Chemical method for rapidly synthesizing silver sulfide film at normal temperature

A chemical method, silver sulfide technology, applied in the field of material chemistry, can solve problems such as difficult to quickly prepare large-area, high-quality thin films, and achieve the effects of large-scale preparation, avoiding influence, and controllable patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparatory work: use the method of magnetron sputtering to sputter a 100nm-thick elemental silver film on the surface of the polyimide film (in this embodiment, use film thickness monitoring to control the film thickness) for use. Preparation of ammonium polysulfide solution: Weigh 0.1 g of sulfur powder and add it to 10 mL of ammonium sulfide aqueous solution (40-48 wt %), stir until the sulfur powder is completely dissolved, and obtain a clear and transparent ammonium polysulfide aqueous solution for use.

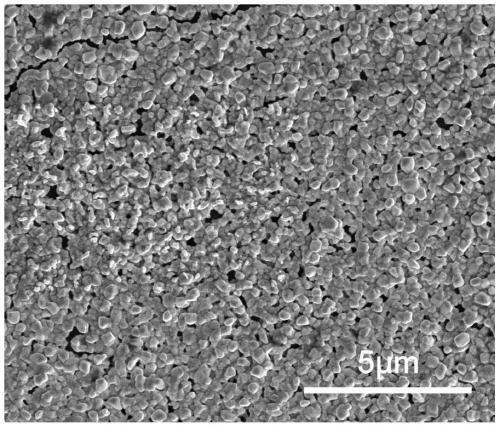

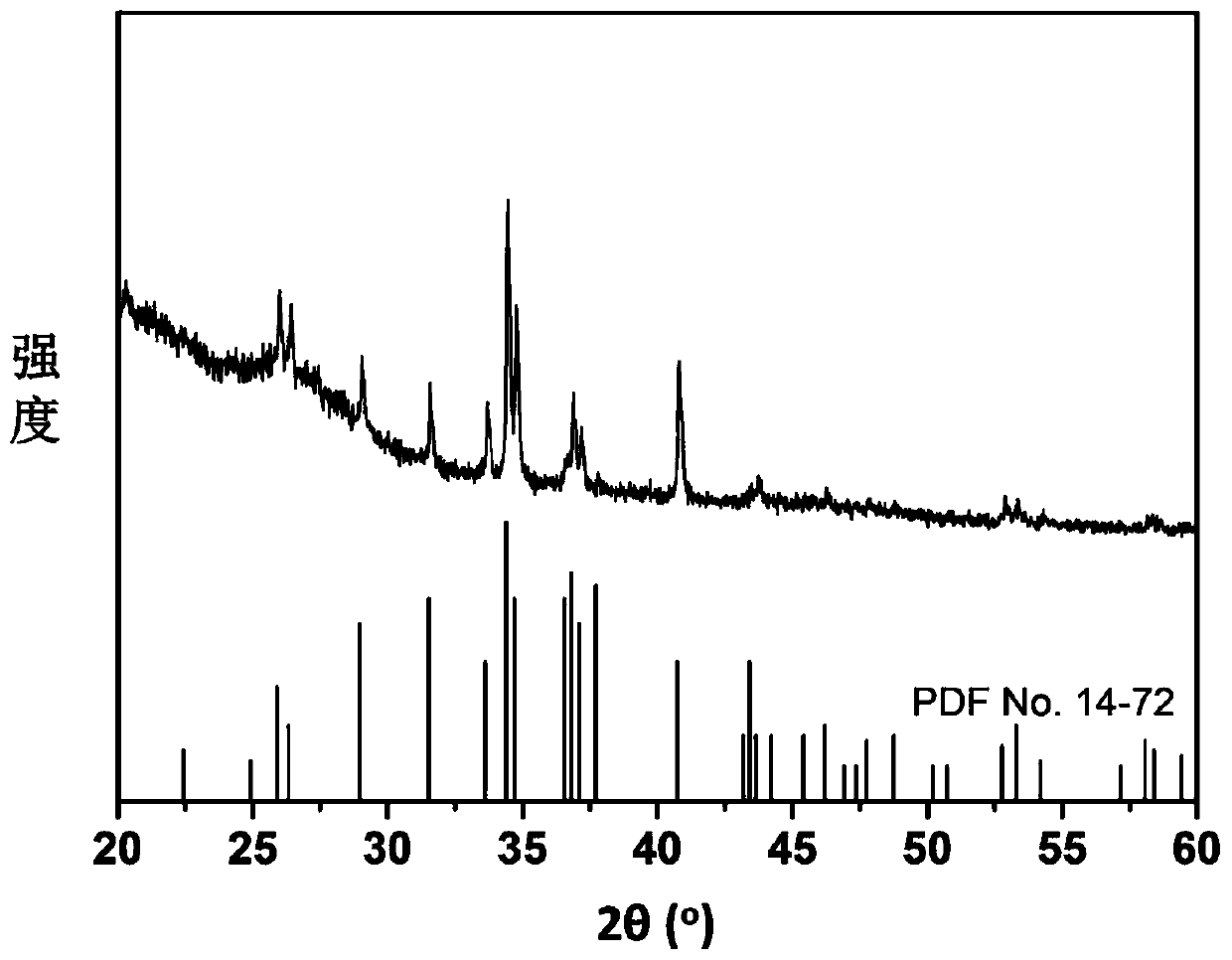

[0031] 2. Reaction steps: Put the substrate material sputtered with a 100nm elemental silver film into the prepared ammonium polysulfide aqueous solution, and react at room temperature and pressure for 20s, and the silver-white elemental silver film is completely transformed into a gray-black silver sulfide film. The formed film was not seen to be detached from the substrate surface during the reaction. The prepared silver sulfide film was carefully cleaned in ...

Embodiment 2

[0033] 1. Preparatory work: use the method of magnetron sputtering to sputter a 100nm-thick elemental silver film on the surface of the polyimide film (in this embodiment, use film thickness monitoring to control the film thickness) for use. Preparation of ammonium polysulfide solution: Weigh 0.2 mg of sulfur powder and add it to 10 mL of ammonium sulfide aqueous solution (40-48 wt %), stir until the sulfur powder is completely dissolved, and obtain a clear and transparent ammonium polysulfide aqueous solution for use.

[0034] 2. Reaction steps: Put the substrate material sputtered with a 100nm elemental silver film into the prepared ammonium polysulfide aqueous solution, and react at room temperature and pressure for 20s, and the silver-white elemental silver film is completely transformed into a gray-black silver sulfide film. The formed film was not seen to be detached from the substrate surface during the reaction. The prepared silver sulfide film was carefully cleaned in...

Embodiment 3

[0036] 1. Preparatory work: use the method of magnetron sputtering to sputter a 300nm thick elemental silver film on the surface of the polyimide film (in this embodiment, use film thickness monitoring to control the film thickness) for use. Preparation of ammonium polysulfide solution: Weigh 0.3g of sulfur powder and add it to 10mL of ammonium sulfide aqueous solution (40-48wt%), stir until the sulfur powder is completely dissolved, and obtain a clear and transparent ammonium polysulfide aqueous solution for use.

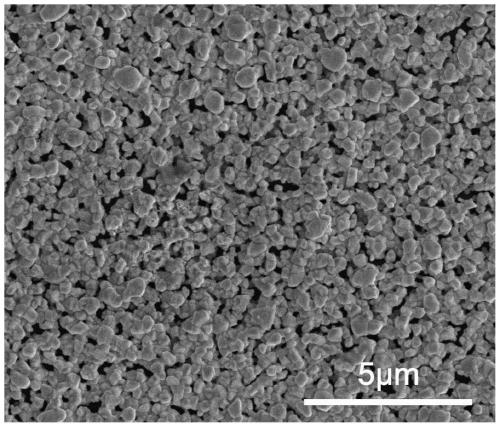

[0037] 2. Reaction steps: Put the substrate material sputtered with a 300nm elemental silver film into the prepared ammonium polysulfide aqueous solution, and react for 50s at normal temperature and pressure, and the silver-white elemental silver film is completely transformed into a gray-black silver sulfide film. During the reaction, it can be seen that the formed film continuously peels off from the substrate surface. The prepared silver sulfide film was careful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com