Automobile drive shaft assembly

A transmission shaft and assembly technology, applied in the field of automobile transmission shaft assembly, can solve the problems of low transmission efficiency, poor sealing, low limit speed, etc., and achieve the effects of extending service life, high bearing capacity and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation will be described in detail below in conjunction with the drawings:

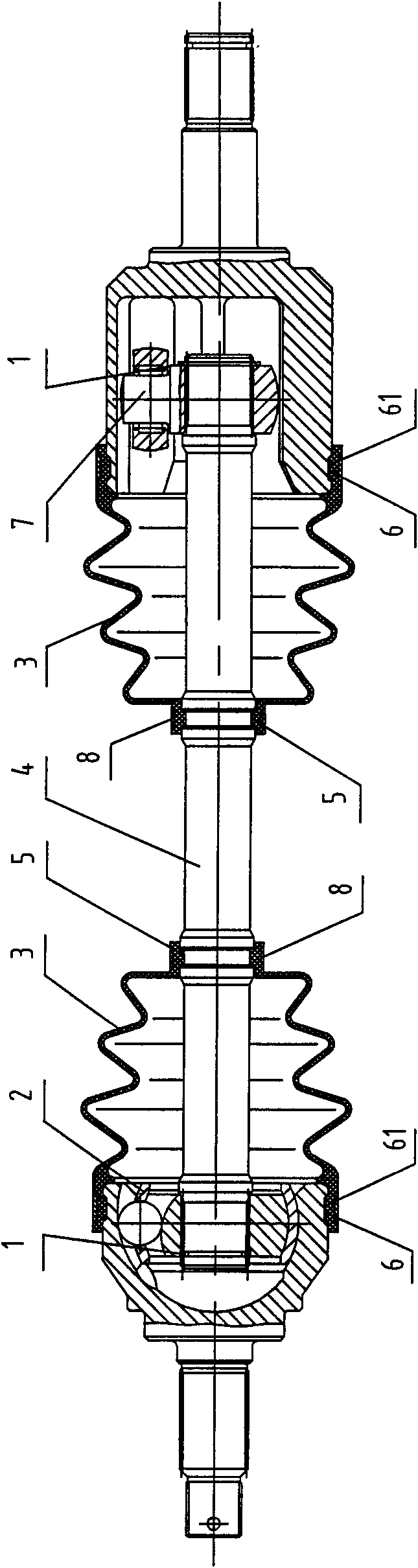

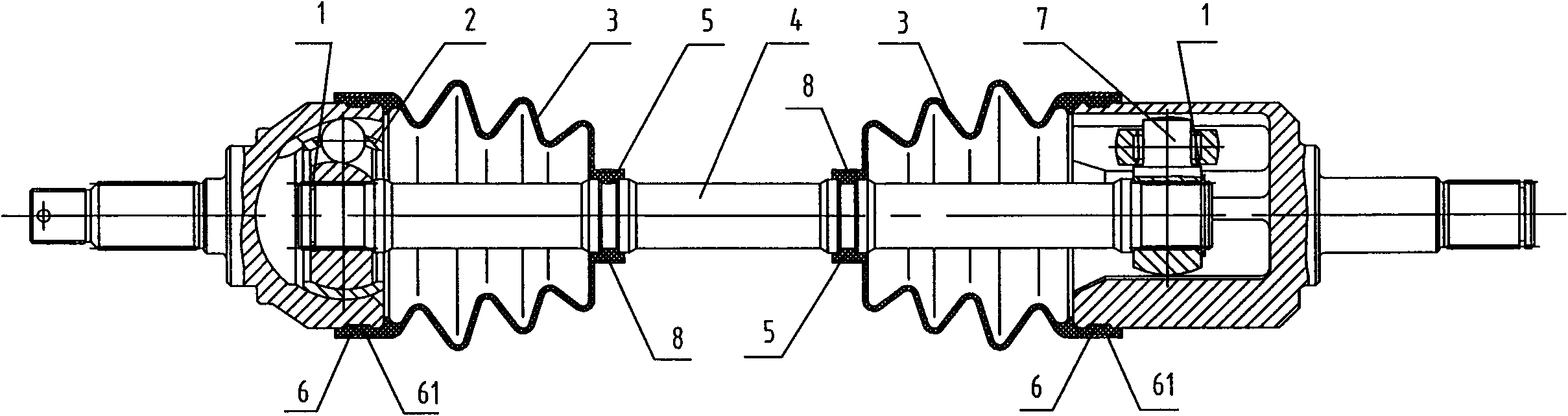

[0011] in figure 1 In an embodiment of the present invention shown, a ball cage and joint bearing combined universal joint drive shaft assembly includes a seven-channel ball cage universal joint 2, a three ball pin constant velocity universal joint 7, There is also a transmission shaft 4 with splines at both ends, an elastic retaining ring 1, a dust cover 3, and a clamp 5. The star sleeve of the seven-channel ball cage universal joint 2 is installed on the outer spline at one end of the transmission shaft 4 through an inner spline and is axially fixed by an elastic retaining ring 1. The three-pin frame of the three-ball-pin type constant velocity universal joint 7 is installed on the external spline at one end of the transmission shaft 4 through the internal spline and is axially fixed by the elastic retaining ring 1. A dust cover 3 and a clamp 5 are provided at the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com