Device and method for preparing oxygen vacancies of catalytic materials

A catalytic material, oxygen vacancy technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unfavorable promotion and application, uncontrollable oxygen vacancy, complicated process, etc., to shorten the time And the steps, the process is simple, and the effect of improving the degree of energy matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

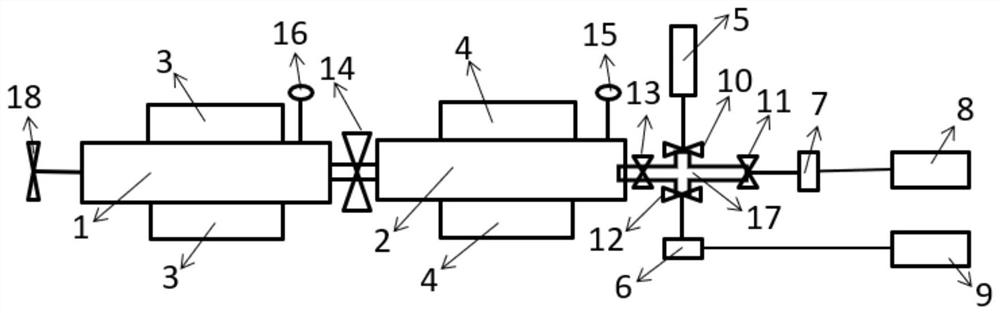

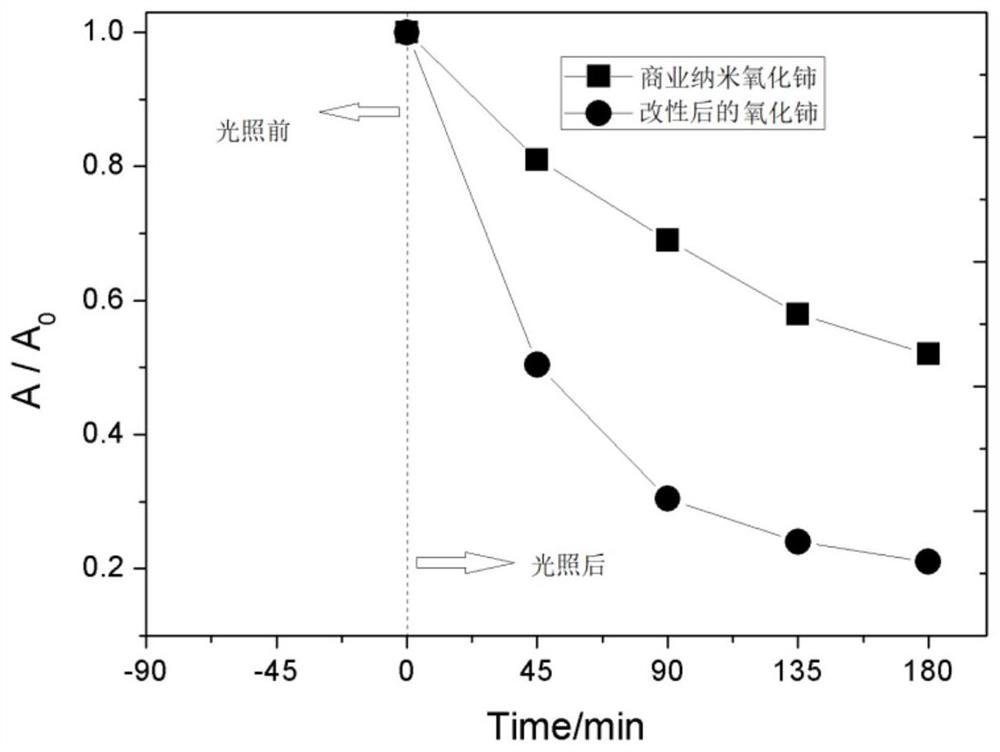

[0043] Use the device of the present invention to carry out hydrogen reduction modification on commercial nano-cerium oxide, and compare the effect of photodegradation of Rhodamine B. The specific implementation steps are as follows:

[0044] (1) Place the nano-cerium oxide material in the second reaction chamber 2, and tighten the fifth valve 14;

[0045] (2) Unscrew the first valve 10 and the fourth valve 13 to evacuate the reaction chamber;

[0046] (3) Tighten the first valve 10, unscrew the third valve 12, fill in 0.2MPa inert gas, and clean the reaction chamber; repeat the above steps 3 to 5 times, then tighten the first valve 10 and the third valve 12 ;

[0047] (4) Select hydrogen as reducing agent, unscrew the second valve 11, feed 0.5MPa H in the reaction chamber 2 , wait for the reading of the second pressure gauge 15 to be stable, then tighten the fourth valve 13;

[0048] (5) Turn on the second heating device 4, the heating rate is 5°C / min, the reaction tempera...

Embodiment 2

[0053] Using the device of the present invention to simultaneously reduce the nanometer monoclinic green tungsten oxide prepared by the hydrothermal method at different temperatures, the specific steps are as follows:

[0054] (1) Place the green tungsten oxide material in the first reaction chamber 1 and the second reaction chamber 2;

[0055] (2) Unscrew the first valve 10 and the fourth valve 13 to evacuate the reaction chamber;

[0056] (3) Tighten the first valve 10, unscrew the third valve 12, fill in 0.2MPa inert gas, and clean the reaction chamber; repeat the above steps 3 to 5 times, then tighten the first valve 10 and the third valve 12 ;

[0057] (4) Select hydrogen as reducing agent, unscrew the second valve 11, feed 0.4MPa H in the reaction chamber 2 , wait for the reading of the second pressure gauge 15 to be stable, then tighten the fourth valve 13 and the fifth valve 14;

[0058] (5) Turn on the first heating device 3, the heating rate is 5°C / min, the reacti...

Embodiment 3

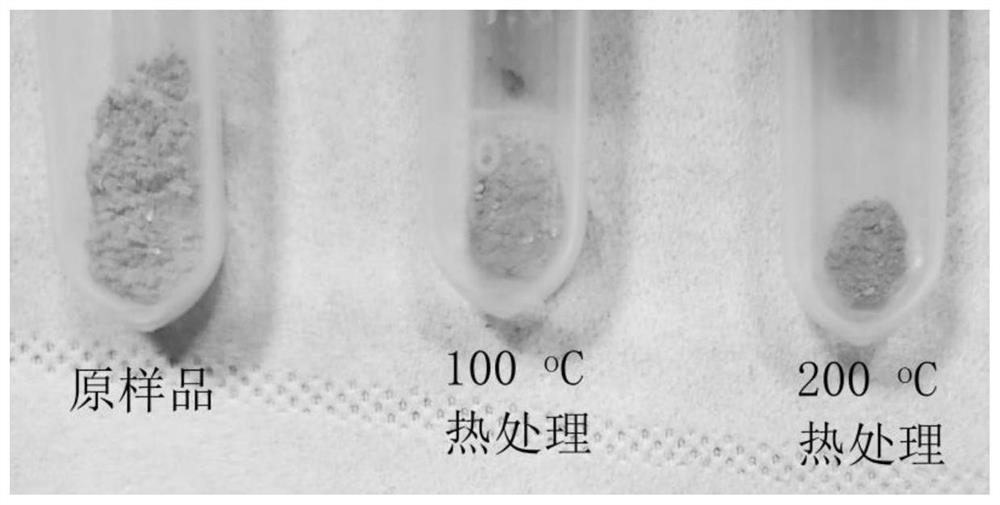

[0062] Using the device of the present invention to simultaneously heat-treat yellow commodity tungsten oxide under different temperature and different atmosphere conditions, the specific steps are as follows:

[0063] (1) Place the yellow tungsten oxide material in the first reaction chamber 1 and the second reaction chamber 2;

[0064] (2) Unscrew the first valve 10 and the fourth valve 13 to evacuate the reaction chamber;

[0065] (3) Tighten the first valve 10, unscrew the third valve 12, fill in 0.2MPa inert gas, and clean the reaction chamber; repeat the above steps 3 to 5 times, then tighten the first valve 10 and the third valve 12 ;

[0066] (3) Adopt step-by-step processing to control the reaction conditions of each reaction chamber, unscrew the first valve 10 and the fifth valve 14, and vacuumize the first reaction chamber 1 and the second reaction chamber 2; the vacuuming ends, Tighten the fifth valve 14 to keep the first reaction chamber 1 vacuum;

[0067] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com