Preparation method of novel conductive silver adhesive with high heat conductivity coefficient and conductive silver adhesive

A technology of conductive silver glue and high thermal conductivity, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of high-performance conductive fields, high void ratio, poor conductivity of conductive particles, etc., and achieve effective Reliable heat conduction network, simple operation process, complete and continuous silver layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

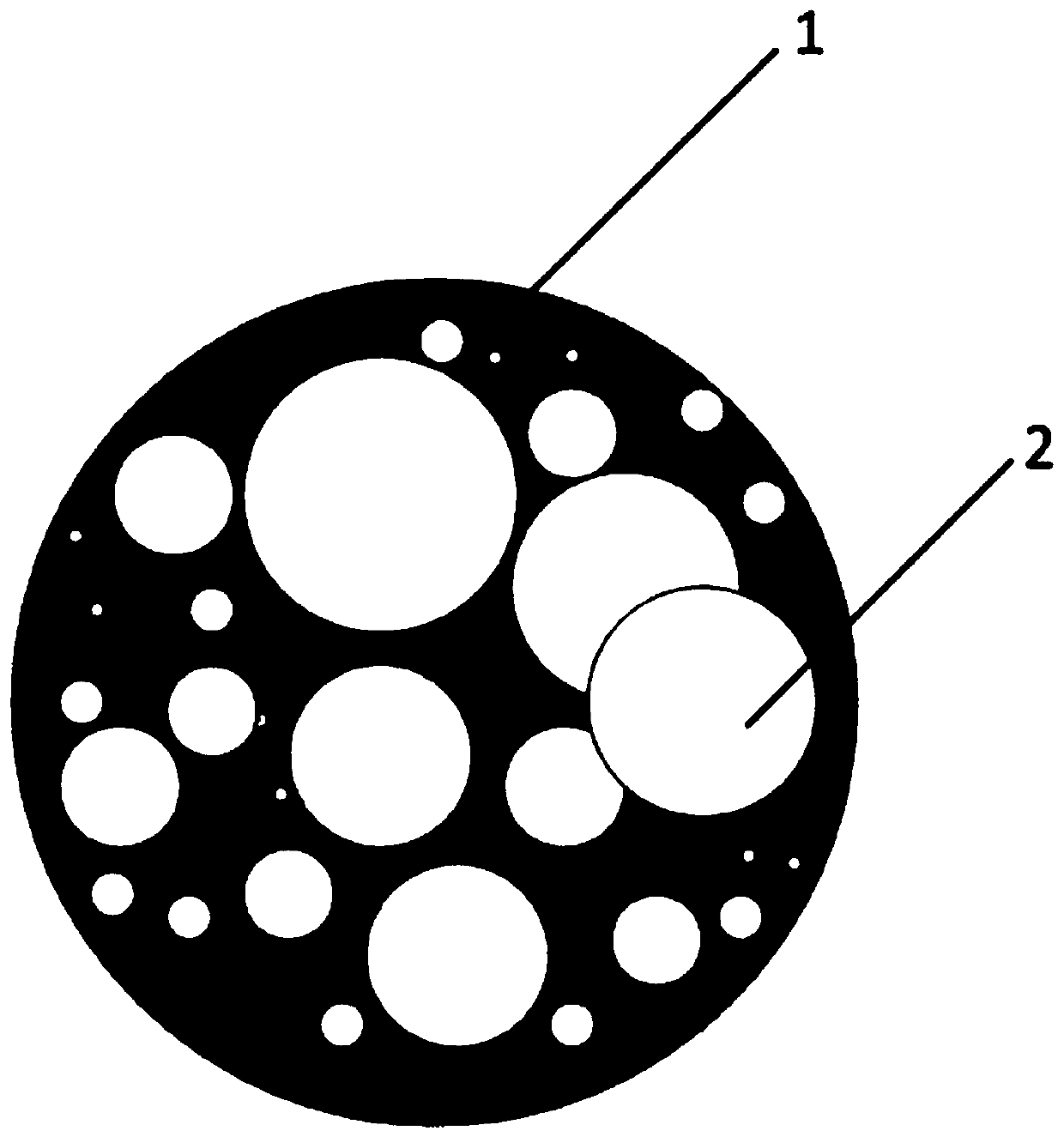

Image

Examples

preparation example Construction

[0031] The preparation method of high thermal conductivity novel conductive silver glue of the present invention comprises the steps:

[0032] S1, preparing silver-coated microbeads by silver-plating on the surface of hollow heat-conducting microbeads;

[0033] S2, preparing the silver-coated microbeads as component A;

[0034] S3, preparing component B;

[0035] S4, adding the component A to the component B, vacuum defoaming and mixing to form a mixed product;

[0036] S5, vacuum filling the mixed product to obtain conductive silver glue.

[0037] Specifically, the preparation method of the silver-coated microbeads described in the step S1 is:

[0038] S11, to remove impurities, add hollow heat-conducting microbeads and deionized water to a high-speed mixer at room temperature and stir for 5min to 15min at a speed of 200r / min to 400r / min. 3 times, then dry at 150°C for 1h to 2h for use;

[0039] S12, pretreatment, the hollow heat-conducting microbeads are mixed with an a...

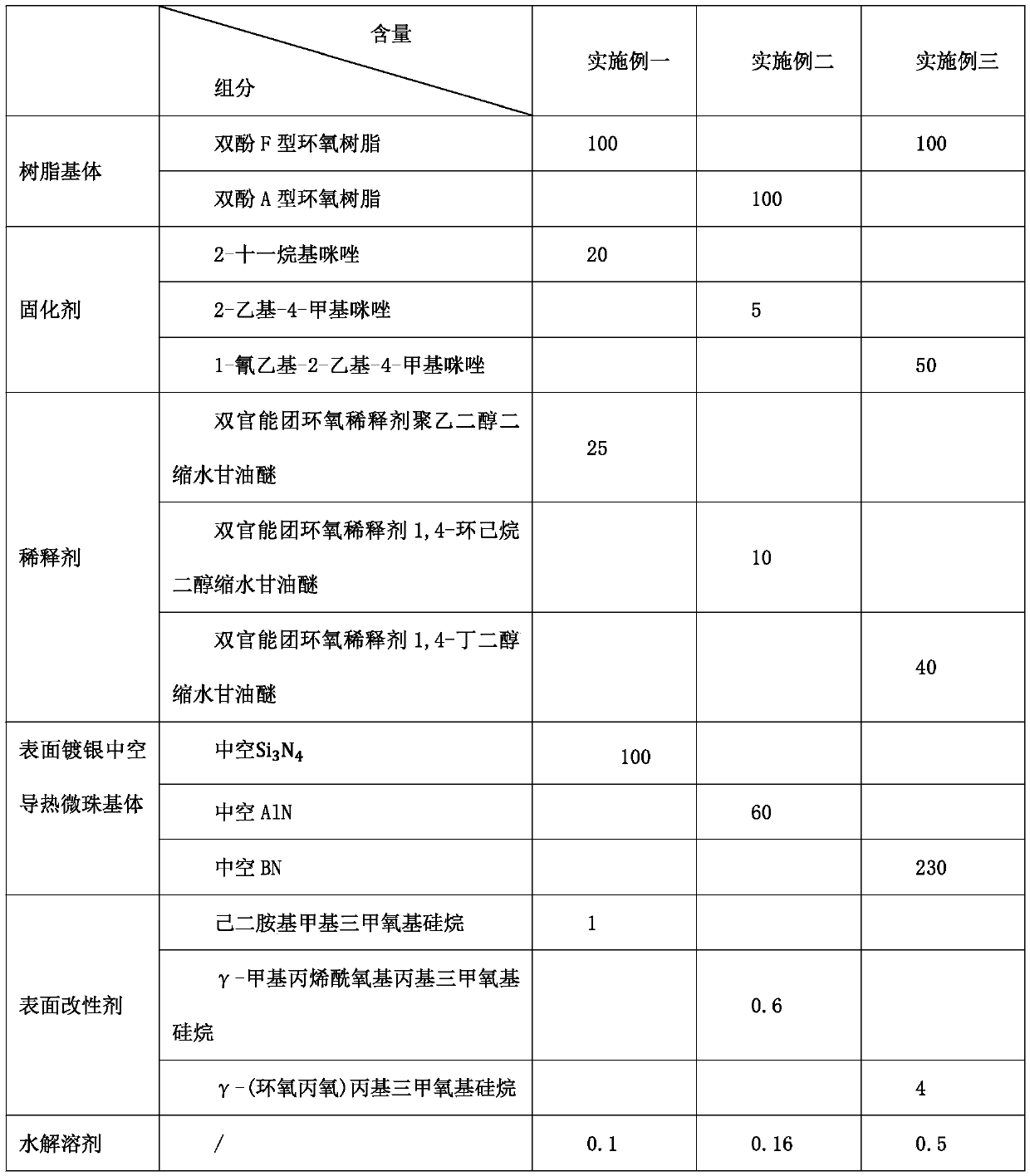

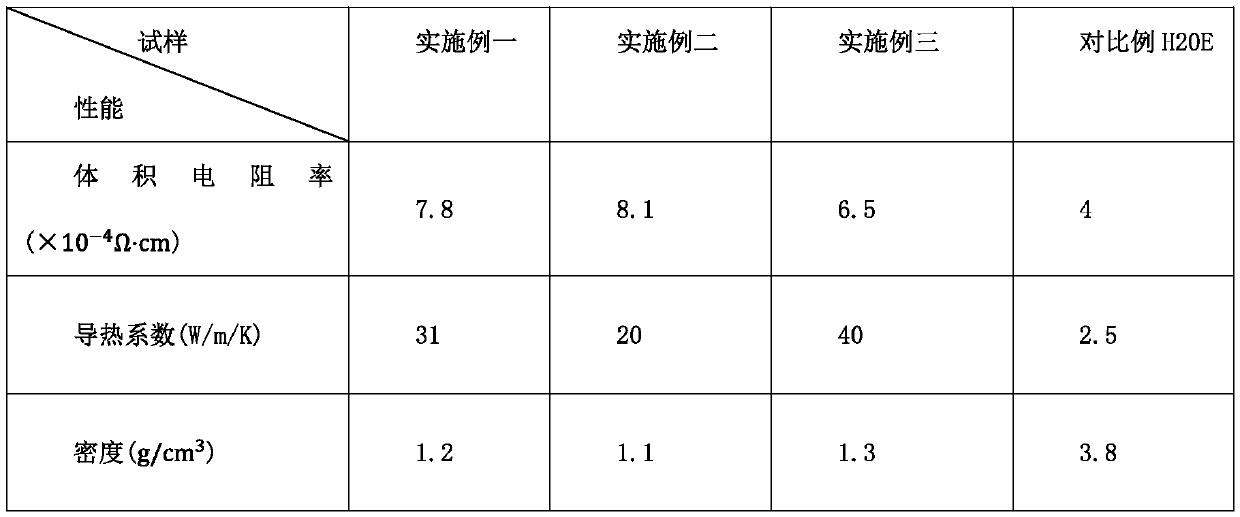

Embodiment 1

[0057] At room temperature the hollow Si 3 N 4 Add the microspheres and deionized water to a high-speed mixer and stir for 5 minutes at a speed of 400r / min. After stopping, pass through a 400-mesh sieve. The impurity removal process is repeated 3 times, and then dried at 150°C for 1 hour. Through alkaline washing solvent, the hollow Si 3 N 4 The microspheres were stirred in a high-speed mixer for 25 minutes at a speed of 200 r / min, and rinsed with deionized water. The pretreated hollow Si 3 N 4 The microspheres were placed on the sample holder, and the air pressure in the vacuum chamber was pumped to 10 -3 Pa level, the argon gas flow rate is 8 sccm, the sputtering power is 150W, the sputtering time is 90min, and the sample temperature is controlled at 150°C.

[0058] According to the components specified in Example 1 in Table 1, first add a hydrolysis solvent to the surface modifier hexamethylenediaminomethyltrimethoxysilane, stir evenly, and mix with the above-mentione...

Embodiment 2

[0060] Add the hollow AlN microspheres and deionized water into a high-speed mixer at room temperature and stir for 10 minutes at a speed of 300 r / min. After stopping, pass through a 400-mesh sieve, and then dry at 150°C for 1.5 hours. The hollow AlN microspheres were stirred in a high-speed mixer for 10 min with an alkali washing solvent at a speed of 400 r / min, and rinsed with deionized water. Put the pretreated hollow AlN microspheres on the sample holder, and pump the air pressure in the vacuum chamber to 10 -3 Pa level, the argon gas flow rate is 10 sccm, the sputtering power is 250W, the sputtering time is 60min, and the sample temperature is controlled at 150°C.

[0061] According to the components specified in Example 2 in Table 1, first add a hydrolysis solvent to the surface modifier γ-methacryloxypropyl trimethoxysilane, stir evenly, and mix with the above-mentioned hollow AlN after silver plating Put the microspheres together into a high-shear stirring tank, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com