Method for curling para-position aramid short fibers

A para-aramid fiber and crimping technology, applied in textiles and papermaking, can solve the problems of high energy consumption, slow heating, difficult to increase steam pressure, etc., and achieve good crimping performance, simple and efficient process, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

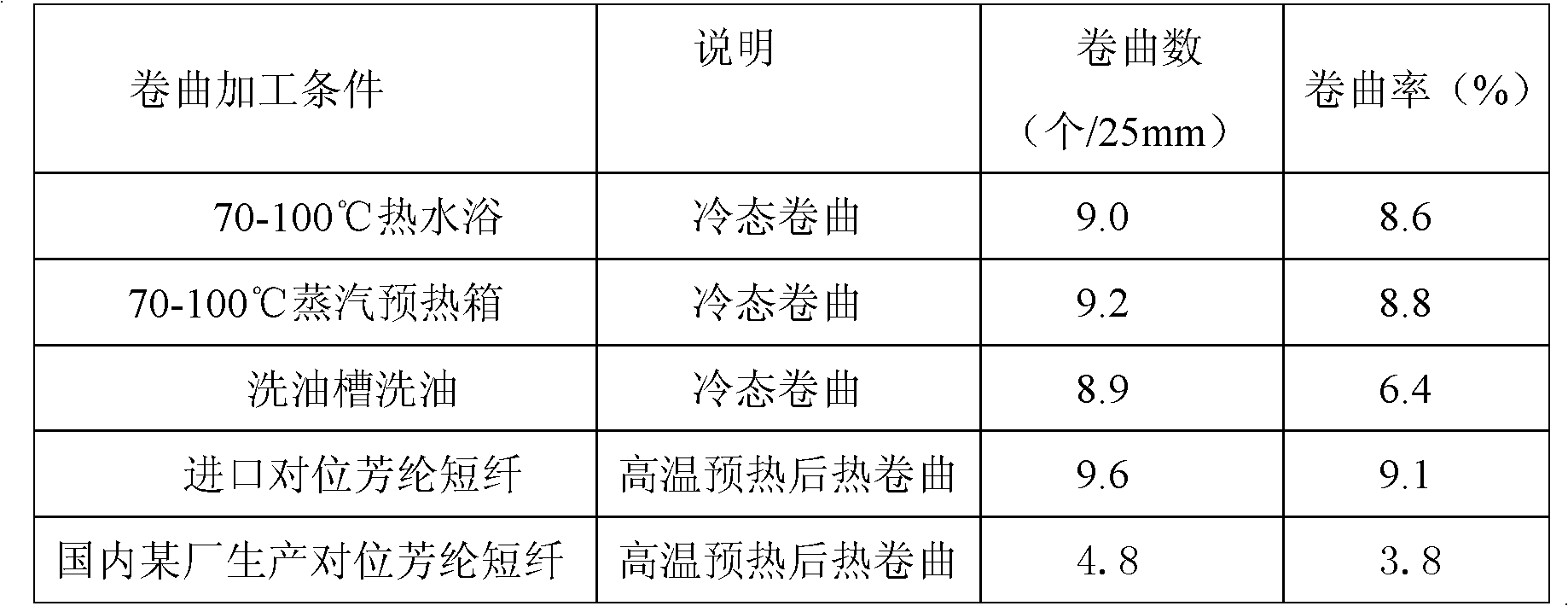

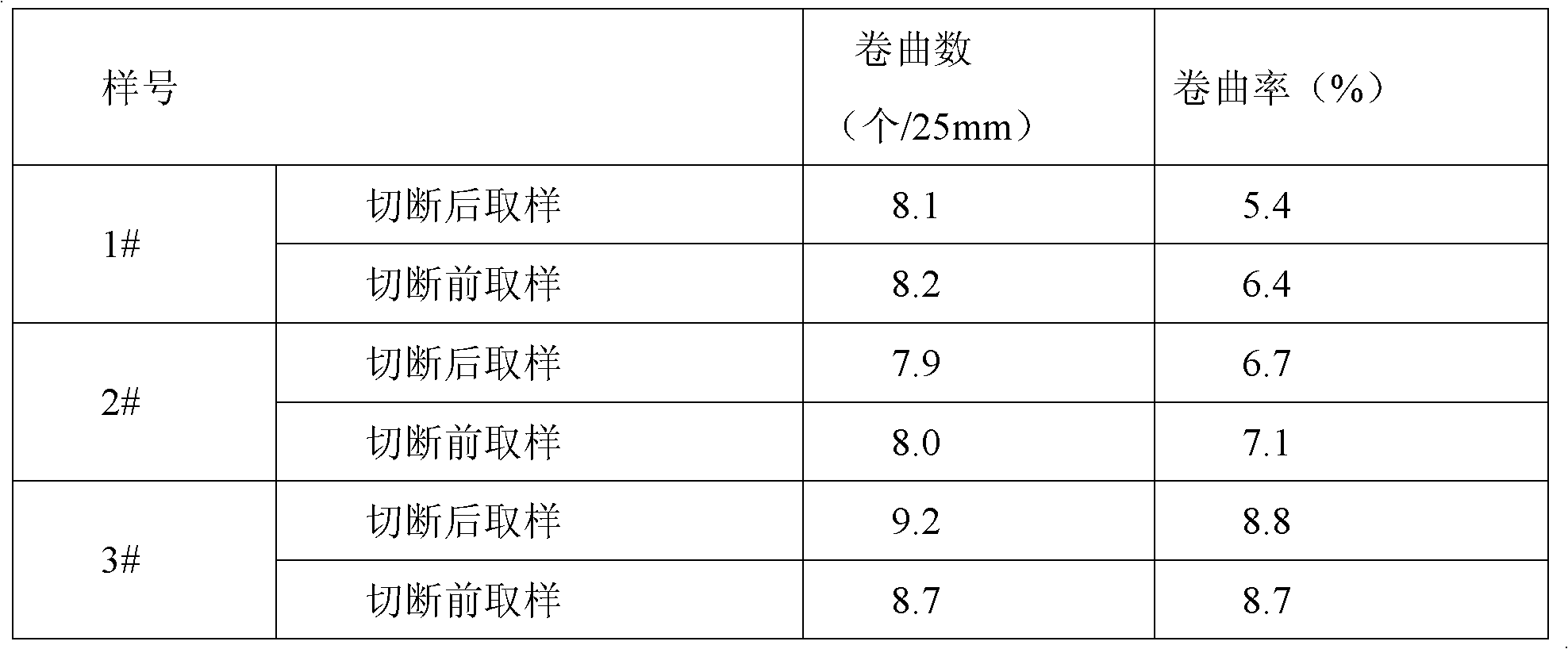

Embodiment 1

[0024] Example 1: 90 para-aramid filaments of 1000D / 500f are assembled into a large tow of 90,000 deniers, and the large tow is soaked in a hot water bath at 90°C for 6-30 seconds, and fed through a crimping machine. The input wheel is sent into the stuffing extrusion type crimping tank for crimping, and the crimping tank does not need to be equipped with a heating device. The main and back pressure of the crimping machine are 0.32Mpa and 0.25Mpa respectively. The speed of feeding the tow into the crimping box is controlled by the speed of the feeding wheel of the crimper to 70m / min. The crimped tow is evenly laid on the hot air Dry it in a drying oven at a temperature of 100°C, and then send it to a cutting machine for cutting after adjusting the tension. The crimp properties of the obtained para-aramid staple fibers are shown in Table 3.

Embodiment 2

[0025] Example 2: 133 para-aramid filaments of 750D / 500f are assembled into a large tow of 100,000 deniers, and the large tow is passed through a steam preheating box at 95°C and sent by the feeding wheel of the crimper Put it into the stuffing extrusion type crimping tank for crimping, and the crimping tank does not need to be equipped with a heating device. The main and back pressure of the crimping machine are 0.20Mpa and 0.17Mpa respectively. The speed of feeding the tow into the crimping box is controlled by the speed of the feeding wheel of the crimper to 50m / min. The crimped tow is evenly laid on the hot air Dry it in a drying oven at a temperature of 95°C, and then send it to a cutting machine for cutting after adjusting the tension. The crimp properties of the obtained para-aramid staple fibers are shown in Table 3.

Embodiment 3

[0026] Example 3: 96 para-aramid filaments of 1250D / 500f are assembled into a large tow of 120,000 deniers, the large tow is washed with oil in the oil washing tank, and fed into the stuffing extrusion through the feeding wheel of the crimper The crimping is carried out in the press-type crimping tank, and the crimping tank does not need to be equipped with a heating device. The main and back pressure of the crimping machine are 0.35Mpa and 0.21Mpa respectively. The speed of feeding the tow into the crimping box is controlled by the speed of the feeding wheel of the crimper to 30m / min. The crimped tow is evenly laid on the hot air Dry it in a drying oven at a temperature of 130°C, and then send it to a cutting machine for cutting after adjusting the tension. The crimp properties of the obtained para-aramid staple fibers are shown in Table 3.

[0027] Table 3 Analysis of physical properties of para-aramid staple fiber samples

[0028] Sample serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com