Graphene composite conductive coating as well as preparation method and application thereof

A graphene composite and conductive coating technology, which is applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high cost, difficulty in uniform dispersion, and large intermolecular force, and achieve stable and low electrical conductivity. Cost, effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

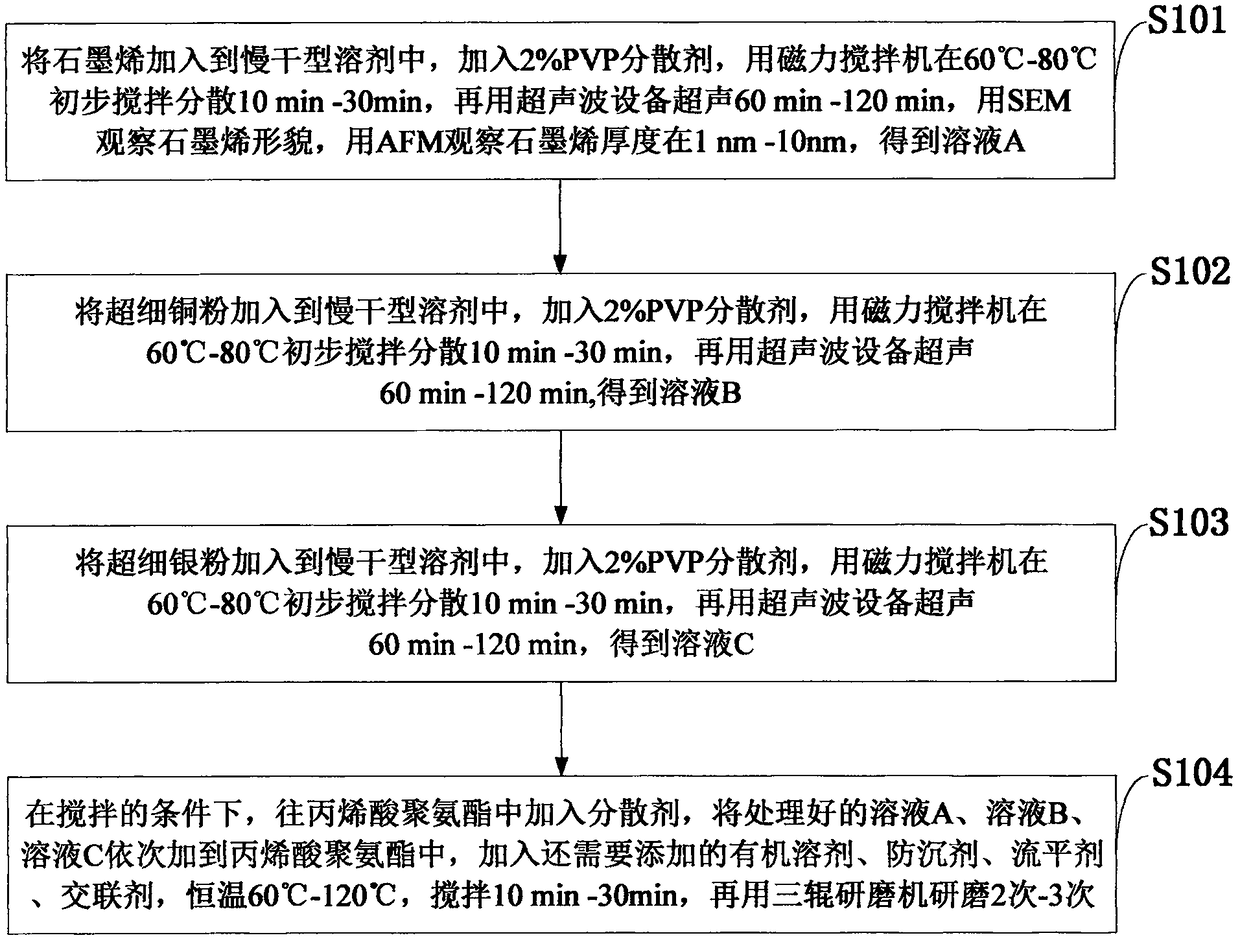

[0036] Such as figure 1As shown, the preparation method of the graphene composite conductive coating provided by the embodiments of the present invention comprises the following steps:

[0037] S101: Add graphene to the slow-drying solvent, add 2% PVP dispersant, use a magnetic stirrer to disperse initially at 60°C-80°C for 10min-30min, then use ultrasonic equipment for 60min-120min, observe graphene with SEM Morphology, using AFM to observe the thickness of graphene at 1nm-10nm, to obtain solution A;

[0038] S102: Add the ultra-fine copper powder into the slow-drying solvent, add 2% PVP dispersant, and use a magnetic stirrer to stir and disperse at 60°C-80°C for 10min-30min, and then use ultrasonic equipment for 60min-120min to obtain solution B ;

[0039] S103: Add the ultra-fine silver powder into the slow-drying solvent, add 2% PVP dispersant, and use a magnetic stirrer to initially stir and disperse at 60°C-80°C for 10min-30min, and then use ultrasonic equipment for 60...

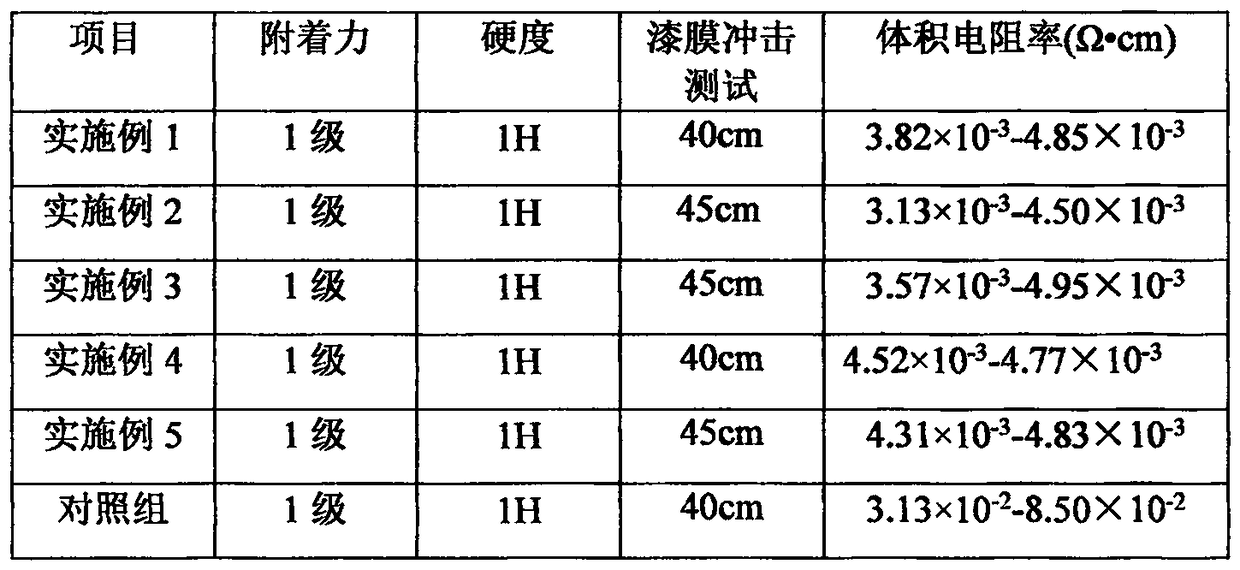

Embodiment 1

[0043] The graphene composite conductive coating provided by the embodiment of the present invention is mainly prepared from the following raw materials: 5-80% resin, 1% graphene, 5% ultra-fine copper powder, 7.2% ultra-fine silver powder, and 0.55%-0.8% dispersant , Fast-drying organic solvent: slow-drying organic solvent (3:2, adjust the ratio according to needs), anti-settling agent 0.3-1%, leveling agent 0.3-1%, cross-linking agent 0.1-1%, etc.

[0044] The preparation method of the graphene composite conductive coating that the embodiment of the present invention provides comprises the following steps:

[0045] (1) Add graphene to the slow-drying solvent, add PVP dispersant, and use a magnetic stirrer to stir and disperse at 60-80°C for 10 minutes, then use ultrasonic equipment for 60-120 minutes, and observe the graphene morphology with SEM. The thickness of graphene was observed at 1-2nm by AFM, and solution A was obtained.

[0046] (2) Add the ultra-fine copper powder...

Embodiment 2

[0050] The graphene composite conductive coating provided by the embodiment of the present invention is mainly prepared from the following raw materials: 5-80% resin, 1.5% graphene, 5 ultra-fine copper powder, 7.2% ultra-fine silver, and 0.55%-0.8% dispersant , Fast-drying organic solvent: slow-drying organic solvent (3:2, adjust the ratio according to needs), anti-settling agent 0.3-1%, leveling agent 0.3-1%, cross-linking agent 0.1-1%, etc.

[0051] The preparation method of the graphene composite conductive coating that the embodiment of the present invention provides comprises the following steps:

[0052] (1) Add graphene to the slow-drying solvent, add PVP dispersant, and use a magnetic stirrer to stir and disperse at 60-80°C for 10 minutes, then use ultrasonic equipment for 60-120 minutes, and observe the graphene morphology with SEM. The thickness of graphene was observed by AFM at 1-2m, and solution A was obtained.

[0053] (2) Add the ultra-fine copper powder into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com