Electroconductive thermoplastic elastomer composition as well as preparation method and applications thereof

A thermoplastic elastomer and composition technology, applied in the field of conductive thermoplastic elastomer composition, SEBS thermoplastic elastomer, can solve the problems that cannot be separated into shapes, cannot be used for normal conduction, and do not meet environmental protection requirements, etc., to achieve good conduction performance, good anti-blocking, uniform conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The thermoplastic elastomer composition in the present embodiment comprises the raw material blending of following component and weight ratio: 30 parts of oil-extended SEBS elastomers, 10 parts of PP powders, 20 parts of conductive carbon blacks, 3 parts of carbon black dispersants , 3 parts of anti-blocking agent, 0.5 part of antioxidant, 0.5 part of PE wax; wherein the oil-extended SEBS elastomer is formed by blending SEBS elastomer and naphthenic system filler oil in a weight ratio of 1 to 3; The antioxidant is hindered phenolic antioxidant irganox1010 or irganox1076 or irganox1790; the carbon black dispersant is a polyol ester compound polymer, and the specific optional grade is sup1400 or epl-3; the anti-adhesive agent is The siloxane polymer with ultra-high molecular weight can be specifically selected as sf-1 or mb50-002.

[0039] Specifically prepared by the following steps:

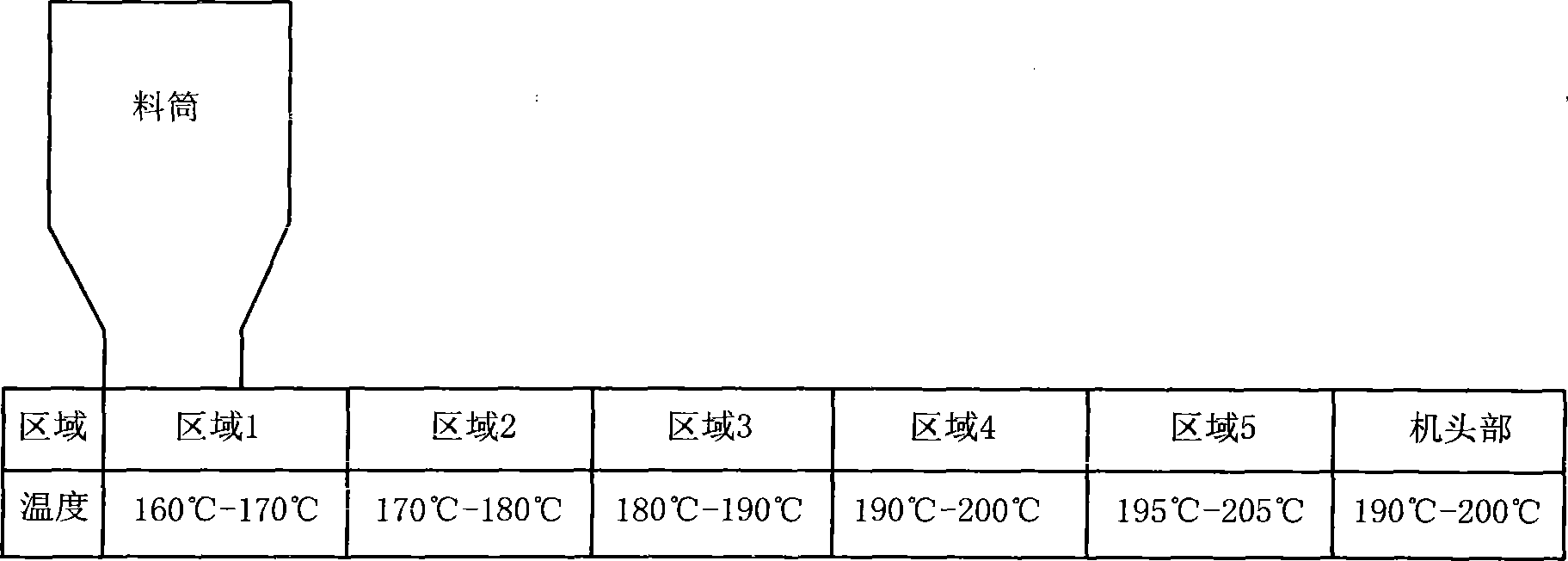

[0040] a. Calculate the required weight of each component according to the weight rat...

Embodiment 2

[0046]The thermoplastic elastomer composition in the present embodiment comprises the raw material blending of following component and weight ratio: 40 parts of oil-extended SEBS elastomers, 18 parts of PP powders, 32 parts of conductive carbon blacks, 4 parts of carbon black dispersants , 4 parts of anti-adhesion agent, 1 part of antioxidant, 1 part of PE wax. Same as Example 1, wherein the oil-extended SEBS elastomer is formed by blending SEBS elastomer and naphthenic-based extender oil in a weight ratio of 1 to 3; wherein the antioxidant is hindered phenolic antioxidant irganox1010 or irganox1076 or irganox1790; the carbon black dispersant is a polyol ester compound polymer, and the specific optional grade is sup1400 or epl-3; the anti-blocking agent is a siloxane polymer with ultra-high molecular weight, specifically Available grades are sf-1 or mb50-002. Its preparation method and application also refer to Example 1. This embodiment is the preferred solution. The thermo...

Embodiment 3

[0048] The thermoplastic elastomer composition in the present embodiment comprises the raw material blending of following component and weight ratio: 50 parts of oil-extended SEBS elastomers, 20 parts of PP powders, 45 parts of conductive carbon blacks, 5 parts of carbon black dispersants , 5 parts of anti-adhesion agent, 2 parts of antioxidant, 2 parts of PE wax. Others are the same as the above-mentioned embodiment. The anti-pinch sensor strip for electric sliding doors of automobiles using the thermoplastic elastomer composition in this embodiment can also meet the above-mentioned index requirements after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com