Method for preparing thiothiamine oxidation liquid and method for preparing thiamine nitrate applying method

A technology of thiamine nitrate and thiothiamine, applied in organic chemistry and other directions, can solve problems such as prolonging production cycle, wasting cold energy, etc., and achieves the effects of ensuring quality and yield, avoiding abnormal situations, and shortening residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] According to one aspect of the present invention, a method for preparing a thiothiamine oxidation liquid, the method comprises: passing the thiothiamine beating liquid and hydrogen peroxide into a microchannel reactor for reaction to obtain the thiothiamine oxidation liquid.

[0038] The invention provides a preparation method of thiothiamine oxidizing solution. In the method, thiothiamine beating solution and hydrogen peroxide are passed into a microchannel reactor for reaction to obtain thiothiamine oxidizing solution. Compared with the existing kettle-type batch-feeding reaction, the above method adopts a microchannel reactor to prepare thiothiamine oxidation liquid, which has a large specific surface area in the reaction section and high cooling efficiency, and is aimed at self-promoting oxidation reactions such as strong exotherms. The reaction can precisely control the temperature of the reaction system, which effectively avoids the over-temperature phenomenon and ...

Embodiment 1

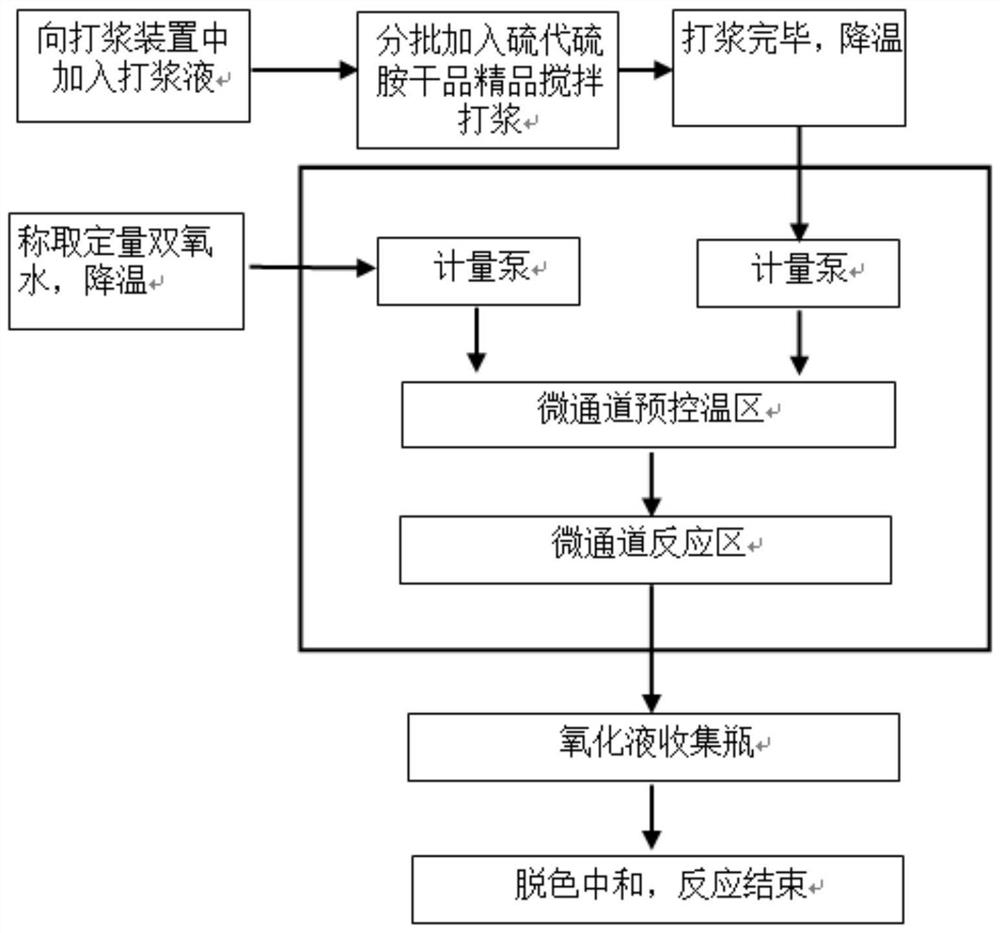

[0066] like figure 1 Shown, a kind of preparation method of thiamine nitrate, described preparation method comprises the following steps:

[0067] 1. Thiamine beating: Add 150g of purified water to the three-necked flask, then add 50g of dry thiothiamine to the purified water several times, add the fine product and stir evenly before continuing to feed, and stir for 30 minutes after adding the fine product and cool down.

[0068] 2. Feeding: The feed rate is controlled by the microchannel reactor, and the refined product after beating is passed into the microchannel reactor according to the ratio of mass flow rate 200:49 with 49g (35%) of cooled hydrogen peroxide. The residence time is controlled at 2 minutes, the reaction temperature is controlled at 25°C, and the oxidation solution is obtained after the reaction is completed, and whether the oxidation solution is qualified or not is checked.

[0069] 3. The obtained oxidized solution was decolorized with 3.4 g of activated...

Embodiment 2

[0073] A preparation method of thiamine nitrate, said preparation method comprising the following steps:

[0074] 1. Thiamine beating: Add 150g of purified water to the three-necked flask, then add 50g of dry thiothiamine to the purified water several times, add the fine product and stir evenly before continuing to feed, and stir for 30 minutes after adding the fine product and cool down.

[0075] 2. Feeding: The feed rate is controlled by the microchannel reactor, and the refined product after beating is passed into the microchannel reactor according to the ratio of mass flow rate 200:49 with 49g (35%) of cooled hydrogen peroxide. The residence time is controlled at 3 minutes, and the reaction temperature is controlled at 23°C to obtain an oxidizing solution after the reaction is completed, and whether the oxidizing solution is qualified is checked.

[0076] 3. Take 170.5 g of the obtained oxidation solution, decolorize it with 3.4 g of activated carbon, neutralize it with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com