A method for manufacturing a large-area zinc oxide nano-micro generator

A manufacturing method and large-area technology, applied in the manufacturing/assembly of piezoelectric/electrostrictive devices, circuits, electrical components, etc., can solve the problems of expensive equipment and small deposition area, and achieve low cost and large film-forming area. , The effect of large-area controllable production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

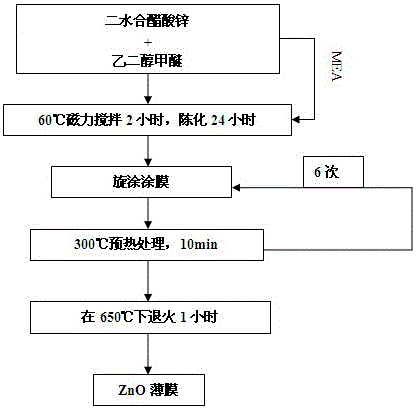

[0040] Example 1 Preparation of large-area ZnO thin films by sol-gel method

[0041] The preparation of large-area ZnO thin films by sol-gel method comprises the following steps:

[0042] 1) Preparation of sol solution: Mix 3.8412g zinc acetate dihydrate with 50ml ethylene glycol methyl ether to obtain a 0.35mol / L zinc acetate dihydrate ethylene glycol methyl ether solution, then add 1.4ml ethanolamine, and use magnetic The stirrer was fully stirred for 2 hours under the condition of 60°C water bath, and the solution was colorless and transparent. Aging at room temperature for 24 hours to obtain a sol solution;

[0043] 2) Cleaning of the substrate: Clean the 6-inch Si silicon wafer with an acetone solution in an ultrasonic cleaner for 30 minutes, then use ethanol for 30 minutes, then deionized water for 15 minutes, and then use HF: deionized water = 1:10 (volume than) the prepared dilute hydrofluoric acid solution to soak the substrate for 10 minutes, rinse it with deionize...

Embodiment 2

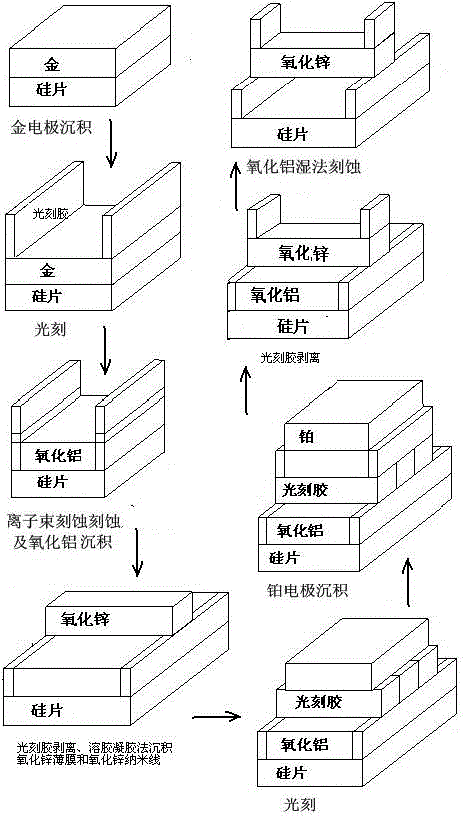

[0051] Embodiment 2 The manufacturing method of large-area ZnO nano-micro generator is characterized in that it comprises the following steps:

[0052] Step 1. Deposit Au electrodes on the cleaned 6-inch Si (100) substrate by electron beam evaporation deposition method; set the rate to 3 angstroms per second, select the high voltage as 600V, set the current to 300-350mA, and power to 180 watts ;

[0053] The second step is to spin coat the photoresist, and spin the Suzhou Ruihong RZJ-304 positive photoresist on the homogenizer at a low speed of 500rpm for 5s, and a high speed of 3000rpm for 30s. Using an ABM lithography machine to expose for 8s, the light intensity is 15mw / cm 2 ;The development time of photoresist depends on the development effect, and the development time depends on the development effect, generally between 8-15 seconds, forming a side wall structure in the Y direction;

[0054] In the third step, the Au without photoresist protection is etched away by ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com