Patents

Literature

59results about How to "Realize large-scale application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

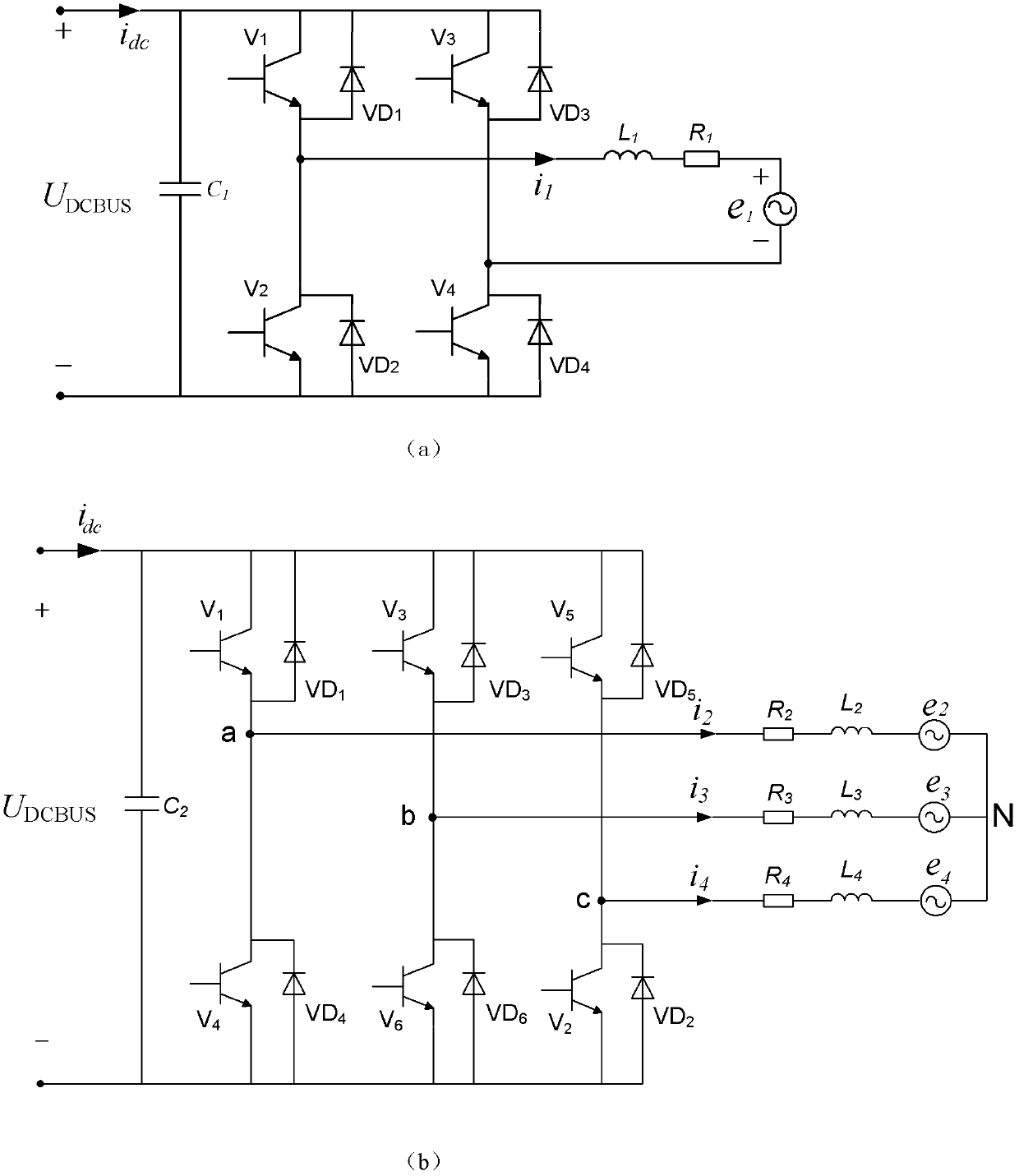

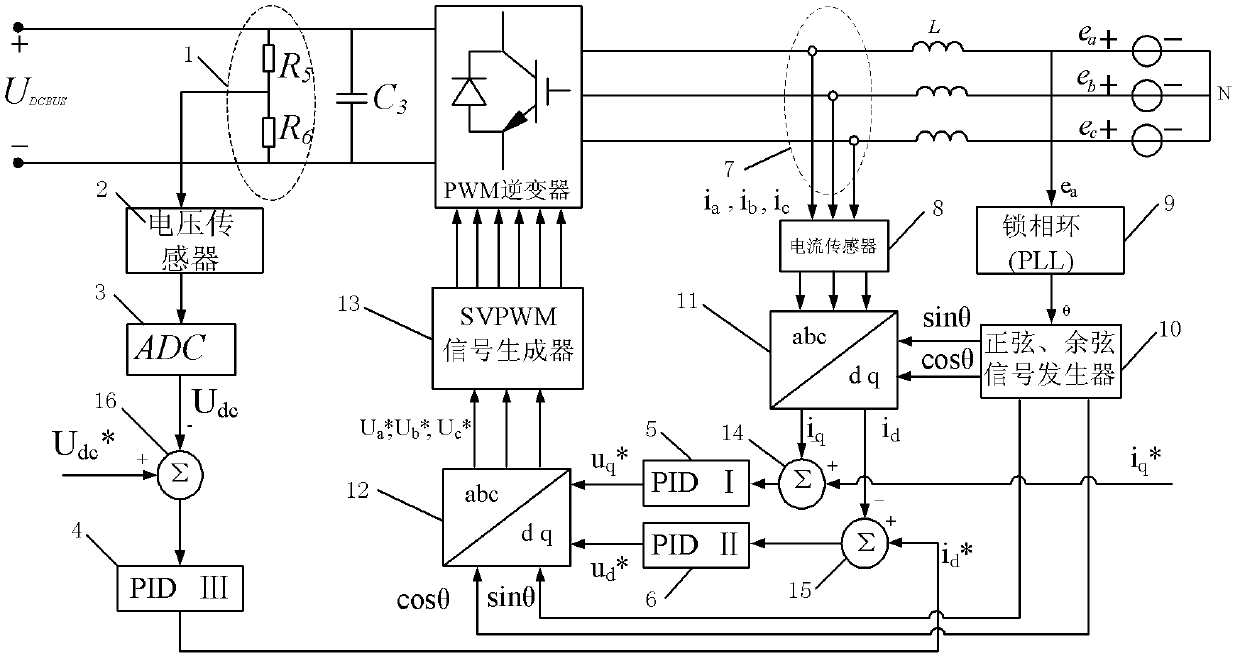

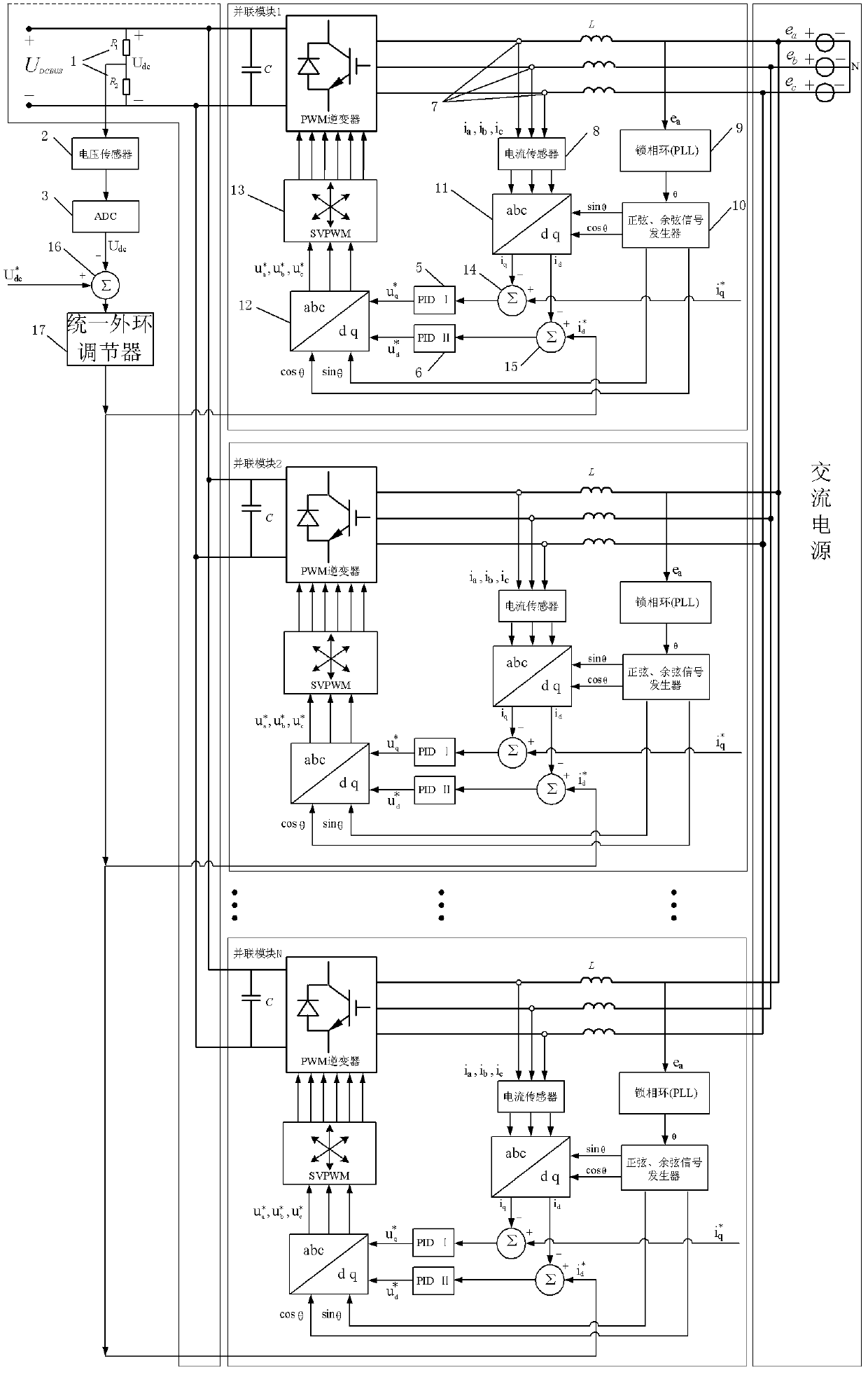

Parallel structure and control method for photovoltaic power generation grid-connected inverter

ActiveCN102185513ASolving Dispersion ProblemsAvoid it happening againAc-dc conversionSingle network parallel feeding arrangementsClosed loopPwm inverter

The invention discloses a parallel structure and a control method for a photovoltaic power generation grid-connected inverter and belongs to the technical field of renewable energy sources. A topological circuit structure of the photovoltaic power generation grid-connected inverter is divided into a parallel structure of single-phase voltage type pulse-width modulation (PWM) inverters and a parallel structure of three-phase voltage type PWM inverters; and in the control method, an outer ring regulator of a control circuit of the parallel voltage type PWM inverters is independent based on a power grid voltage-oriented vector control technology in a control mode of voltage outer ring and current inner ring so as to form a common unified outer ring regulator; control strategies of various inverters are simplified into single closed loop current control so as to achieve the consistency of energy flow directions of the parallel voltage type PWM inverters and avoid ring current; and the parallel current sharing of the voltage type PWM inverters is realized. Therefore, multiple modules of the voltage type PWM inverters are connected in parallel to realize high-power modularized large-scale application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

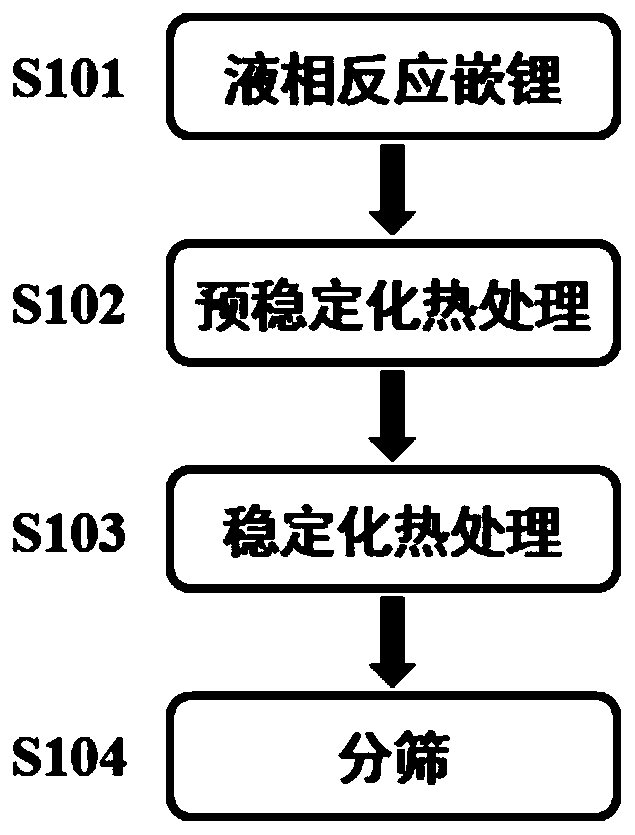

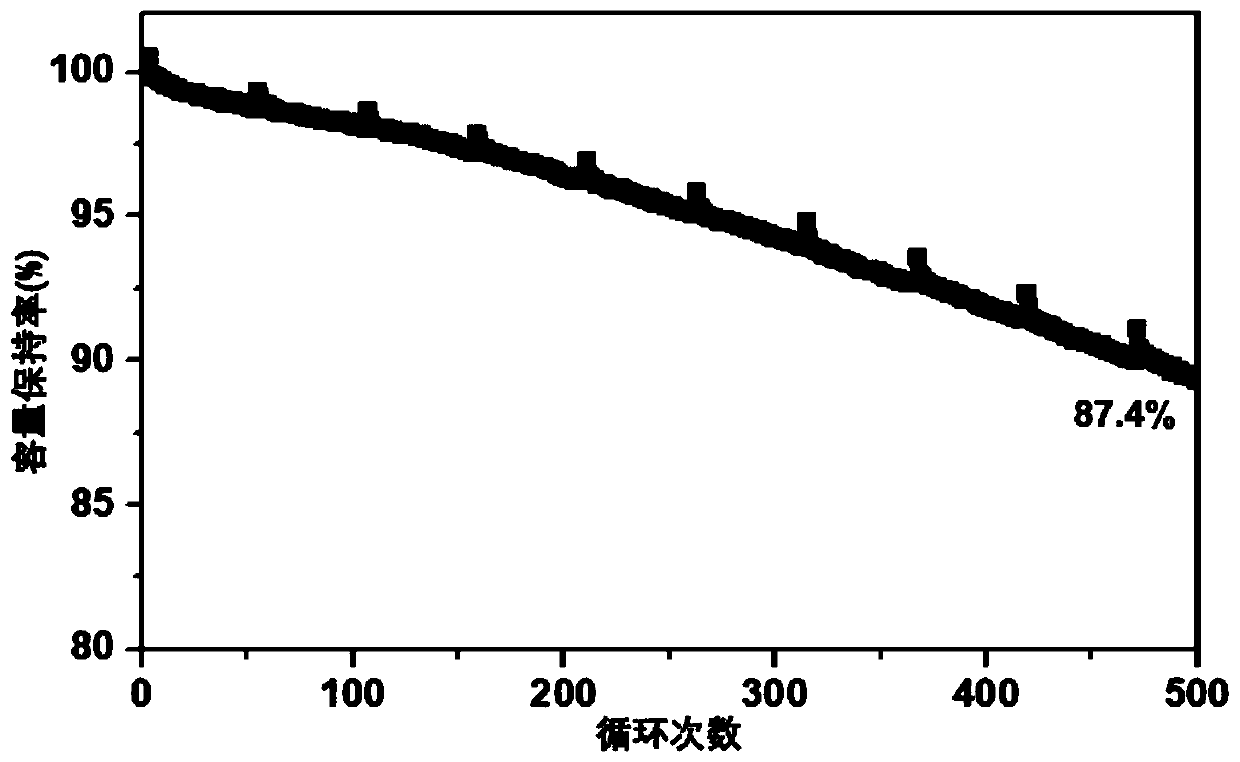

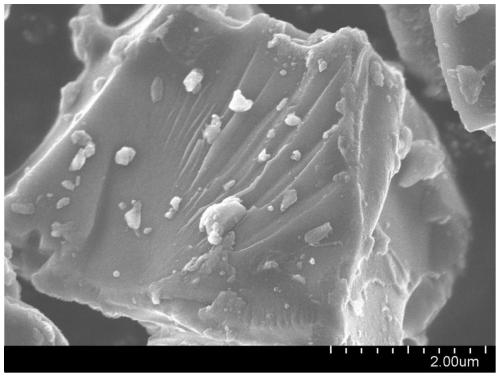

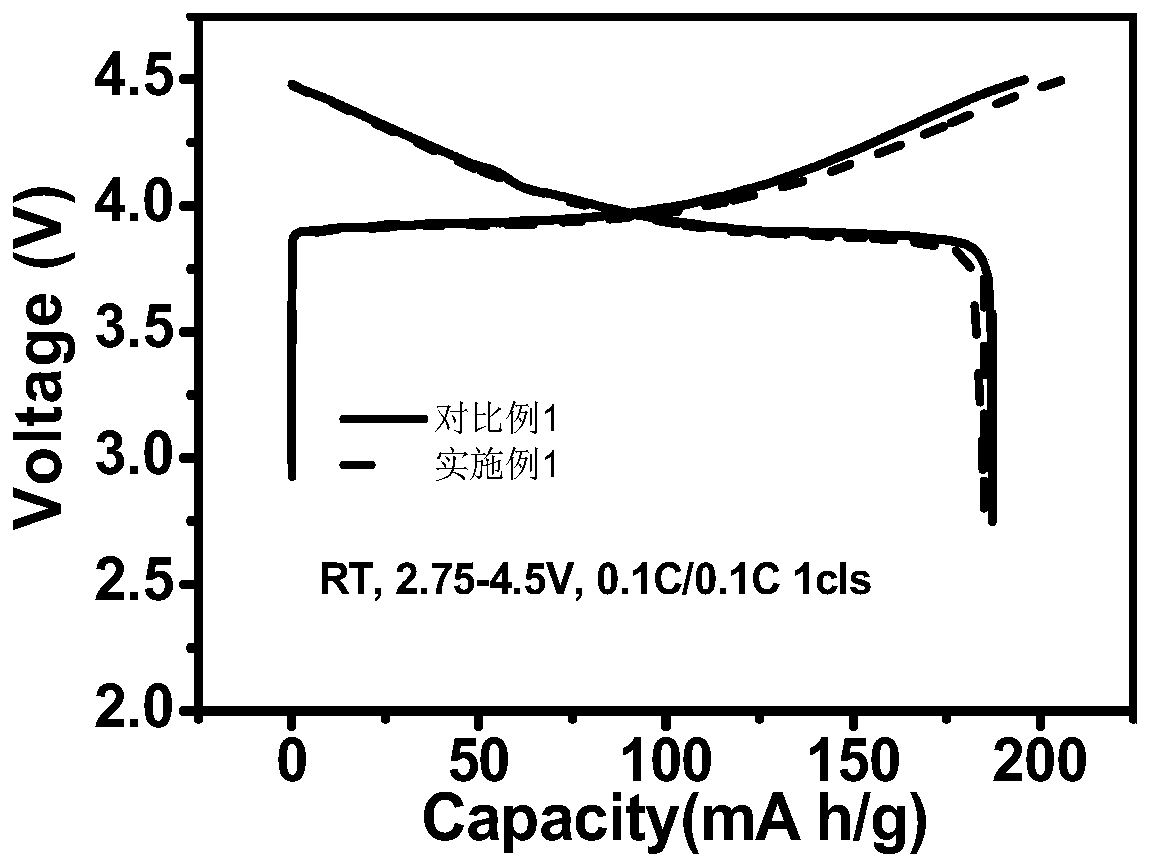

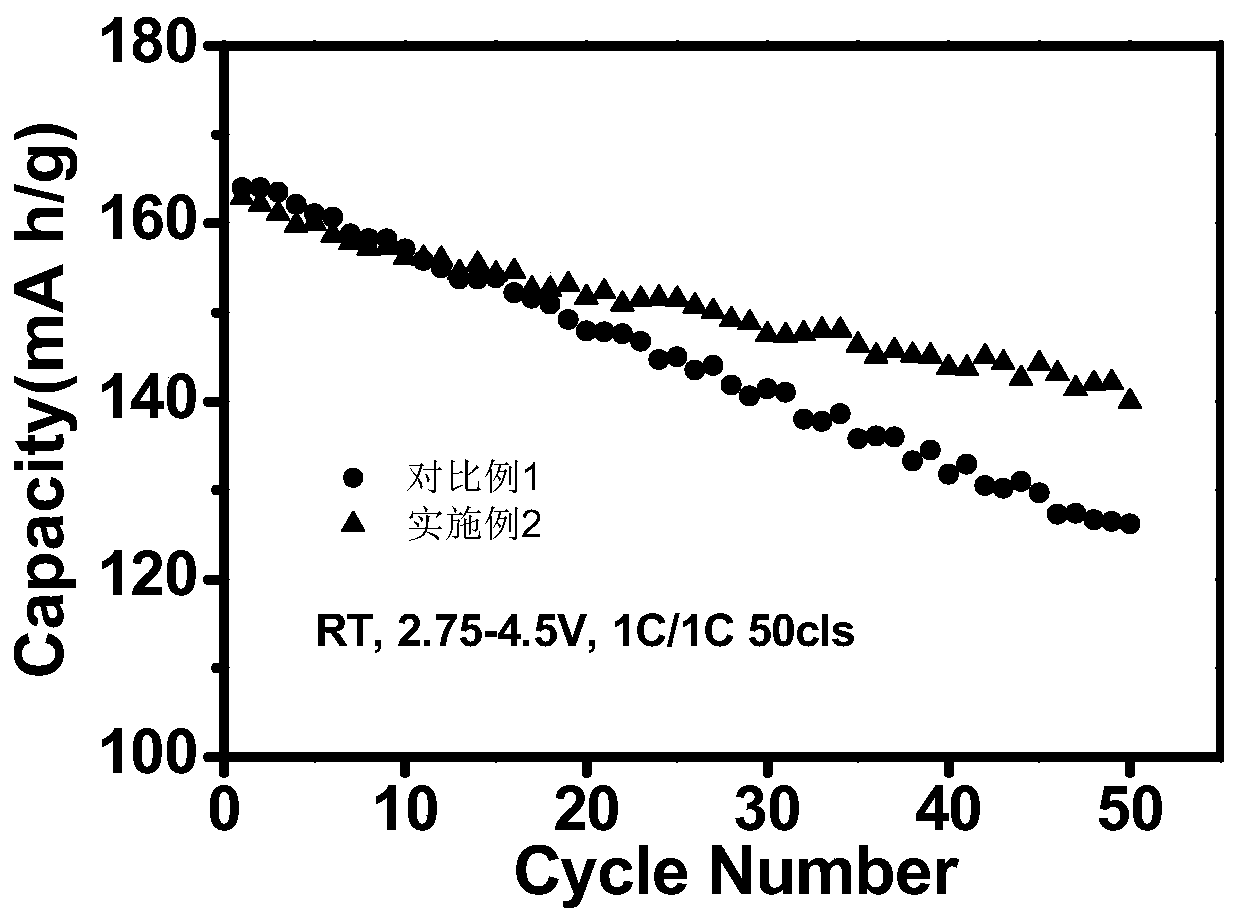

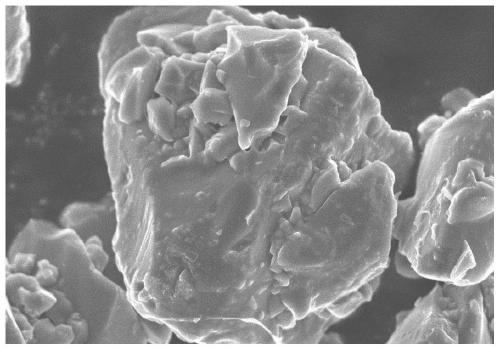

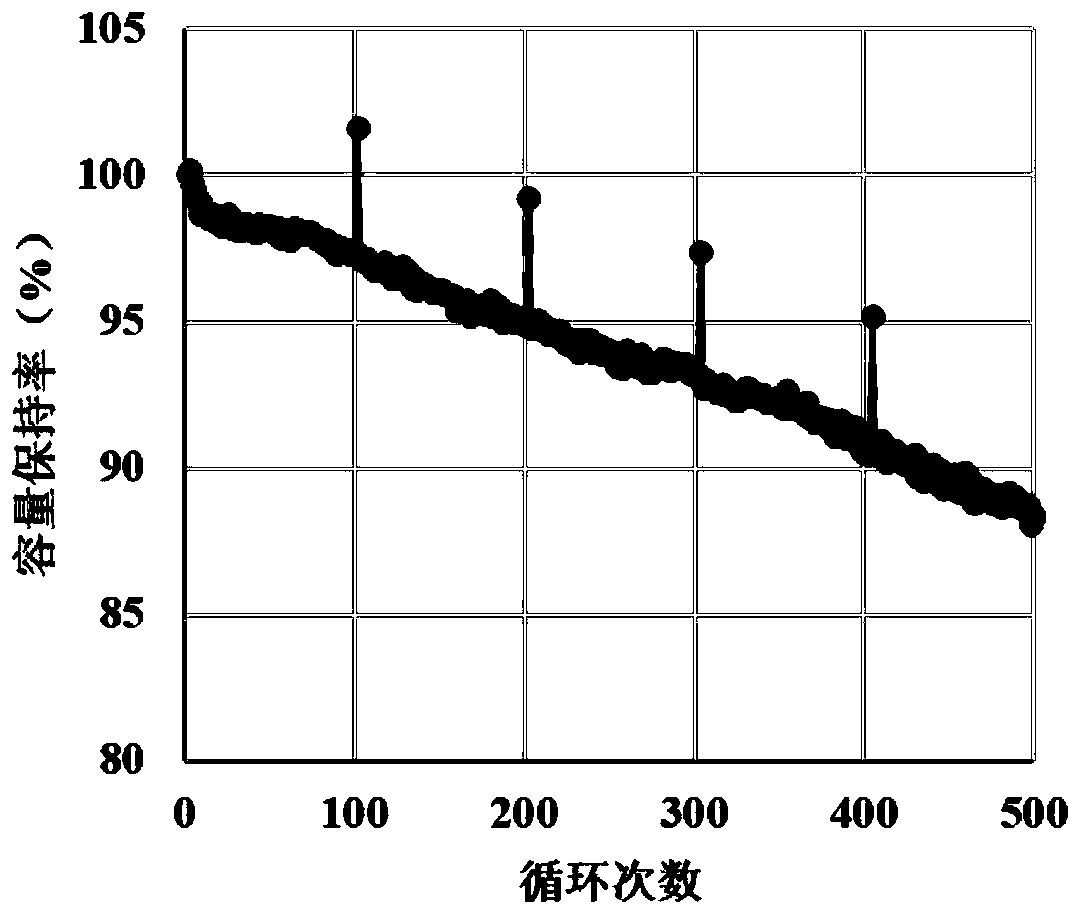

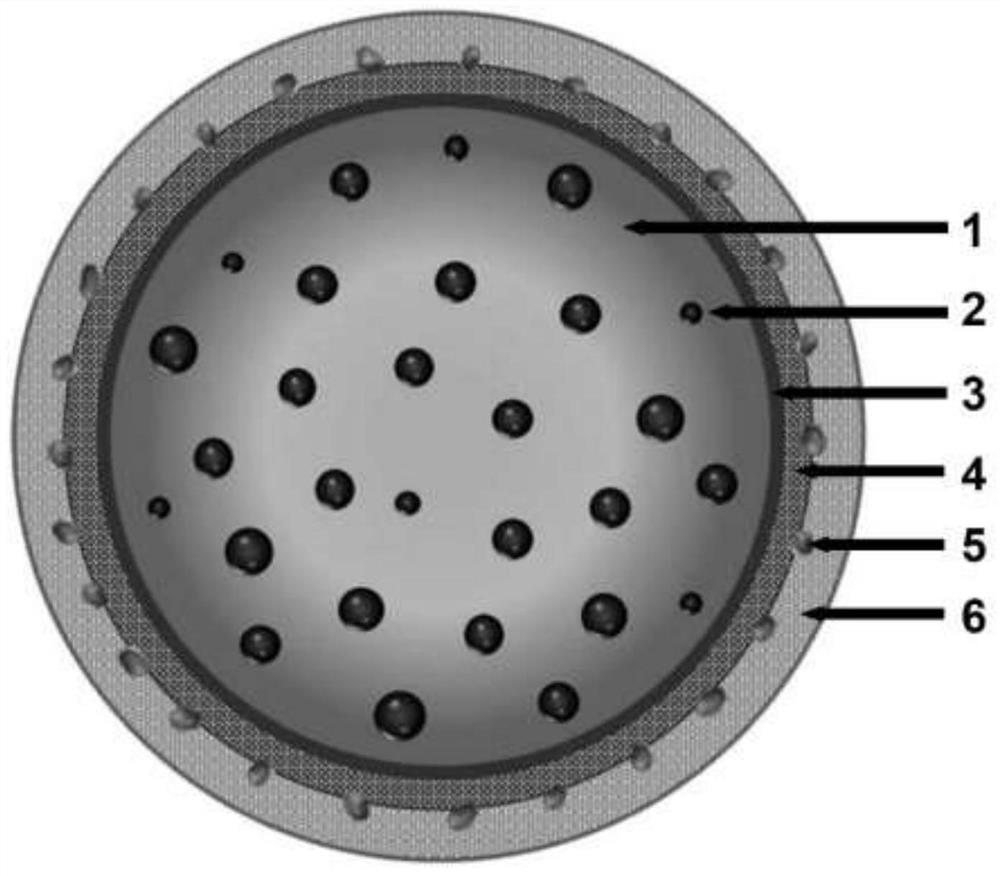

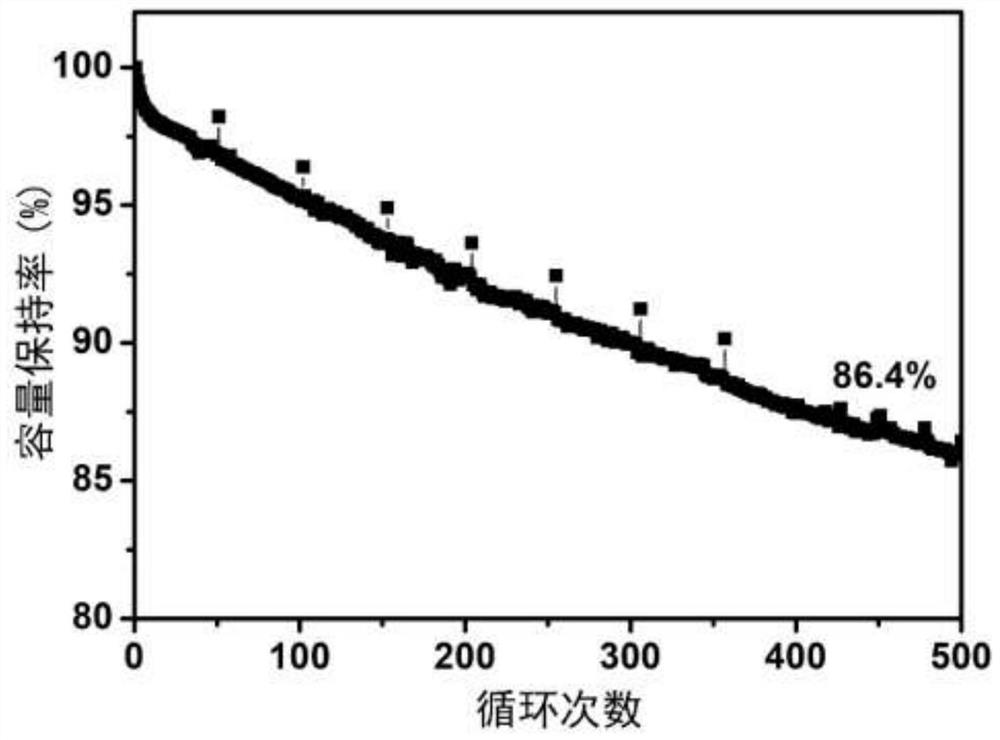

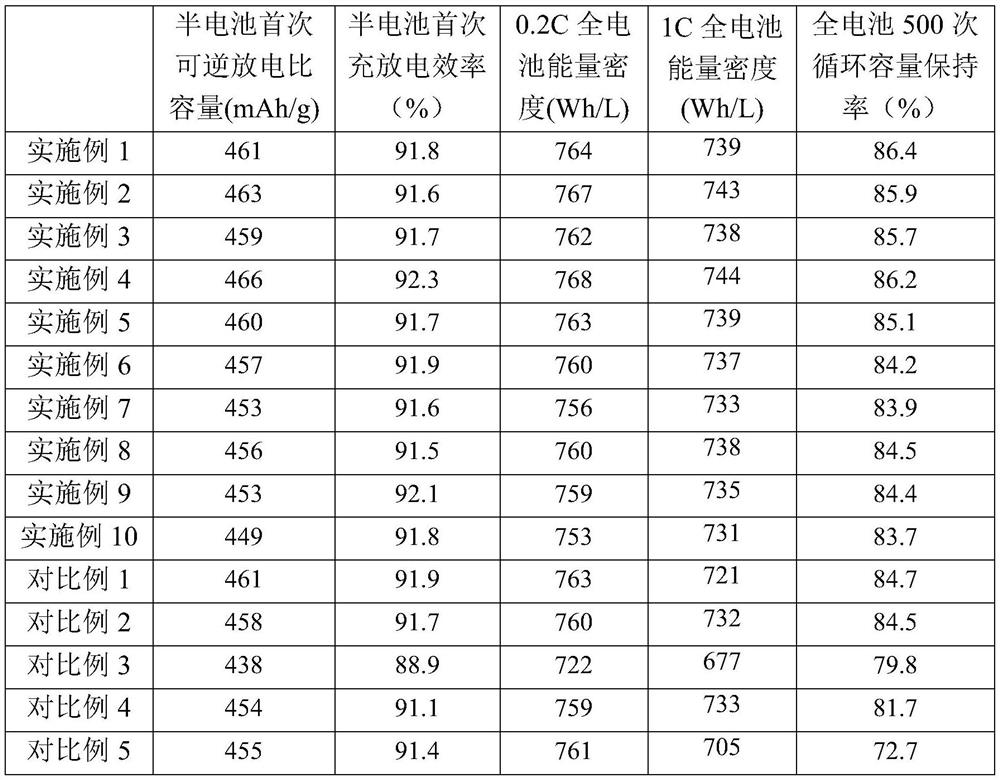

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

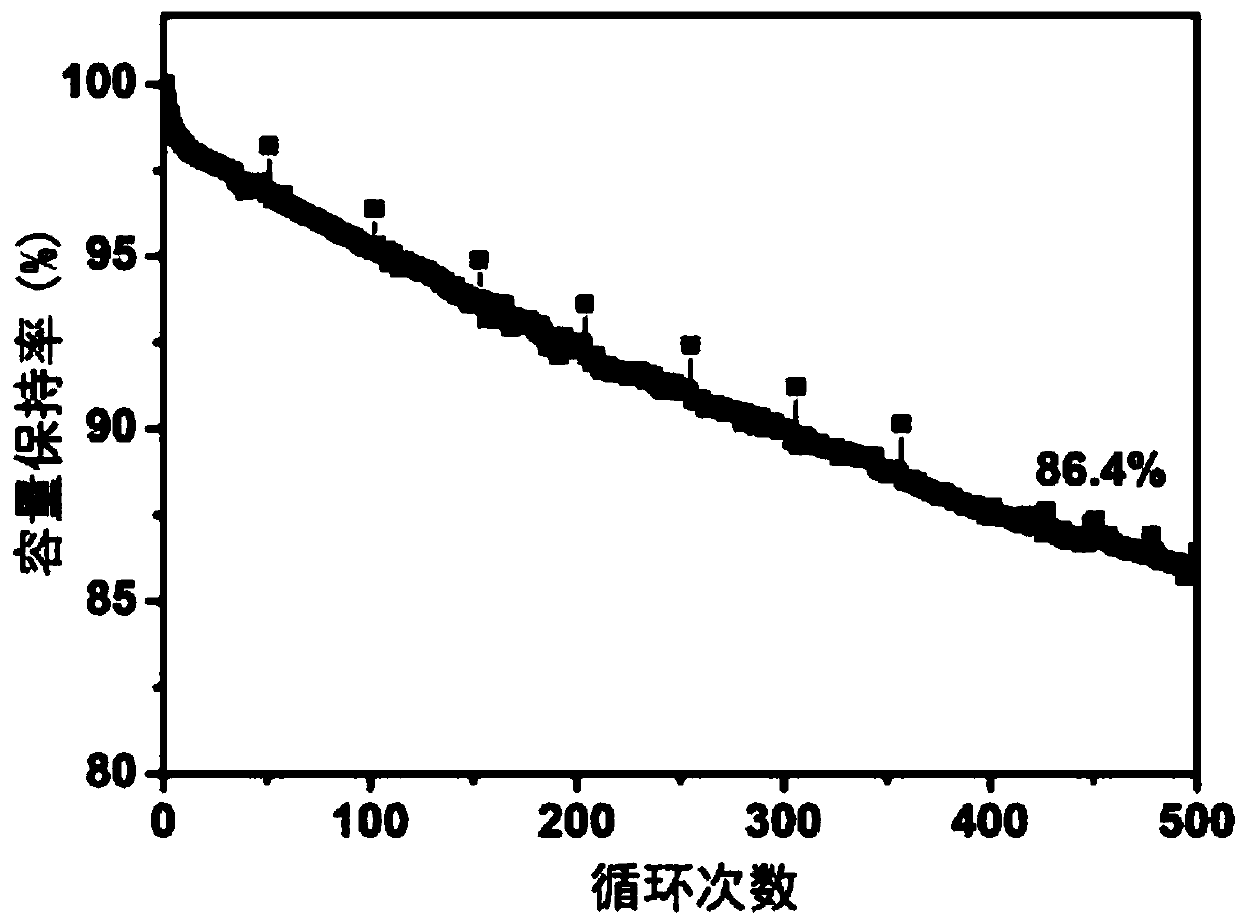

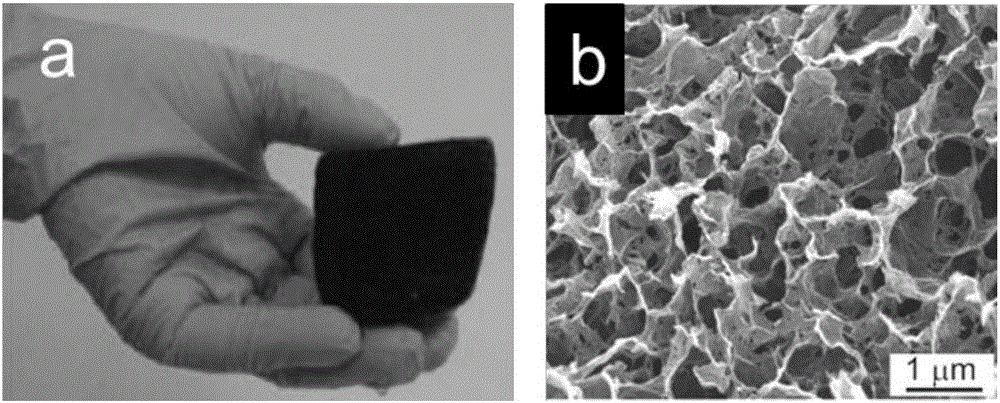

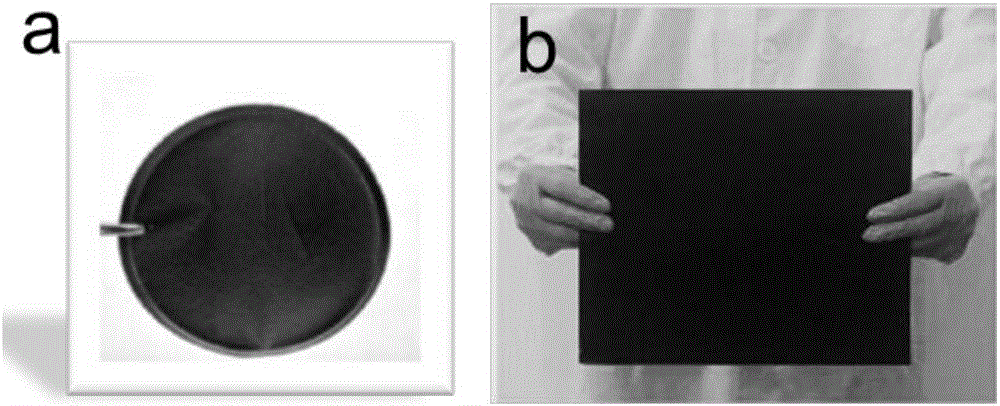

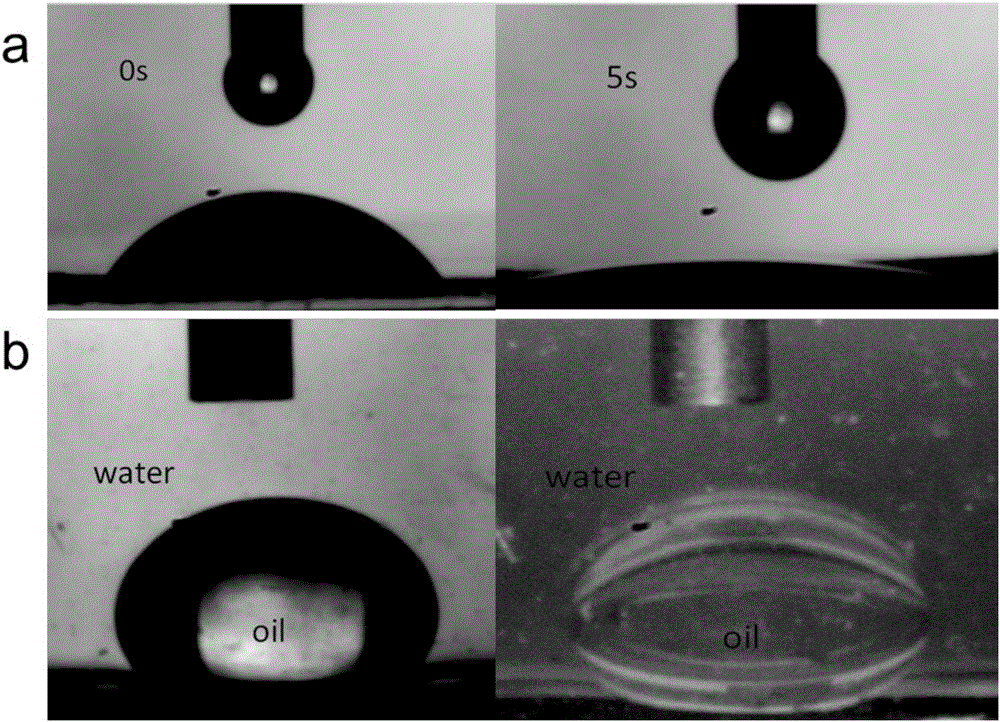

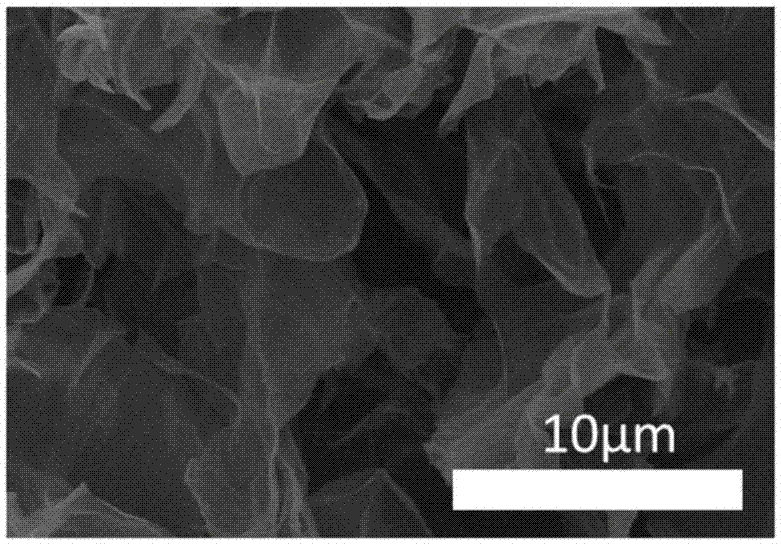

Preparation method of graphene foam-polydopamine composite membrane, product prepared with preparation method and application of product

ActiveCN106422816AImprove mechanical propertiesRealize large-scale applicationSemi-permeable membranesFatty/oily/floating substances removal devicesMaterials scienceHydrochloride

The invention discloses a preparation method of a graphene foam-polydopamine composite membrane, a product prepared with the preparation method and an application of the product. The preparation method comprises steps as follows: (1) preparation of graphene foam-polydopamine: the pH value of a graphene oxide solution is adjusted, dopamine hydrochloride is added, a precursor solution is obtained and subjected to a hydrothermal reaction, and graphene foam-polydopamine is obtained; (2) preparation of the graphene foam-polydopamine composite membrane: graphene foam-polydopamine is added to N,N-dihydroxyethylglycine and mixed with a temperature-sensitive polymer, the mixture is stirred and subjected to vacuum filtration, and the temperature-sensitive graphene foam-polydopamine composite membrane is obtained. The graphene foam-polydopamine composite membrane prepared through improvement of overall process design, reaction conditions of steps and the like of a key preparation process has good temperature sensitivity and excellent super-hydrophilic property and underwater super-lipophobicity and is very applicable to oil-water separation.

Owner:HUAZHONG UNIV OF SCI & TECH

Anode active material and preparation method and application thereof

ActiveCN111180693AIncrease capacityImprove Coulombic efficiencyCell electrodesSecondary cellsPhysical chemistrySilicon oxide

The invention relates to an anode active material and a preparation method and application thereof. The anode active material includes: silicon oxide particles; and elemental silicon nanoparticles dispersed in the silicon oxide particles, wherein the median particle size of the monatomic silicon nanoparticles is 0.2-20 nm; the silicon oxide particles comprise lithium, the lithium in the silicon oxide particles comprises a lithium silicate compound, and the lithium silicate compound comprises one or more of Li2Si2O5, Li6Si2O7, Li2SiO3, Li8SiO6 and Li4SiO4. The anode active material disclosed bythe invention has the advantages of high capacity and coulombic efficiency, good multiplying power and cycle performance, the low expansion rate and the like when being used in a secondary battery. The preparation method is good in repeatability and high in safety. The secondary battery provided by the invention has the characteristics of high volume energy density, good rate capability, good cycling stability, low expansion rate and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

FeCoNi@C/carbon fiber aerogel composite absorbing material and preparation method thereof

ActiveCN110983492ASimple manufacturing methodFacilitate large-scale applicationOther chemical processesArtifical filament manufactureCarbon compositesCarbon fibers

The invention discloses a FeCoNi@C / carbon fiber aerogel composite absorbing material. The composite absorbing material comprises a carbon fiber matrix and a FeCoNi@ carbon composite nanosphere, wherein the FeCoNi@ carbon composite nanosphere is loaded on the surface of the carbon fiber matrix. The composite absorbing material takes carbon fibers as the matrix, and the microspherical FeCoNi@C derived from FeCoNi-MOF is loaded on the surface of the matrix; the prepared composite material solves a problem that a single carbon material and a monometallic MOF derivative material lack a plurality ofeffective electromagnetic wave loss mechanisms to cooperate, the good impedance matching is obtained, the better absorption efficiency is achieved, and the composite material is an ideal selection ofa novel light-weight and efficient microwave absorbing material.

Owner:SOUTHEAST UNIV

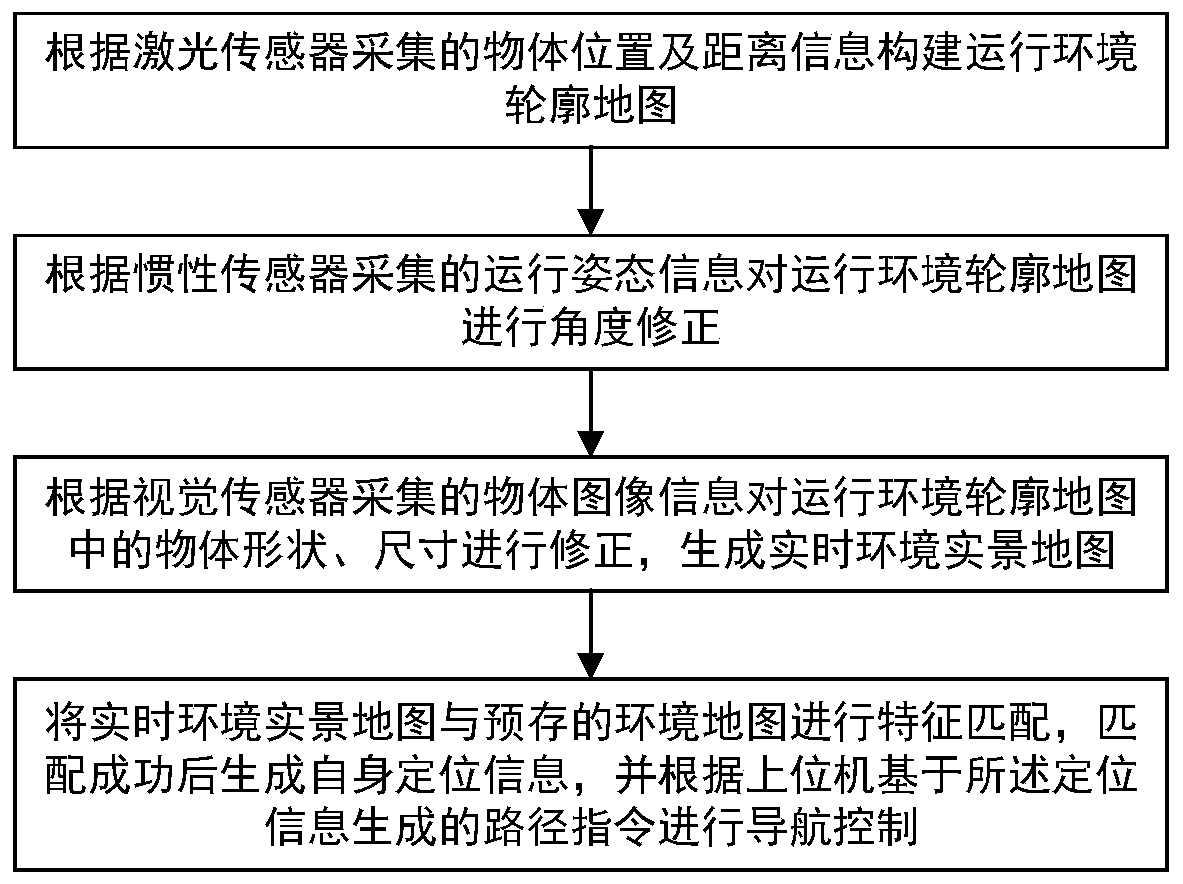

Universal autonomous navigation control method and device and device terminal

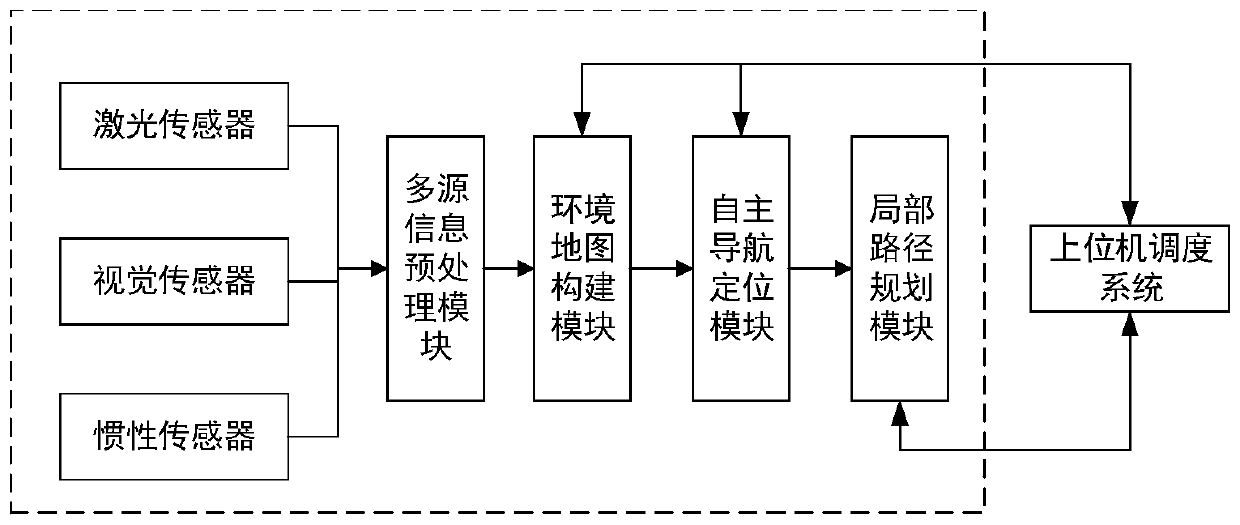

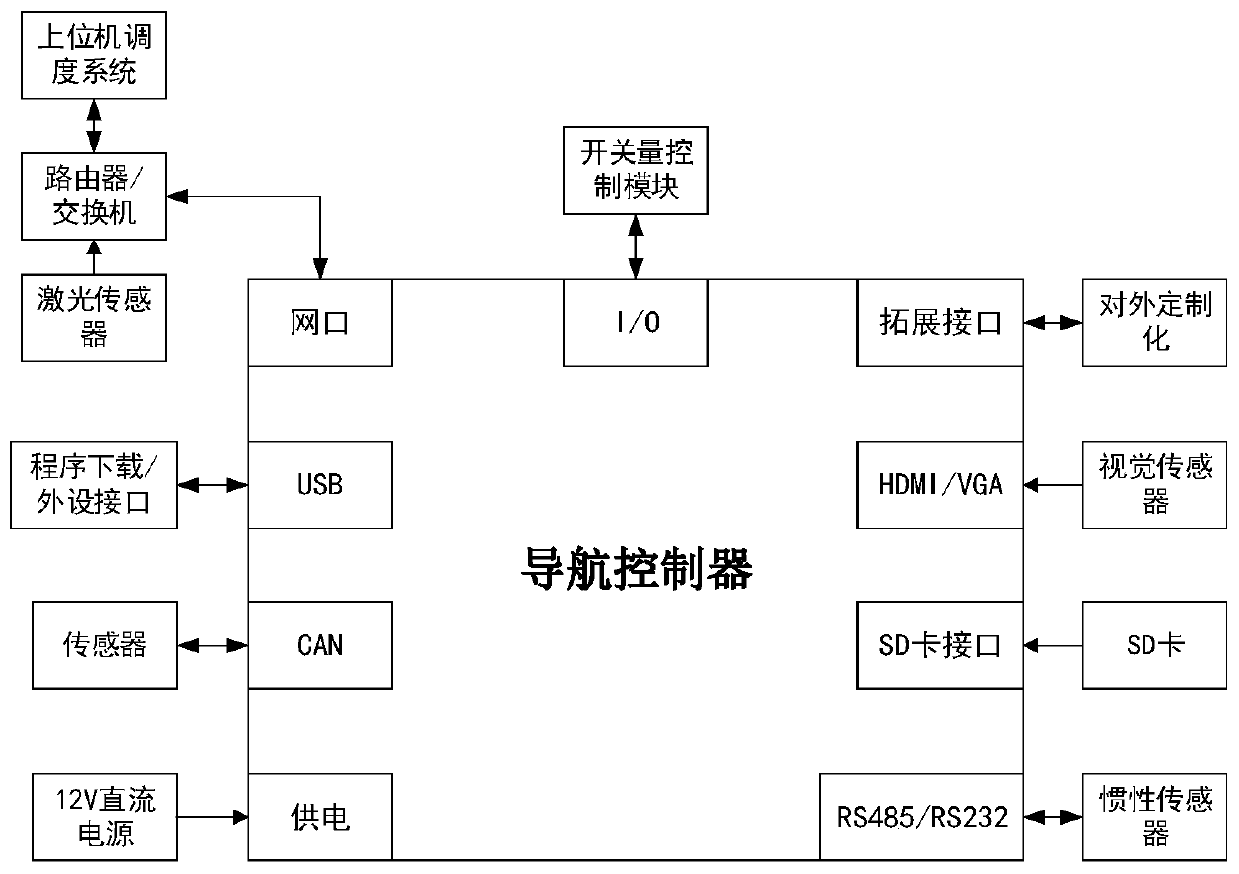

ActiveCN110440811ASolve the problem of switching applications that cannot meet the various working scenarios of AGVRealize autonomous navigation and positioningNavigational calculation instrumentsNavigation by speed/acceleration measurementsRoad surfaceLaser sensor

The invention discloses a universal autonomous navigation control method and device and a device terminal. The method comprises the steps of building an operating environment profile map according toan object position and distance information obtained by a laser sensor; obtaining flatness information of an operating environment road surface according to operating attitude information obtained byan inertial sensor and carrying out angle correction on the operating environment profile map on the basis of the flatness information; correcting the shape and size of an object in the operating environment profile map according to object image information obtained by a vision sensor and generating a real-time environment live map; and carrying out feature matching on the real-time environment live map and a pre-stored environment map, generating own positioning information after matching successfully, and carrying out navigation control on the basis of a path instruction generated by the positioning information according to an upper computer. The universal autonomous navigation control method and device can be applied to different working scenes and software upgrading and updating are not needed, so that the problem that a traditional navigation method cannot meet switching applications of multiple working scenes is solved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

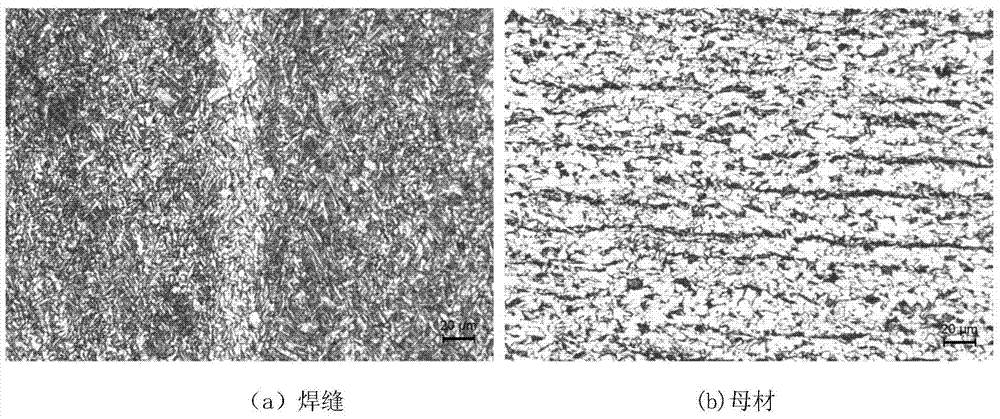

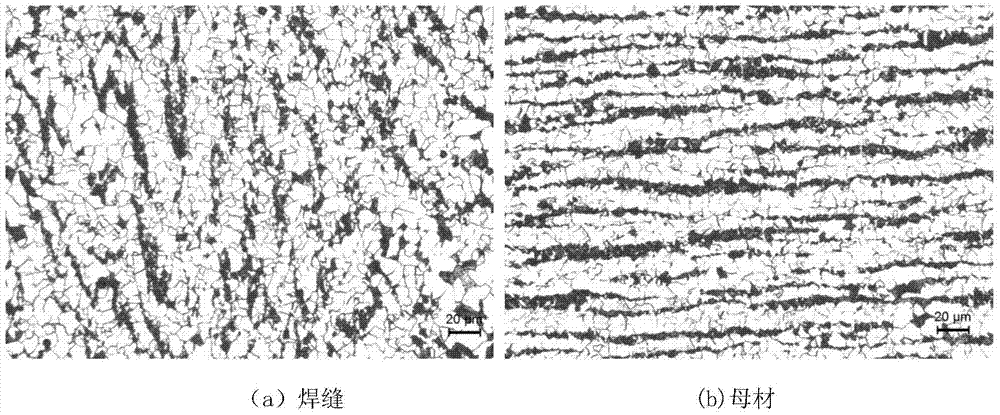

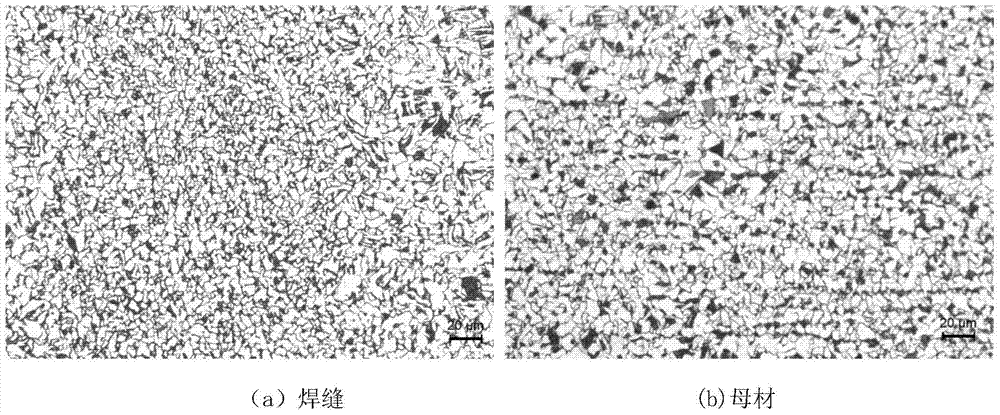

J55-steel-grade SEW expandable casing tube and manufacturing method thereof

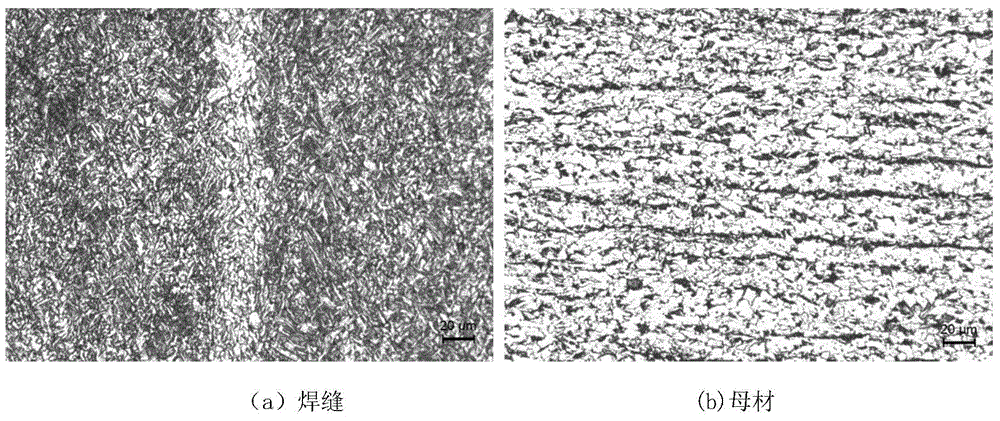

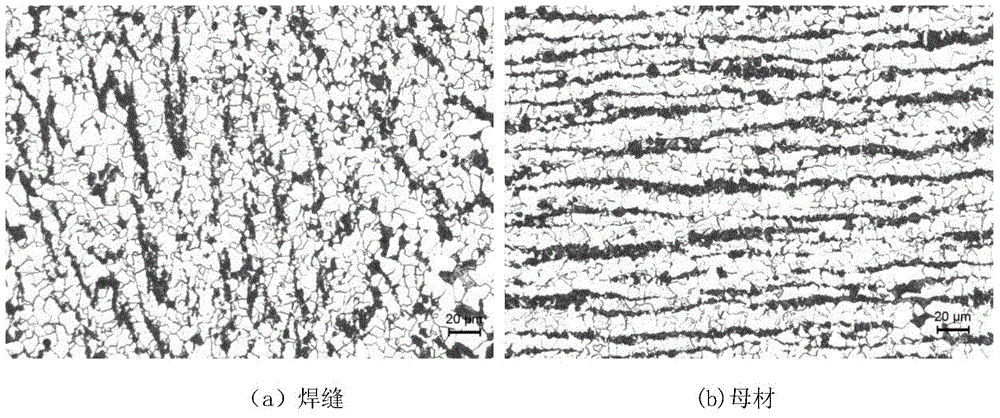

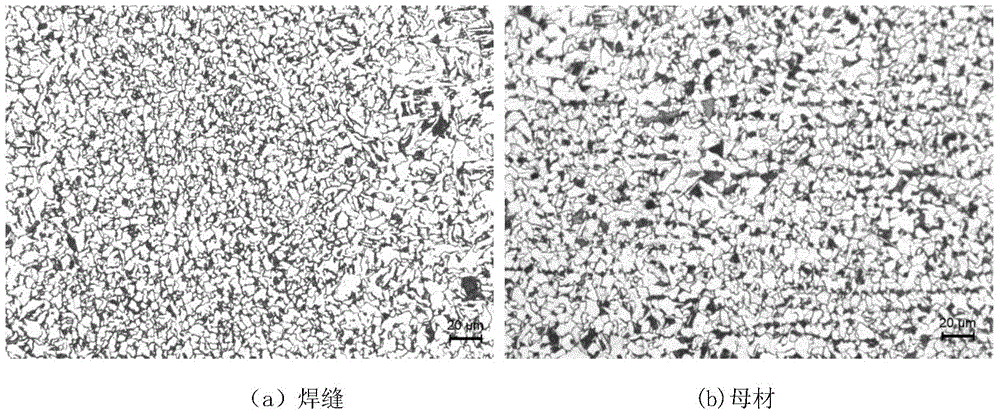

The invention discloses a J55-steel-grade SEW expandable casing tube and a manufacturing method thereof. The manufacturing method comprises following steps: (1) quickly heating a HFW welding tube blank through a middle-frequency induction furnace to 960-1020 DEG C; (2) performing multiple-pass full-tube thermal-stretch reducing to the HFW welding tube blank; and (3) rotationally passing the thermal-stretch reduced tube blank at 750-850 DEG C through an on-line-controlled cooling apparatus to quickly cool the tube blank to 250-450 DEG C and finally air-cooling the tube blank to room temperature. In the invention, by means of a one-step method, high-precision thermal moulding and target organism adjustment and control of the tube are achieved, thereby significantly reducing the production costs such as energy consumption. Through HFW welding, full-tube thermal-stretch reduction and on-line-controlled cooling, microstructure differences between welding seams and the base material can be eliminated, thereby achieving uniform organism performance of the full tube (including the base material and the welding seams) and further achieving excellent uniform deformation performance. Meanwhile, a banded structure is eliminated and a double-phase or multi-phase organism which is formed by reasonable combination of soft-phases and hard-phases with a large amount of ferrite and a less amount of bainite or martensite as the main composition, so that the J55-steel-grade SEW expandable casing tube has a high inner diameter expansion rate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Metal ion supplementing composite alloy powder as well as preparation method and application thereof

InactiveCN110492072AReduce manufacturing costThe preparation method is matureCell electrodesSecondary cells servicing/maintenanceAlloyCarbonate

The invention discloses metal ion supplementing composite alloy powder. The composite alloy powder comprises: alloy AxBy powder particles and a protective layer M covering the surfaces of the alloy AxBy powder particles, wherein A is one of Li, Na, Mg and K; B is one or more of Mg, Ca, Al, Ge, Sn, Sb, Zn, Si, Si / C, SiOz and SiOz / C materials; wherein AxBy is an alloy, an intermetallic compound or asolid solution of A and B, and the protective layer M is a single-layer protective layer or a double-layer protective layer composed of one or more of a metal simple substance, a metal oxide, carbon,carbonate of A, silicate of A or carbonate containing metal elements in B. The metal ions compensated by the alloy powder can meet the requirements of the battery on the active metal ions, so that the performance of the battery is obviously improved.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Deep-dewatering conditioning agent suitable for high-grade anaerobic digested sludge and application thereof

InactiveCN108164124AEnhance flocculation performanceImprove dehydration effectSludge treatment by de-watering/drying/thickeningWater contentChemistry

The invention relates to a deep-dewatering conditioning agent suitable for high-grade anaerobic digested sludge and application thereof. The conditioning agent is prepared from a composite flocculantand a surface active agent, wherein in solid content of the sludge, the adding amount of the composite flocculant is 2% to 4.5%, and the adding amount of the surface active agent is 1.5% to 3%; the composite flocculant is inorganic / organic composite flocuulant, and the surface active agent is sodium dodecyl sulfate and / or lauryl sodium sulfate. A synergistic effect between the composite flocculantand the surface active agent is utilized to effectively improve sludge dewatering performance, and the situation that a water content of mud cake is reduced to 60% or less is effectively achieved after the sludge is dewatered.

Owner:BEIJING DRAINAGE GRP CO LTD

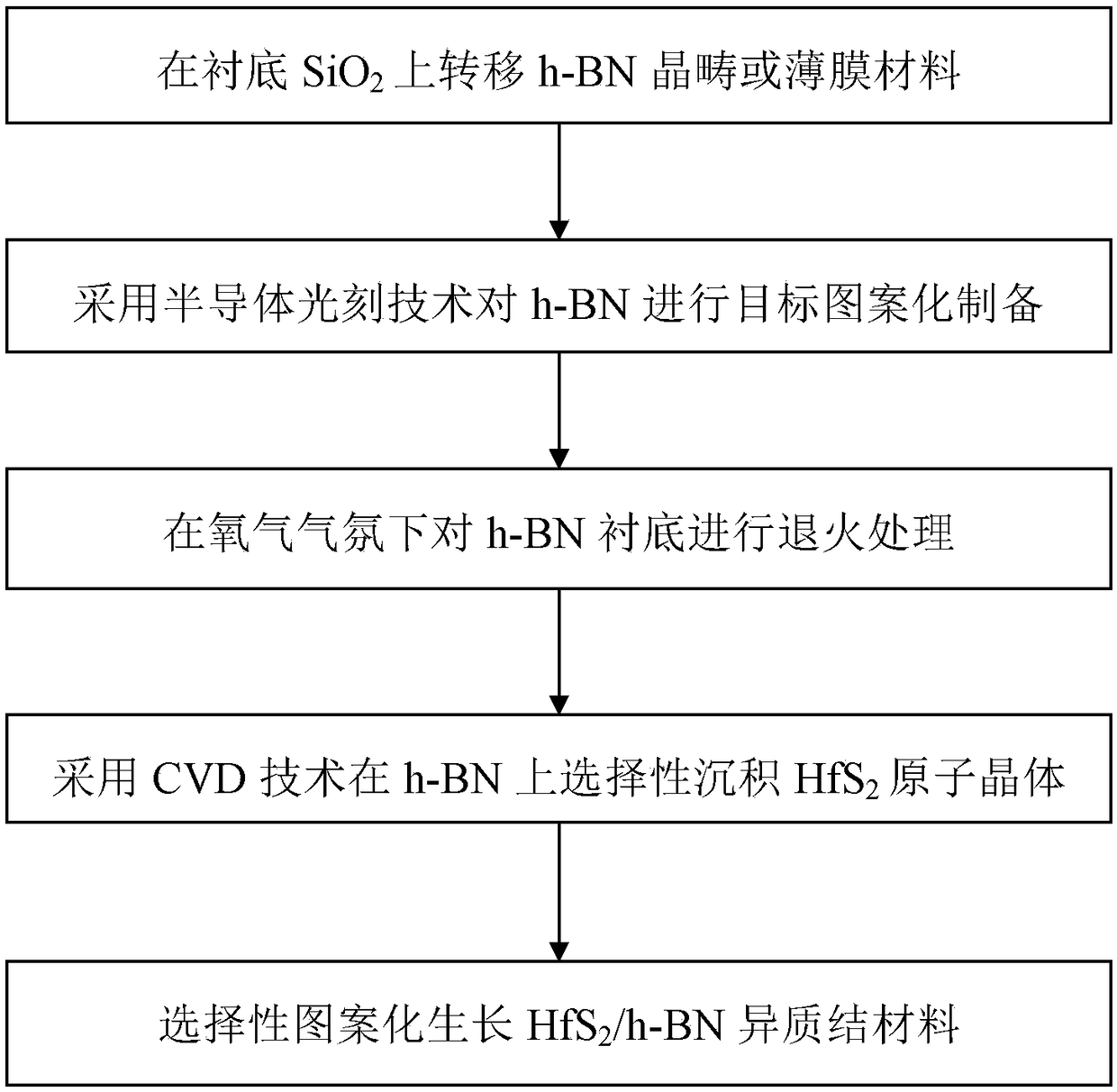

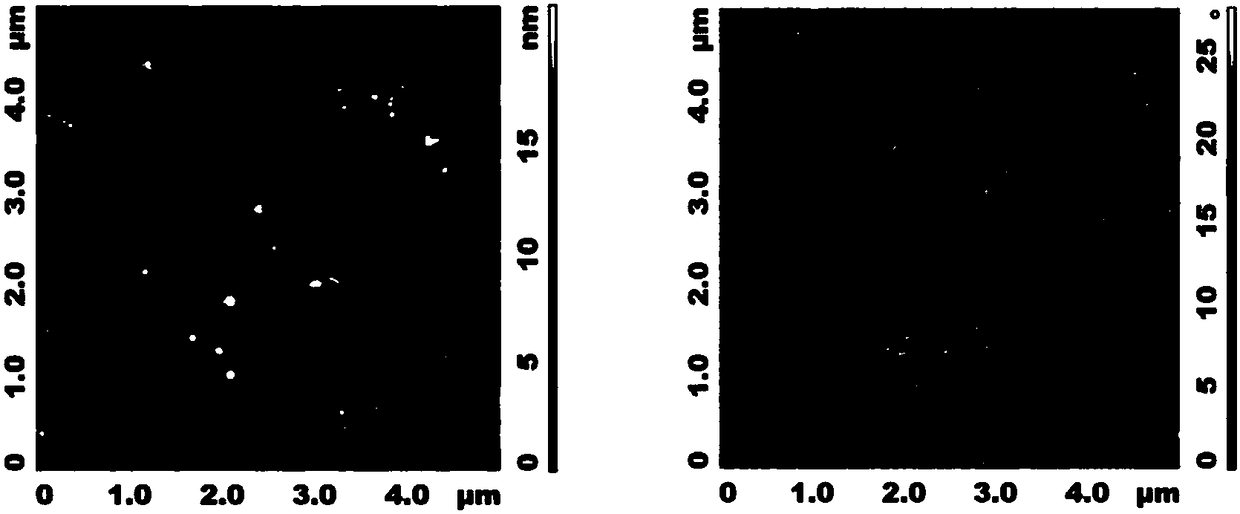

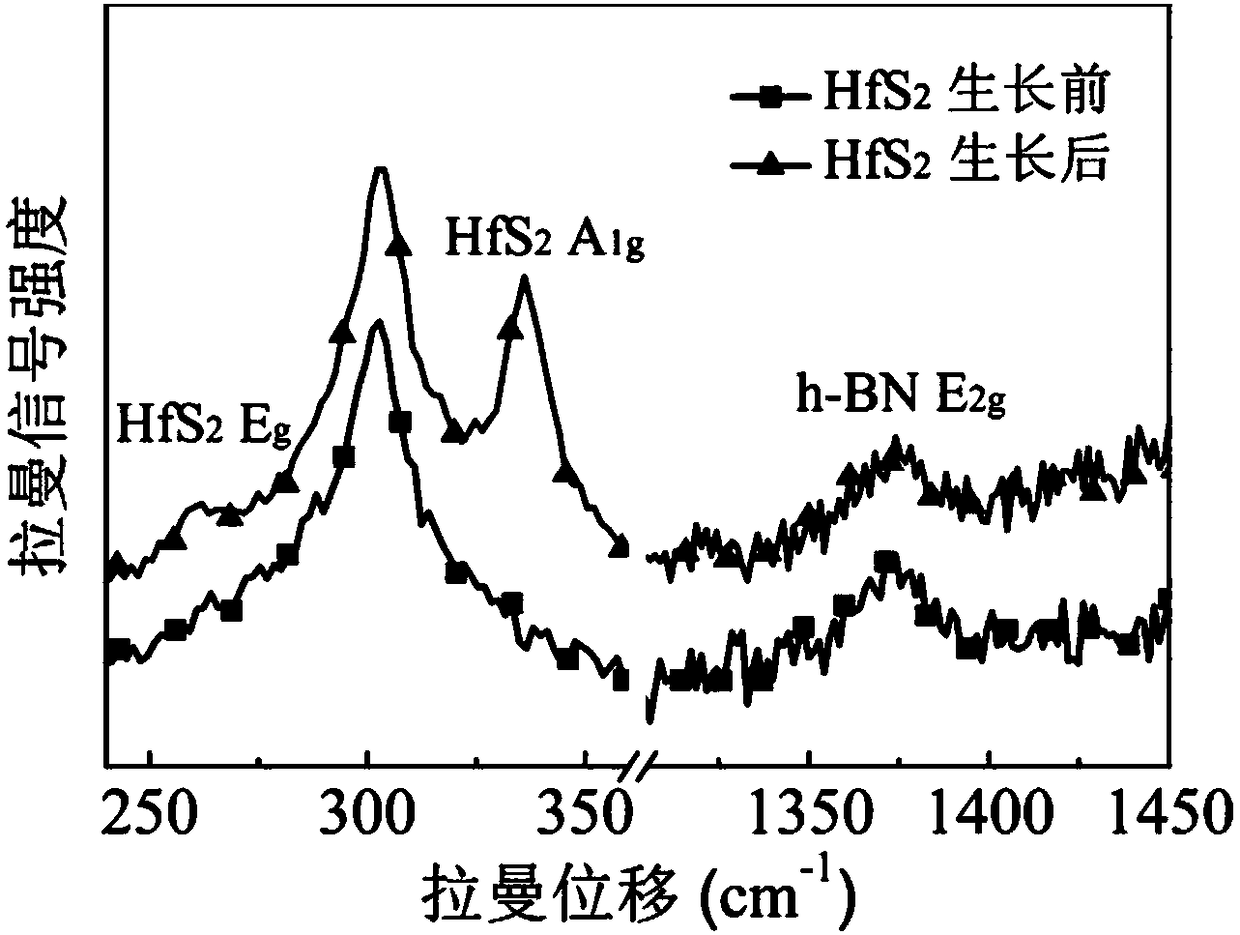

Method for preparing HfS2/h-BN heterojunction material by selective patterning

InactiveCN108198753AControllableRealize large-scale applicationSemiconductor/solid-state device manufacturingHeterojunctionOrganic matter

The invention provides a method for preparing an HfS2 / h-BN heterojunction material by selective patterning. The method comprises the following steps of 1, transferring an h-BN crystal domain or a thinfilm material to a target substrate; 2, performing target patterning photoetching on h-BN transferred onto the target substrate; 3, annealing the h-BN substrate under an oxygen atmosphere to remove an organic matter resided on a surface of the h-BN; and 4, growing an HfS2 atomic crystal on a surface of the h-BN substrate after annealing is completed, and selectively preparing the HfS2 / h-BN heterojunction material. The HfS2 / h-BN heterojunction material is simple in preparation process, low in cost and high in controllability, and importance significance is brought to mass integrated productionand application of an HfS2 / h-BN material-based photoelectric device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

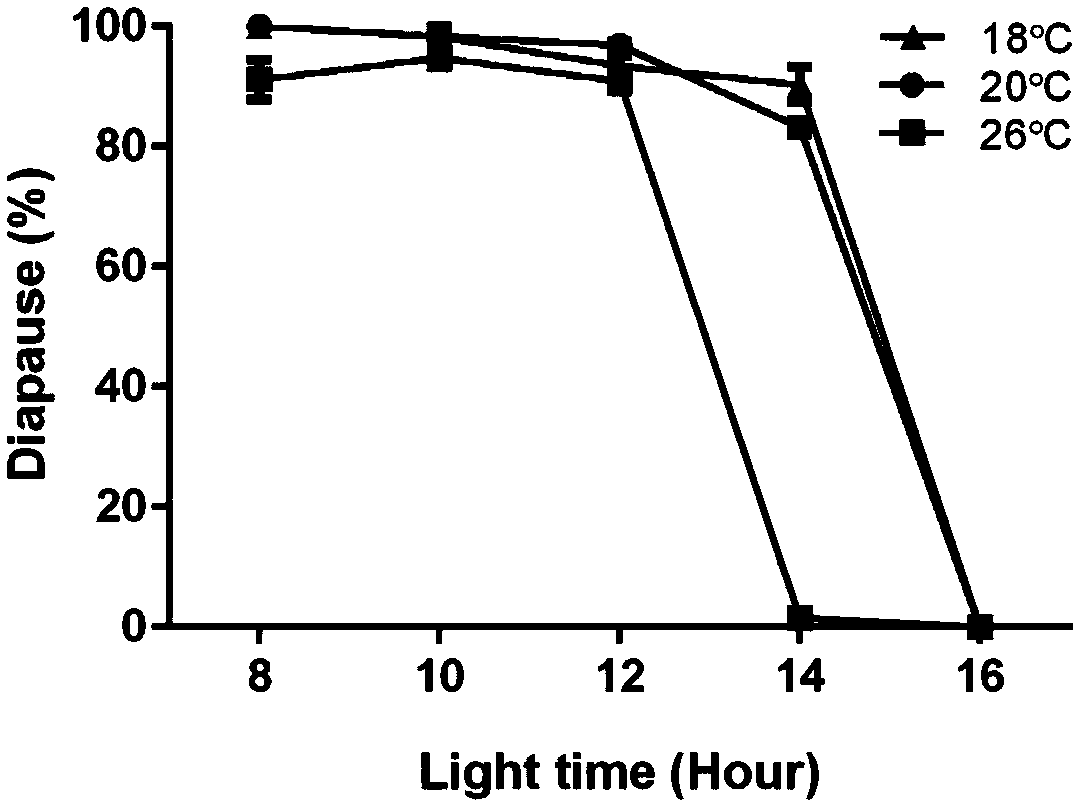

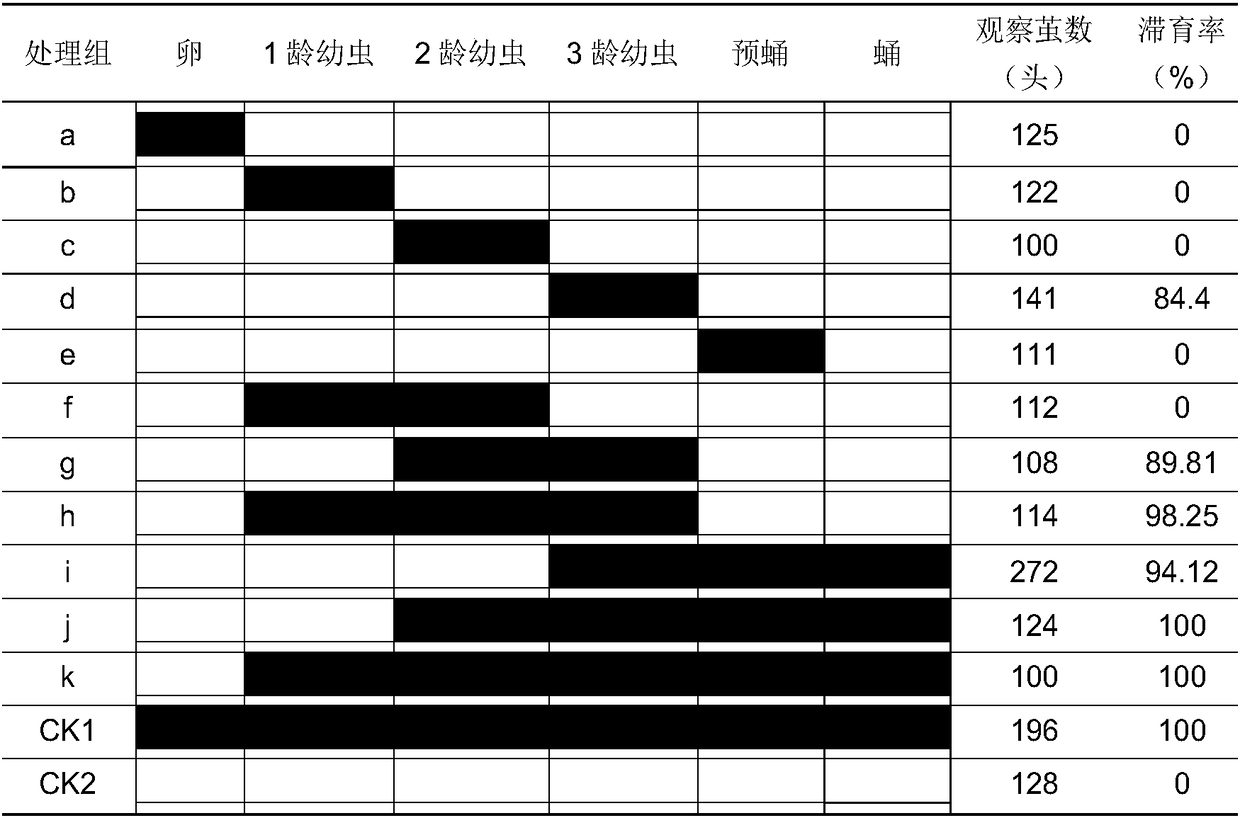

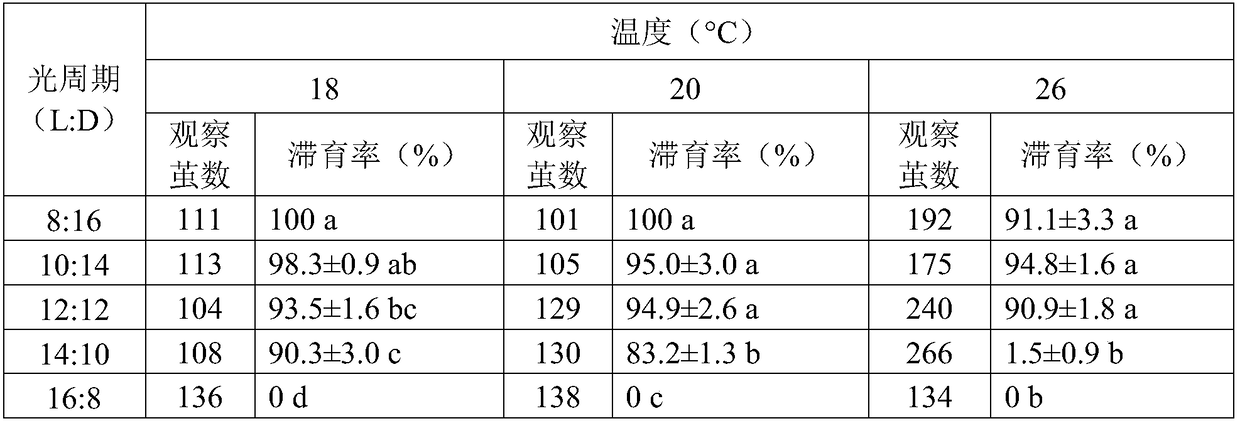

Diapause inducing method for chrysopa formosa brauer

InactiveCN108056071ARealize manual regulationAchieving annual multiplicationAnimal husbandryDiapauseInsect pupa

The invention provides a diapause inducing method for chrysopa formosa brauer. The method includes the following steps of 1, selecting the whole larval phase of chrysopa formosa brauer as the diapauseregulation and control timing, and adopting chrysopa formosa brauer at the regulation and control timing as diapause inducing objects; 2, placing chrysopa formosa brauer selected in the step 1 underan inducing environmental condition, and regulating and controlling the combination of illumination time length, temperature and total inducing time length every day to enable chrysopa formosa brauerto enter a diapause state, wherein the everyday illumination time length adopts a photoperiod of (8-12) L:(16-12) D, the temperature is 18-26 DEG C, and a continuous inducing time period starts from an annual-larva period to a pupal period. The method has the advantages that manual regulation and control of the growth process of chrysopa formosa brauer can be achieved, the diapause characteristiccan be applied to biological prevention and control to prolong the shelf life of natural enemy products, ensure safe long-distance transportation of the products and improve the disaster control effect, and a technical guarantee is provided for annual propagation expansion and large-scale application of the natural enemy insect products.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

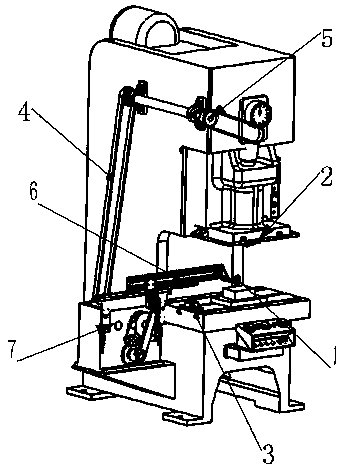

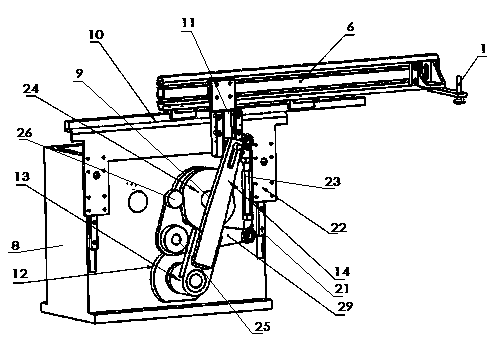

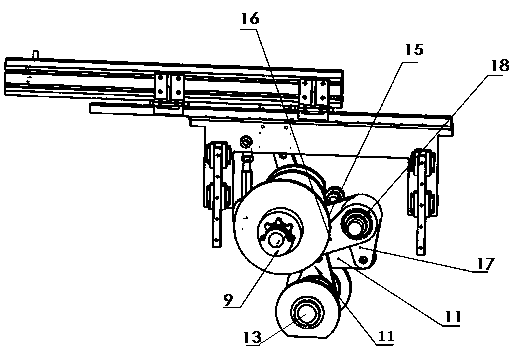

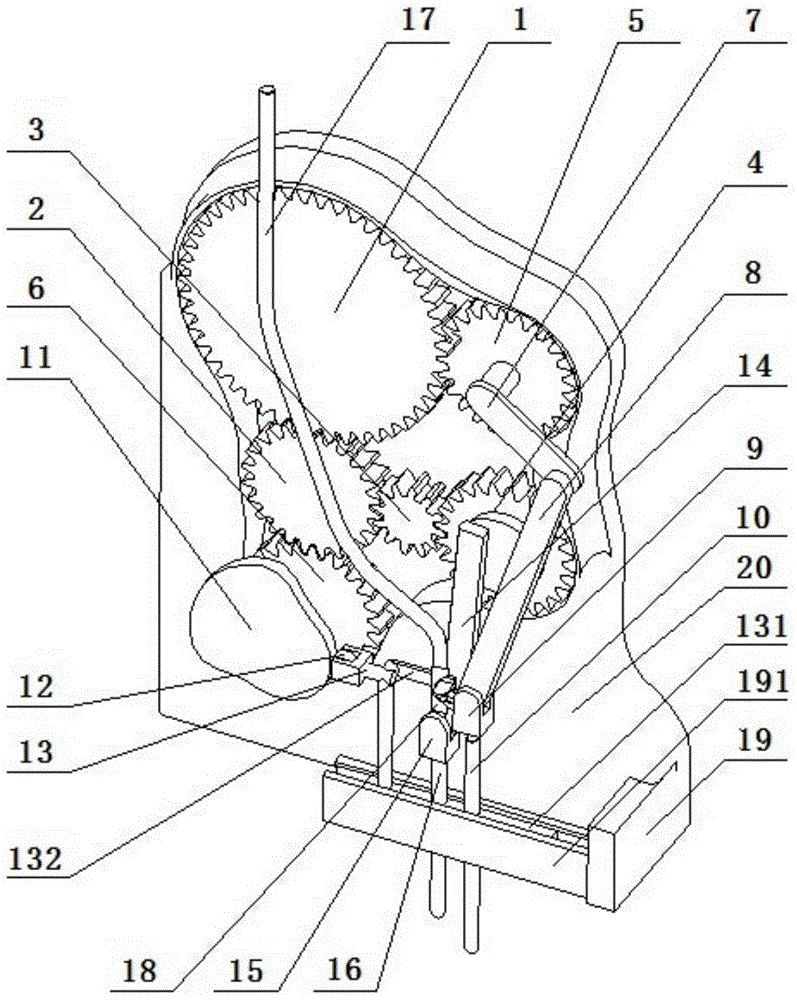

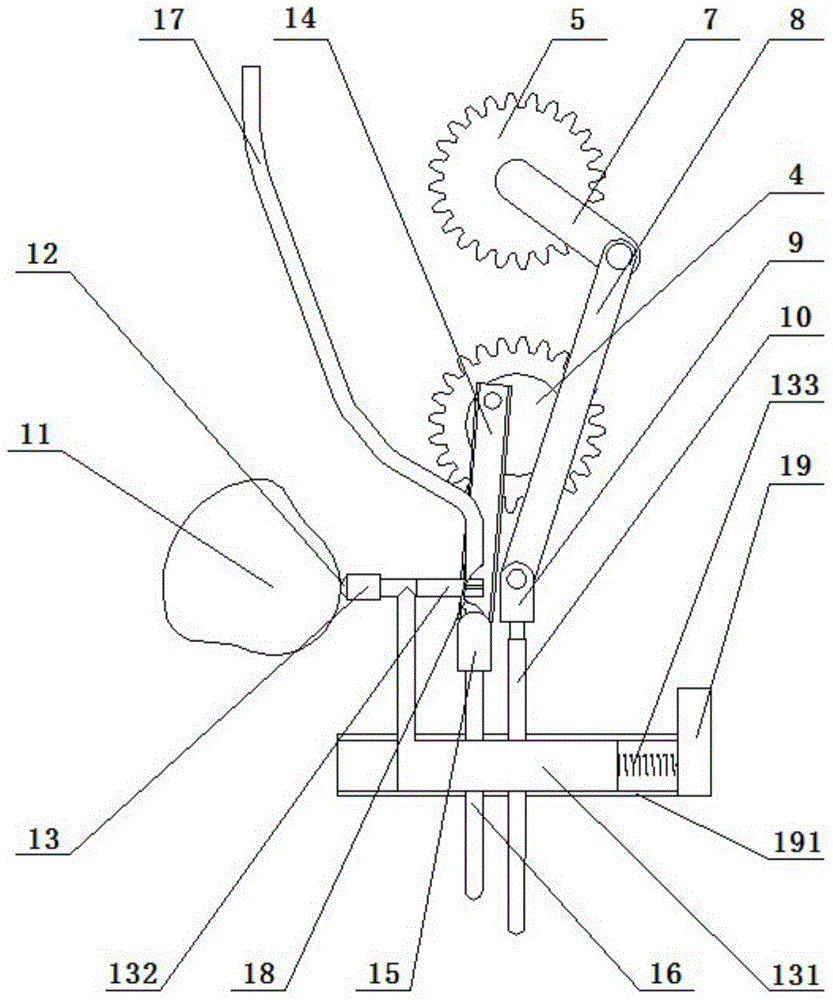

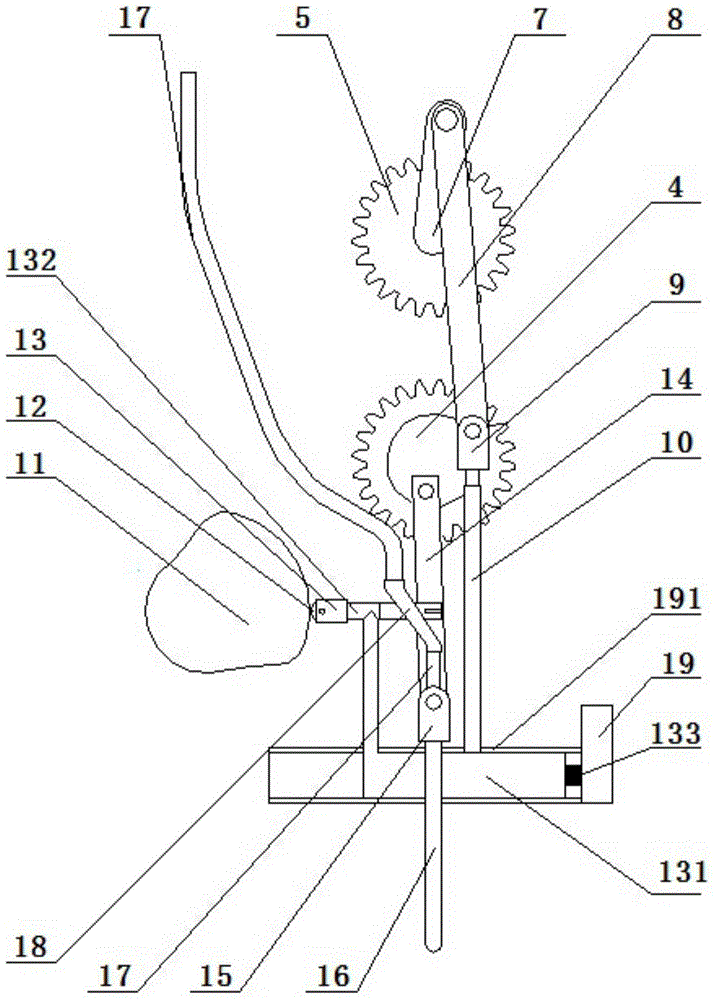

Mechanical arm feeding system

PendingCN111085621AHigh speedIncrease productivityMetal-working feeding devicesPositioning devicesRobot handGear wheel

The invention discloses a mechanical arm feeding system. The system comprises a punch, and a feeding mechanical arm mounted on the feeding side of the punch, the feeding mechanical arm is in work connection with a punch drive device through a chain, the feeding mechanical arm comprises a feeding support, an X-axis-direction motion guide rail device mounted on the feeding support, a Z-axis-direction motion guide rail device mounted on the side of the feeding support, an X-axis driving mechanism in drive connection with X-axis-direction motion guide rail device, a Z-axis driving mechanism in drive connection with the Z-axis-direction driving mechanism and a main driving shaft mounted on the support, in connection with the chain through a gear and capable of providing power for the X-axis driving mechanism and the Z-axis driving mechanism. The mechanical arm feeding system is high in speed, production efficiency is high, operation is easy and convenient, the equipment structure is simple,investment cost is low, operation is easy, manual operation is not needed, and the mechanical arm can be operated only through operating an equipment main engine.

Owner:南京智必达自动化科技有限公司

Graphene oxide slurry, miniature graphene electrode and preparation method thereof and miniature graphene supercapacitor

ActiveCN107331529ANot easy to reuniteImprove uniformityHybrid capacitor electrodesInksCapacitanceSupercapacitor

The invention discloses graphene oxide slurry, a miniature graphene electrode and a preparation method thereof and a miniature graphene supercapacitor. The graphene oxide slurry comprises the following components in parts by weight: 15-35 parts of graphene oxide, 1-3 parts of bonding resin and 150-200 parts of a solvent. The miniature graphene electrode is prepared from the graphene oxide slurry through the steps of printing and reduction. The miniature graphene supercapacitor comprises the miniature graphene electrode and an electrolyte, wherein the electrolyte covers a positive electrode and a negative electrode of the miniature graphene electrode. The preparation route from the graphene oxide electrode to the graphene electrode and then to the miniature graphene supercapacitor is simple and low in cost. The prepared miniature graphene supercapacitor with a two-dimensional planar structure is good in capacitance performance and convenient for being integrated into a chip electronic product.

Owner:NAT UNIV OF DEFENSE TECH

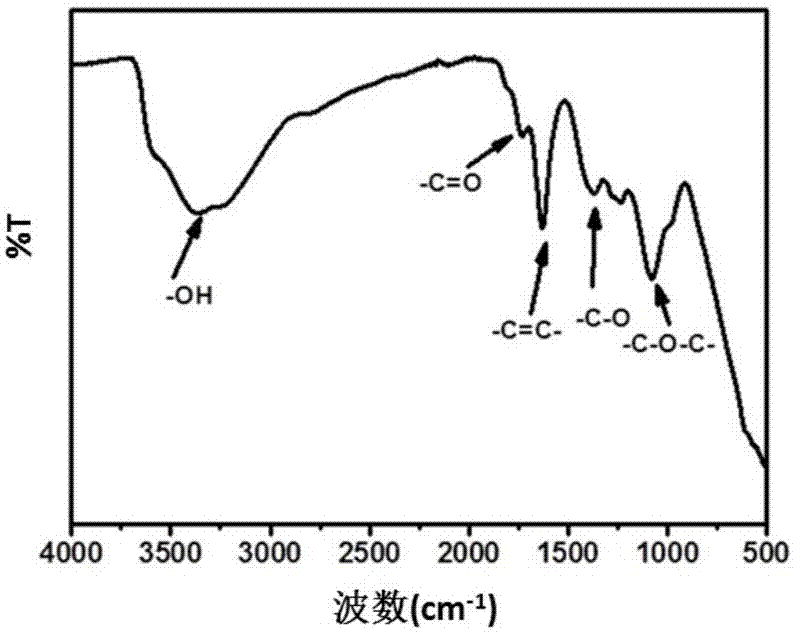

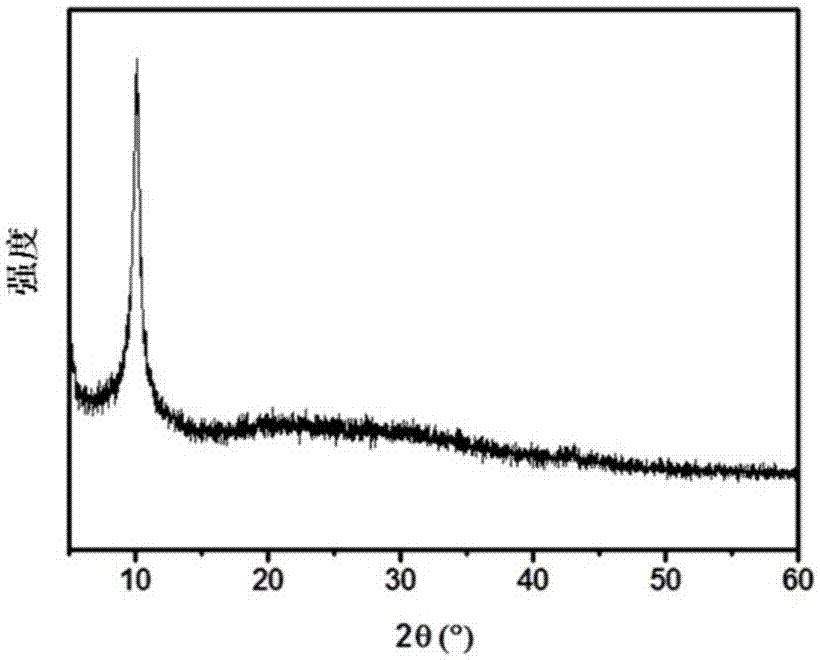

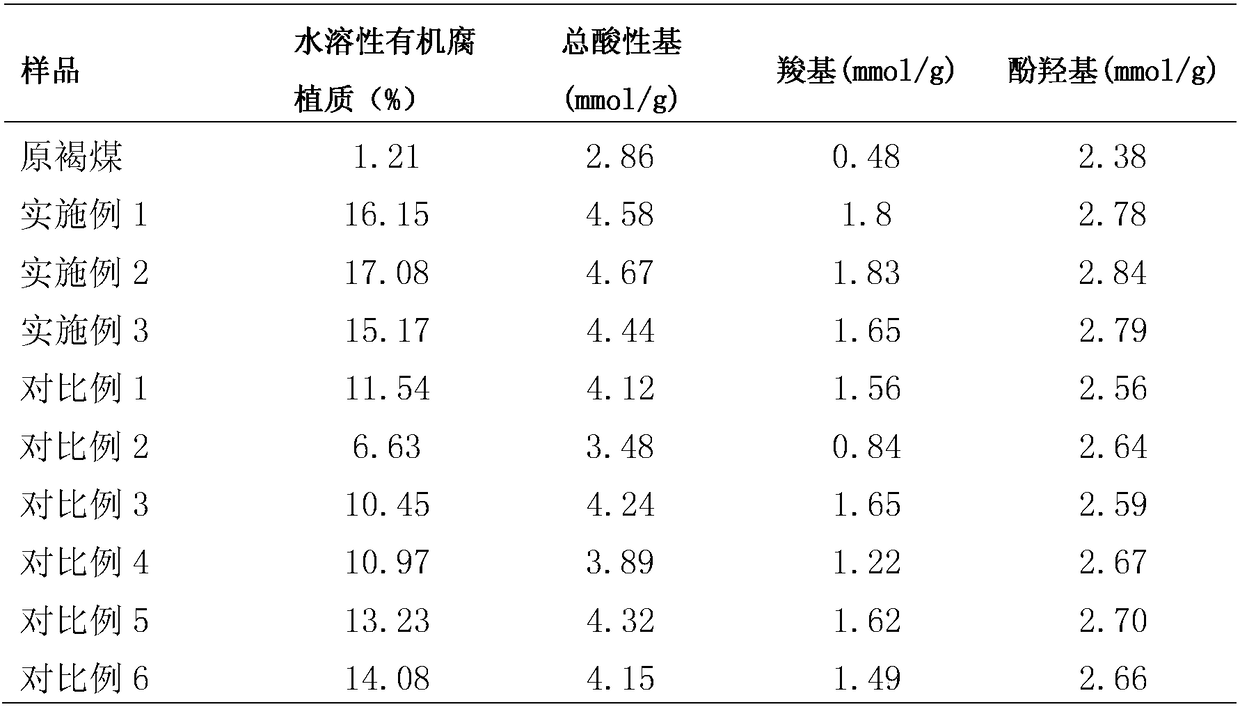

Method for activating lignite

ActiveCN108083860AImprove oxidation capacityReduce dosageOrganic fertilisersFertilizer mixturesEnvironmental resistanceWater soluble

The invention discloses a method for activating lignite. The method comprises the following steps: mixing lignite powder, a photocatalytic oxidizing agent and water uniformly; and completely stirringunder the condition of ultraviolet irradiation, adding the oxidizing agent in batches, and reacting at 30 to 60 DEG C for 0.15 to 24 hours to obtain activated lignite, wherein the photocatalytic oxidizing agent is titanium dioxide. By the method provided by the invention, the water-soluble organic humus content and the active group content of the lignite can be increased very obviously and large-scale application of the lignite is further realized; and the method provided by the invention is environment-friendly, pollution-free, short in process route, low in cost, simple in requirement on equipment and mild in condition, and can be applied to industrialized mass production.

Owner:QUJING NORMAL UNIV +2

Negative electrode active material for battery and preparation method thereof

ActiveCN111162269ALower pHDoes not affect rheological propertiesMaterial nanotechnologyCell electrodesElectrical batterySilicon oxygen

The invention relates to a negative electrode active material for a battery. The negative electrode active material comprises the negative electrode active material particles, and the negative electrode active material particles contain a silica compound and comprise a lithium element, the doped metal M1 and the doped metal M2, wherein the metal M1 comprises one or more of titanium, magnesium, zirconium, zinc, aluminum, yttrium and calcium, the metal M1 comprises one or more of copper, nickel, iron, manganese, cobalt and chromium, the metal M2 comprises one or more of copper, nickel, iron, manganese, cobalt and chromium, and the metal M1 and the metal M2 account for 0.01-25 wt%, preferably 0.05-15 wt%, more preferably 0.1-10 wt% and more preferably 0.1-5 wt% of the content of the negativeelectrode active material. The battery prepared from the negative electrode active material has the advantages of high capacity, high coulombic efficiency, long cycle life and high water resistance.

Owner:BERZELIUS (NANJING) CO LTD +1

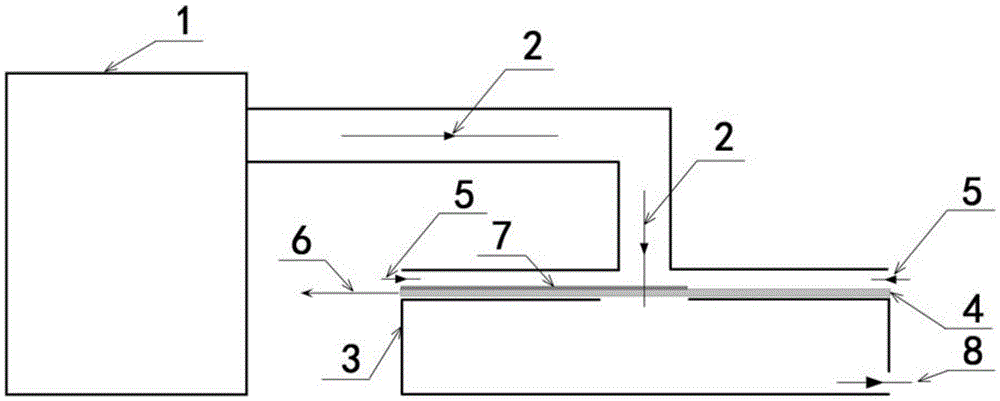

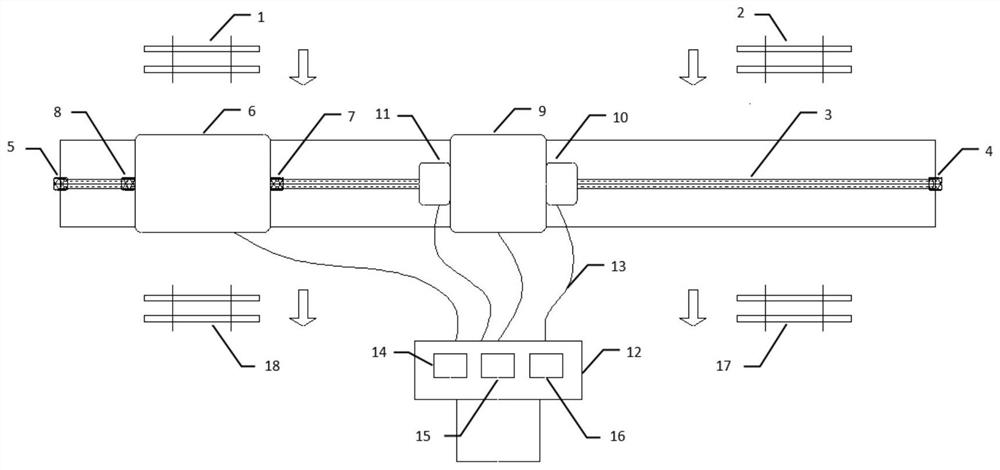

Gas-phase continuous preparation method and special device for single-walled carbon nanotube film

The invention relates to a preparation method of single-walled carbon nanotubes by a floating catalyst chemical vapor deposition process and a film continuous collection technology thereof, and specifically relates to a gas-phase continuous preparation method of a single-walled carbon nanotube film and a special device. The preparation method comprises the steps of depositing the single-walled carbon nanotubes synthesized by the floating catalyst chemical vapor deposition process onto the surface of a microporous filter membrane moving at a uniform speed by utilizing a gas-phase suction filtration device under normal-pressure and room-temperature conditions, controlling the movement speed of the microporous filter membrane, and regulating and controlling the gas flow balance to obtain a large-area, uniform and density-controllable single-walled carbon nanotube film. According to the gas-phase continuous film-forming technology of the single-walled carbon nanotubes, provided by the invention, the large-scale preparation of the large-area, uniform and density-controllable single-walled carbon nanotube film is realized under the normal-pressure and room-temperature conditions, the preparation method has important significance in promoting the progress of the single-walled carbon nanotube film in the field of large-scale preparation and application of optoelectronic devices, and the film has application in the field of large-scale preparation of the optoelectronic devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Light-transmitting thin non-woven degradable agricultural mulching film and preparation method

ActiveCN107567896AGood effectHigh tensile strengthPlant protective coveringsSulfite saltPlastic mulch

The invention belongs to the technical field of agricultural mulching film preparation, and provides light-transmitting thin non-woven degradable agricultural mulching film and a preparation method. The method comprises the steps that firstly, hemp fibers are cut into long fibers, and colloidal materials, starch, dust and the like are scattered, sieved and removed; a mixed solution of sodium hydroxide and sodium sulfite is adopted for soaking treatment, paper slurry is obtained by means of a blasting method, and thin-layer non-woven fabric with large holes is prepared through the processes ofslurry grinding, beating and papermaking; the large holes are painted with thermoplastic starch, and the light-transmitting thin non-woven degradable agricultural mulching film can be prepared after hot-pressing and plasticizing molding. Compared with traditional methods, the method overcomes the defect of low transmittance of hemp fiber mulching film and the technical bottleneck that low thickness and high strength cannot be achieved at the same time.

Owner:吴雨潞

Ultra-energy-saving electric radiator

PendingCN108072093ARealize large-scale applicationHeating fuelLighting and heating apparatusThermal efficiencyRural development

The invention discloses an ultra-energy-saving electric radiator. The ultra-energy-saving electric radiator consists of a radiator body, a heat accumulation box and an electric heating element. In a 25 m<2> three-step energy-saving building room which accords with requirement of the ministry of housing and urban-rural development, temperature required by the China winter heating design specification can be reached with an input power of 220W; and heating efficiency is 454.5%.

Owner:陈有孝

Method for recovering protein in fish extract by using carrageenan as flocculating agent

InactiveCN103819536ASimple processFast flocculationPeptide preparation methodsFish ProteinsFish extract

The invention discloses a method for recovering protein in fish extract by using carrageenan as a flocculating agent. The method comprises the steps of adjusting a pH value of the fish extract to 3.0-8.0; adding a carrageenan solution with a mass concentration of 1-5% into the fish extract with the pH value adjusted; subjecting the carrageenan and protein in the fish extract to a flocculating reaction thoroughly; standing and layering to precipitate the protein; and separating solid from liquid to obtain the protein. According to the method, no harmful ingredient to human body is introduced; a process is simple; operation cost is low; operation time is short; possibility of the fish protein deterioration is reduced; and the protein in the fish extract is effectively recovered. The method has economic benefits and environment benefits.

Owner:JIANGNAN UNIV

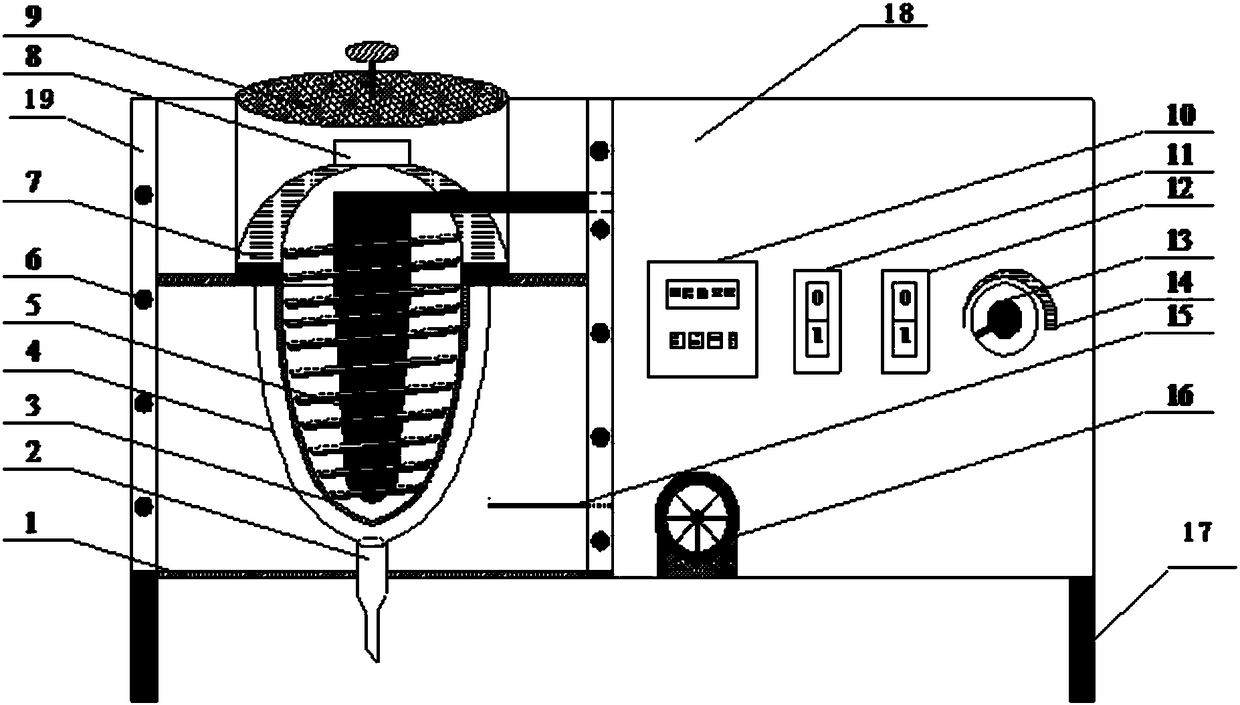

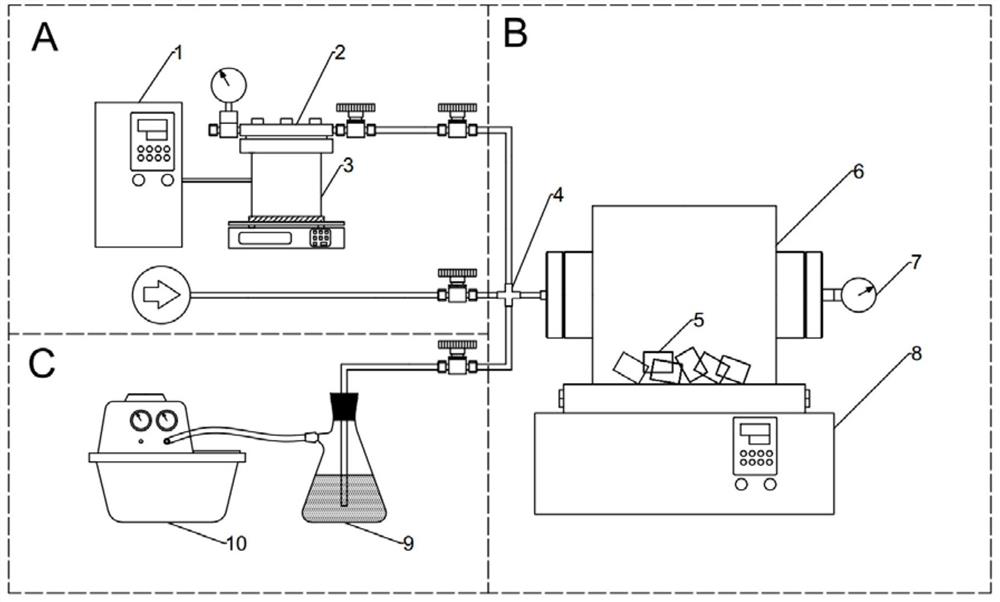

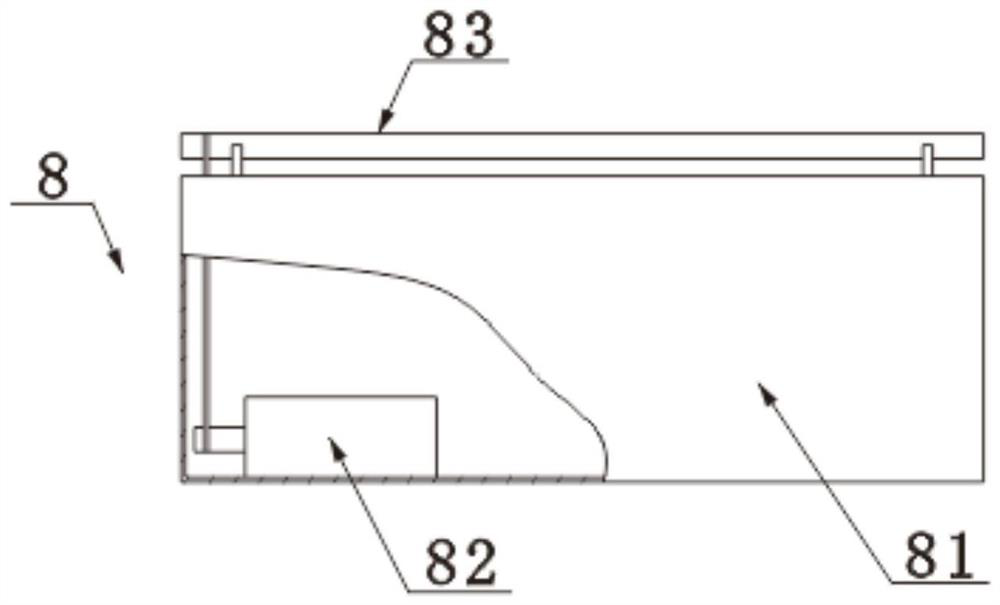

Method for testing real viscosity of rubber asphalt and equipment of method

The invention discloses equipment for testing the real viscosity of rubber asphalt. A plurality of heating rods are arranged inside the side wall of a shell; an ellipsoid metal shell is arranged inside the shell; an ellipsoid filtering net is positioned inside the ellipsoid metal shell; a wide threaded rotor is arranged inside the ellipsoid filtering net; a guide tube is connected with the bottomof the ellipsoid metal shell; a conveyer belt is arranged around the wide threaded rotor on the upper side of the ellipsoid metal shell. The invention further provides a method for testing the real viscosity of rubber asphalt. The rubber asphalt filtering equipment disclosed by the invention is simple, intelligent and convenient to operate, molten rubber asphalt can be filtered by using a 200-meshsieve, filtered waste tire rubber powder can be discharged outside the equipment, heat preservation can be also achieved, properties of the rubber asphalt can be maintained, and the heat preservationtime can be shortened for later viscosity testing; the testing accuracy can be remarkably improved since the filtered rubber asphalt is tested at five different rotation speeds instead of one rotation speed, and errors can be reduced.

Owner:甘肃省公路工程质量试验检测中心有限公司

A wave energy conversion power generation device

ActiveCN103511168BRealize large-scale applicationAchieve high power generationMachines/enginesSafety/regulatory devicesImpellerShock wave

The invention relates to the technical field of power generation devices, and discloses a wave energy conversion power generation device. According to the wave energy conversion power generation device, wave energy is utilized, large-scale application is achieved, and high-power generation is achieved. The wave energy conversion power generation device comprises a base, a wave chopping assembly, a power generation assembly, a lifting assembly and a control assembly. When the wave energy conversion power generation device is used, a lifting control cabinet of the control assembly adjusts wave chopping guide board lifters of the lifting assembly, a coupling box lifter and a generator lifter according to the tide and wave; wave chopping guide boards can reach the optimum height and gradient, and therefore the wave passes through the wave chopping guide boards, forms the shock wave peak at the board tops, then impacts an impeller assembly at the optimum height to rotate and is conveyed through a transmission shaft chain, a generator is made to generate power, and produced power is sent out through a power distribution cabinet; under the action of the control assembly, the wave chopping assembly and the power generation assembly can lift in the base along with the tide, and ceaseless power generation is achieved.

Owner:福建中夷海洋能源科技有限公司

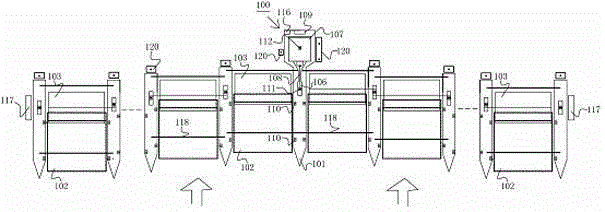

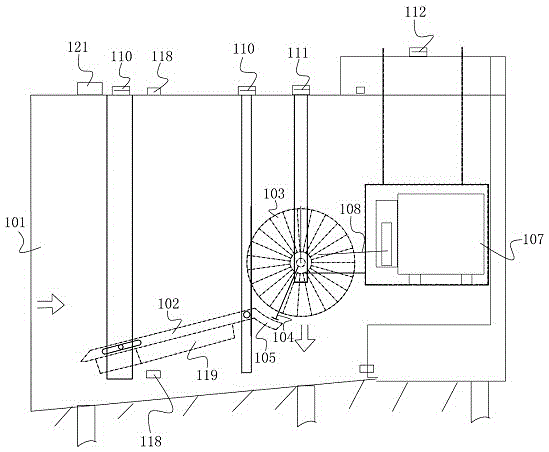

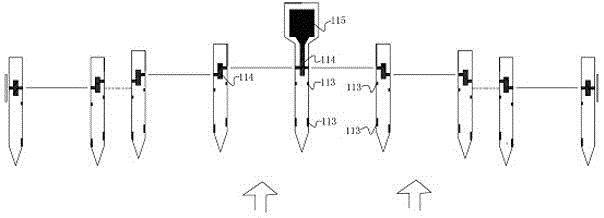

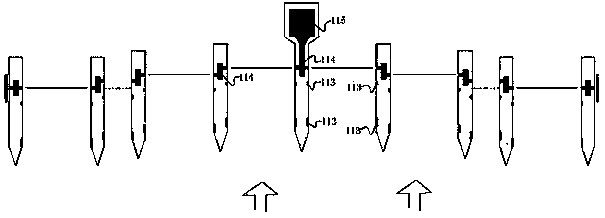

Drilling and sand filling device

InactiveCN104969692ARealize large-scale applicationImprove work efficiencySoil lifting machinesPlantingCamMechanical engineering

The invention relates to the technical field of agricultural machinery, and especially relates to a drilling and sand filling device. The device is composed of a box body, a drilling mechanism, a sand filling mechanism, and a cam pushing mechanism. The box body is composed of a gear box, a power gear and a guiding plate. The guiding plate is fixedly connected to the lower end of the gear box. A horizontal guiding slot is connected to the guiding plate. The power gear is arranged in the gear box. The drilling mechanism comprises a drilling gear, a crank, a connection rod, a needle sleeve and a drilling needle. The sand filling mechanism comprises a sand filling gear, a connection rod, a pipe sleeve, a sand discharge pipe, and a sand guiding device. The cam pushing mechanism comprises a cam gear, a cam, a roller, and a cam driven rod. According to the invention, the drilling mechanism and the filling mechanism are orderly combined, such that sequential drilling-sand filling action steps are performed at a same position. Accordingly, the working efficiency is improved; the improvement agent large-scale application is realized; and the precise filling is achieved. The device facilitates the development and popularization of soil improvement technologies.

Owner:CHINA AGRI UNIV

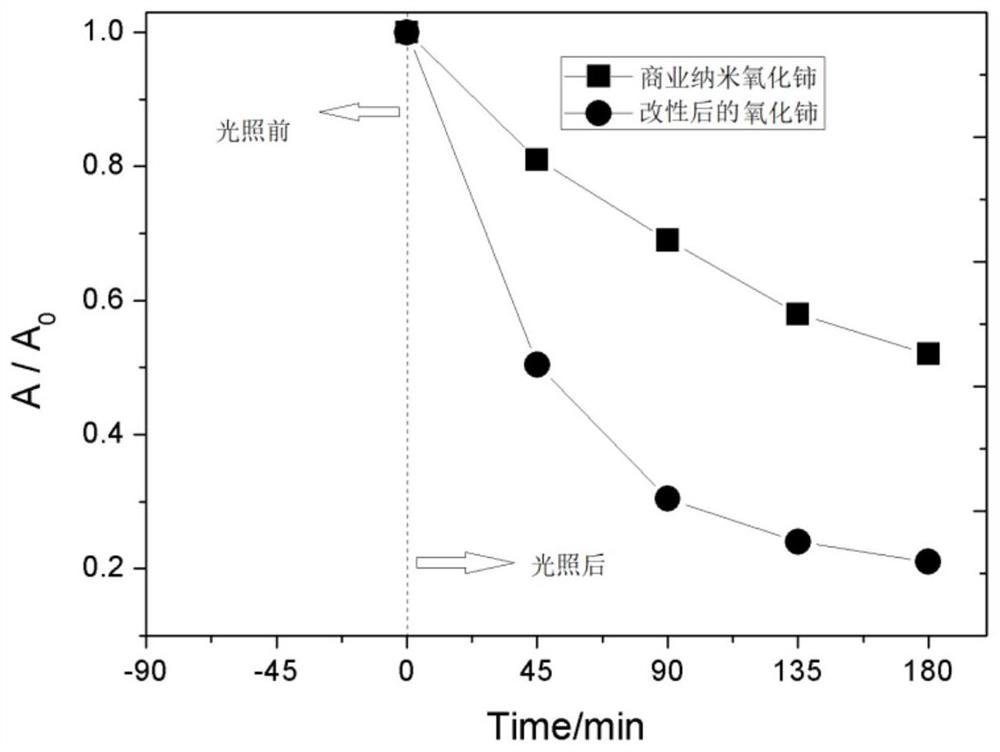

Device and method for preparing oxygen vacancies of catalytic materials

PendingCN112791720AShorten the timeReduce stepsHeat treatmentsCatalyst activation/preparationPtru catalystOxygen vacancy

The invention belongs to the technical field of new material preparation, and particularly relates to a device for preparing oxygen vacancies of catalytic materials. The device comprises a reaction cavity, a vacuum pump, an inert gas tank, a reducing gas tank and a gas premixing chamber, and the vacuum pump, the reaction cavity, the inert gas tank and the reducing gas tank are communicated with the gas premixing chamber through valves. By adjusting the valve, the vacuum pump vacuumizes the reaction cavity, the reaction cavity is cleaned through inert gas, and reducing gas is introduced into the reaction cavity, so that oxygen vacancy manufacturing is achieved. According to the invention, vacuum heat treatment and controllable preparation of oxygen vacancies are integrated together, so that the material treatment time and steps are greatly shortened, and nano photocatalysts with different crystal structures and rich oxygen vacancies can be prepared.

Owner:HANGZHOU DIANZI UNIV

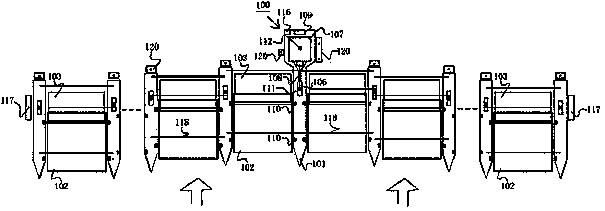

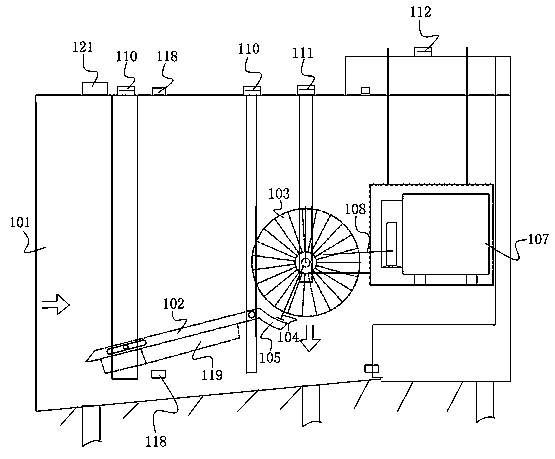

Wave energy conversion power generation device

ActiveCN103511168ARealize large-scale applicationAchieve high power generationMachines/enginesSafety/regulatory devicesImpellerShock wave

The invention relates to the technical field of power generation devices, and discloses a wave energy conversion power generation device. According to the wave energy conversion power generation device, wave energy is utilized, large-scale application is achieved, and high-power generation is achieved. The wave energy conversion power generation device comprises a base, a wave chopping assembly, a power generation assembly, a lifting assembly and a control assembly. When the wave energy conversion power generation device is used, a lifting control cabinet of the control assembly adjusts wave chopping guide board lifters of the lifting assembly, a coupling box lifter and a generator lifter according to the tide and wave; wave chopping guide boards can reach the optimum height and gradient, and therefore the wave passes through the wave chopping guide boards, forms the shock wave peak at the board tops, then impacts an impeller assembly at the optimum height to rotate and is conveyed through a transmission shaft chain, a generator is made to generate power, and produced power is sent out through a power distribution cabinet; under the action of the control assembly, the wave chopping assembly and the power generation assembly can lift in the base along with the tide, and ceaseless power generation is achieved.

Owner:福建中夷海洋能源科技有限公司

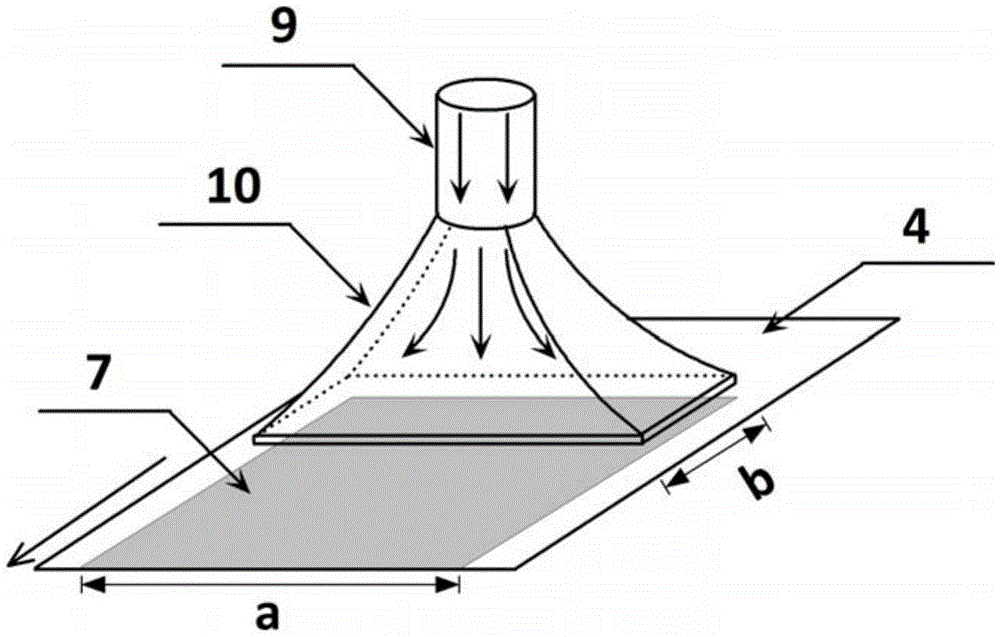

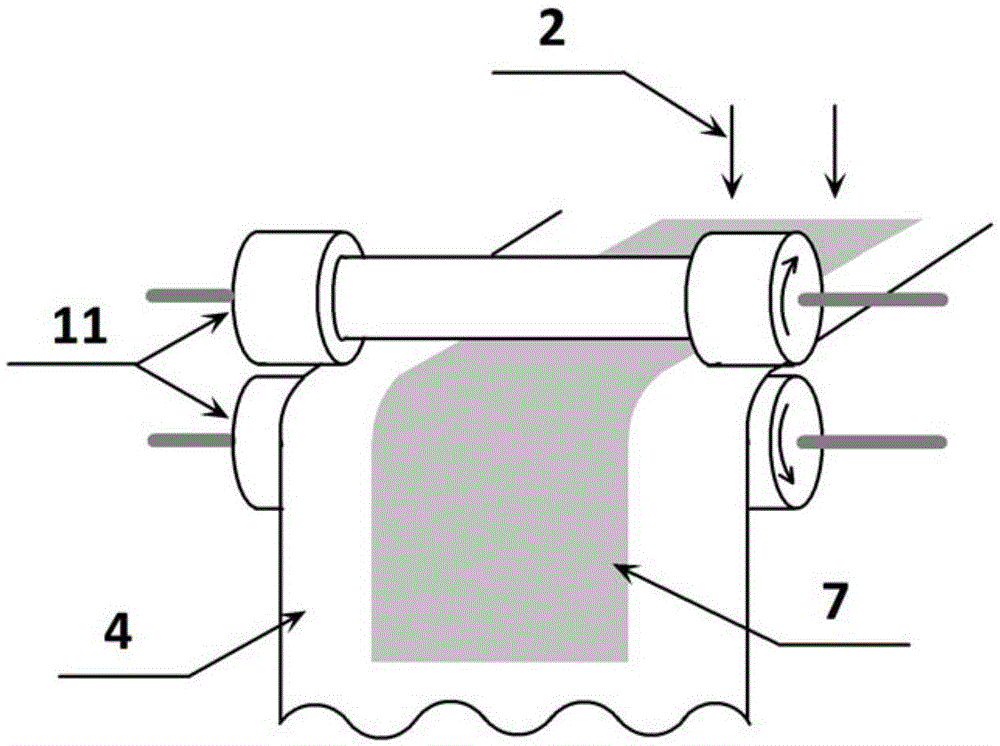

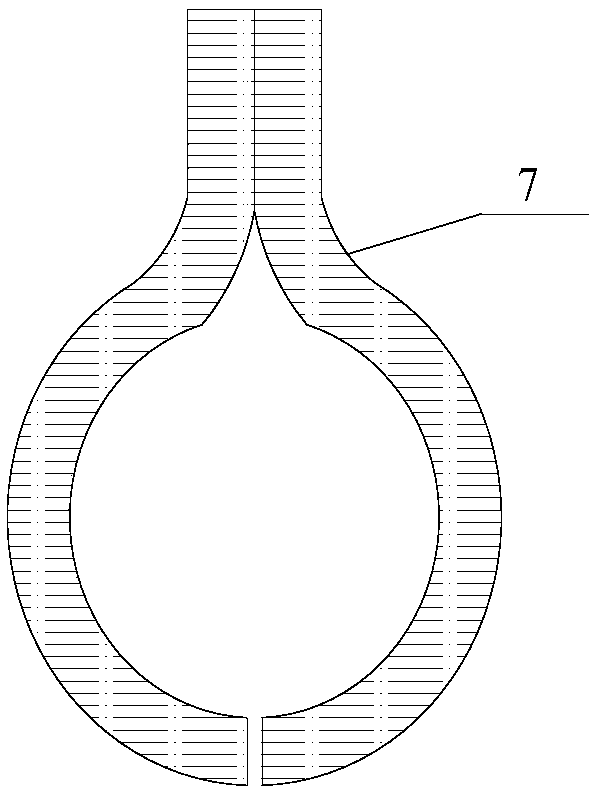

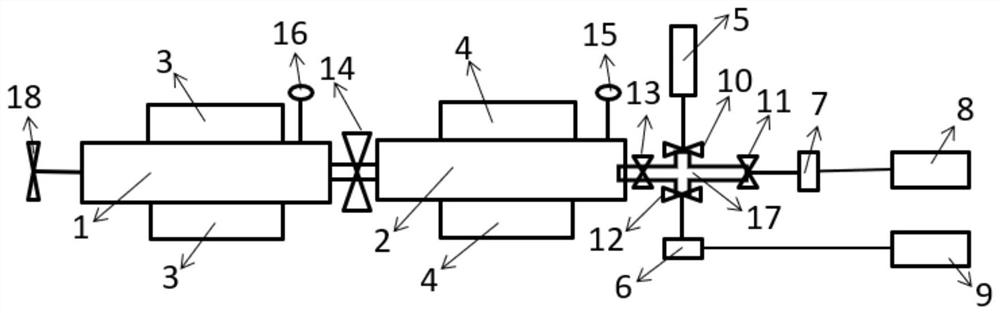

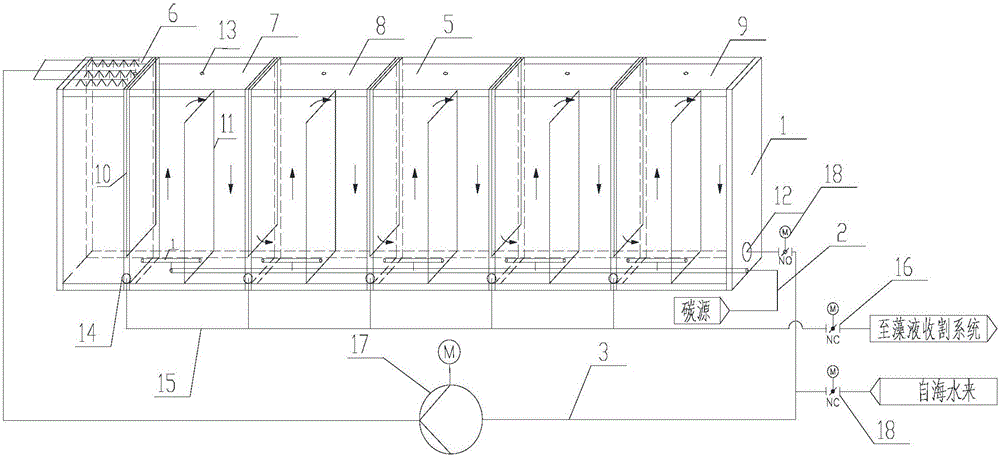

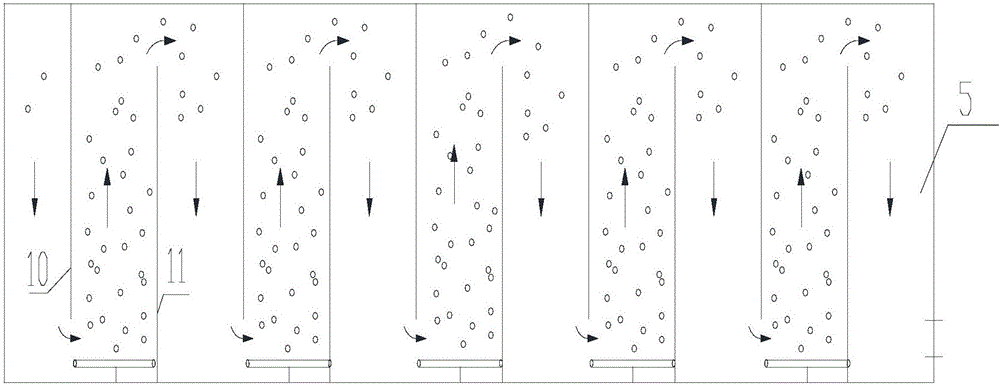

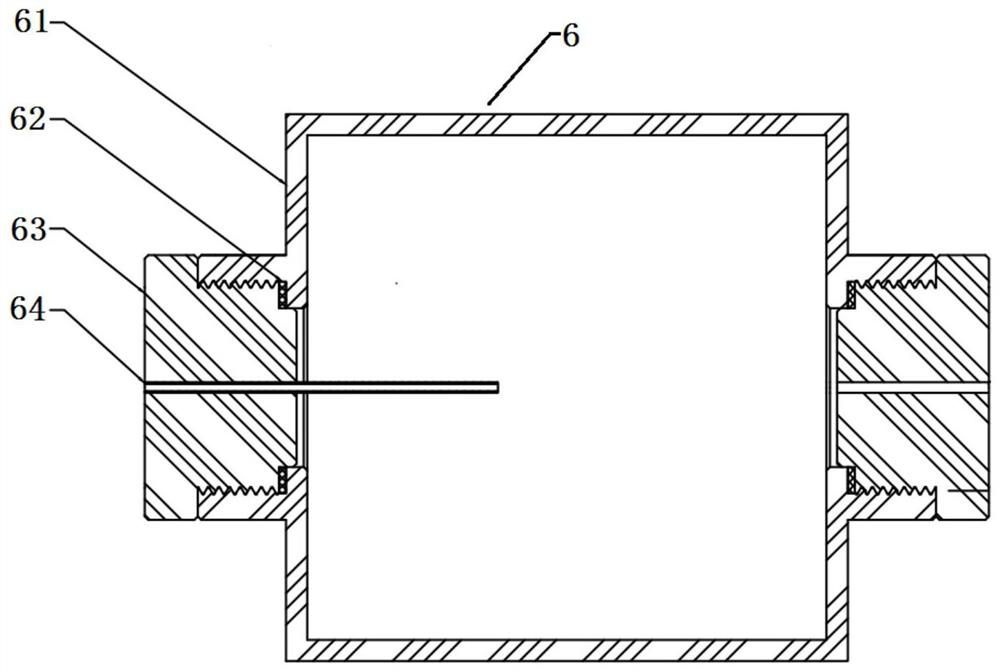

Flat-plate photobioreactor device system

InactiveCN106367315ARealize large-scale applicationIncrease mass transfer rateBioreactor/fermenter combinationsBiological substance pretreatmentsAeration systemPhotobioreactor

The invention relates to a flat-plate photobioreactor device system. The flat-plate photobioreactor device system comprises a photobioreactor body, an aeration system, an algae liquid circulation system and a spray system, wherein the photobioreactor body comprises a reactor shell, a spray area and reaction areas; n stages of reaction areas are available, n is greater than 1, the n stages of reaction areas are partitioned by inner partition boards, and space is reserved between the inner partition boards and the bottom of the reactor shell, so that algae liquid can enter each reaction area from the spray area; flow guide plates are arranged in the reaction areas along the flowing direction of the algae liquid, and are positioned in the central positions of the reaction areas; space is reserved between the flow guide plates of the n stages of reaction areas and the top of the reactor shell. The flat-plate photobioreactor device system has the beneficial effects that the large-scale application of the microalgae carbon fixation technology can be realized, the problems that the traditional stirring mixing method is poor in mixing effect, and the shear force generated by stirring can severely damage the cellular structure of the microalgae are solved, the sufficient mixing of CO2 and the algae liquid in the photobioreactor is guaranteed, and the CO2 mass transfer rate is improved.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

A rotary drum reactor for pulse chemical vapor deposition coating and its application

ActiveCN111218669BRealize large-scale applicationAvoid stickingChemical vapor deposition coatingReaction rateChemical vapor deposition

The invention discloses a drum type reactor for pulse chemical vapor deposition coating and application thereof. The reactor includes a precursor supply part, a reaction part, and an exhaust gas treatment part; the precursor supply part includes a first gas supply part and a second gas supply part, and the first gas supply part includes a source bottle with a heating device; the second gas supply part It is connected to the air and sucked in by the negative pressure of the reaction part; the reaction part includes the reaction drum and the driving device for driving the reaction drum, and the reaction drum is placed horizontally on the driving device; the tail gas treatment part is used for vacuuming the reaction drum and absorbing reaction after the exhaust. Reactor among the present invention is mainly used for anatase TiO 2 For pulse chemical vapor deposition coating, the reactor with this structure can improve the gas-solid phase contact conditions, solve the problem of slow reaction caused by difficult gas diffusion, speed up the reaction rate of gas phase coating, and simplify the operating conditions, avoiding the Uneven thickness, raw material loss, dust pollution and other effects in the tiling process.

Owner:SICHUAN UNIV

Continuous counterweight concrete coating and curing agent online spraying equipment and method for sea pipes

ActiveCN110883926BGuaranteed continuityIncrease the level of automationCeramic shaping apparatusCoating systemControl engineering

The invention discloses continuous submarine pipeline counterweight concrete coating and curing agent online spraying equipment and method. The equipment comprises a pipe inlet device, a counterweightcoating rail, a counterweight coating trolley, a counterweight concrete spraying and coating system, curing agent spraying systems, an industrial personal computer and a pipe outlet device. The industrial personal computer is connected with the counterweight coating trolley, the counterweight concrete spraying and coating system and the curing agent spraying systems. According to the invention, the curing agent spraying systems are mounted on the two adjacent sides of the counterweight concrete spraying and coating system; counter weight concrete spraying and coating control and curing agentonline spraying control are associated and integrated; the on-line continuity and synchronous matching performance of concrete spraying and coating operation and curing agent spraying operation are guaranteed; the overall automation level and construction efficiency are improved; and large-scale application of the novel curing agent curing technology in the field of submarine pipeline spraying type counterweight concrete is achieved.

Owner:海油发展珠海管道工程有限公司

A feconi@c/carbon fiber airgel composite wave-absorbing material and its preparation method

ActiveCN110983492BSimple manufacturing methodFacilitate large-scale applicationOther chemical processesArtifical filament manufactureCarbon fibersMicrowave

The invention discloses a FeCoNi@C / carbon fiber airgel composite wave-absorbing material. The composite wave-absorbing material includes a carbon fiber matrix and FeCoNi@carbon composite nano-microspheres, and the FeCoNi@carbon composite nano-microspheres are loaded on the surface of the carbon fiber matrix. In the present invention, carbon fiber is used as a matrix, and microspherical FeCoNi@C derived from FeCoNi-MOF is loaded on its surface. The prepared composite material solves the lack of multiple effective electromagnetic wave loss mechanisms of a single carbon material and a single-metal MOF-derived material. The problems, good impedance matching and better absorption efficiency are obtained, and it is an ideal choice for new lightweight and efficient microwave absorbing materials.

Owner:SOUTHEAST UNIV

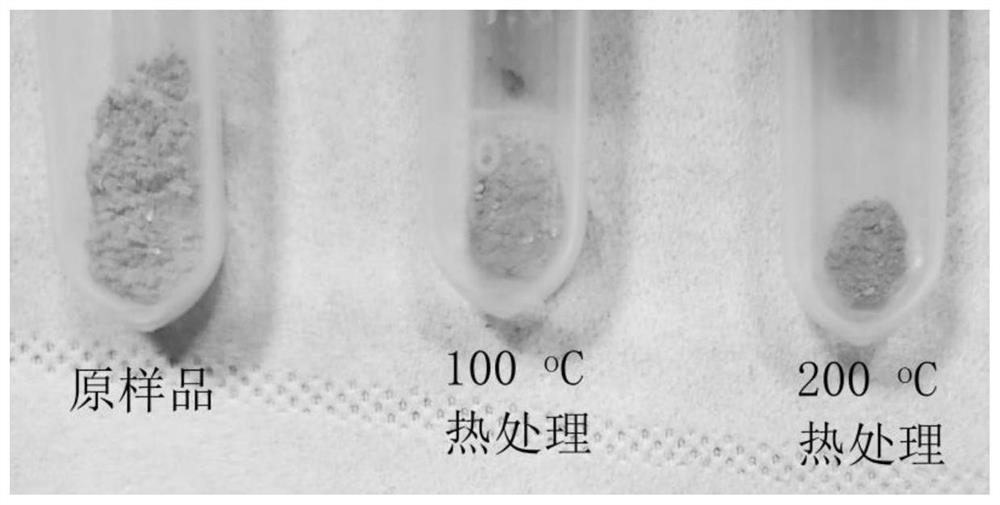

A doped multilayer core-shell silicon-based composite material for lithium-ion batteries and its preparation method

ActiveCN109599551BInhibits and buffers swellingPrevent partial failureMaterial nanotechnologyNegative electrodesCarbon filmSilicon oxygen

The invention relates to a doped multilayer core-shell silicon-based composite material for lithium-ion batteries and a preparation method thereof. The material is doped with at least one non-metallic element and a A metal element, the structure of which is to use element-doped silicon-oxygen compound particles as the core, and a multilayer composite film tightly coated on the surface of the core particle as the shell; the core particle contains uniformly dispersed elemental silicon nanoparticles, wherein The content of doping elements gradually decreases from the outside to the inside and there is no obvious interface. At the same time, the surface of the inner core particles forms a dense lithium silicate compound due to the doping of lithium elements; the multilayer composite film is a carbon film layer and is composed of A doped composite film layer composed of carbon film layer and other element components. When used in the negative electrode of lithium-ion batteries, it has electrochemical characteristics such as high capacity, good rate performance, high Coulombic efficiency, good cycle performance, and low expansion rate.

Owner:BERZELIUS (NANJING) CO LTD +1

A kind of j55 steel grade sew expansion sleeve and its manufacturing method

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com