Method for purifying ethylene dichloride in vinyl chloride rectification raffinate

A technology for dichloroethane and vinyl chloride, applied in the field of dichloroethane purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

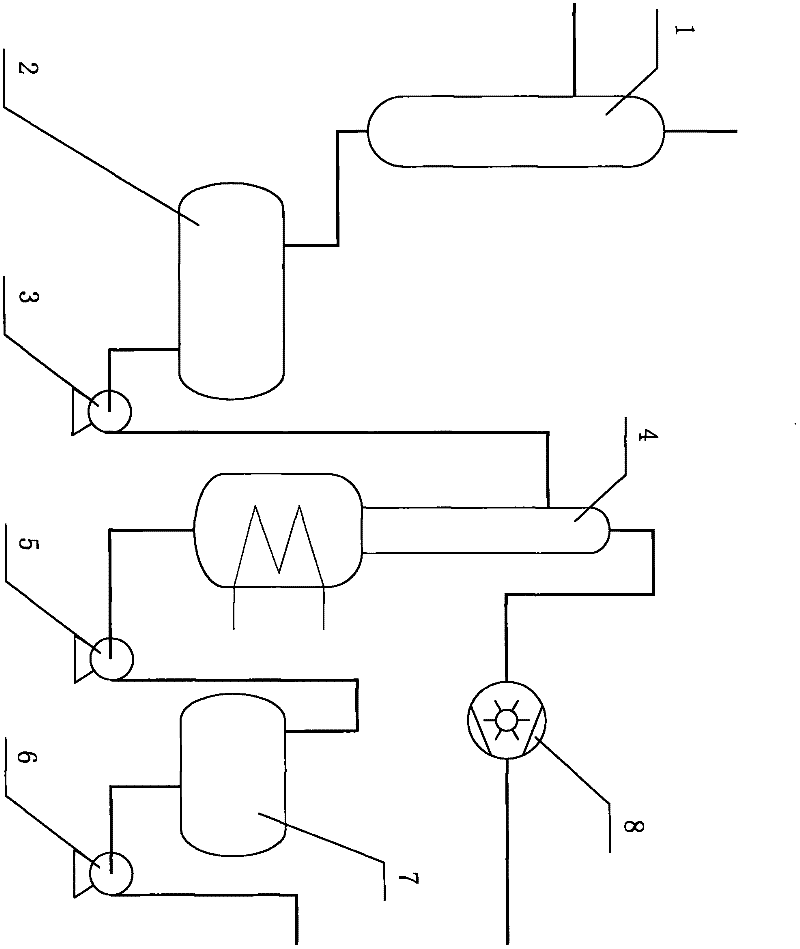

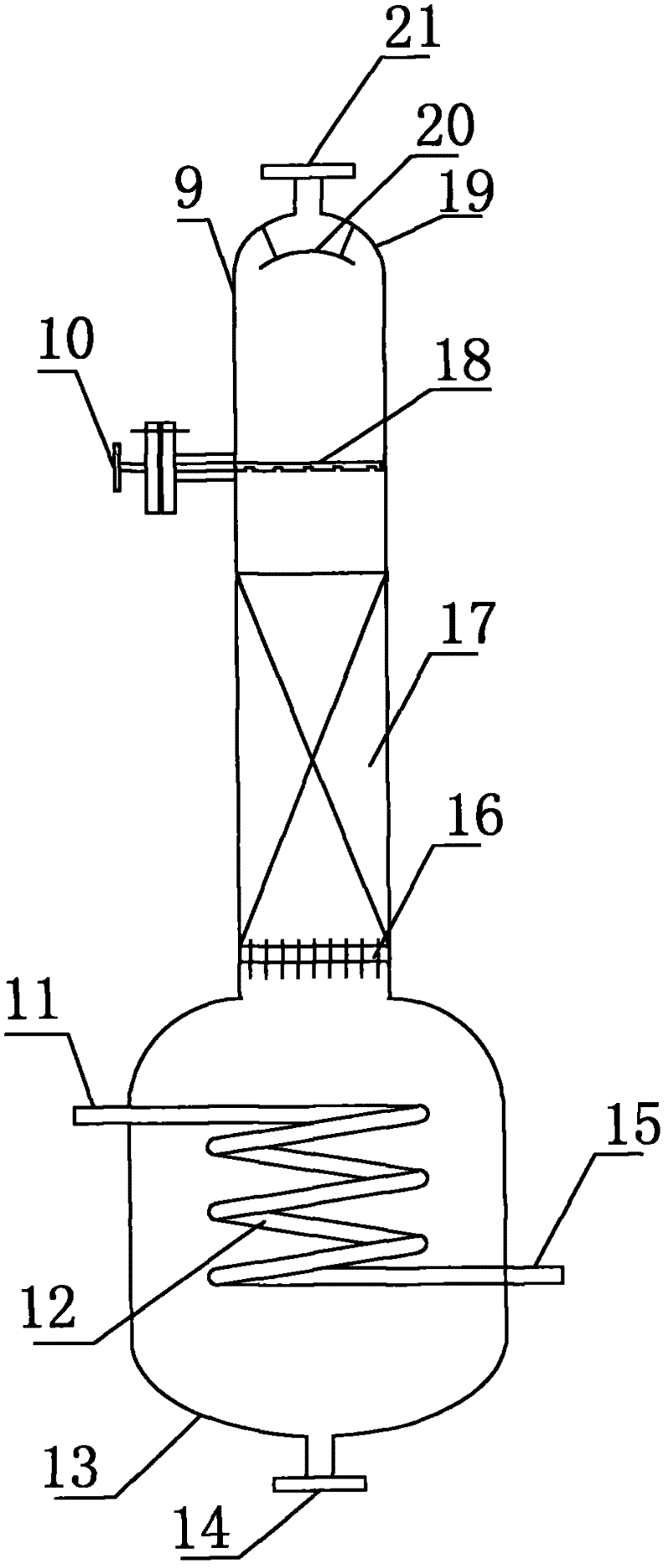

[0019] Refer to attached figure 1 Among them, this embodiment includes the following steps: the crude vinyl chloride solution enters the rectification tower 1, and after distillation, pure vinyl chloride gas is produced at the top of the rectification tower, and rectification raffinate is produced at the bottom of the rectification tower, and the rectification raffinate is stored In the raffinate tank 2, it is transported in the vacuum distillation tower 4 by the raffinate pump 3, and the impurity gas in the rectification raffinate is sloughed off from the vacuum distillation tower top by vacuum pump 8 decompression, from the vacuum distillation tower tower Obtain the dichloroethane solution with a mass percentage content≥98% at the bottom, utilize the dichloroethane pump 5 to transport the dichloroethane solution from the bottom of the vacuum distillation tower to the dichloroethane tank 7 for storage, and reuse the finished product Pump 6 is sold on truck.

[0020] The diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com