Conductive hollow double-ingredient parallel composite fiber and preparation method thereof

A composite fiber, two-component technology, applied in the field of synthetic fibers, can solve the problems of low dielectric constant and conductivity, low output of conductive fibers, poor conductivity, etc., and achieve excellent curling properties, good elasticity, and extremely conductive properties good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

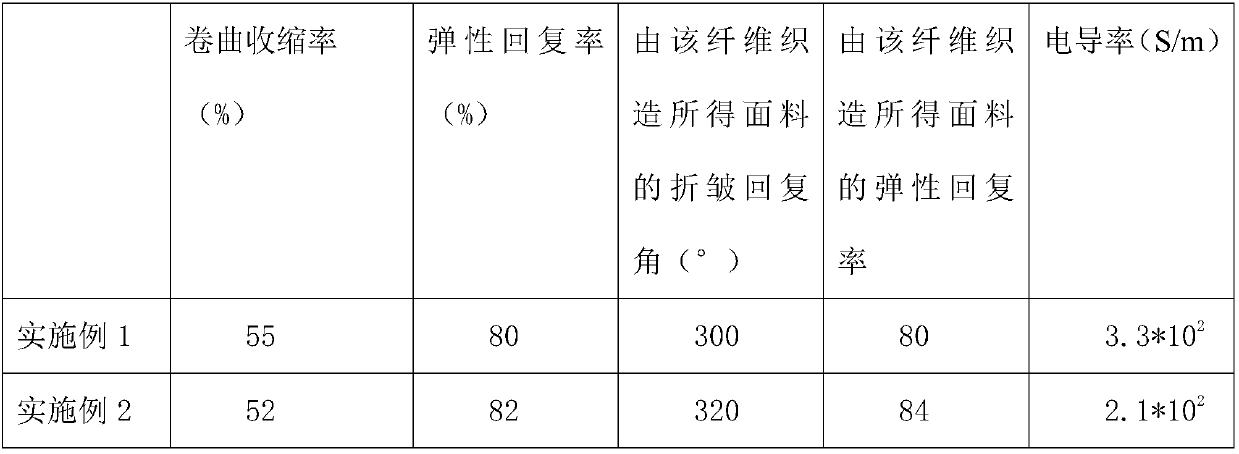

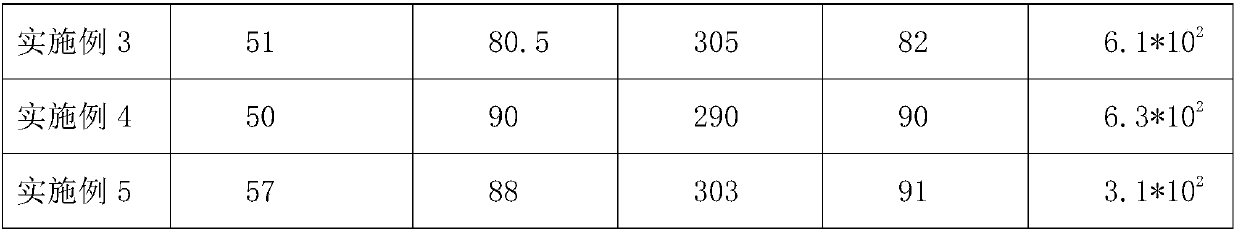

Embodiment 1

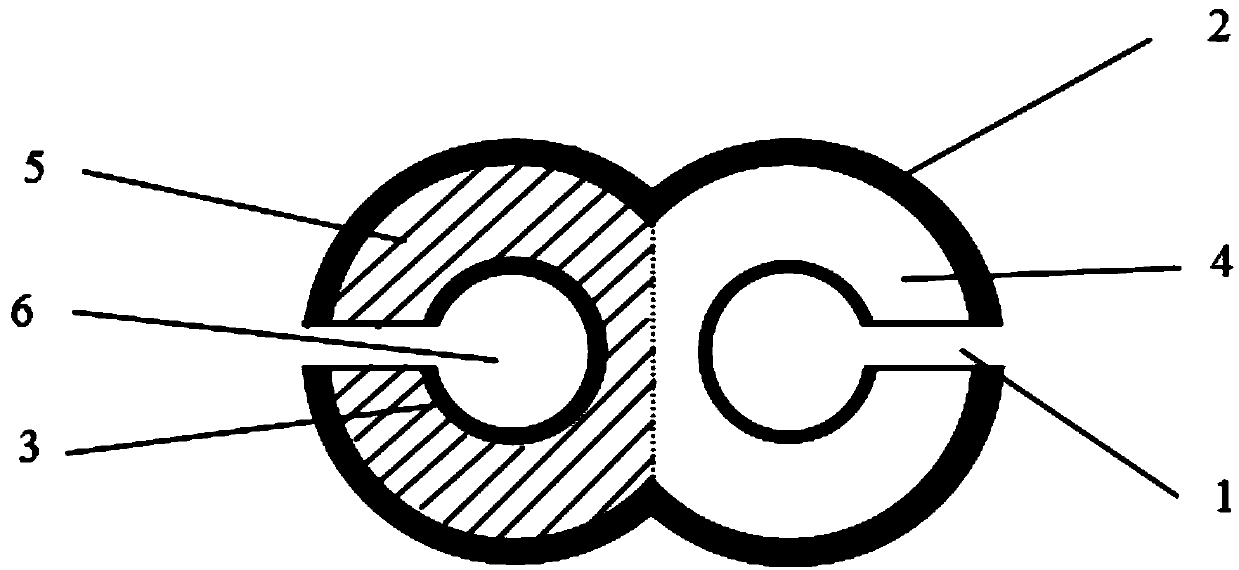

[0032] see figure 1 , a conductive hollow two-component side-by-side composite fiber, the composite fiber is formed by side-by-side two components of A component 4 and B component 5, and the cross-sectional shape of the two-component composite fiber is "∞" or Dumbbell shape or double ellipse shape or double rectangle shape or "I" shape, hollow structures 6 are respectively arranged in the two components of the composite fiber, the hollow structures 6 are provided with openings 1 connected to the outside, and the hollow structures 6 form Conductive coatings are provided on the inner surface 3 of the composite fiber and the outer surface 2 of the composite fiber.

[0033] The mass ratio of the A component 4:B component 5 is 10:90.

[0034] The conductive coating is a graphene / nano-metal particle composite coating solution, and the metal therein can be Pt, Pd, Au, or Ag;

[0035] The cross-section of the hollow structure 6 is circular or square or cross-shaped or elliptical or ...

Embodiment 2

[0050] see figure 1 , a conductive hollow two-component side-by-side composite fiber, the composite fiber is formed by side-by-side two components of A component 4 and B component 5, and the cross-sectional shape of the two-component composite fiber is "∞" or Dumbbell shape or double ellipse shape or double rectangle shape or "I" shape, hollow structures 6 are respectively arranged in the two components of the composite fiber, the hollow structures 6 are provided with openings 1 connected to the outside, and the hollow structures 6 form Conductive coatings are provided on the inner surface 3 of the composite fiber and the outer surface 2 of the composite fiber.

[0051] The mass ratio of the A component 4:B component 5 is 45:55.

[0052] The conductive coating is a graphene / nano-metal particle composite coating solution, and the metal therein can be Pt, Pd, Au, or Ag;

[0053] The cross-section of the hollow structure 6 is circular or square or cross-shaped or elliptical or ...

Embodiment 3

[0068] see figure 1 , a conductive hollow two-component side-by-side composite fiber, the composite fiber is formed by side-by-side two components of A component 4 and B component 5, and the cross-sectional shape of the two-component composite fiber is "∞" or Dumbbell shape or double ellipse shape or double rectangle shape or "I" shape, hollow structures 6 are respectively arranged in the two components of the composite fiber, the hollow structures 6 are provided with openings 1 connected to the outside, and the hollow structures 6 form Conductive coatings are provided on the inner surface 3 of the composite fiber and the outer surface 2 of the composite fiber.

[0069] The mass ratio of the A component 4:B component 5 is 20:80.

[0070] The conductive coating is a graphene / nano-metal particle composite coating solution, and the metal therein can be Pt, Pd, Au, or Ag;

[0071] The cross-section of the hollow structure 6 is circular or square or cross-shaped or elliptical or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com