionized water with the spray gun to rinse the residual Cleaning solution, the temperature of deionized water is 23°C;

[0034] Next, spray a wetting solution (32°C) on the cleaned surface. The mixed solution of deisopropanol and hydrophilic treatment agent HYDRO310 is the wetting solution. After staying for 3 minutes, spray deionized water with a spray gun to clean the residual wetting solution. The temperature of deionized water is 23°C;

[0035] Once again, the configured silver ammonia solution A (silver nitrate 10g / l) and reducing agent B liquid are sprayed onto the surface of the grooved mold after wetting simultaneously with a double-headed spray gun to form a bright, dense silver layer. The spray gun pressure is 0.5Mpa, the distance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com