Wave energy conversion power generation device

A power generation device and wave energy conversion technology, applied in safety devices, engine components, machines/engines, etc., can solve the problems of high cost, low power generation of power generation devices, and difficulty in large-scale application, and achieve low cost, avoid damage, The effect of avoiding the attack of huge waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

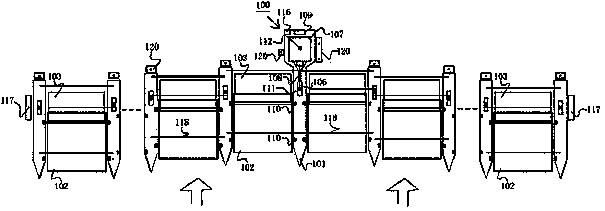

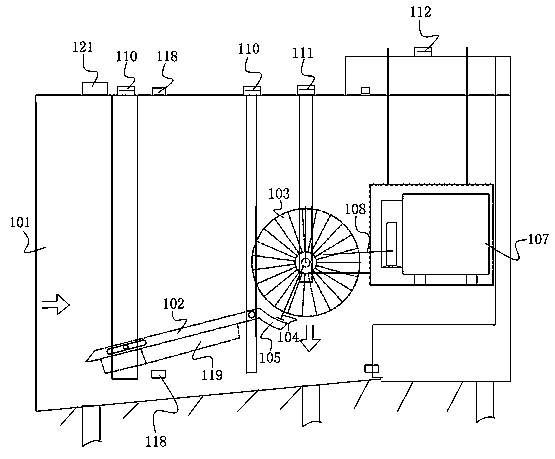

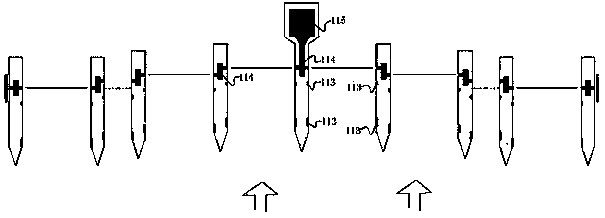

[0026] Such as Figure 1 to Figure 3 As shown, a wave energy conversion power generation device 100 of the present invention includes: a base 101, a chopping component, a power generation component, a lifting component and a control component.

[0027] The base 101 is a solid body built at a suitable water depth, and has height, length, and width suitable for water depth, tidal range, operating equipment, and the like.

[0028] The wave-cutting assembly includes at least one wave-cutting unit, each wave-cutting unit is separately arranged on the base 101 and provided with a wave-cutting guide plate 102 and an impeller 103, and the wave-cutting guide plate 102 and the impeller 103 are arranged at intervals. In this embodiment, each wave-cutting unit is provided with a limit rod 104 to limit the minimum distance between the wave-cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com