Composite shearing semi-solid state metal rheological slurry preparation method

A semi-solid metal and slurry technology, which is applied in the field of semi-solid metal slurry preparation, can solve the problems of small internal friction stirring force and inability to obtain alloy structure, etc., to achieve easy control, avoid high energy consumption, and temperature controllability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

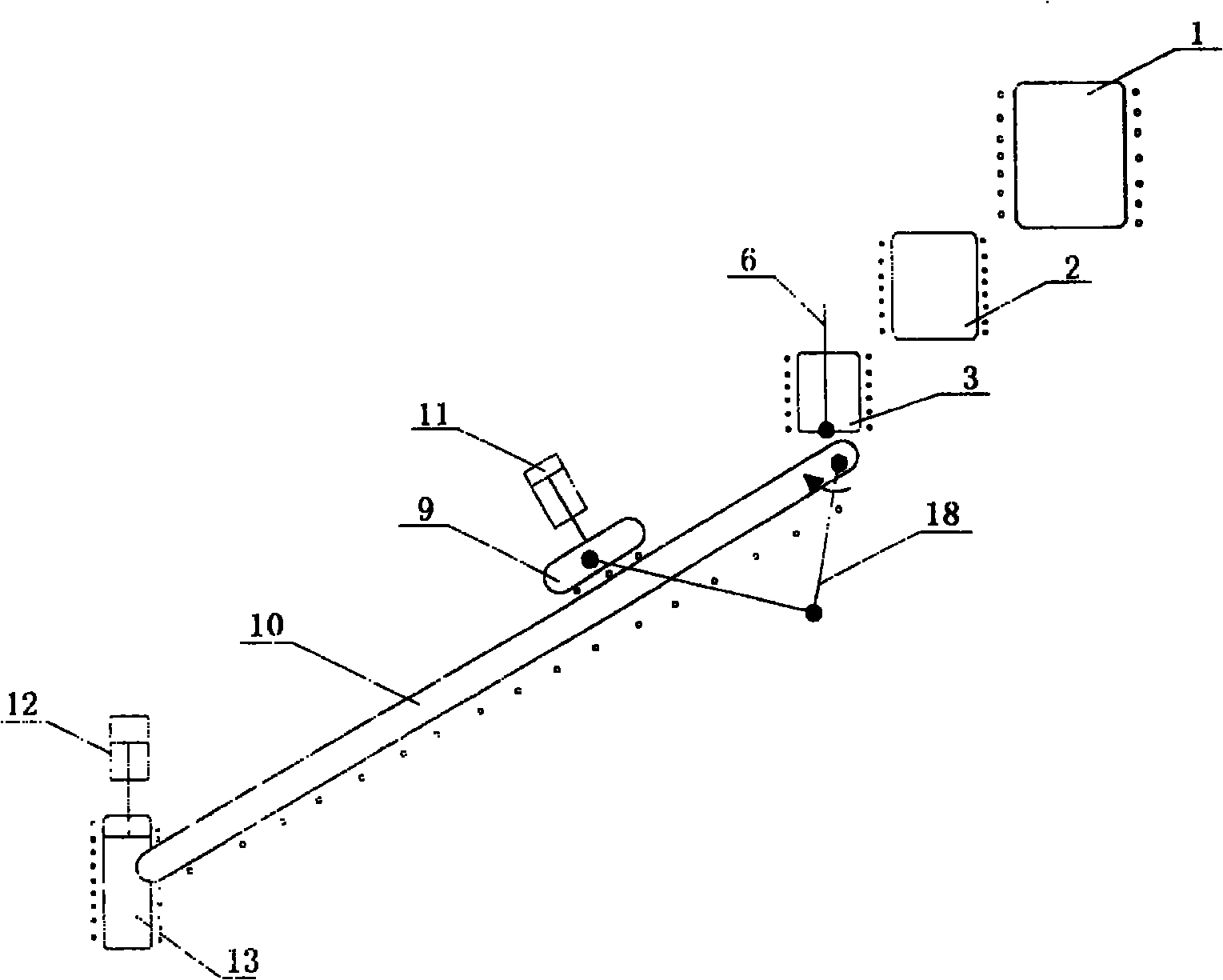

Method used

Image

Examples

Embodiment 1

[0047] The liquidus temperature of the A357 alloy used is 615°C; the inclination of the lower washboard used is 50°, the sliding length of the upper washboard is 500mm, and the sliding time of the upper washboard is 1.5S.

[0048] Precisely control the superheated A357 alloy liquid in the range of 690±3°C; quantitatively add 1-1.2Kg; preheat the upper washboard to 575-585±5°C, then control the temperature; the lower washboard is formed from the lower end to the upper end, and the temperature is from 575°C to 650°C gradient temperature field. The pressure of the upper washboard to the lower washboard is 7Mpa. The shearing time of the slurry is controlled to be 0.8-1.2s. T of A357 alloy ss = 575°C. Keep the slurry in the heat preservation mold at about 577±3°C for 3.5 to 5 minutes to control the solid phase fraction of the alloy slurry between 0.4 and 0.6. When enough semi-solid slurry is prepared, the semi-solid slurry is extruded into a cast iron mold by an extrusion cylin...

Embodiment 2

[0052] Magnesium alloy materials are light in weight. Taking the commonly used AZ91D as an example, its specific gravity is 1.8, which is only 1 / 4 of that of steel and about 2 / 3 of that of aluminum alloy. Compared with commonly used metals, magnesium alloys have many advantages such as higher specific rigidity, specific strength, machinability, vibration damping, thermal conductivity, and recyclability, as well as anti-electromagnetic wave characteristics. In recent years, under the trend of environmental protection and lightweight, magnesium alloy workpieces have gradually been widely used in 3C products and automobiles.

[0053] The liquidus temperature of the AZ91D magnesium alloy used is 595°C; the T of the AZ91D magnesium alloy ss =570°C; the inclination of the lower washboard used is 45°, the sliding length of the upper washboard is 480mm, and the sliding time of the upper washboard is 1.5S.

[0054] Precisely control the overheated AZ91D alloy liquid in the range of 61...

Embodiment 3

[0057] The liquidus temperature of the die steel Cr12 used is about 1600°C; the T of the die steel Cr12 ss =1400°C; the inclination of the lower washboard used is 55°, the sliding length of the upper washboard is 400mm, and the sliding time of the upper washboard is 1.2S.

[0058] Precisely control the superheated Cr12 alloy liquid in the range of 1690±10°C; quantitatively feed 3~3.5Kg; after the upper washboard is preheated to 1570~1615±5°C, the temperature is controlled; the lower washboard is formed from the upper end to the lower end, and the temperature is from 1650°C Gradient temperature field to 1390°C. The pressure of the upper washboard to the lower washboard is 6Mpa. The shearing time of the slurry is controlled to be 0.8-1.2S. The slurry is kept in a heat preservation mold at a temperature of about 1400±5°C for 15-30 seconds to control the solid phase fraction of the alloy slurry between 0.4 and 0.6. When enough semi-solid slurry was prepared, the semi-solid slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com