A method for treating antirust paint layer of steel aviation parts with glass pellets

A technology of aviation parts and glass pellets, which is applied in the direction of pretreatment surface, coating, and liquid coating device on the surface, etc. It can solve the problems of large production deformation, reduce the deformation of parts, improve the bonding force, and improve the appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

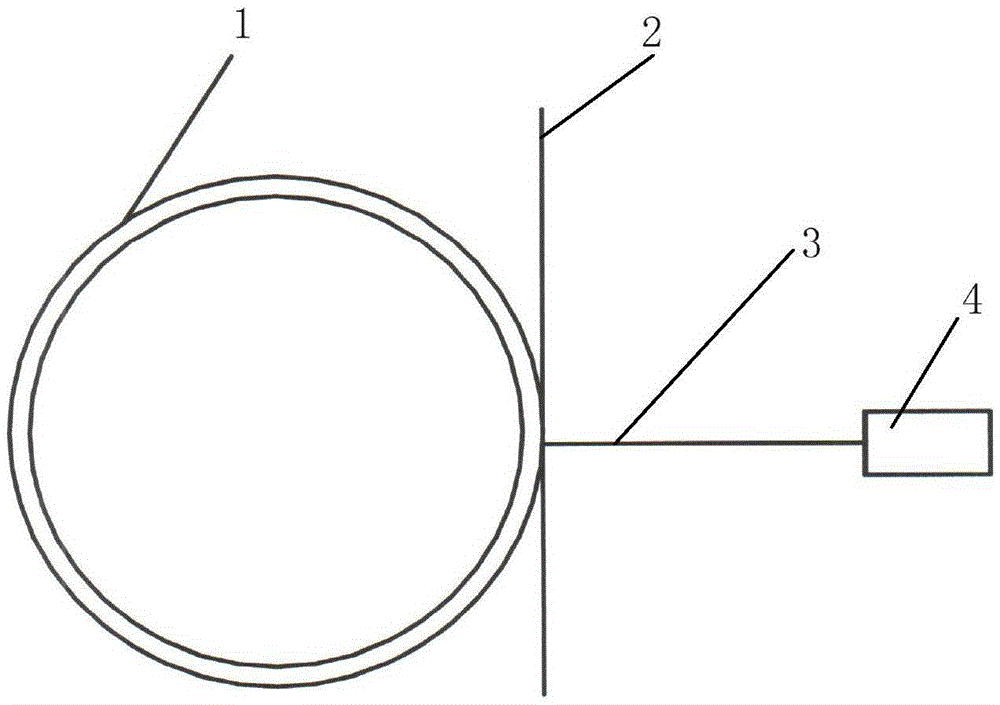

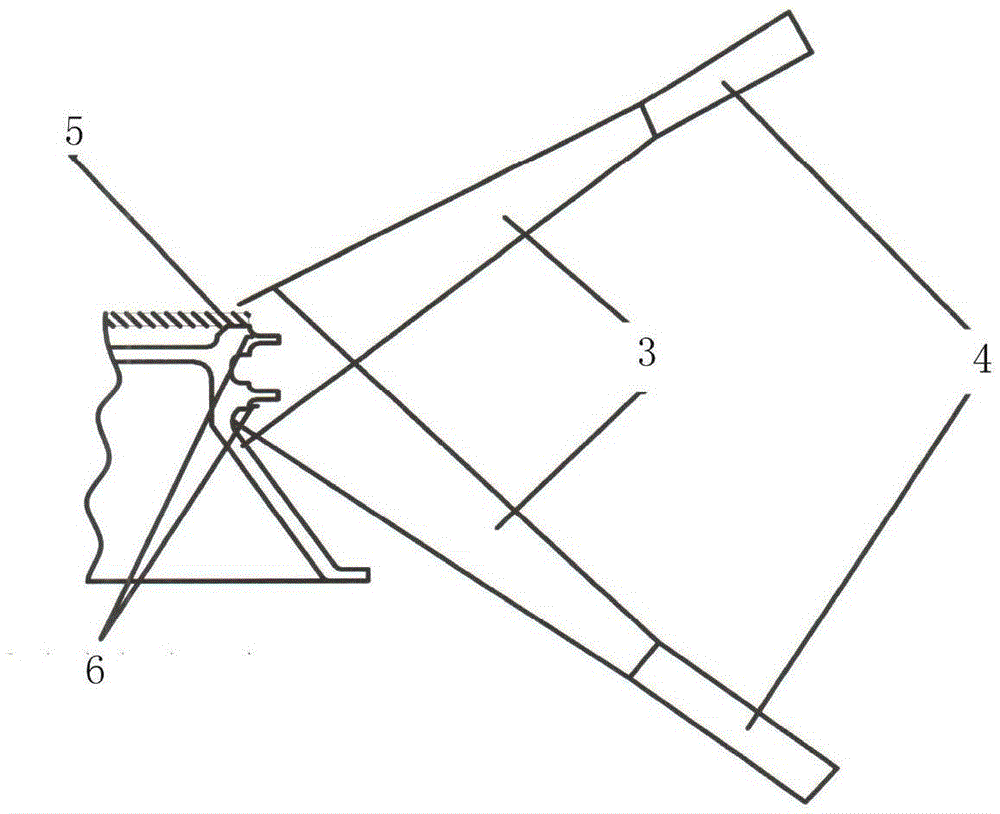

[0022] Example: such as figure 1 Shown, the present invention is used for typical part spraying treatment, and process step is:

[0023] Surface preparation--non-painted surface protection--sand blowing--painting--baking and curing--intermediate inspection and rework--glass shot treatment--final characteristic inspection, the details are as follows:

[0024] (1) Surface preparation process: use alkaline detergent (741) to remove oil, check the continuity of the water film after immersion for 15-20 minutes, and dry it with water-free and oil-free compressed air; for local slight pollution, acetone or alcohol is allowed Wipe to remove oil and remove pollutants on the surface of parts; put 120-220 mesh alumina sand particles into special equipment for dry blasting treatment. When blowing sand, the air pressure is 0.2-0.55MPa, and the distance from the nozzle to the part is 100-200mm;

[0025] (2) Non-painted surface protection process: Protect the area that does not need to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com