Gas-phase continuous preparation method and special device for single-walled carbon nanotube film

A technology of single-wall carbon nanotubes and special devices, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not meeting the requirements of continuous film formation and hindering single-wall carbon nanotube films Problems such as large-scale application process and inapplicability of single-walled carbon nanotube films have been achieved to achieve large-scale preparation and application, difficulty in uniformity control, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

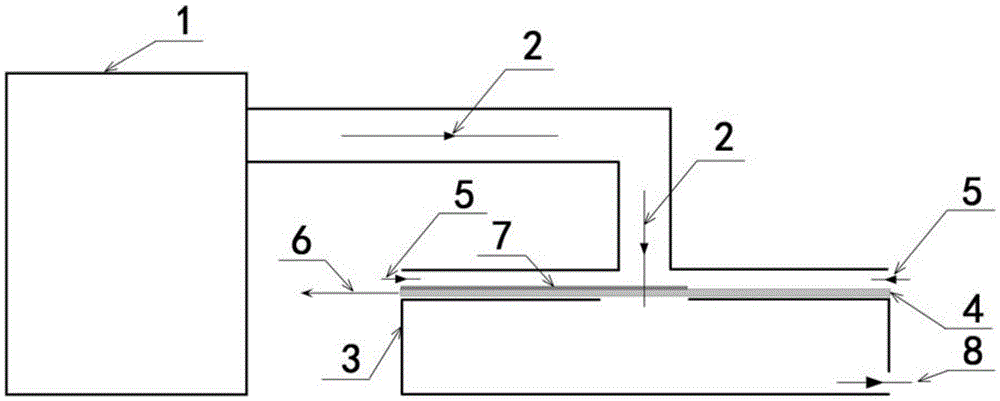

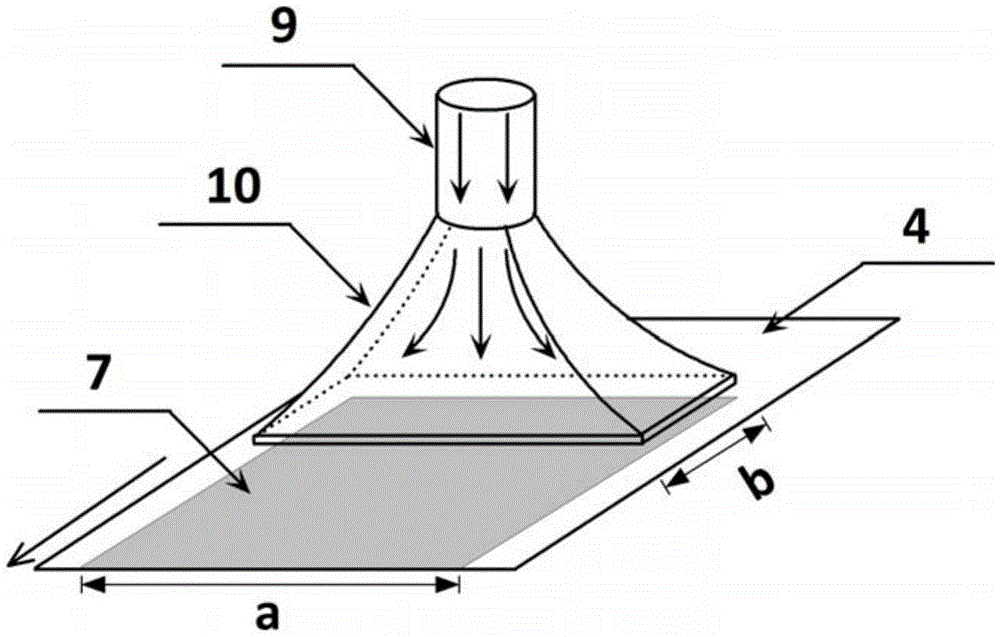

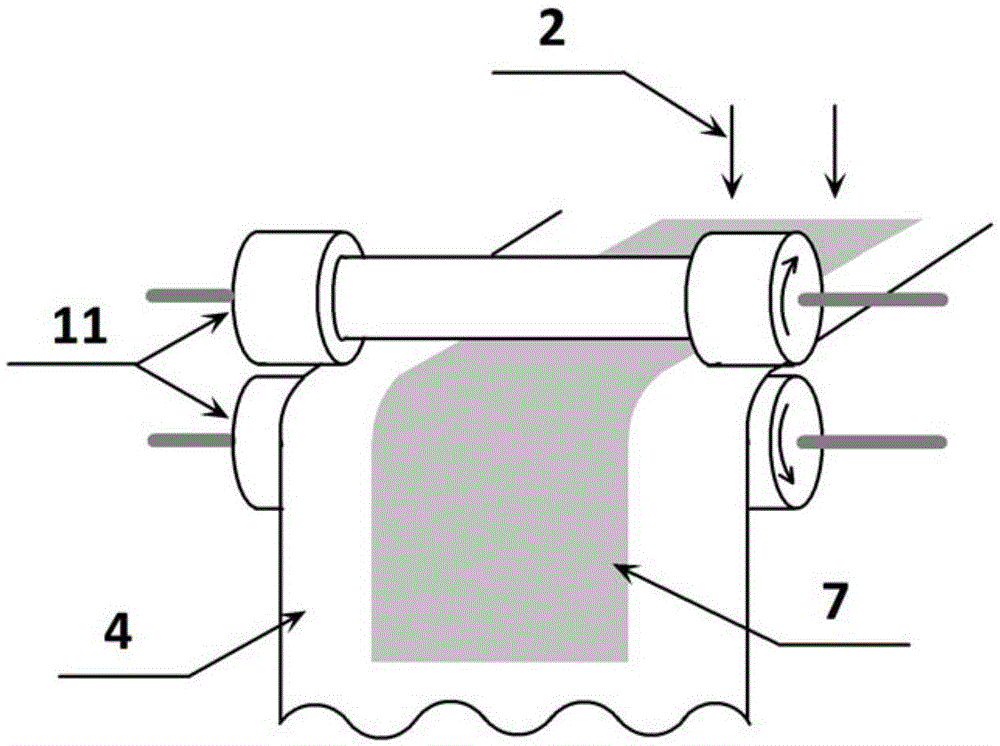

[0047] In this embodiment, the gas-phase continuous film-forming device of single-walled carbon nanotubes is as figure 1 shown. Single-walled carbon nanotubes were prepared by floating catalyst chemical vapor deposition, using hydrogen as the carrier gas, methane as the growth carbon source, ferrocene as the catalyst precursor, and elemental sulfur as the growth promoter, in which ferrocene and elemental sulfur were fully Mix evenly and press into sheets. The mixing mass ratio of ferrocene and elemental sulfur is 200:1. The catalyst precursor is placed in the quartz boat at the inlet of the reaction chamber. In the heating stage, feed hydrogen gas with a flow rate of 500 sccm into the reaction chamber, and at the same time turn on the mechanical pump in the collection device, adjust the pressure regulating control valve so that the pumping rate is maintained at about 500 sccm, and the temperature of the chamber is raised from room temperature to 1100 °C . After the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com