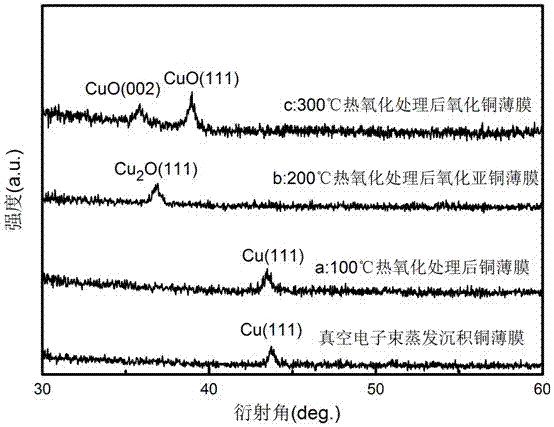

Preparation method for single-phase P type cuprous oxide thin film

A technology of cuprous oxide and thin film, which is applied in the field of photocatalytic materials, can solve the problem that it is difficult to obtain a single equality, and achieve the effects of uniform growth, large film forming area and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a single-phase P-type cuprous oxide film, comprising the following steps:

[0025] (1) Cleaning of quartz substrate

[0026] Control the temperature at 0°C, and use pure acetone, absolute ethanol, and deionized water to clean the quartz substrate with ultrasonic waves for 5 minutes in sequence;

[0027] (2) Place the cleaned quartz substrate in step (1) on the coating fixture and fix it;

[0028] (3) Put the copper film material in the graphite crucible, and place the gun baffle of the vacuum coating machine between the quartz substrate and the copper film material;

[0029] The purity of described copper film material is 99.99%;

[0030] (4) Using the vacuum electron beam evaporation method, at room temperature, control the vacuum chamber pressure of the vacuum coating machine to 5.0×10 -4 -7×10 -4 Pa, first pre-evaporate the copper film material for 10 minutes, then adjust the beam current of the vacuum coating machine, deposit a metal copp...

Embodiment 2

[0052] A method for preparing a single-phase P-type cuprous oxide film, comprising the following steps:

[0053] (1) Cleaning of quartz substrate

[0054] Control the temperature at 0°C, and use pure acetone, absolute ethanol, and deionized water to clean the quartz substrate with ultrasonic waves for 10 minutes in sequence;

[0055] (2) Place the cleaned quartz substrate in step (1) on the coating fixture and fix it;

[0056] (3) Put the copper film material in the graphite crucible, and place the gun baffle of the vacuum coating machine between the quartz substrate and the copper film material;

[0057] The purity of described copper film material is 99.99%;

[0058] (4) Using the vacuum electron beam evaporation method, at room temperature, control the vacuum chamber pressure of the vacuum coating machine to 5.0×10 -4 -7×10 -4 Pa, first pre-evaporate the copper film material for 7 minutes, then adjust the beam current of the vacuum coating machine, deposit a metal copp...

Embodiment 3

[0061] A method for preparing a single-phase P-type cuprous oxide film, comprising the following steps:

[0062] (1) Cleaning of quartz substrate

[0063] Control the temperature at 0°C, and use pure acetone, absolute ethanol, and deionized water to perform ultrasonic cleaning on the quartz substrate for 20 minutes;

[0064] (2) Place the cleaned quartz substrate in step (1) on the coating fixture and fix it;

[0065] (3) Put the copper film material in the graphite crucible, and place the gun baffle of the vacuum coating machine between the quartz substrate and the copper film material;

[0066] The purity of described copper film material is 99.99%;

[0067] (4) Using the vacuum electron beam evaporation method, at room temperature, control the vacuum chamber pressure of the vacuum coating machine to 5.0×10 -4 -7×10 -4 Pa, first pre-evaporate the copper film material for 5 minutes, then adjust the beam current of the vacuum coating machine, deposit a metal copper film o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com