Tube alignment type condensation polymerization reaction kettle

A polycondensation reaction and tube-and-tube technology is applied in the field of tube-and-tube polycondensation reaction kettles, which can solve the problems of inability to carry out the reaction of high-viscosity materials, and achieve the effects of good film-forming effect, reliable use and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

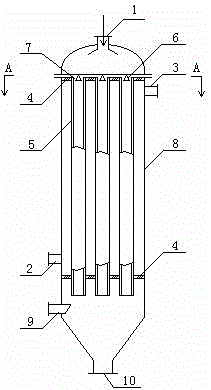

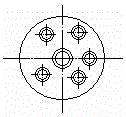

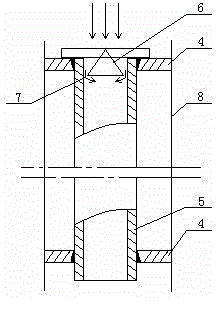

[0014] Embodiment of the present invention: a tube plate 4 is arranged in the vertical shell 8, the tube plate 4 is connected to the tube array 5, a material distributor 6 is arranged at the upper end of the tube array 5, and the upper end nozzle of the tube array 5 is connected to the material distributor 6 An annular gap 7 is left between them; a feed inlet 1 is set at the top of the vertical shell 8, and a discharge port 10 is set at the lower end; a heating medium inlet pipe 2 is set at the lower side of the vertical shell 8, and a heating medium inlet pipe 2 is set at the side of the vertical shell 8. A heating medium outlet pipe 3 is arranged on the upper part; a vacuum suction port 9 is also arranged on the middle and lower part of the side of the vertical housing 8 .

[0015] Two tube sheets 4 are arranged in the vertical casing 8 , which are respectively arranged in the upper part and the lower part of the vertical casing 8 .

[0016] The number of row tubes 5 is at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com