Method for activating lignite

A technology of lignite and lignite powder, which is applied in the field of coal chemical industry, can solve the problems of low production cost and achieve the effects of improving oxidation efficiency, good oxidation effect and improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

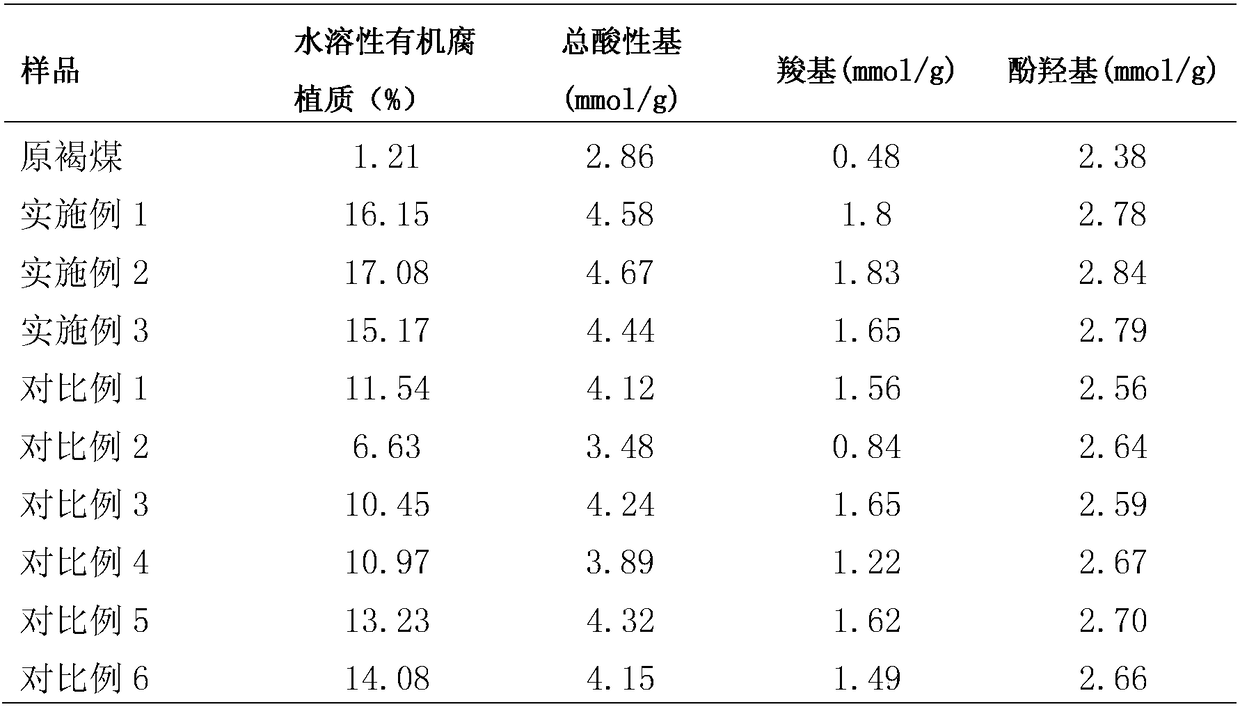

Examples

Embodiment 1

[0034] A method for activating lignite, comprising the steps of:

[0035]Using lignite as the initial raw material, crush 200g of lignite into powder with particle size less than or equal to 20 meshes, add 0.10g of P25 titanium dioxide photocatalytic oxidant with an average particle size of 25nm and 200g of water, and mix evenly; Stir continuously under the conditions, and add 200ml of aqueous hydrogen peroxide solution with a mass fraction of 15% in 5 times (add 40ml each time, add once every 20 minutes). Stir fully under constant temperature and normal pressure to make it react for 4 hours; the reaction product is dried to obtain the activated lignite solid product.

Embodiment 2

[0037] A method for activating lignite, comprising the steps of:

[0038] Using lignite as the initial raw material, crush 200g of lignite into powder with particle size less than or equal to 20 meshes, add 0.20g of P25 titanium dioxide photocatalytic oxidant with an average particle size of 25nm and 200g of water, and mix evenly; Stir continuously under the conditions, and add 150ml of aqueous hydrogen peroxide solution with a mass fraction of 15% in 3 times (50ml each time, add once every 30 minutes). , fully stirred under normal pressure to make it react for 2.5 hours; the reaction product was dried to obtain an activated lignite solid product.

Embodiment 3

[0040] A method for activating lignite, comprising the steps of:

[0041] Using lignite as the initial raw material, crush 200g of lignite into powder with a particle size of less than or equal to 20 meshes, add 0.20g of P25 titanium dioxide photocatalyst with an average particle size of 25nm and 250g of water, and mix evenly; , stirring continuously, and adding 100ml of aqueous hydrogen peroxide solution with a mass fraction of 30% in 5 times (adding 20ml each time, adding once every 20 minutes). Stir under pressure and allow it to react for 1.5 hours; the reaction product is dried to obtain an activated lignite solid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com