All-solid-state lithium-air battery composite positive electrode material and all-solid-state lithium-air battery

A composite positive electrode material and air battery technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve the problems of large battery polarization, poor cycle performance, and low safety performance , to achieve large specific surface area, strong adsorption capacity, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A composite positive electrode sheet was prepared, and a polymer electrolyte of MIL-53 (Al), polyethylene oxide (PEO), and lithium bistrifluoromethanesulfonimide (LiTFSI) was prepared.

[0034] Preparation of composite positive electrode sheet: Weigh 0.03g of LiI, 0.15g of PEO, 0.03g of carbon nanotube (CNT) and 0.03g of MIL-53(Al), add 9g of acetonitrile to it, stir well to make it uniform, and then The solvent was volatilized for 6 hours, and then volatilized at 80° C. for 24 hours, cut into sheets with a thickness of 60 μm and a mass of 0.005 g to obtain a composite positive electrode sheet.

[0035]Preparation of solid electrolyte membrane: Dissolve 0.08g of MIL-53(Al) and 0.23g of LiTFSI in 9mL of acetonitrile, stir for 2h, add 0.4g of PEO, stir for 24h, evaporate the solvent at room temperature for 6h, and then After volatilization for 24 hours, a polymer electrolyte membrane with a thickness of 150 μm was obtained.

[0036] The prepared composite positive electr...

Embodiment 2

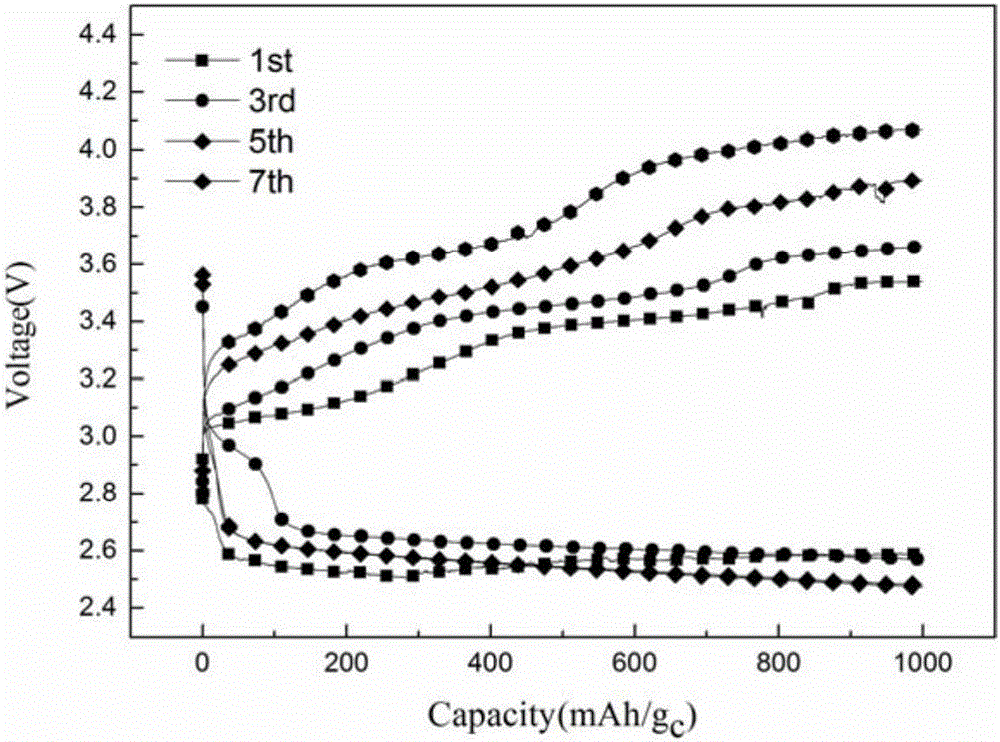

[0038] Prepare the same composite positive electrode sheet and polymer electrolyte as in Example 1, and assemble it into an all-solid lithium-air battery. At 70°C, the current density is 150mA / g c , the cut-off capacity is 1000mA / g c Under the conditions of the test, the voltage difference of the first cycle is 0.7V, and the charge-discharge voltage difference after 5 cycles is 1.3V. Specific cycle test data such as figure 2 shown.

Embodiment 3

[0040] Composite positive electrode sheets were prepared, and polymer electrolyte membranes of MIL-53 (Al), polyethylene oxide (PEO), and lithium bistrifluoromethanesulfonimide (LiTFSI) were prepared (according to the method in Example 1).

[0041] Preparation of composite positive electrode sheet: Weigh 0.03g of LiTFSI, 0.15g of PEO, 0.06g of carbon nanotube (CNT) and 0.03g of MIL-53(Al), add 9g of acetonitrile to it, stir well to make it uniform, and then The solvent was volatilized for 6 hours, and then volatilized at 80° C. for 24 hours, cut into sheets with a thickness of 60 μm and a mass of 0.005 g to obtain a composite positive electrode sheet.

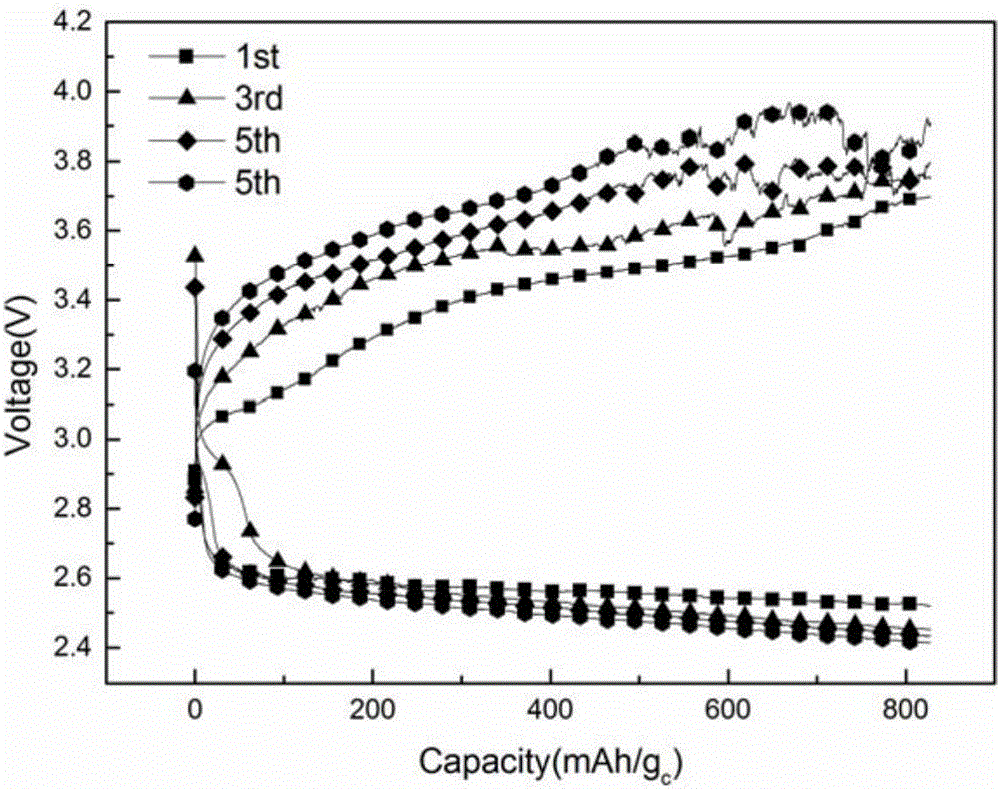

[0042] The prepared composite positive electrode sheet, polymer electrolyte membrane and lithium sheet were assembled into a button battery, and the current density was 150mA / g at 80°C c , the cut-off capacity is 1000mA / g c Under the conditions of constant current charge and discharge test. The voltage difference of the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com