Polycrystalline ingot casting anti-arcing furnace crucible cover plate and use method thereof

A technology for polycrystalline ingot casting and arc prevention, which is applied to the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, etc., can solve the problems of heating element damage, safety impact, and poor gas discharge in an ingot furnace. Achieve the effect of eliminating arc damage, safe and stable production, and prolonging use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

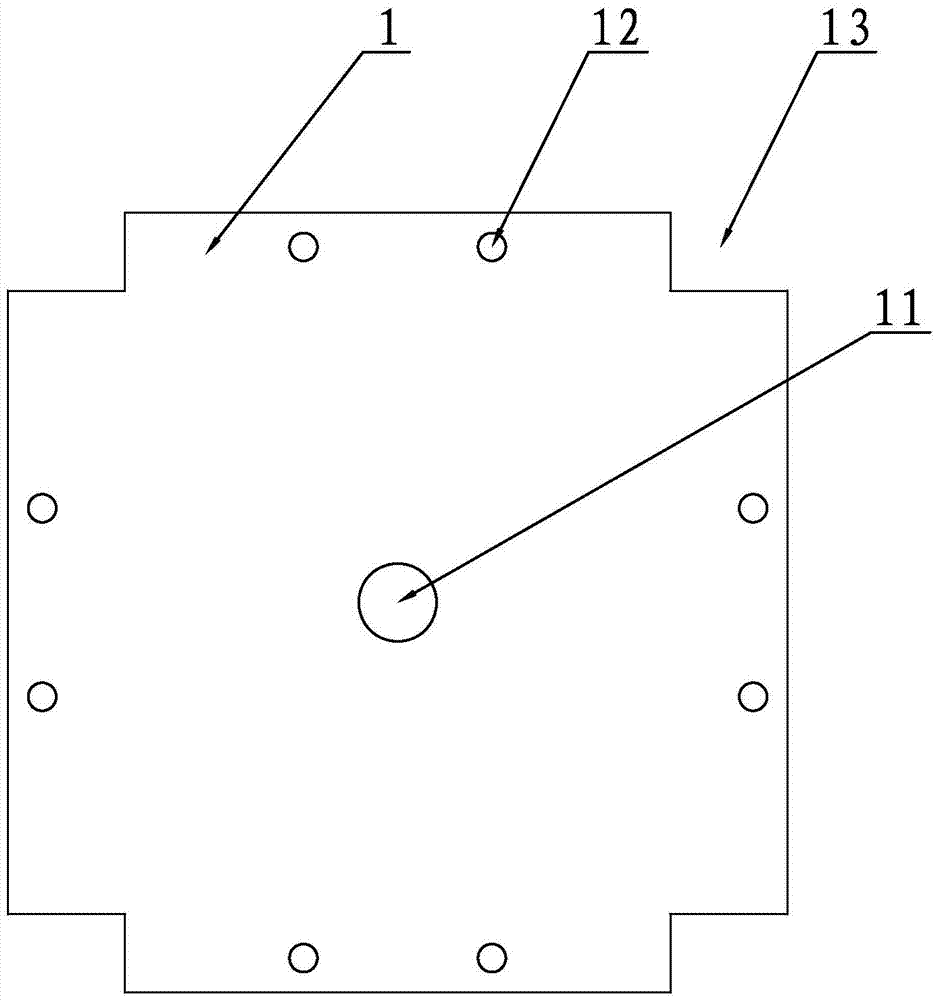

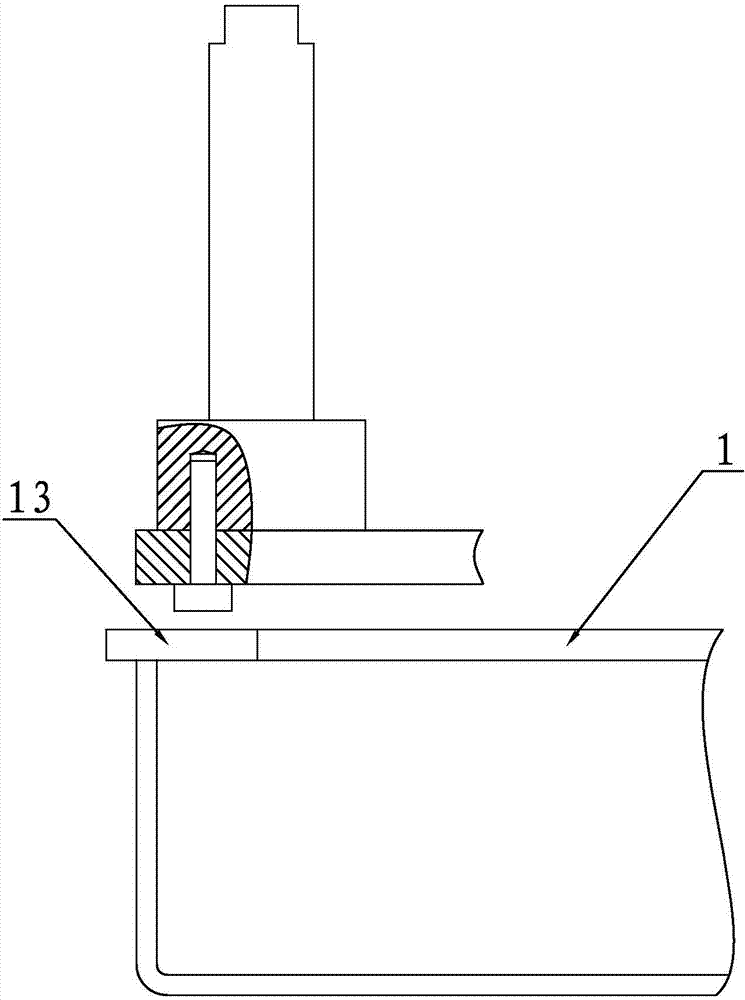

[0018] Embodiment 1: A polycrystalline ingot draw arc furnace crucible cover plate, as shown in the figure, it includes a square cover plate body 1, a central hole 11 and a vent hole 12 are arranged on the square cover plate body 1, and the central hole 11 is set at the center of the square cover body 1, and the four corners of the square cover body 1 are provided with escape gaps 13. The avoidance gap 13 is any one of a square, a right-angled isosceles triangle or a right-angle sector. In this example, the avoidance gap 13 is a square, and the side length is the distance between the outer surface of the guard plate and the inner surface of the crucible.

Embodiment 2

[0019] Embodiment 2: The difference from Embodiment 1 is that the avoidance gap 13 is a right-angled equilateral triangle whose side length is the distance from the outer surface of the guard plate to the inner surface of the crucible.

Embodiment 3

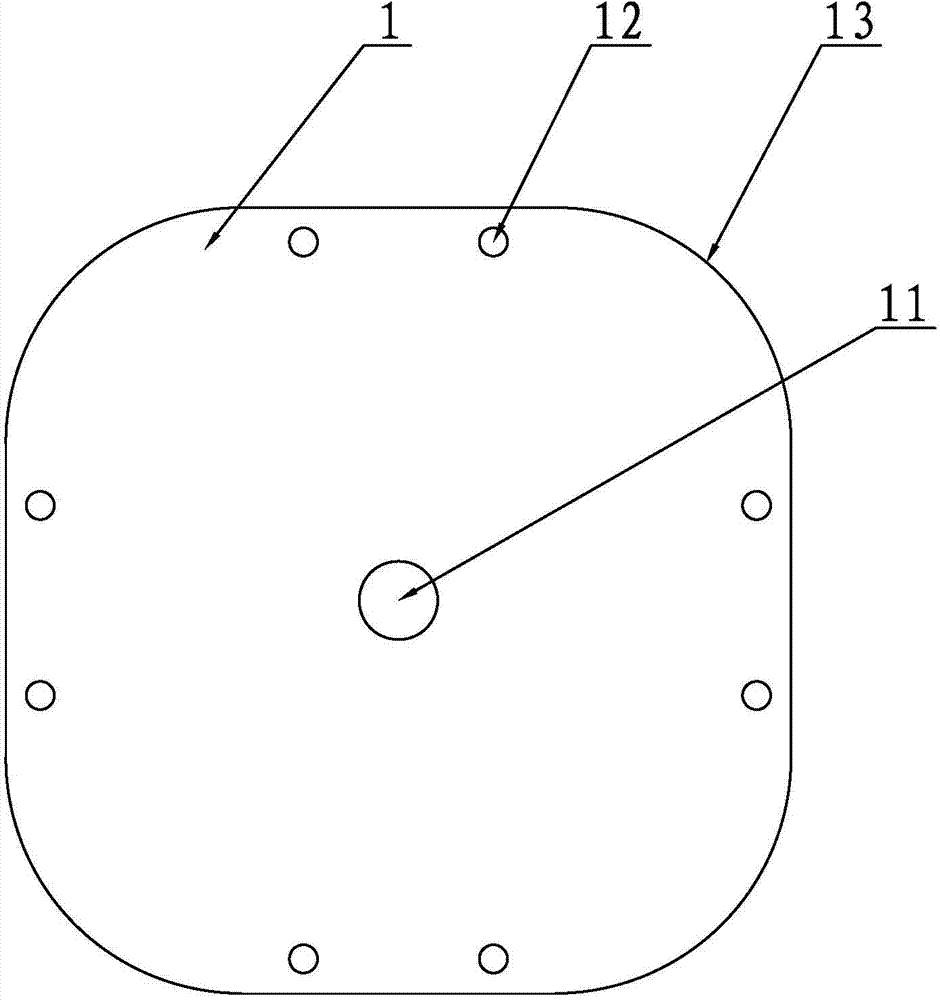

[0020] Embodiment 3: The difference from Embodiment 1 is that the avoidance gap 13 is in the shape of a right-angle fan, and the radius of the right-angle fan is the distance from the outer surface of the guard plate to the inner surface of the crucible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com