Preparation method of graphene foam-polydopamine composite membrane, product prepared with preparation method and application of product

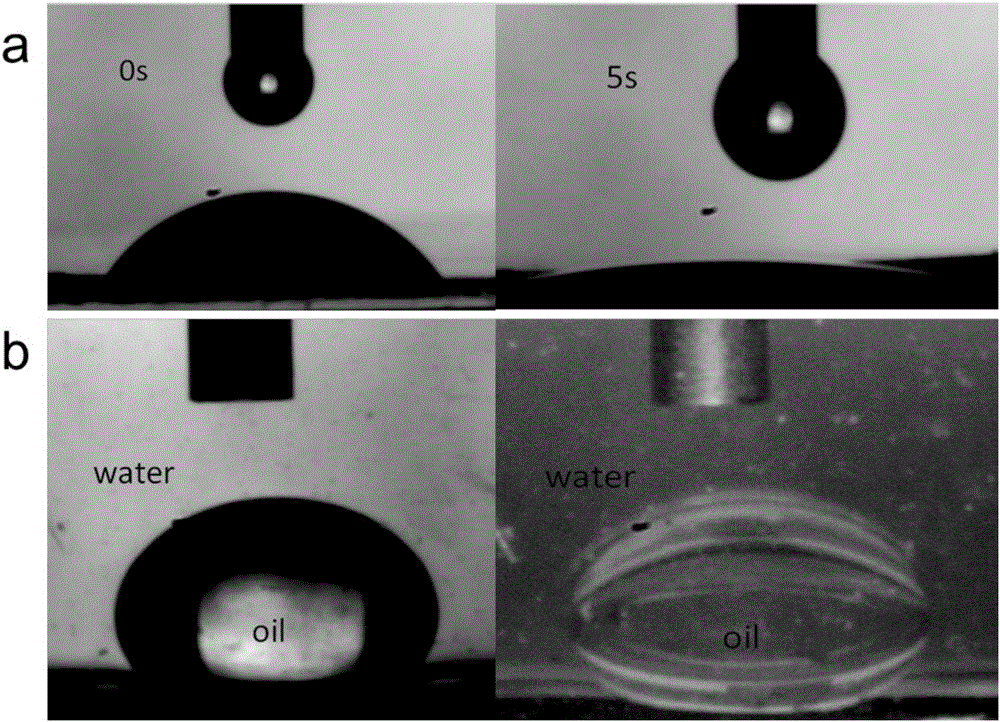

A technology of graphene foam and polydopamine, which is applied in membrane technology, semi-permeable membrane separation, grease/oily substance/suspton removal device, etc. It can solve the problems of reduced membrane flux and efficiency, pending research, and low separation efficiency , achieve high oil recovery rate, increase microporous structure, and enhance hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Include the following steps:

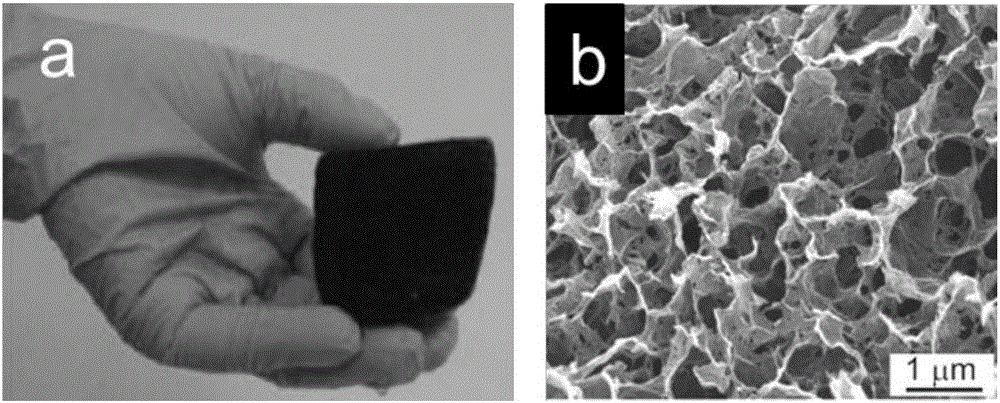

[0036] (1) Preparation of graphene foam-polydopamine: Mix Tris-HCl with graphene oxide solution, adjust pH, and then ultrasonically disperse graphene oxide sheets in a single sheet. Then add dopamine hydrochloride to ultrasonically disperse, prepare a mixture of graphene oxide and dopamine hydrochloride, and carry out hydrothermal reaction. After the reaction was finished, it was naturally cooled to room temperature, and the resulting black circular gel column was soaked and washed with deionized water, and finally freeze-dried to obtain graphene foam-polydopamine.

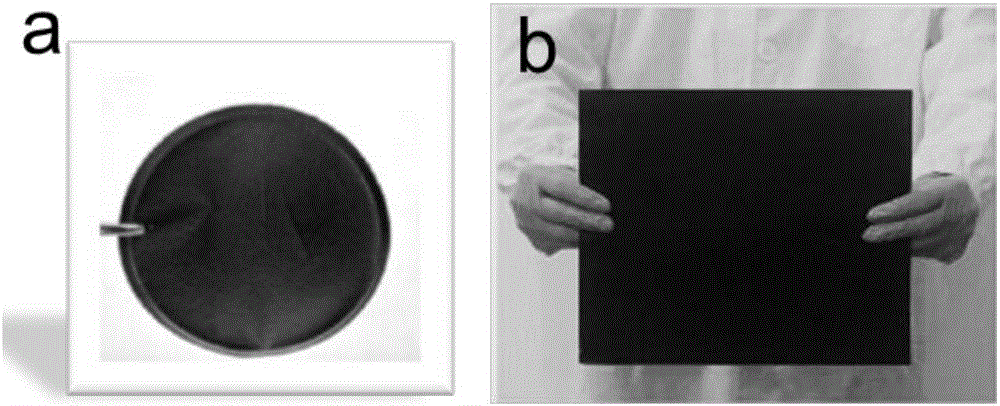

[0037] (2) Preparation of temperature-sensitive graphene foam-polydopamine composite film: the graphene foam-polydopamine was ground into small pieces, and then added to N,N-dihydroxyethylglycine for ultrasonic dispersion. Afterwards, it is mixed with N,N-dihydroxyethylglycine solution (prepared in advance) in which the temperature-sensitive polymer is dissolved, stirred and ...

Embodiment 2

[0046] Include the following steps:

[0047] (1) Preparation of graphene foam-polydopamine: Mix Tris-HCl with graphene oxide solution, adjust pH, and then ultrasonically disperse graphene oxide sheets in a single sheet. Then add dopamine hydrochloride to ultrasonically disperse, prepare a mixture of graphene oxide and dopamine hydrochloride, and carry out hydrothermal reaction. After the reaction was finished, it was naturally cooled to room temperature, and the resulting black circular gel column was soaked and washed with deionized water, and finally freeze-dried to obtain graphene foam-polydopamine.

[0048] (2) Preparation of temperature-sensitive graphene foam-polydopamine composite film: the graphene foam-polydopamine was ground into small pieces, and then added to N,N-dihydroxyethylglycine for ultrasonic dispersion. After that, it is mixed with N,N-dihydroxyethylglycine solution in which the temperature-sensitive polymer is dissolved, stirred and reacted, and finally t...

Embodiment 3

[0056] Include the following steps:

[0057] (1) Preparation of graphene foam-polydopamine: Mix Tris-HCl with graphene oxide solution, adjust pH, and then ultrasonically disperse graphene oxide sheets in a single sheet. Then add dopamine hydrochloride to ultrasonically disperse, prepare a mixture of graphene oxide and dopamine hydrochloride, and carry out hydrothermal reaction. After the reaction was finished, it was naturally cooled to room temperature, and the resulting black circular gel column was soaked and washed with deionized water, and finally freeze-dried to obtain graphene foam-polydopamine.

[0058] (2) Preparation of temperature-sensitive graphene foam-polydopamine composite film: the graphene foam-polydopamine was ground into small pieces, and then added to N,N-dihydroxyethylglycine for ultrasonic dispersion. After that, it is mixed with N,N-dihydroxyethylglycine solution in which the temperature-sensitive polymer is dissolved, stirred and reacted, and finally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com