Method and device for preparing rare earth doped gallium nitride light-emitting film

A technology of rare earth doping and luminescent thin film, which is applied in the direction of vacuum evaporation plating, metal material coating process, coating, etc., can solve the problems of unsuitable application fields, expensive equipment and operating costs, etc., and achieve no damage to the doping process, Strong adhesion and high growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

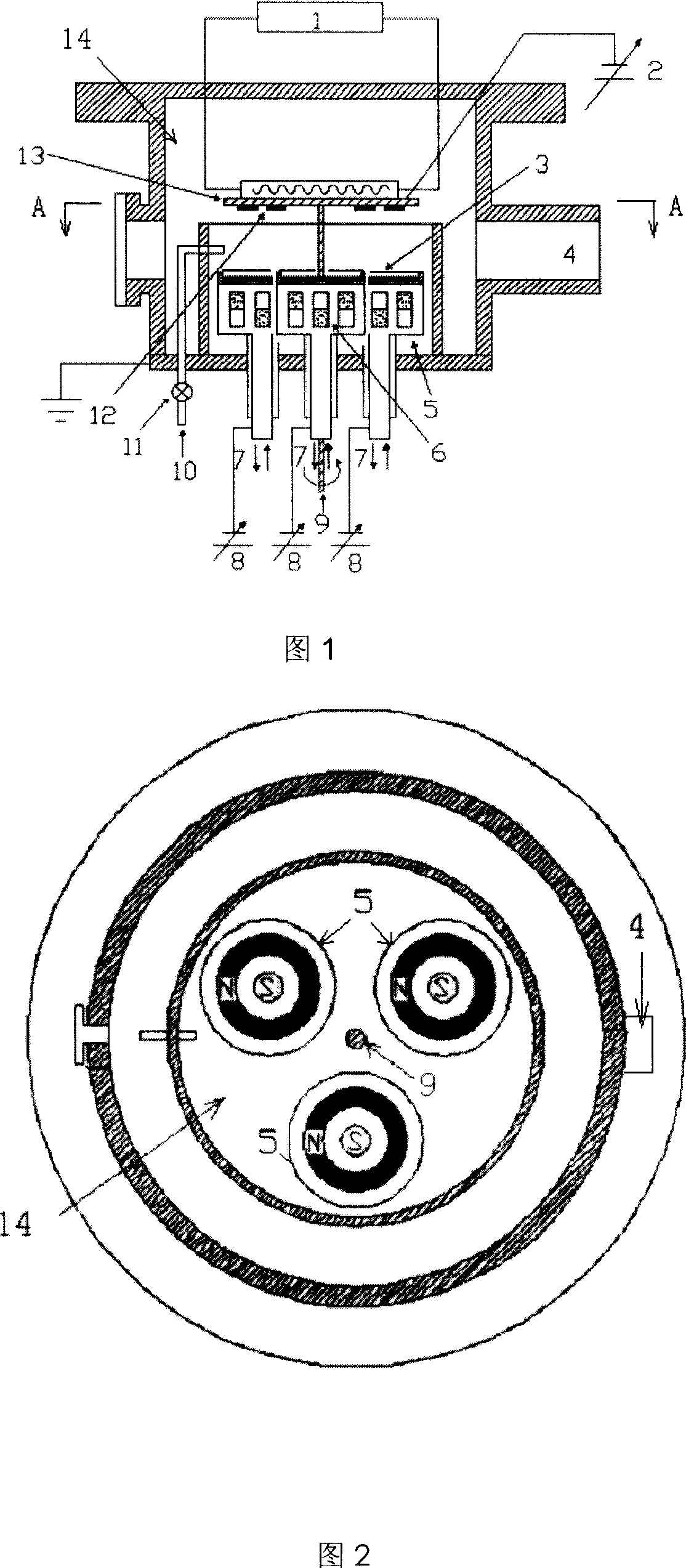

[0021] There are 3 magnetron target pools in the vacuum chamber, and the metal gallium in the 2 target pools is doped with single rare earth powder (particle size 10 μm) of Tm and Er respectively. The doping ratio of Tm to the target is 1 at.%, and the doping ratio of Er to the target is 10 at.%. Another target pool is not doped with rare earth elements. Adjust the distance from the substrate holder to the target surface to be 11cm. Vacuum to 10 -4 Below pa, after the vacuum degree is stable, pass a mixed gas of nitrogen and argon 1:99 (volume ratio) to make the working vacuum reach 4.0 Pa, and keep the vacuum degree at this time unchanged. Turn on the chiller to cool down the temperature of the target pool to below 10°C. Rotate the substrate to the top of the target pool not doped with rare earth elements, turn on the DC sputtering power supply of the target, without heating the substrate, deposit a layer of amorphous gallium nitride film at low temperature for 5 minutes. ...

Embodiment 2

[0023] There are 3 magnetron target pools in the vacuum chamber, and the metal gallium in one target pool is doped with Tm and Er rare earth nano-powders (particle size 100nm). The doping amount of Tm is 0.8 at.%, and the doping amount of Er is 1 at.%. The second target pool is doped with rare earth nanopowder (particle diameter: 80nm) with Eu element, and the mass content of the rare earth nanopowder of Eu element is 0.5 at.%. The third target pool is not doped with rare earth elements. Adjust the distance from the substrate holder to the target surface to 10cm. Vacuum to 10 -4 Pa below, until the vacuum is stable. Pass a mixed gas of nitrogen and argon 3:5 (volume ratio) to make the working vacuum reach 0.1 Pa, and keep the vacuum at this time constant. Turn on the chiller to cool down the temperature of the target pool to below 10°C. First rotate the substrate to the top of the target pool not doped with rare earth elements, turn on the DC sputtering power supply of th...

Embodiment 3

[0025] There are 3 magnetron target pools in the vacuum chamber. First, rare earth nano-powders (particle size: 50nm) of Tm and Er are doped in metal gallium in one target pool. The doping amount of Tm is 0.5at.%, and the doping amount of Er The amount is 2.0 at.%. The second target pool is doped with the nano-powder (50nm of particle diameter) of Eu element and the nano-powder (50nm of particle diameter) of Tm, and the mass content of the rare-earth nano-powder of Eu element is 1.0at.%, Tm doping amount is 1.0 at.%. The third target pool is not doped with rare earth elements. Adjust the distance from the substrate holder to the target surface to 8cm. Vacuum to 10 -4Below Pa, after the vacuum degree is stable. Nitrogen is passed to make the working vacuum reach 0.5 Pa, and the vacuum degree at this time remains unchanged. Turn on the chiller to cool down the temperature of the target pool to below 10°C. First rotate the substrate to the top of the target pool not doped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com