Falling film type devolatilizer and falling film element thereof

A devolatilizer and falling film technology, applied in the field of chemical production equipment, can solve the problems of limited flow range of production materials, difference in residence time, reduction in residence time, etc., to meet the requirements of large capacity, high quality, uniform and controllable residence time, Controllable effect of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

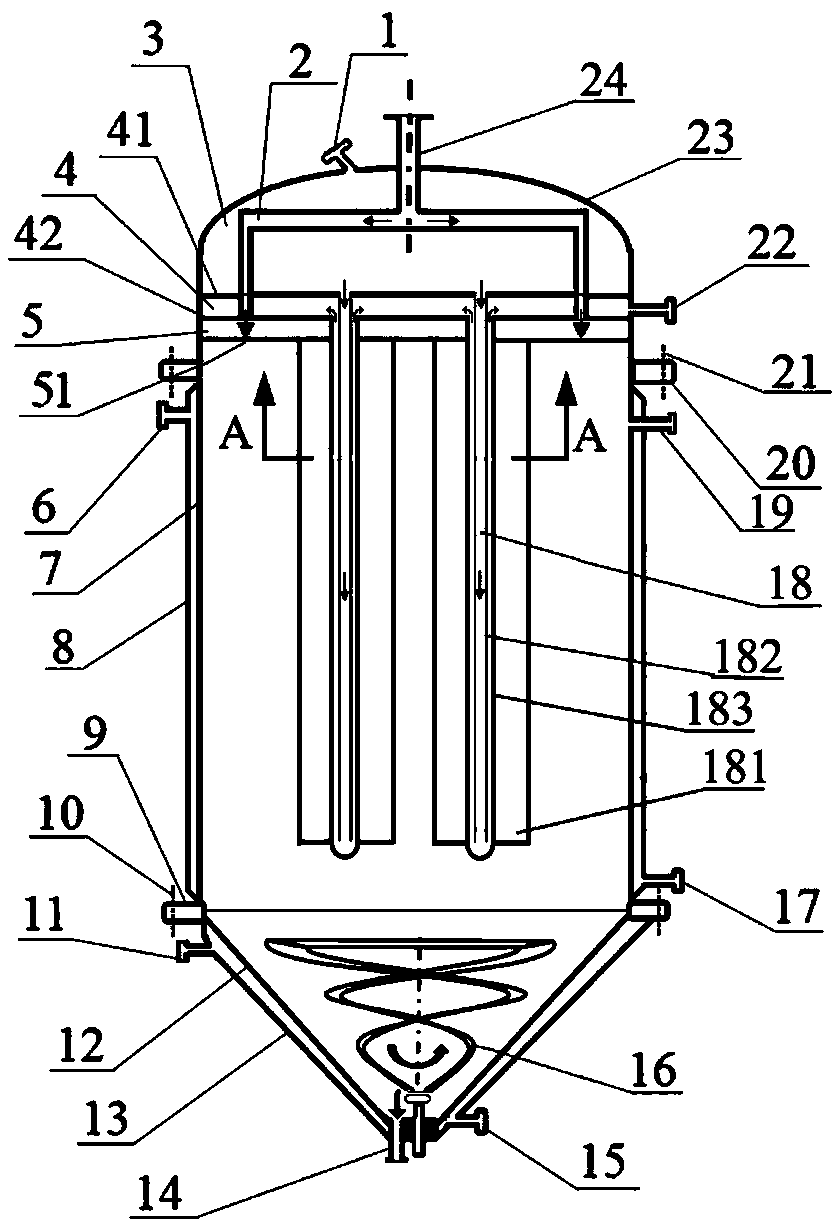

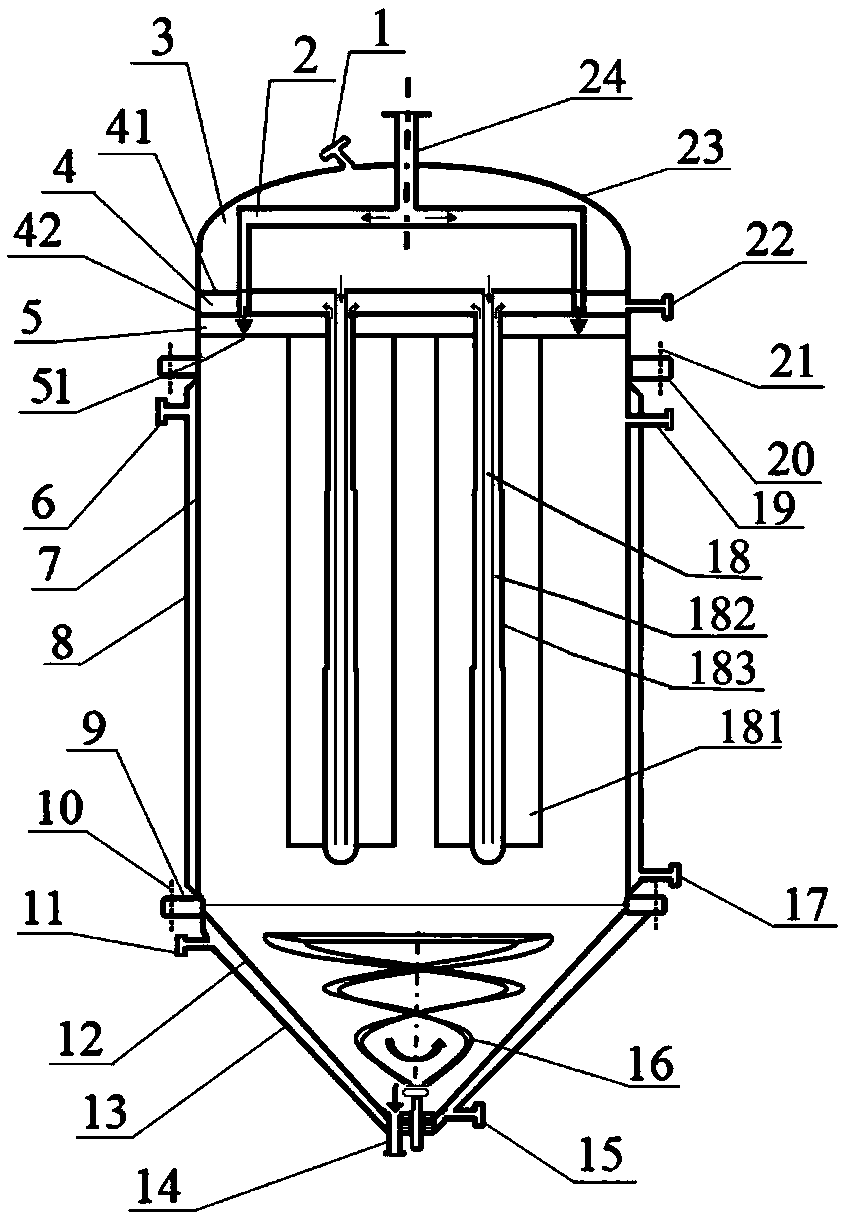

[0043] Embodiment 1, with reference to attached figure 1 , image 3 and Figure 10 ;

[0044] A falling film devolatilizer provided in this embodiment, such as figure 1 As shown, it includes a vertical shell 7, a cover head 23 connected to the upper end of the vertical shell 7, a bottom shell 12 at the lower end, a material inlet 24, a vacuum pumping port 21, and a material outlet 14. The devolatilizer is provided with a material box body 5 and a plurality of falling film elements 18, there are a plurality of falling film flow channels 18a on the falling film element 18, the material inlet 24 communicates with the material box body 5, and the bottom plate of the material box body 5 is a cloth film plate 51, and a cloth film plate 51 A film cloth structure is provided, and each falling film channel 18a is assigned a film cloth structure.

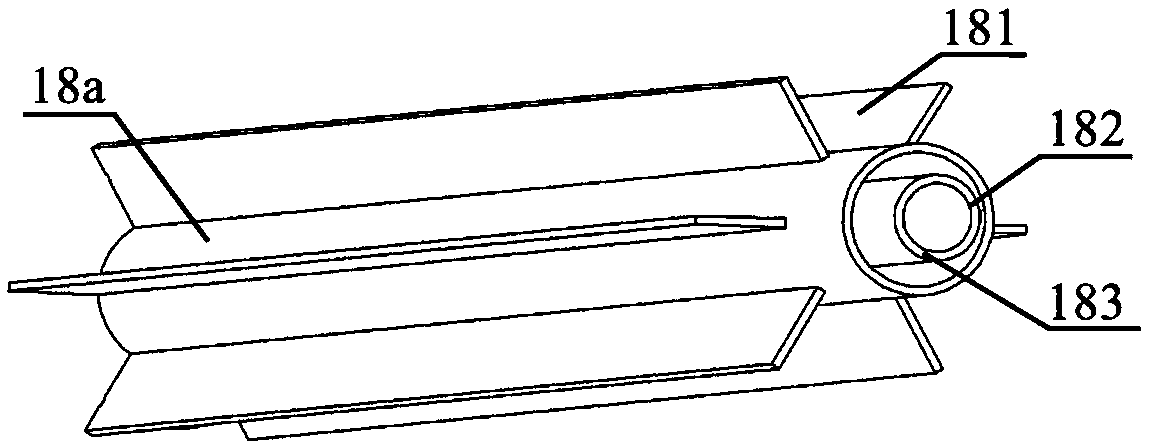

[0045] A plurality of axial limiting walls 181 are distributed on the outer periphery of the falling film element 18, and the falling fi...

Embodiment example 2

[0060] With intrinsic viscosity being 0.65dL / g the PET melt that molecular weight distribution index is 1.65 is as raw material, carry out devolatilization reaction to produce high molecular weight PET, the flow rate of each falling film element is 20kg / h, other parts are the same as embodiment 1, can The intrinsic viscosity of the obtained product was 1.01dL / g, and the molecular weight distribution index was 1.53.

Embodiment example 3

[0062] like Figure 4 As shown, the falling film element 18 with an axial stop wall is a straight pipe with a constant diameter, and there are crosspieces 184 equally spaced between the adjacent axial stop walls 181 on the falling film element 18, and other The part is the same as in Example 1; using the optimal structure scheme, using PET melt with an intrinsic viscosity of 0.65dL / g and a molecular weight distribution index of 1.65 as raw material, the devolatilization reaction is carried out to produce high molecular weight PET, and the flow rate of each falling film element is 20kg / h, the intrinsic viscosity of the obtained product is 1.02dL / g, and the molecular weight distribution index is 1.51.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com