Real-time control method for coal gas dynamic balancing in steel plants based on cabinet position prediction

A real-time control and dynamic balance technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as the long time it takes for the gas system to return to normal, hidden dangers in production, and reduced gas utilization. Improve the overall utilization efficiency and reduce the effect of urban environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

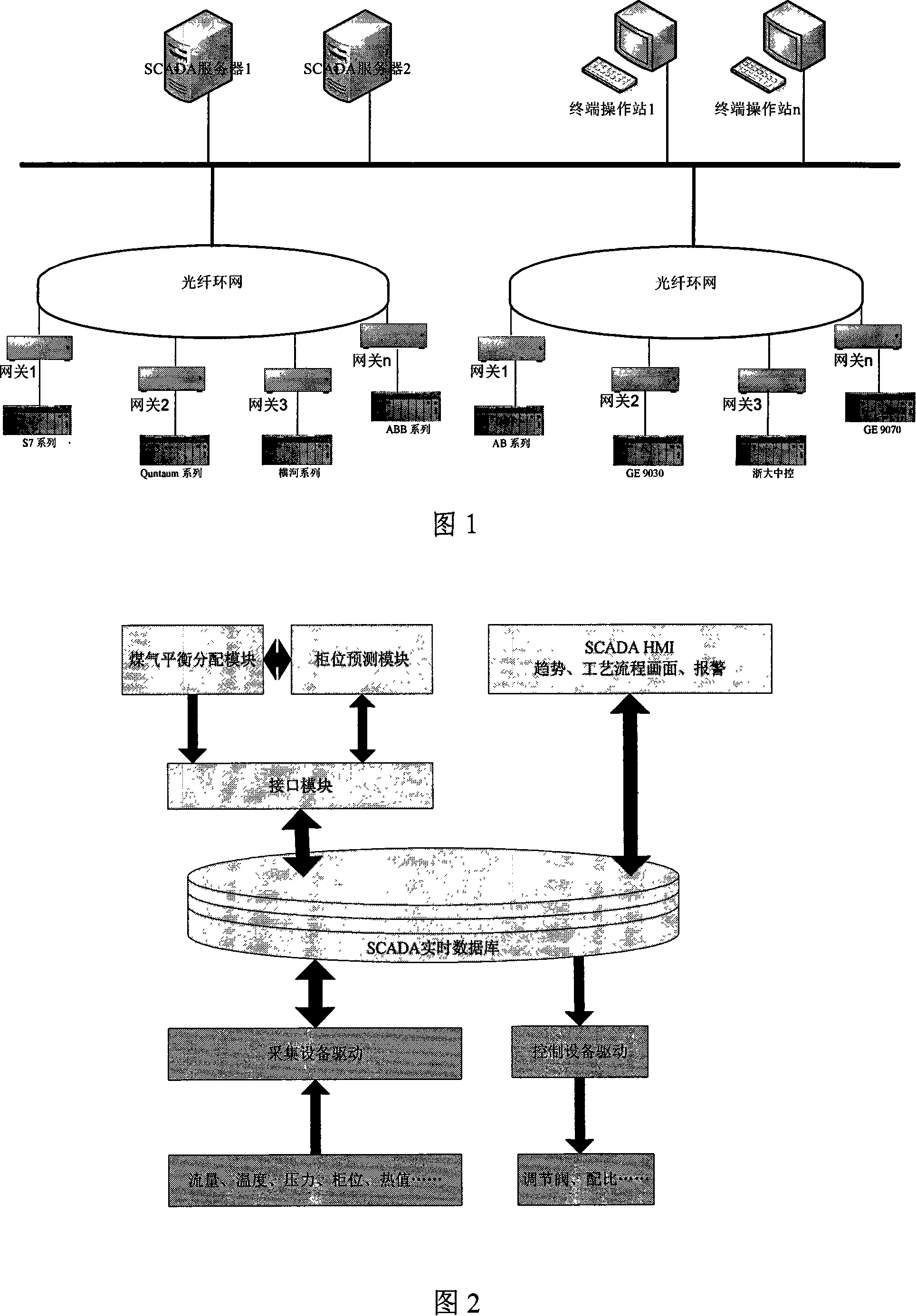

[0025] Fig. 1 shows the data acquisition and supervisory control system (Supervisory Control and Data Acquisition hereinafter referred to as SCADA system) of the present invention. As shown in the figure, the data collection and control of the present invention are realized based on the existing basic programmable logic controller (Program Logic controller hereinafter referred to as PLC) or distributed control system (hereinafter referred to as DCS) of the gas system. Each industrial-grade gateway is converted into a unified communication protocol, and the optical fiber ring network is used to realize the data collection and control of the SCADA system. The data acquisition and monitoring control system SCADA reads the key parameters of the on-site gas system into the SCADA real-time database through multiple groups of front-end measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com